Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Study On Retrofitted R.C.C. Building by Different NDT Methods

Caricato da

IOSRjournalTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Study On Retrofitted R.C.C. Building by Different NDT Methods

Caricato da

IOSRjournalCopyright:

Formati disponibili

IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE)

e-ISSN: 2278-1684,p-ISSN: 2320-334X, Volume 12, Issue 3 Ver. I (May. - Jun. 2015), PP 85-89

www.iosrjournals.org

Study on Retrofitted R.C.C. Building by Different NDT Methods

Nikhil L. Jagtap1, Prof. P.R. Mehetre2

1

(Final year student of M.E.(Structure),Civil, SND COE & RC, Yeola / SPPU, Pune, Maharashtra, India)

2

(Department of Civil Engineering, SND COE & RC, Yeola / SPPU, Pune, Maharashtra, India)

Abstract : In this project, condition of the existing structure is assessed using NDTS and it is proposed to

extend the structure. The building was designed according to the state of the art over 40 years ago, it did not

meet the present day requirement. The project study deals with strengthening and enhancement of performance

of existing structure by means of Retrofitting, so that structure can perform well when it would be subjected to

additional loads over it. Building is residential community building having G+2 storey. Utility or purpose of

building is for society gatherings. Number of floors proposed to extend are three. The present work deals with

NDT on existing structural elements, determination of load and moment carrying capacity of structural elements

before and after extension, method applied for strengthening of structure and design of the existing structural

elements such as R.C.C. beams and columns according to the load carrying capacity required.

Keywords - Confinement, jacketing, NDT test, strengthening.

I.

Introduction

A R.C.C structure is designed to have a capacity to carry combined loads (dead, live and seismic loads)

at certain safety level and at certain degree of reliability. When this design is finally executed in construction

process, the expected performance of the structural building should come into satisfaction. However, this ideal

condition is not always realized. Almost all the structures are constructed of R.C.C and even though it is a

wonderful construction material, but once set it is very difficult to increase its strength. The performance of

building reduces in terms of safety level, strength or capacity due to the variety of causes or situations such as

deterioration of concrete, unskilled work, alteration of building units, larger loads due to extension of structure

etc. These structures behaves or performs normally during their entire life span but at the end of design period of

structure, the structure may not be capable to take the existing loads and obviously it will not be possible to take

the extra loads on it. This pose a more difficult scenario for a structural engineer than designing and constructing

a new building. Enhancement of the performance of such a deficient buildings can be done by increasing the

strength and the strength of building can be increased by the process of retrofitting. R.C.C Buildings can be

made to undergo three different Rs namely Repair, Rehabilitation and Retrofitting. Repair is partial

improvement of the degraded strength of a building after an earthquake. Rehabilitation is a functional

improvement, wherein the aim is to achieve the original strength of a building after an earthquake. Retrofitting

means structural strengthening and enhancement of performance of deficient structural elements of a building to

a pre-defined performance level whether or not an earthquake has occurred. The performance of a retrofitted

structure is aimed higher than that of original structure. The structural elements are strengthened according to

the load carrying capacity required. Retrofitting of deficient existing building to improve the performance will

be a pathway to assure the future safety of the structure. There are several retrofit techniques for strengthening

the structure and one of the retrofit technique named as jacketing is applied for strengthening proposed existing

structure in this project. In recent years, RCC jacketing is commonly used to increase the seismic strength of a

R.C framed structure, for rehabilitation of structures damaged by an earthquake or for strengthening of an

undamaged structure made necessary by revision on structural design or for taking additional loads.

II.

Jacketing Techniques

Jacketing is one of the most frequently and popularly used technique to strengthen reinforced concrete

structures. It is mostly for strengthening the R.C columns. With this method, axial strength and stiffness of the

original column is increased. Jacketing is a process of fastening durable material over concrete and filling the

gap with grout. Jacketing restores the section of an existing member by encasement in a new concrete. This

technique is applicable for protecting the member against further deterioration as well as for strengthening.

Strengthening of existing structures is needed when a) Load carried by the column is increased due to either

increasing the number of floors or due to mistakes in the design. b) The compressive strength of the concrete or

the percentage and type of the reinforcement is not according to the codes requirement.

DOI: 10.9790/1684-12318589

www.iosrjournals.org

85 | Page

Study on Retrofitted R.C.C. Building by Different NDT Methods

2.1 Jacketing of column

Column failures have caused the most significant failures of reinforced concrete structures. To prevent

the column failure mechanism during earthquakes, column should never be the weaker components in the whole

structure. Practical methods available for strengthening existing R.C column include adding concrete jackets,

steel jackets, FRP jackets, external prestressing wires, strands or belts and steel collars.

2.2 RCC jacketing of column

RCC jacketing of column consists of adding concrete with longitudinal and transverse reinforcement

around the existing columns. Additional concrete and reinforcement contributes to the increase in strength.

Reinforced concrete jacketing can be employed as a repair or strengthening scheme. R.C.C jacketing increases

the member size significantly, also increases the members stiffness and is useful where deformations are to be

controlled. Shear and axial load carrying capacity of the structural members can be enhanced by this method.

This method provides better solution for avoiding buckling problem, if the column in building is found to be

slender. The resulting cured member not only strengthens the reinforced concrete member but also acts as an

excellent barrier to the corrosion agents, which are detrimental to concrete and the reinforcement. In addition,

the original function of the building can be maintained, as there are no major changes in the geometry of the

building with this technique.

2.3 Steps in the jacketing process

Adding steel connectors into the existing column in order to fasten the new stirrups and vertical steel bars of

the jacket at spaces not more than 50cm. These connectors are added into the column by making holes 3 4

mm larger than the diameter of the used steel connector and 1015cm depth.

Filling the holes with appropriate epoxy material and inserting the connector into the hole.

The size of the jacket and the number and diameter of the steel bars used in jacketing process depend on the

structural analysis of the column.

Installing the new vertical steel bars and stirrups according to the designed dimensions and diameters.

Coating the existing column with appropriate epoxy material which would guarantee the bond between old

and the new concrete.

Pouring the concrete of the jacket before the epoxy material dries. Concrete used should be of the low

shrinkage consisting of small aggregates, sand, cement and additional materials to prevent shrinkage.

Fig 1. Picture showing column jacketing

III.

Methods Of Ndt Test

Non-destructive testing (NDT) is defined as the determination of the physical condition of an object

without affecting that objects ability. NDT methods have been in use for about 4 decades, and in this period, the

development has taken place to such an extent that it is now considered as a powerful method for evaluating

existing concrete structures with regard to their strength, durability and quality.

Various non-destructive methods of testing concrete have been developed:

1. Surface hardness tests

2. Rebound test

3. Ultrasonic test

4. Penetration and pull out tests

DOI: 10.9790/1684-12318589

www.iosrjournals.org

86 | Page

Study on Retrofitted R.C.C. Building by Different NDT Methods

5.

6.

7.

8.

9.

Dynamic or vibration tests

Combined methods

Radioactive and nuclear methods

Magnetic and electrical methods

Acoustic emission techniques

The commonly used non-destructive tests are the Rebound hammer tests and Ultrasonic pulse velocity test. So

the methods used in this work are also Schmidt rebound hammer test and ultrasonic pulse velocity test.

3.1 Ultrasonic pulse velocity test

UPV is the important NDT method used for testing concrete. This method has gained considerable

popularity all over the world. This method involves a measurement of travel time over a known path length

pulse of ultrasonic compressional waves. The pulses are generated by use of pulse generator circuit. The pulse

generator circuit consists of electronic circuit for generating pulses and a transducer. The pulses are introduced

into concrete by a piezoelectric transducer and similar transducer acts a receiver to monitor the surface vibration

cause by the arrival of the pulse. A timing circuit is used to to measure the time for the pulse to travel from the

transmitting to receiving transducers. The path length between the transducer divided by time of travel gives the

average velocity of wave. The pulse velocity is determined by the equation.

Pulse Velocity

Path Length

Transit Time

Generally, the higher the pulse velocity, the higher the quality and durability of concrete or lower quality

concrete is by lower velocity.

Fig 2. Ultrasonic pulse velocity instrument.

I.S. 13311-1992 code of practice for Ultra sonic pulse Velocity explains the details of pulse velocity and

condition of concrete.

Table 1. Quality of concrete as per IS 13311(part I) 1992

1

2

3

4

Ultrasonic pulse velocity

(km/sec)

Above 4.5 km/sec

3.5 to 4.5 km/sec

3 to 3.5 km/sec

Below 3 km/sec

Quality of concrete

Excellent

Good

Medium

Doubtful

3.2 Schmidt rebound hammer test

Schmidt rebound hammer developed in 1948 by a Ernst Schmidt a Swiss engineer for testing concrete,

based upon rebound principle when a hammer strikes concrete. The degree of rebound is an indication of

hardness of concrete. It consists of a spring control hammer that slides on a plunger within a tubular housing.

The plunger is extended from the body of the instrument, which causes a catch mechanism to grab hold of the

hammer. The body of the instrument is then pushed towards the concrete surface which stretches the spring

attached to the hammer and body. When pushed to the limit, the catch is released and the hammer is propelled

towards the concrete by combination of gravity and spring forces. After then hammer strikes up to the shoulder

of plunger and it rebounds. The rebound distance travelled by a spring control mass is called the rebound

number and it is measured on a scale which is attached to a rider. This test can be conducted horizontally,

vertically or at any intermediate angle. After knowing rebound number, the calibration chart is used which

shows the relationship between compressive strength and rebound number.

DOI: 10.9790/1684-12318589

www.iosrjournals.org

87 | Page

Study on Retrofitted R.C.C. Building by Different NDT Methods

Fig 3. Schmidt rebound hammer instrument

Fig 4. Calibration chart

3.3 Picture showing performance of NDT test

Fig 5. Performance of UPV & Schmidt rebound hammer test

Fig 6. Line plan of R.C.C. building

DOI: 10.9790/1684-12318589

www.iosrjournals.org

88 | Page

Study on Retrofitted R.C.C. Building by Different NDT Methods

IV.

Results

To evaluate concrete condition of R.C.C structure, we have performed Ultrasonic Pulse Velocity test

and rebound hammer tests on various R.C.C members.

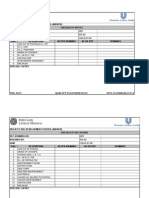

Table 2: Schmidt rebound hammer test result

Sr. No.

1

2

3

4

5

6

7

8

9

10

11

12

13

Particulars

C-13

C-08

C-02

C-10

C-15

C-17

C-19

C-23

C-39

C-20

C-18

C-16

C-11

Rebound No.

36,32,24, 28,26

30,28,26, 30,28

34,28,32,30,28,26

34,30,26, 28,20

36,32,28,22,22

34,32,30,26,26

32,28,26,22,32

34,30,24,26,22

24,28,34,26,22

28,24,2634,24,32

32,32,30,28,24,26

34,30,28,30,28,24

32,26,32,22,36,20

Average

29.2

28.4

29.6

27.6

28

29.6

28

27.2

26.8

28

28.6

29

28

Compressive Strength in

N/mm2

22.1

20.6

22.2

18.8

20.2

22.4

20.2

18.4

18

20.2

20.8

22

20.2

Based on the NDT results:

As per the Non destructive Tests carried out on existing structure, it is observed that the Ultrasonic Pulse

Velocity Results with direct, semi direct and indirect methods indicates the maximum readings are below

3km/sec and between 3.0 km/sec to 3.5km/sec.

As per the Ultrasonic pulse velocity test (refer to IS 13311 (Part I) 1992 Non Destructive Testing of

concrete methods of test, Ultrasonic Pulse Velocity).It is observed that quality of concrete is medium and

doubtful.

As per Rebound Hammer test (refer to IS 13311 (Part II) 1992 Non- Destructive Testing of concrete methods of test,

Rebound Hammer ) the readings of Rebound Hammer indicates the probable

compressive strength of concrete is M18 TO M22.

V.

Conclusion

The project study deals with strengthening and enhancement of performance of existing structure so

that structure can perform well when subjected to additional loads over it. The present work deals with NDT on

existing structural elements/determination of load and moment carrying capacity of structural elements before

and after extension, method applied for strengthening of structure ,design of the existing structural elements

such as R.C.C beams and columns according to the load carrying capacity required.

This work can be further extended to:

Strengthening of the existing structure with different retrofitting techniques.

Study on the performance of the existing structure after retrofitting.

Study can be done by increasing the additional floors on existing structure and requirement of strengthening

for that.

Study of R.C.C. column may be checked by different NDT methods.

References

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

Pravin S Waghmare, Jacketing technique for retrofitting of structures, International

journal of advanced engineering research

and studies, Vol. I, Issue: 15-2011

Bhavar Dadasaheb O, Dhake Pravinchandra D, Ogale ramesh A, Retrofitting of existing R.C.C building by method of jacketing,

International journal of research in modern engineering and emerging technology Vol 1, Issue:5-2013

Dr. Gopal L. Rai, Different strenghtening techniques for R.C columns, R and M international pvt. Ltd.

Mahdi shariati, Nor Hafizah ramli-sulong, Mohammad Mehdi Arabnejad k.h, Payam shafigh and Hamid sinaei, Assessing the

strength of reinforced concrete structures through ultrasonic pulse velocity and schmidt rebound hammer tests, Scientific research

and essays vol.6 (1)-2011.

A.k. Singh, Dr. R.S. Jangid, Dr. Gopal L. Rai, Structural Retrofitting - a case study, Municipal Corporation, Mumbai-2009

IS 13311(1992), Code of practice for Non Destructive Testing of concrete methods of test part: 1 Ultrasonic pulse test, Bureau

of Indian standards (BIS), New Delhi.

IS 13311(1992), Code of practice for Non Destructive Testing of concrete methods of test part: 2 Rebound Hammer test,

Bureau of Indian standards (BIS), New Delhi.

IS 1893 (2002). Indian Standard criteria for Earthquake Resistant Design of structures part 1 : General Provisions and Buildings ,

Bureau of Indian standards (BIS), New Delhi.

IS 456: (2000), Plain and Reinforced Concrete Code of Practice Fourth Revision, Bureau of Indian standards (BIS), New Delhi.

DOI: 10.9790/1684-12318589

www.iosrjournals.org

89 | Page

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- "I Am Not Gay Says A Gay Christian." A Qualitative Study On Beliefs and Prejudices of Christians Towards Homosexuality in ZimbabweDocumento5 pagine"I Am Not Gay Says A Gay Christian." A Qualitative Study On Beliefs and Prejudices of Christians Towards Homosexuality in ZimbabweInternational Organization of Scientific Research (IOSR)Nessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Socio-Ethical Impact of Turkish Dramas On Educated Females of Gujranwala-PakistanDocumento7 pagineSocio-Ethical Impact of Turkish Dramas On Educated Females of Gujranwala-PakistanInternational Organization of Scientific Research (IOSR)Nessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Attitude and Perceptions of University Students in Zimbabwe Towards HomosexualityDocumento5 pagineAttitude and Perceptions of University Students in Zimbabwe Towards HomosexualityInternational Organization of Scientific Research (IOSR)Nessuna valutazione finora

- A Proposed Framework On Working With Parents of Children With Special Needs in SingaporeDocumento7 pagineA Proposed Framework On Working With Parents of Children With Special Needs in SingaporeInternational Organization of Scientific Research (IOSR)Nessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- A Review of Rural Local Government System in Zimbabwe From 1980 To 2014Documento15 pagineA Review of Rural Local Government System in Zimbabwe From 1980 To 2014International Organization of Scientific Research (IOSR)Nessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Role of Extrovert and Introvert Personality in Second Language AcquisitionDocumento6 pagineThe Role of Extrovert and Introvert Personality in Second Language AcquisitionInternational Organization of Scientific Research (IOSR)Nessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Impact of Technologies On Society: A ReviewDocumento5 pagineThe Impact of Technologies On Society: A ReviewInternational Organization of Scientific Research (IOSR)100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- An Evaluation of Lowell's Poem "The Quaker Graveyard in Nantucket" As A Pastoral ElegyDocumento14 pagineAn Evaluation of Lowell's Poem "The Quaker Graveyard in Nantucket" As A Pastoral ElegyInternational Organization of Scientific Research (IOSR)Nessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Assessment of The Implementation of Federal Character in Nigeria.Documento5 pagineAssessment of The Implementation of Federal Character in Nigeria.International Organization of Scientific Research (IOSR)Nessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Comparative Visual Analysis of Symbolic and Illegible Indus Valley Script With Other LanguagesDocumento7 pagineComparative Visual Analysis of Symbolic and Illegible Indus Valley Script With Other LanguagesInternational Organization of Scientific Research (IOSR)Nessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Edward Albee and His Mother Characters: An Analysis of Selected PlaysDocumento5 pagineEdward Albee and His Mother Characters: An Analysis of Selected PlaysInternational Organization of Scientific Research (IOSR)Nessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Investigation of Unbelief and Faith in The Islam According To The Statement, Mr. Ahmed MoftizadehDocumento4 pagineInvestigation of Unbelief and Faith in The Islam According To The Statement, Mr. Ahmed MoftizadehInternational Organization of Scientific Research (IOSR)Nessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Relationship Between Social Support and Self-Esteem of Adolescent GirlsDocumento5 pagineRelationship Between Social Support and Self-Esteem of Adolescent GirlsInternational Organization of Scientific Research (IOSR)Nessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Importance of Mass Media in Communicating Health Messages: An AnalysisDocumento6 pagineImportance of Mass Media in Communicating Health Messages: An AnalysisInternational Organization of Scientific Research (IOSR)Nessuna valutazione finora

- Role of Madarsa Education in Empowerment of Muslims in IndiaDocumento6 pagineRole of Madarsa Education in Empowerment of Muslims in IndiaInternational Organization of Scientific Research (IOSR)Nessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Topic: Using Wiki To Improve Students' Academic Writing in English Collaboratively: A Case Study On Undergraduate Students in BangladeshDocumento7 pagineTopic: Using Wiki To Improve Students' Academic Writing in English Collaboratively: A Case Study On Undergraduate Students in BangladeshInternational Organization of Scientific Research (IOSR)Nessuna valutazione finora

- Designing of Indo-Western Garments Influenced From Different Indian Classical Dance CostumesDocumento5 pagineDesigning of Indo-Western Garments Influenced From Different Indian Classical Dance CostumesIOSRjournalNessuna valutazione finora

- Steel Box Girder Bridges Design Guides and Methods PDFDocumento22 pagineSteel Box Girder Bridges Design Guides and Methods PDFbahrullmusaffaNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Conclusion: Table 6.1 Concrete Quality of Wheat Silo (Big)Documento5 pagineConclusion: Table 6.1 Concrete Quality of Wheat Silo (Big)Permana GiwaNessuna valutazione finora

- Column-Base Plate Foundation Design Report, How To Design Base Plate Connections, Sample Design Report, ColumnBase Software, PCEESoft Inc.Documento5 pagineColumn-Base Plate Foundation Design Report, How To Design Base Plate Connections, Sample Design Report, ColumnBase Software, PCEESoft Inc.ircivilcivilNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Bailey Bridge: Comprehensive Training For DPWH Field Engineers April 22, 2013Documento63 pagineBailey Bridge: Comprehensive Training For DPWH Field Engineers April 22, 2013Edhz AmbalesNessuna valutazione finora

- Practicum: (On-the-Job Training)Documento36 paginePracticum: (On-the-Job Training)Francis Philippe Cruzana CariñoNessuna valutazione finora

- Design in Timber To Ms 544 Part2: Course OutcomeDocumento20 pagineDesign in Timber To Ms 544 Part2: Course OutcomeMuhd FaridNessuna valutazione finora

- Bills of Quantities For The Proposed Apartment BuildingDocumento164 pagineBills of Quantities For The Proposed Apartment BuildingAnonymous qOBFvINessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- DDMDocumento47 pagineDDMTezinNessuna valutazione finora

- SAP2000 V 15 Hands On TrainingDocumento228 pagineSAP2000 V 15 Hands On Trainingclam2014100% (3)

- Project: Steel Building Design Case Study Subject: Project Plan SHEET 1 of 131Documento22 pagineProject: Steel Building Design Case Study Subject: Project Plan SHEET 1 of 131avmurugan87Nessuna valutazione finora

- 02) PIPE244.5x6.3 V-BRACE - GUSSET PLT.Documento117 pagine02) PIPE244.5x6.3 V-BRACE - GUSSET PLT.Asaru Deen100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Causes and Prevention of Cracks in BuildingDocumento47 pagineCauses and Prevention of Cracks in BuildingvishalgoreNessuna valutazione finora

- Checklist - Civil WorksDocumento25 pagineChecklist - Civil WorksJagoan Neon0% (1)

- Designers' Guide To EN 1994-2 Rules For Bridges (2006)Documento212 pagineDesigners' Guide To EN 1994-2 Rules For Bridges (2006)Gregor Kokot100% (1)

- Footing Pressure CalculationDocumento7 pagineFooting Pressure Calculationabdul samadNessuna valutazione finora

- Construction Steps of BuildingDocumento5 pagineConstruction Steps of BuildingRK DanishNessuna valutazione finora

- Compressive Strength of OPC: Types of Cement 3 Days 7 Days 28 DaysDocumento13 pagineCompressive Strength of OPC: Types of Cement 3 Days 7 Days 28 DaysAsghar Hussain Shah S/o Zubair Shah MS Engg. Management (Swat Campus)Nessuna valutazione finora

- Module 1Documento135 pagineModule 1Alesther MarianoNessuna valutazione finora

- Practical Design To Eurocode 2: Course OutlineDocumento33 paginePractical Design To Eurocode 2: Course Outlinejosif100% (1)

- Civil Engg Site Data CompendiumDocumento212 pagineCivil Engg Site Data CompendiumIlancheral NedumaranNessuna valutazione finora

- GB 50204-2002 Code For Acceptance of Construction Quality of Concrete Structures. Part 1Documento70 pagineGB 50204-2002 Code For Acceptance of Construction Quality of Concrete Structures. Part 1Dilnesa EjiguNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Strucsyll PDFDocumento44 pagineStrucsyll PDFaishwarya biradarNessuna valutazione finora

- 3 - General NotesDocumento5 pagine3 - General Notesgaurav saxenaNessuna valutazione finora

- NBC 105.2020Documento111 pagineNBC 105.2020Debendra Dev KhanalNessuna valutazione finora

- Basha Infill 16WCEE 2017Documento13 pagineBasha Infill 16WCEE 2017Jalal KeNessuna valutazione finora

- Bearing Plate ThicknessDocumento30 pagineBearing Plate ThicknessMahbub AlamNessuna valutazione finora

- CHAPTER 2 .Colunm DesignDocumento17 pagineCHAPTER 2 .Colunm DesignDechas Mohammed100% (1)

- Gesualdo 2014Documento8 pagineGesualdo 2014Átila MarconcineNessuna valutazione finora

- Dog House Plans 12 - MetricDocumento4 pagineDog House Plans 12 - MetricDevika PrithiNessuna valutazione finora

- Construction of Nayagav Fa S Anicut, Bhat:, P.S. Dungarpur, Dist. Dun ArpurDocumento98 pagineConstruction of Nayagav Fa S Anicut, Bhat:, P.S. Dungarpur, Dist. Dun ArpurRajendra BadjatyaNessuna valutazione finora

- The Great Bridge: The Epic Story of the Building of the Brooklyn BridgeDa EverandThe Great Bridge: The Epic Story of the Building of the Brooklyn BridgeValutazione: 4.5 su 5 stelle4.5/5 (59)

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetDa EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetValutazione: 4.5 su 5 stelle4.5/5 (10)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda Cans (Father's Day Gift for Science and Engineering Curious Dads)Da EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda Cans (Father's Day Gift for Science and Engineering Curious Dads)Nessuna valutazione finora