Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

CVEN 3502 - PART 4 - Non-Traditional Water Sources

Caricato da

zhunsheanTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

CVEN 3502 - PART 4 - Non-Traditional Water Sources

Caricato da

zhunsheanCopyright:

Formati disponibili

24/08/2014

Introduction to Membrane Processes

Part 2 Water Treatment

CHEN 6071: Water & Wastewater Engineering

School of Chemical Engineering

Part 4 Non-traditional waters

The objective of these slides is to cover the following information:

1.

What are non-traditional waters and what are the treatment

objectives for membranes in these applications

2

2.

F

Features

off

Assessment: On-line quiz questions covering your understanding of:

1.

Salt and water transport across semi-permeable membranes

2.

Pre-treatment requirements and common forms of fouling in

reverse osmosis

Tutorial:

T

t i l U

Use off equations

ti

on reverse osmosis

i ffrom course ttextt

(Environmental Engineering: principles & practice)

24/08/2014

Non-traditional waters refer to sources of water contain levels of salts

and organics that are higher than surface waters or potable groundwater

Examples include;

S

Seawater

t (TDS > 30000 mg/L)

/L)

Municipal Waste (TDS 1000 mg/L)

Brackish Groundwater (2000-15000 mg/L)

Water requires treatment to remove salts

Illawarra Water Reclamation Plant

& Gold Coast Desalination

And organics prior to use

Reverse osmosis and Nanofiltration are

membrane processes that are used

to remove salts

Reverse osmosis is the process where pressure is applied

in excess of the osmotic gradient to reverse flow due to

osmosis

24/08/2014

What equations describe water & salt movement

across the membrane?

Water Transport Fw = A a Pnet

Salt Transport Fs = B (C)

Where;

a

A

Pnet

B

C

= water permeability coefficient (m3 /m2/Pa)

= membrane area

= net driving pressure

= salt permeability

= concentration gradient

Water flux can be written as:

24/08/2014

Where pa (Average imposed pressure gradient)

is calculated by:

Osmotic pressure gradient

24/08/2014

Salt passage (or flux of solute species)

Solute concentration gradient

24/08/2014

What Pressure is needed for RO?

Pnet = Pfeed - p where:

Pnet

Pfeed

P

Ppermeate

P

2

- P

Permeate

=

=

=

=

Net driving pressure

Feed pressure

Osmotic press

pressure

re differential across the membrane

Feed/Brine pressure differential

Permeate pressure

Typical Osmotic Pressures

Conc.

(mg/L)

Osmotic Press,

(kPa)

NaCl

1,000

100

LiCl

1,000

160

MgSO4

1,000

25

Sucrose

1,000

Seawater

35,000

2700

Species

24/08/2014

How does permeate quality change with

operating conditions?

Calculate permeate concentration (mg/L) at constant C across the

membrane with increasing water transport

Pnet

(kPa)

500

1000

1500

2000

Permeate

Water

(l/min)

1

2

3

4

Permeate

Salt

(mg/min)

1,000

?

?

?

Permeate

Concentration

(mg/l)

1,000

?

?

?

RO Process Control

Systems designed to operate at constant flow

FIT

VFD

Permeate

Feed

RO Feed Pump

With VFD

FIT

Concentrate

Concentrate Flow

Control Valve

Variable

Controlling Device

Permeate Flow Feed pump speed ( P aSpeed2)

Recovery

Concentrate valve

24/08/2014

Components of an RO System

Chemical Cond.

Acid

Scale Inhibitor

Screens

Beach Wells

Intake

Cl

Cleaning

i

Waste

In-line Coagulation

Direct Filtration

MF/UF

Pretreatment

Cartridge

Filtration

RO

Waste

Chlorination/

Stabilisation

Storage &

Distribution

Brine

Spiral Wound RO & NF Elements

24/08/2014

Making a Spiral Wound Membrane

Step 1

Step 2

Fold

Salty

Water

Salty

Water

Salty

Water

Fresh

Water

Permeate Spacer

Membrane

Fresh

Water

Making a Spiral Wound Membrane

Step 4

Step 3

Salty

S

lt

Water

Fresh

Water

Salty

Water

Permeate tube

with holes

Salty

S

lt

Water

Fresh

Water

Salty

Water

Salty

Water

24/08/2014

Making a Spiral Wound Membrane

Salty

Water

Step 5

Step 6

Brine Spacer

Salty

Water

Salty

Water

Fibreglass

casing

Fresh

Water

Salty

Water

Salty

Water

Brine Spacer

Fresh

Water

Finished RO Membranes (2, 4, 8 & 16 diameter)

10

24/08/2014

RO Element are assembled into Pressurized

Vessels

Seal

Feed

Concentrate

Permeate

Permeate

collection tube

Permeate tube coupling

Pressure vessel

Spiral Wound RO Element

Pressure Vessel Assembly

Feed

O-rings

Interconnector

Brine Seal

Permeate

Head Seal

Pressure Vessel

Thrust Cone

Head

End Adapter

R.O. Element

Concentrate

Retaining Ring

11

24/08/2014

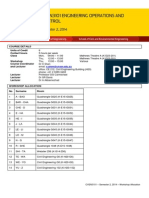

RO Skid consist of multiple pressure vessels

arranged as 1, 2 or 3 staged arrays.

Kwinana Water Reclamation Plant

e WA

Perth

Orange County Water District, CA, USA

System recovery increases with number of stages.

Recovery limited by a variety of factors including the solubility of salts in the

feed, the osmotic pressure and the maximum pressure of the vessels

3 x 2 x 1 concentrate-staged array

12

24/08/2014

A two-pass, two-staged system

RO Designs are Generic

RO racks have similar design

Rack size varies based on

plant capacity

Increase no. of pressure

vessels to increase rack

capacity

Standard element size of 8 x

40 (20 cm by 100 cm)

13

24/08/2014

RO System Space Requirements

Key RO Train Dimensions

Vertical spacing

450 mm

Horizontal spacing

300 mm

Submersible

Pump

Skid

Access for membrane replacement

Lets return to the components of a RO System

Chemical

Conditioning

Intake

Screens

Beach wells

Pretreatment

Acid

Scale Inhibitor

RO

In-Line Coagulation

Direct Filtration

MF/UF

Cartridge Filtration

Chlorination

Stabilization

Storage &

Distribution

Brine

Cleaning

Waste

Waste

14

24/08/2014

Assessing pretreatment for RO

RO Feed tank lining failed. Tank lining between MF and RO.

Cartridge filters would have reduced risk.

Pre-trearment matches the fouling tendency of the

water based on the Silt Density Index (SDI)

SDI is calculated number based on filtration of a sample through

a 0.45 micron filter pad.

SDI is calculated by following formula:

100 (1 T1/T2)

SDI15 =

15

Where T1 is time in seconds to filter initial 500 ml of sample and

T2 is time in seconds to filter final 500 ml of sample

A d 15 minutes

And

i t is

i allowed

ll

d to

t pass between

b t

ti d sample

timed

l intervals.

i t

l

Source

Water at >

30 psii

Ball Valve

Pressure

Regulator

Pressure

Gauge

Vent

(optional)

To

p

Millipore Filter Holde

Ba

se

500

ml

15

24/08/2014

Pre-treatment requirements

Cartridge filters (5-40 micron)

Typically used on ground water

SDI feed water 3-5

SDI product

d t<3

Media filters (conventional or direct)

Some surface waters

Some groundwaters (where Iron & aluminium removal required

Seawater desalination

SDI Feedwater > 6

Total coliform < 103 cfu/100 ml

Membrane Filtration

Wastewater recycling

SDI Feedwater > 6

Total coliform > 103 cfu/100 ml

Comparison of RO Pretreatment on Seawater

Slide Courtesy of Rob Huehmer, CH2M Hill

16

24/08/2014

Chemical Addition Systems

Inorganic scale formation in RO

3 general scale types

Alkaline or carbonate

eg: CaCO3

Non Alkaline or sparingly

soluble salts

eg: Al(OH)3, CaF2, CaSO4,

Mg3(PO4)2

Silica (polymerised and

silicates)

Scale Risk Assessment

LSI/SDSI>0 is scale forming

Note:

LSI: TDS <10,000 mg/L

SDSI: TDS > 10,000 mg/L

Ion Product in > F x Solubility

concentrate

Product

(IPc)

(Ksp)

F = 0.8 (w/o antiscalant)

Polymerisation @ 150 200 mg/L

Silicates @ pH > 9 in presence of

trivalent metals

17

Potrebbero piacerti anche

- Potential Expansion of Portland-Cement Mortars Exposed To SulfateDocumento3 paginePotential Expansion of Portland-Cement Mortars Exposed To SulfatezhunsheanNessuna valutazione finora

- Length Change of Hydraulic-Cement Mortars Exposed To A Sulfate SolutionDocumento8 pagineLength Change of Hydraulic-Cement Mortars Exposed To A Sulfate SolutionzhunsheanNessuna valutazione finora

- CVEN 4402 - Workshop - Week 7Documento50 pagineCVEN 4402 - Workshop - Week 7zhunsheanNessuna valutazione finora

- 2014 S2 CVEN3101 Workshop AllocationDocumento1 pagina2014 S2 CVEN3101 Workshop AllocationzhunsheanNessuna valutazione finora

- Groundwater Education Investment Fund Project Borehole Infrastructure ReportDocumento3 pagineGroundwater Education Investment Fund Project Borehole Infrastructure ReportzhunsheanNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Excel Sales Report TemplateDocumento3 pagineExcel Sales Report TemplateMark11311100% (1)

- Mensuration & Calculation For Plumbing by Daleon PDFDocumento101 pagineMensuration & Calculation For Plumbing by Daleon PDFmanny daleon100% (1)

- Vulgare Mill.) Terhadap Bakteri Staphylococcus Aureus ATCC 25923Documento8 pagineVulgare Mill.) Terhadap Bakteri Staphylococcus Aureus ATCC 25923MUHAMMAD RIZKY HUSULUDINNessuna valutazione finora

- SP485Documento10 pagineSP485DmitriyNessuna valutazione finora

- Lipid WorksheetDocumento2 pagineLipid WorksheetMANUELA VENEGAS ESCOVARNessuna valutazione finora

- About Ramfs Rootfs InitramfsDocumento7 pagineAbout Ramfs Rootfs InitramfsNavaneethNessuna valutazione finora

- Chapter3 Torsion FinalDocumento78 pagineChapter3 Torsion FinalNaveen KumarNessuna valutazione finora

- (Solved) Hydration of 1-Hexene 1-Hexene To 2 Hexanol Equation Write The Equation of The Reaction - Course HeroDocumento2 pagine(Solved) Hydration of 1-Hexene 1-Hexene To 2 Hexanol Equation Write The Equation of The Reaction - Course HeroJdkrkejNessuna valutazione finora

- ch12 칼리스터 재료과학과 공학 답지Documento71 paginech12 칼리스터 재료과학과 공학 답지hayun9999999Nessuna valutazione finora

- MATH 10 - Q4 - WEEK 1 - MODULE 1 - Illustrating-The-Measures-Of-Position-Quartiles-Deciles-And-PercentilesDocumento23 pagineMATH 10 - Q4 - WEEK 1 - MODULE 1 - Illustrating-The-Measures-Of-Position-Quartiles-Deciles-And-PercentilesLyle Isaac L. Illaga67% (27)

- Characterization and Manufacture of Braided Composites For Large Commercial Aircraft StructuresDocumento44 pagineCharacterization and Manufacture of Braided Composites For Large Commercial Aircraft StructuresnicolasNessuna valutazione finora

- Series: 973 - 1327 KWM (Gross) at 1500 RPMDocumento18 pagineSeries: 973 - 1327 KWM (Gross) at 1500 RPMlahcen boudaoudNessuna valutazione finora

- Canal RegulatorDocumento13 pagineCanal RegulatorBibhuti Bhusan Sahoo100% (1)

- Chapter 5 and 6 TestDocumento5 pagineChapter 5 and 6 TestPAYNessuna valutazione finora

- Using H2 As A Gas Turbine FuelDocumento8 pagineUsing H2 As A Gas Turbine FuelFutureGreenScienceNessuna valutazione finora

- Design-of-Experiments Study To Examine The Effect of Polarity On Stud WeldingDocumento8 pagineDesign-of-Experiments Study To Examine The Effect of Polarity On Stud WeldingtazzorroNessuna valutazione finora

- Test Class MethodsDocumento7 pagineTest Class Methodsvarun.chintatiNessuna valutazione finora

- DSP Lab 6Documento7 pagineDSP Lab 6Ali MohsinNessuna valutazione finora

- Mathematics IDocumento1 paginaMathematics IYadav MaheshNessuna valutazione finora

- RulesonEarthquake - AccelerographDocumento17 pagineRulesonEarthquake - AccelerographmjfprgcNessuna valutazione finora

- Is.11921.1993 Fuel Efficiency StandardDocumento12 pagineIs.11921.1993 Fuel Efficiency StandardParminder SinghNessuna valutazione finora

- Conte R Fort WallDocumento30 pagineConte R Fort Wallmirko huaranccaNessuna valutazione finora

- Eaton 10 Speed Service ManualDocumento186 pagineEaton 10 Speed Service ManualKeith McCann100% (1)

- How Does An Air Ejector Work?Documento2 pagineHow Does An Air Ejector Work?rajishrrrNessuna valutazione finora

- Erection Manual Hydro-1Documento63 pagineErection Manual Hydro-1rajfab100% (1)

- ReviewerDocumento6 pagineReviewerNeo GarceraNessuna valutazione finora

- RoboticsDocumento41 pagineRoboticsMark Jason100% (3)

- Circuit Diagrams P160110 Rev.0Documento24 pagineCircuit Diagrams P160110 Rev.0tuyetden613Nessuna valutazione finora

- 2 Parameter Circular (61-80)Documento6 pagine2 Parameter Circular (61-80)Papan SarkarNessuna valutazione finora

- Rapid Prototyping PPT SeminarDocumento32 pagineRapid Prototyping PPT SeminarShantha Kumar G C0% (1)