Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

033-Itp For Piping Installation Ag and Ug PDF

Caricato da

Köksal PatanDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

033-Itp For Piping Installation Ag and Ug PDF

Caricato da

Köksal PatanCopyright:

Formati disponibili

Pearl GTL

Project

Shell Project No: HP-3000-QAT

Project Document Number: T- 4.250.918

Purchase Order Number:

2MH127

Tag/Item Number(s):

N/A

Unit(s):

ASU

PCWBS:

LINDE ENGINEERING

Contractor Project No:

Project Rev.: A

Page 2 of 10

5887

QATAR SHELL GTL PROJECT (PEARL)

C2 AIR SEPARATION UNITS CONSTRUCTION

27.07.08

Ready for Construction

AB

EO

AG

RFC

23.12.07

Issued for Company comments

BR

AU/MC

ZG

ICC

15.12.07

Issued for Review

BR

AU/MC

ZG

IFR

02.12.07

Issued for Internal Review

BR

AU/MC

ZG

IIR

Date

Description

GAMA

Rev.

No.

Project

Rev

No.

Prepared Checked Approved

By

By

By

ORIGINATOR

Status

Document Title:

LINDEGINEERING AG

INSPECTION TEST PLAN FOR PIPING INSTALLATION

A/G AND U/G

Document No.

Contractor

LOC470

Gama Qatar Co. W. L. L.

GAM

ITP

QAC

GTL

033

Org.

Code

Doc.

Type

Disc.

Code

Geogr.

Area

Seq.

No

Rev.

No

Project Document Number: T-4.250.918

Vendor Code

Rev No: A

QSGTL PEARL PROJECT

Document No.: GAM-ITP-QAC-GTL-033

C2 ASU Construction Works

ITP FOR PIPING INSTALLATION -AG/UG (FSI)

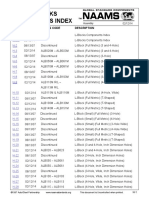

S. GAMA QATAR

X. CONTRACTOR QC

DATE: 27.07.08 REV. D

C. COMPANY

A. THIRD PARTY (TPI)

I: INSPECTION / TEST

R: DOCUMENT ISSUED/REPORT REVIEW

S: SURVEILANCE

H: HOLD POINT (Notification Required and Presence Mandatory). W: WITNESS (Notification Required but Presence not Mandatory)

Item

Activity

Test

Frequency

1.0

DOCUMENTATION

1.1

Contractor isometric drawings /

Spool drawings

1.2

Approved W.P.S.

1.3

Approved PQRs

100%

1.4

Welder Performance

Qualifications

T.4.

100%

1.5

Verify calibration of inspection,

measuring and test equipment

100%

2.0

MATERIALS

2.1

Receiving inspection /

Verification of Material

100%

2.2

Storage & Segregation of

Material

100%

2.3

Welding consumable control &

storage procedure

100%

100%

Reference Document

T.4.234.542;T.4.250.935;

T.4.250.936

Acceptance Criteria

Respon

sible

Party

Verifying Documents

RFC

QCI

RFC

WI

GAM-QCR-QAC-GTL-106

WI

GAM-QCR-QAC-GTL-105

T.4.251.025; T.4.250.938

T.4.251.025; T.4.250.938

DEP 30.10.60.18;ASME SEC

IX;ASME B31.3;

GAM-QCR-QAC-GTL-100

T.13.377.441;T.13.377.433E;

T.4.250.939

WI

WSD-QC 2

WSD-QC 3

DEP 30.10.60.18; T.13.377.433E;

T.13.377.441; T.13.377.437E

QCI

Calibration certificate

I/R

T.4.250.927;T.4.250.928;

T.13.376.797E; T.13.377.438E

QCI

LINDE MRCR SYSTEM

T.4.250.927;T.4.250.928;

T.4.250.932

T.13.377.454E; T.13.377.438E

QCI

I/R

T.4.250.915

ASME SEC II PART C

T-4.250.918 Rev.A

100%

WPSs / PQRs; T.4.250.931

DEP 30.10.60.18; T.13.377.433E;

T.13.377.437E

T.13.377.441;T.4.096.687

WI

Test certificate 3.1 B

Page 4 of 10

QSGTL PEARL PROJECT

Document No.: GAM-ITP-QAC-GTL-033

C2 ASU Construction Works

ITP FOR PIPING INSTALLATION -AG/UG (FSI)

S. GAMA QATAR

X. CONTRACTOR QC

DATE: 27.07.08 REV. D

C. COMPANY

A. THIRD PARTY (TPI)

I: INSPECTION / TEST

R: DOCUMENT ISSUED/REPORT REVIEW

S: SURVEILANCE

H: HOLD POINT (Notification Required and Presence Mandatory). W: WITNESS (Notification Required but Presence not Mandatory)

Item

Activity

2.4

Cutting /Transfer of heat No.s

2.5

PAMI

3.0

WELDING

3.1

Welder identification and

performance verification

Test

Frequency

100%

100%

100%

Issue of welding consumable

to welder

100%

3.3

Fit-up and tack welding

100%

Root pass visual inspection

3.5

Root pass magnetic check for

Drawings;T.4.250.928

Acceptance Criteria

DEP 30.10.60.18; ASME B 31.3

T.13.377.433E; T.13.376.815E

DEP 31.38.01.11; DEP

31.38.01.31; T.13.376.796E;

T.4.250.934;T.4.250.938

T.4.250.938;T.4.250.939

Respon

sible

Party

Verifying Documents

QCI

GAM-QCR-QAC-GTL-072

WI

WSD-QC 4

WI

WSD-QC 2

I/R

WI

GAM-QCR-QAC-GTL-060

DEP 30.10.60.18; T.13.377.433E ;

T.13.377.441 ASME B 31.3

3.2

3.4

Reference Document

100%

T.4.250.931: T.4.250.938

T.4.250.938;T.4.250.936

WPSs / PQRs

T.4.250.938;T.4.250.935;

T.4.250.937

DEP 30.10.60.18;ASME B 31.3

T.13.377.433E; DEP 31.38.01.31;

T.13.376.796E; T.13.377.441

WI

DEP 30.10.60.18; ASME B31.3

T.13.377.433E; T.13.377.441

WI

100%

Stainless steel materials

GAM-QCR-QAC-GTL-098

WI

GAM-QCR-QAC-GTL-098

WI

GAM-QCR-QAC-GTL-107

T.4.250.938

DEP 30.10.60.18 T.13.377.433E

3.6

Dissimilar joint welding

T-4.250.918 Rev. A

100%

Page 5 of 10

QSGTL PEARL PROJECT

Document No.: GAM-ITP-QAC-GTL-033

C2 ASU Construction Works

ITP FOR PIPING INSTALLATION -AG/UG (FSI)

S. GAMA QATAR

X. CONTRACTOR QC

DATE: 27.07.08 REV. D

C. COMPANY

A. THIRD PARTY (TPI)

I: INSPECTION / TEST

R: DOCUMENT ISSUED/REPORT REVIEW

S: SURVEILANCE

H: HOLD POINT (Notification Required and Presence Mandatory). W: WITNESS (Notification Required but Presence not Mandatory)

Item

3.7

Activity

Test

Frequency

Inter pass temp controlling /

100%

Reference Document

Acceptance Criteria

Respon

sible

Party

Verifying Documents

T.4.250.938

DEP 31.38.01.31;ASME B31.3

T.13.376.796E;

WI

AS PER WPS

WI

GAM-QCR-QAC-GTL-042

GAM-QCR-QAC-GTL-043

WI

GAM-QCR-QAC-GTL-098

DEP 30.10.60.18;ASME B31.3

T.13.377.433E; T.13.377.441 DEP

31.38.01.31; T.13.376.796E;

WI

GAM-QCR-QAC-GTL-090

T.4.250.931

DEP 30.10.60.18; ASME B31.3

T.13.377.433E; T.13.377.441

WI

GAM-QCR-QAC-GTL-098

WI

GAM-QCR-QAC-GTL-083

T.4.250.913;T.4.250.938

DEP 30.10.60.18;ASME B31.3

T.13.377.433E DEP 31.38.01.31;

T.13.376.796E; T.13.377.441

WI

WSD-QC 5

S/R

S/R

S/R

T.4.250.914;T.4.250.938

DEP 31.38.01.31; ASME B31.3

T.13.376.796E;

WI

WSD-QC 6

WSD-QC 7

I/R

I/R

cleaning

3.8

Arc strike control and repair

3.9

Weld identification and

marking

3.10

Welding, purge log (St-steel),

process parameter monitoring

3.11

Visual Inspection of Welds

4.0

POST WELD HEAT TREATMENT

4.1

PWHT

4.2

5.0

5.1

HARDNESS Test (if required)

100%

100%

100%

100%

T.4.250.938

DEP 30.10.60.18;ASME B 31.3

T.13.377.433E; T.13.377.441

T.4.250.938;T.4.250.935

T.4.250.938; T.4.250.901

WPSs / PQRs

100%

100%

NON DESTRUCTIVE EXAMINATION

Radiographic Film Interpretation/

ultrasonic examination

T-4.250.918 Rev. A

100%

Page 6 of 10

QSGTL PEARL PROJECT

Document No.: GAM-ITP-QAC-GTL-033

C2 ASU Construction Works

ITP FOR PIPING INSTALLATION -AG/UG (FSI)

S. GAMA QATAR

X. CONTRACTOR QC

DATE: 27.07.08 REV. D

C. COMPANY

A. THIRD PARTY (TPI)

I: INSPECTION / TEST

R: DOCUMENT ISSUED/REPORT REVIEW

S: SURVEILANCE

H: HOLD POINT (Notification Required and Presence Mandatory). W: WITNESS (Notification Required but Presence not Mandatory)

Item

5.2

Activity

Liquid Penetrant

Respon

sible

Party

Verifying Documents

T.4.250.909;T.4.250.938

WI

WSD-QC 9

I/R

I/R

WI

WSD-QC 8

I/R

I/R

WSD-QC 10

I/R

I/R

I/R

Test

Frequency

Reference Document

100%

Acceptance Criteria

5.3

Magnetic particle

100%

T.4.250.911;T.4.250.938

5.4

FERRITE CHECK

100%

T.4.250.933

DEP 30.10.60.18; T.13.377.433E

;T.13.377.441

WI

6.0

REPAIR CONTROL

6.1

6.2

Repair authorization

100%

T.4.250.940

DEP 30.10.60.18; T.13.377.433E

WI

Removal of defects

100%

T.4.250.940

ASME B31.3

WI

Repair welding

100%

T.4.250.940; T.4.250.901

PWHT control

100%

T.4.250.913

6.5

Hardness test (if required)

100%

T.4.250.912

6.6

NDE of repaired weld

100%

6.7

NDE (TRACERS)

100%

T.4.250.940;T.4.250.938

7.-0

FINAL INSPECTION

7.1

Dimensional check

100%

T.4.250.936;

Spool Drawings

7.2

Flanges Alignment

100%

T.4.250.936

6.3

6.4

T-4.250.918 Rev. A

T.4.250.940;T.4.250.938

DEP 30.10.60.18;ASME B31.3

T.13.377.433E;T.13.377.441

DEP 30.10.60.18;ASME B31.3

T.13.377.433E; T.13.377.441 DEP

31.38.01.31; T.13.376.796E;

DEP 31.38.01.31;ASME B 31.3

T.13.376.796E;

ASME B 31.3

ASME B 31.3;DEP 31.38.01.31;

T.13.376.796E;DEP 31.38.01.11;

T.13.376.815E

DEP 31.38.01.11; T.13.376.815E;

ASME B 31.3;DEP 31.38.01.31;

T.13.376.796E;DEP 61.10.08.11

GAM-QCR-QAC-GTL-097

WI

WI

GAM-QCR-QAC-GTL-083

S/R

S/R

S/R

WI

WSD-QC 5

I/R

I/R

WI

SAME AS ACTIVITY 5.0

I/R

I/R

WI

WSD-QC 11

I/R

I/R

QCI

GAM-QCR-QAC-GTL-091

QCI

GAM-QCR-QAC-GTL-058

Page 7 of 10

QSGTL PEARL PROJECT

Document No.: GAM-ITP-QAC-GTL-033

C2 ASU Construction Works

ITP FOR PIPING INSTALLATION -AG/UG (FSI)

S. GAMA QATAR

X. CONTRACTOR QC

DATE: 27.07.08 REV. D

C. COMPANY

A. THIRD PARTY (TPI)

I: INSPECTION / TEST

R: DOCUMENT ISSUED/REPORT REVIEW

S: SURVEILANCE

H: HOLD POINT (Notification Required and Presence Mandatory). W: WITNESS (Notification Required but Presence not Mandatory)

Item

Activity

Test

Frequency

Reference Document

Acceptance Criteria

Respon

sible

Party

Verifying Documents

7.3

Torquing of bolts

100%

T.4.250.936

DEP 31.38.01.11; T.13.376.815E

QCI

GAM-QCR-QAC-GTL-041

7.4

Hydraulic Tensioning of bolting

in special flanges/components

100%

T.4.250.936

DEP 31.38.01.11; T.13.376.815E

QCI

GAM-QCR-QAC-GTL-041

7.5

Piping properly supported

T.4.250.936

DEP 31.38.01.11;ASME B 31.3

T.13.376.815E;DEP

31.38.01.29:T.13.376.807E

QCI

GAM-QCR-QAC-GTL-091

7.6

Installation of spring supports

QCI

GAM-QCR-QAC-GTL-093

7.7

Installation of cold/special

supports

QCI

GAM-QCR-QAC-GTL-092

7.8

Support base grouting (if

required)

7.9

Painting of support

7.10

7.11

Inspection and verification of

orifice meter run installation

Valve installation (direction of

flow)

100%

100%

100%

T.4.250.936

T.4.250.936

T.4.250.935

DEP 34.19.20.31;

T.13.376.815E;ASME B 31.3

QCI

GAM-QCR-QAC-GTL-086

T.4.250.916

DEP 30.48.00.31; T.13.376.799

QCI/WI

GAM-QCR-QAC-GTL-055

100%

T.4.250.936

DEP 31.38.01.11; T.13.376.815E

DEP 61.38.10.10;T.13.375.791E

QCI

GAM-QCR-QAC-GTL-095

100%

T.4.250.936

QCI

GAM-QCR-QAC-GTL-091

W/R

QCI

GAM-QCR-QAC-GTL-094

QCI

GAM-QCR-QAC-GTL-091

I/R

100%

100%

7.12

Installation of bellows

100%

T.4.250.936

7.13

Installation of inline items

100%

T.4.250.936

7.14

7.15

Test pack preparation and

submission

Preparation of pre-test punch

list

T-4.250.918 Rev. A

DEP 31.38.01.11; T.13.376.815E;

DEP 31.38.01.29; T.13.376.807E

DEP 31.38.01.11; T.13.376.815E

ASME B 31.3

100%

QCI

T.4.250.908;Test Pack

100%

DEP 31.40.40.38;DEP 61.10.08.11

QCI

GAM-QCR-QAC-GTL-066

Page 8 of 10

QSGTL PEARL PROJECT

Document No.: GAM-ITP-QAC-GTL-033

C2 ASU Construction Works

ITP FOR PIPING INSTALLATION -AG/UG (FSI)

S. GAMA QATAR

X. CONTRACTOR QC

DATE: 27.07.08 REV. D

C. COMPANY

A. THIRD PARTY (TPI)

I: INSPECTION / TEST

R: DOCUMENT ISSUED/REPORT REVIEW

S: SURVEILANCE

H: HOLD POINT (Notification Required and Presence Mandatory). W: WITNESS (Notification Required but Presence not Mandatory)

Item

7.16

Activity

Clearance of pre-test punch

list

Test

Frequency

Reference Document

Acceptance Criteria

100%

Respon

sible

Party

Verifying Documents

QCI

I/R

7.17

As-built documentation

100%

T.4.250.908;T.4.250.936

DEP 31.40.40.38;T.13.377.441

QCI

7.18

Material traceability records

100%

T.4.250.928

T.13.377.438E

QCI

GAM-QCR-QAC-GTL-072

100%

T.4.250.908; T.4.250.938

DEP 31.40.40.38

WI

GAM-QCR-QAC-GTL-087

NDE REPORTS

T.4.250.936; T.4.250.915

DEP 31.38.01.11; T.13.376.815E

QCI

GAM-QCR-QAC-GTL-111

7.19

Check of welding / NDE

records

7.20

Calibration verification and

Installation of safety / Relief

valves

7.21

Pressure test

100%

T.4.250.908

DEP 31.38.01.11; T.13.376.815E;

ASME B 31.3;DEP 31.38.01.31;

T.13.376.796E

QCI

GAM-QCR-QAC-GTL-065

GAM-QCR-QAC-GTL-112

7.22

Preparation of post test punch

list

100%

T.4.250.908

DEP 61.10.08.11

QCI

GAM-QCR-QAC-GTL-067

7.23

Post test punch list clearance

100%

QCI

GAM-QCR-QAC-GTL-067

7.24

Flawless Start-up Initiative

(FSI) - Cleanliness

7.25

Flawless Start-up Initiative

(FSI) - Tightness

T-4.250.918 Rev. A

100%

Internal

Cleaning

a) Loose

Bolt

b) Wrong

Type of

Bolt

c) Bolt

tightening

T.4.250.908

T.13.377.360 Rev E

&T.4.096.688

No external materials inside the

pipe & Internal Cleaning shall be

done before erection the pipe

Site Eng

T.13.377.360 Rev E,

DEP 31.38.01.11- Gen

Full Tight without leak

Site Eng

Visual

Joint Integrity Control

Procedure T.13.377.453 ,

T.13.376.815 & Flaw

List

Page 9 of 10

QSGTL PEARL PROJECT

Document No.: GAM-ITP-QAC-GTL-033

C2 ASU Construction Works

ITP FOR PIPING INSTALLATION -AG/UG (FSI)

S. GAMA QATAR

X. CONTRACTOR QC

DATE: 27.07.08 REV. D

C. COMPANY

A. THIRD PARTY (TPI)

I: INSPECTION / TEST

R: DOCUMENT ISSUED/REPORT REVIEW

S: SURVEILANCE

H: HOLD POINT (Notification Required and Presence Mandatory). W: WITNESS (Notification Required but Presence not Mandatory)

Item

Activity

Test

Frequency

7.26

Turn over of quality documents

100%

T-4.250.918 Rev. A

Reference Document

T.4.250.908: T.4.251.035

Acceptance Criteria

Respon

sible

Party

Verifying Documents

QCI

QC DOSSIER

Page 10 of 10

I/R

Potrebbero piacerti anche

- 048-Itp For Installation of Hvac Unit PDFDocumento8 pagine048-Itp For Installation of Hvac Unit PDFKöksal Patan100% (4)

- 030-Itp For Ug GRP Piping PDFDocumento22 pagine030-Itp For Ug GRP Piping PDFKöksal Patan89% (9)

- 035-Itp For Pumps PDFDocumento30 pagine035-Itp For Pumps PDFKöksal Patan100% (3)

- 026-Itp For Structural Steel PDFDocumento18 pagine026-Itp For Structural Steel PDFKöksal Patan100% (11)

- 031-Itp For Piping Fabrication Ag and Ug PDFDocumento11 pagine031-Itp For Piping Fabrication Ag and Ug PDFKöksal Patan100% (5)

- 038-Pro Welding Consumable Control Procedure PDFDocumento20 pagine038-Pro Welding Consumable Control Procedure PDFKöksal Patan100% (7)

- Itp For Tank Fabrication & Installation Work1 - Rev02Documento22 pagineItp For Tank Fabrication & Installation Work1 - Rev02mister pogi100% (3)

- Itp For Aboveground Piping Metallic (Fabrication, Erection, Installation and Pressure Testing)Documento24 pagineItp For Aboveground Piping Metallic (Fabrication, Erection, Installation and Pressure Testing)Rakhesh Rajeevan100% (3)

- Fit Up Report Format-1Documento1 paginaFit Up Report Format-1BalkishanDyavanapellyNessuna valutazione finora

- Itp For Piping Fabrication and Erection CorrectionDocumento4 pagineItp For Piping Fabrication and Erection CorrectionAnand Ramachandran67% (3)

- Piping Reinstatement: Inspection Test Report Form NoDocumento2 paginePiping Reinstatement: Inspection Test Report Form NoFrancisco75% (4)

- Itp PipingDocumento15 pagineItp PipingEkhy Transmisi100% (1)

- 003 ITP UG PipingDocumento4 pagine003 ITP UG Pipingrvsingh70100% (1)

- ITP For Piping SystemsDocumento6 pagineITP For Piping SystemsP SHANKAR BABU100% (16)

- ITP Heat ExchangerDocumento3 pagineITP Heat ExchangerĐỗ Thị Huyền100% (3)

- Welding Report For PipingDocumento1 paginaWelding Report For PipingRifki HasyaNessuna valutazione finora

- RTR Pipe Hydrotest ProcedureDocumento13 pagineRTR Pipe Hydrotest ProcedureMohammad Rizwan0% (1)

- Equipment Erection, Static and RotaryDocumento8 pagineEquipment Erection, Static and RotaryHamada ELaraby60% (5)

- Inspection Test Plan For Pipeline JobsDocumento6 pagineInspection Test Plan For Pipeline Jobsمحمد أزها نو الدينNessuna valutazione finora

- ITP Installation of Boiler - R1Documento14 pagineITP Installation of Boiler - R1crys100% (4)

- Material Inspection Report: Project Name Date InspDocumento22 pagineMaterial Inspection Report: Project Name Date InspRafiqKuNessuna valutazione finora

- Fabrication Erection and Installation Procedure For PipingDocumento60 pagineFabrication Erection and Installation Procedure For Pipinghasan_676489616Nessuna valutazione finora

- ITP - PipingDocumento7 pagineITP - PipingRiaz Rasool100% (2)

- ITP For Pipeline (Sampel)Documento5 pagineITP For Pipeline (Sampel)Reza RkndNessuna valutazione finora

- Itp StructureDocumento47 pagineItp StructureMohammed Ady Ganjar100% (4)

- Itp PipingDocumento4 pagineItp Pipingerdemlix100% (2)

- Piping Release Report (Spool For Paint)Documento2 paginePiping Release Report (Spool For Paint)Siddiqui Abdul Khaliq100% (1)

- Inspection and Test Plan For Structural Steel Erection: ITP NO: 7979-ITP-ME-019 Rev.2Documento8 pagineInspection and Test Plan For Structural Steel Erection: ITP NO: 7979-ITP-ME-019 Rev.2Santosh Kumar Bogela100% (12)

- Field Itp For Piping Work Samur Project Rev-5 (23 April 2013)Documento28 pagineField Itp For Piping Work Samur Project Rev-5 (23 April 2013)Echik KiciNessuna valutazione finora

- Installation Procedure For Pressure VesselDocumento8 pagineInstallation Procedure For Pressure VesselSamuel Babu100% (1)

- Itp For Pipeline at SiteDocumento3 pagineItp For Pipeline at Siteanang_pri100% (2)

- ITP For HDPEDocumento2 pagineITP For HDPEAshraf Mohammed75% (4)

- Attachment 6 - Piping Test Package (Manifold 204, 205) (Pages 56 To 121) - A4A0Z7Documento66 pagineAttachment 6 - Piping Test Package (Manifold 204, 205) (Pages 56 To 121) - A4A0Z7indusampath100% (2)

- Inspection and Test PlanDocumento58 pagineInspection and Test PlanTouil Houssem100% (1)

- Underground Piping Pressure Test RecordDocumento1 paginaUnderground Piping Pressure Test RecordPaulSwinbankNessuna valutazione finora

- F-Qa-03a Material - Receiving - Storage and Handling Inspection ChecklistDocumento1 paginaF-Qa-03a Material - Receiving - Storage and Handling Inspection ChecklistHilal mohamedNessuna valutazione finora

- Inspection and Test Plan - PipingDocumento15 pagineInspection and Test Plan - PipingFerdie OS100% (5)

- MS-M-063 Rev. 1 - Air Fin Cooler InstallationDocumento6 pagineMS-M-063 Rev. 1 - Air Fin Cooler InstallationwalitedisonNessuna valutazione finora

- ITP For Field Erected Tank Rev ADocumento9 pagineITP For Field Erected Tank Rev AHoang Tuan Kiet100% (1)

- ITP For CW and ACW Piping WorkDocumento8 pagineITP For CW and ACW Piping WorkPhong DoNessuna valutazione finora

- A Prior To Erection (Rotating Equipments) : 2 Calibration of Testing / Checking EquipmentsDocumento4 pagineA Prior To Erection (Rotating Equipments) : 2 Calibration of Testing / Checking EquipmentsGaapchu100% (2)

- Painting & Inspection FormatDocumento1 paginaPainting & Inspection FormatABEC Trombay siteNessuna valutazione finora

- ItpDocumento7 pagineItpJose Sherin100% (1)

- Piping Tie in Procedure Rev ADocumento15 paginePiping Tie in Procedure Rev AAnh Võ95% (19)

- ITP For Piping WorksDocumento3 pagineITP For Piping WorksOrlando1949100% (3)

- ITP Static EquipmentDocumento12 pagineITP Static Equipmentaamirapi100% (3)

- Hydrostatic Test Procedure: Salalah Ammonia ProjectDocumento6 pagineHydrostatic Test Procedure: Salalah Ammonia ProjectAbdelkhak KhallaNessuna valutazione finora

- 1.method Fabrication Spool (r2)Documento13 pagine1.method Fabrication Spool (r2)sethu109175% (20)

- 008 - Field Hydrotest ProcedureDocumento17 pagine008 - Field Hydrotest Procedurekaruna346100% (2)

- Hydrotest Check List PDFDocumento1 paginaHydrotest Check List PDFSaut Maruli Tua Samosir100% (1)

- 3 - Hdpe - Itp Pipe WeldingDocumento2 pagine3 - Hdpe - Itp Pipe WeldingAttiq Ahmad Choudhry89% (9)

- Method Work Statement Pipe Welding WorksDocumento17 pagineMethod Work Statement Pipe Welding WorksSanjana AhujaNessuna valutazione finora

- 047-Itp For Oxygen Lines Fabrication and Installation PDFDocumento28 pagine047-Itp For Oxygen Lines Fabrication and Installation PDFKöksal PatanNessuna valutazione finora

- 038-Itp For Coldboxes PDFDocumento25 pagine038-Itp For Coldboxes PDFKöksal PatanNessuna valutazione finora

- 036-ITP For Compressor PDFDocumento29 pagine036-ITP For Compressor PDFKöksal PatanNessuna valutazione finora

- 032-Itp For Painting and Coating PDFDocumento19 pagine032-Itp For Painting and Coating PDFKöksal Patan80% (20)

- 034-ITP For Air Cooled Steam Condenser PDFDocumento41 pagine034-ITP For Air Cooled Steam Condenser PDFKöksal PatanNessuna valutazione finora

- 050-Itp For Installation of Air Intake Filter PDFDocumento17 pagine050-Itp For Installation of Air Intake Filter PDFKöksal PatanNessuna valutazione finora

- 045-ITP For MASONRY & PLASTERING WORKS (Buildings) PDFDocumento10 pagine045-ITP For MASONRY & PLASTERING WORKS (Buildings) PDFKöksal Patan83% (12)

- 044-ITP For Installation of Gypsum Board (Buildings) PDFDocumento10 pagine044-ITP For Installation of Gypsum Board (Buildings) PDFKöksal Patan100% (3)

- 015-MS For Night Works PDFDocumento16 pagine015-MS For Night Works PDFKöksal Patan80% (5)

- 014-MS For General Scaffolding PDFDocumento33 pagine014-MS For General Scaffolding PDFKöksal Patan100% (2)

- 016-CIVIL - MS Anchor Bolt Installation PDFDocumento14 pagine016-CIVIL - MS Anchor Bolt Installation PDFKöksal Patan71% (7)

- 017-CIVIL-MS For Installation of Fence & Gate PDFDocumento18 pagine017-CIVIL-MS For Installation of Fence & Gate PDFKöksal Patan100% (6)

- 015-Method Statement For Painting Works (Building) PDFDocumento21 pagine015-Method Statement For Painting Works (Building) PDFKöksal Patan86% (21)

- 013-MS For Mass Concrete Works PDFDocumento26 pagine013-MS For Mass Concrete Works PDFKöksal Patan100% (1)

- 013-MS Utilization of Hilti DX 76 PDFDocumento51 pagine013-MS Utilization of Hilti DX 76 PDFKöksal PatanNessuna valutazione finora

- 046-ITP For INSTALLATION OF MAC-BAC-ST MACHINERY UNIT PDFDocumento18 pagine046-ITP For INSTALLATION OF MAC-BAC-ST MACHINERY UNIT PDFKöksal PatanNessuna valutazione finora

- 014-MS For Bolt Tightening (Piping& Equipments) PDFDocumento23 pagine014-MS For Bolt Tightening (Piping& Equipments) PDFKöksal PatanNessuna valutazione finora

- 050-Itp For Installation of Air Intake Filter PDFDocumento17 pagine050-Itp For Installation of Air Intake Filter PDFKöksal PatanNessuna valutazione finora

- 012-MS For Wall Cladding, Roof Cladding & Life Line Installation PDFDocumento16 pagine012-MS For Wall Cladding, Roof Cladding & Life Line Installation PDFKöksal Patan91% (11)

- 049-Itp For Lighting and Small Power (Building) PDFDocumento15 pagine049-Itp For Lighting and Small Power (Building) PDFKöksal Patan100% (1)

- 012-Civil - MS Ag and Ug Coating of Concrete Surfaces PDFDocumento18 pagine012-Civil - MS Ag and Ug Coating of Concrete Surfaces PDFKöksal PatanNessuna valutazione finora

- 011-Method Statement For Repair of Concrete Works PDFDocumento25 pagine011-Method Statement For Repair of Concrete Works PDFKöksal Patan91% (33)

- 010-MS For Welding and Hot Works For General Activities at TSF Area PDFDocumento17 pagine010-MS For Welding and Hot Works For General Activities at TSF Area PDFKöksal PatanNessuna valutazione finora

- 047-Itp For Oxygen Lines Fabrication and Installation PDFDocumento28 pagine047-Itp For Oxygen Lines Fabrication and Installation PDFKöksal PatanNessuna valutazione finora

- 045-ITP For MASONRY & PLASTERING WORKS (Buildings) PDFDocumento10 pagine045-ITP For MASONRY & PLASTERING WORKS (Buildings) PDFKöksal Patan83% (12)

- 043-ITP FOR Water Proofing (Buildings) PDFDocumento13 pagine043-ITP FOR Water Proofing (Buildings) PDFKöksal Patan100% (3)

- 010-MS For Grouting PDFDocumento33 pagine010-MS For Grouting PDFKöksal PatanNessuna valutazione finora

- 008-MS For Prefabrication of CS, TT & CN Pipe Spools PDFDocumento23 pagine008-MS For Prefabrication of CS, TT & CN Pipe Spools PDFKöksal PatanNessuna valutazione finora

- 038-Itp For Coldboxes PDFDocumento25 pagine038-Itp For Coldboxes PDFKöksal PatanNessuna valutazione finora

- 041 - ITP For Painting (Building) PDFDocumento12 pagine041 - ITP For Painting (Building) PDFKöksal Patan78% (9)

- 044-ITP For Installation of Gypsum Board (Buildings) PDFDocumento10 pagine044-ITP For Installation of Gypsum Board (Buildings) PDFKöksal Patan100% (3)

- 009-Method Statement - Main Erection Sequence For Acc PDFDocumento68 pagine009-Method Statement - Main Erection Sequence For Acc PDFKöksal Patan100% (6)

- 008-CIVIL-MS Backfilling Works PDFDocumento16 pagine008-CIVIL-MS Backfilling Works PDFKöksal Patan100% (1)

- 039-Itp For Embedded Plate PDFDocumento7 pagine039-Itp For Embedded Plate PDFKöksal PatanNessuna valutazione finora

- 040-ITP For Repair of Steam Distribution Manifold PDFDocumento11 pagine040-ITP For Repair of Steam Distribution Manifold PDFKöksal PatanNessuna valutazione finora

- 009-Civil-Ms Concrete Works PDFDocumento27 pagine009-Civil-Ms Concrete Works PDFKöksal PatanNessuna valutazione finora

- 007-MS For Structural Steel Assembly Warehouse, Workshops PDFDocumento25 pagine007-MS For Structural Steel Assembly Warehouse, Workshops PDFKöksal PatanNessuna valutazione finora

- Experiment 6 - DistillationDocumento5 pagineExperiment 6 - DistillationRohit BiswasNessuna valutazione finora

- List Barang WCPDocumento84 pagineList Barang WCPMaz ZildaneNessuna valutazione finora

- IPE 203 Fall 2020 Mist (Sec A)Documento2 pagineIPE 203 Fall 2020 Mist (Sec A)Ayesha MalihaNessuna valutazione finora

- Answer Any Five Questions From Section-BDocumento1 paginaAnswer Any Five Questions From Section-BCharyNessuna valutazione finora

- Lec 5 Tissue Processing 4 PDFDocumento3 pagineLec 5 Tissue Processing 4 PDFVLADIMIR MICHAEL HUMPHREY GARLEJONessuna valutazione finora

- AWS SWPS MatrixDocumento12 pagineAWS SWPS MatrixMalcolm DiamondNessuna valutazione finora

- Water Heater SizeDocumento118 pagineWater Heater SizeAli MustafaNessuna valutazione finora

- 06 Coating FailuresDocumento57 pagine06 Coating Failuresaamirsaddiq100% (1)

- Minex enDocumento3 pagineMinex enMaria Eugenia GranadosNessuna valutazione finora

- Surface Solutions: Wim Geurts - Sales EngineerDocumento22 pagineSurface Solutions: Wim Geurts - Sales EngineerLeon GalindoNessuna valutazione finora

- Types of SteelDocumento6 pagineTypes of SteelKhadeeja AslamNessuna valutazione finora

- 5 - - 懶人包 - Production of FertilizerDocumento7 pagine5 - - 懶人包 - Production of Fertilizer1126playpubgNessuna valutazione finora

- ASTM A694 F60 - Heat Treatment and Mechanical Properties - ICRF 2012Documento3 pagineASTM A694 F60 - Heat Treatment and Mechanical Properties - ICRF 2012Noushad Bin JamalNessuna valutazione finora

- L-Blocks Components Index: Page Date Naams Code DescriptionDocumento54 pagineL-Blocks Components Index: Page Date Naams Code DescriptioncblairNessuna valutazione finora

- Lab Report 4 WeldingDocumento8 pagineLab Report 4 Weldingayman suleriNessuna valutazione finora

- JCL Inc Is A Major Chip Manufacturing Firm That SellsDocumento1 paginaJCL Inc Is A Major Chip Manufacturing Firm That SellsAmit PandeyNessuna valutazione finora

- VZ 58 Shell DeflectorDocumento15 pagineVZ 58 Shell DeflectoromikamiNessuna valutazione finora

- TE-24100 AMP Read MeDocumento2 pagineTE-24100 AMP Read Meayberkyurtsever22Nessuna valutazione finora

- Fixings - Screws BoltsDocumento38 pagineFixings - Screws BoltsNghia NguyenNessuna valutazione finora

- Group 4 - OXY LaundryDocumento4 pagineGroup 4 - OXY LaundrywildanNessuna valutazione finora

- Sikaswell ps-2010Documento3 pagineSikaswell ps-2010Kenji TanNessuna valutazione finora

- 3.0. CementDocumento10 pagine3.0. CementJohn luckyNessuna valutazione finora

- Machine Screw ThreadsDocumento2 pagineMachine Screw ThreadsMoaed KanbarNessuna valutazione finora

- How To Weld Fully Austenitic Stainless SteelsDocumento20 pagineHow To Weld Fully Austenitic Stainless SteelsCarlos Bermejo AlvarezNessuna valutazione finora

- IndiaPaperBrochure For Web1Documento4 pagineIndiaPaperBrochure For Web1Robert DsouzaNessuna valutazione finora

- Reverse Osmosis Design GuidelinesDocumento2 pagineReverse Osmosis Design Guidelineswacsii ccasullaNessuna valutazione finora

- Aironix Hidden Linear Slot DiffusersDocumento9 pagineAironix Hidden Linear Slot DiffusersNayif MuhammedNessuna valutazione finora

- Fishing Tools For 8 and Half HoleDocumento1 paginaFishing Tools For 8 and Half HolehamidNessuna valutazione finora

- Fundamentals & Overview of Foam Suppression System For Aircraft Hangar, Petrochemical Industries & Chemical Storage WarehousesDocumento137 pagineFundamentals & Overview of Foam Suppression System For Aircraft Hangar, Petrochemical Industries & Chemical Storage Warehousesjose abelardo brilloNessuna valutazione finora

- 2006 Mech TechDocumento12 pagine2006 Mech TechMcfoster DaleyNessuna valutazione finora