Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

T1002-PSV-1453 Type - 2600

Caricato da

Jonson CaoTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

T1002-PSV-1453 Type - 2600

Caricato da

Jonson CaoCopyright:

Formati disponibili

TYPE 2600 SAFETY RELIEF VALVE

Maintenance

The Type 2600 Relief/Safety Relief valves are designed to have a

short simmer, then to open rapidly to the full open position, and to

re-seat at a controlled pressure. When the valve is in its fully lifted

position, the discharge area is controlled by the bore of the nozzle,

which ensures that flow calculations for various mediums can be

reliably made.

The most frequent operation to be carried out is a precise check,

made a regular intervals, to observe whether any obvious faults

exist in the different parts of the valve. It should be checked first of all

that there are no leakages: these must always be avoided,

especially when the medium is poisonous, highly volatile or very

expensive. Carry out periodic venting for valves with a lifting device

to check regular operation. During these tests the pressure must be

at least 75% of the full working pressure.

Valves are supplied in sizes to 1 and can be manufactured in

Gunmetal, Cast Steel and Stainless Steel with ends screwed

male x female, female x female or flanged to customers

requirements.

Overhaul

Valves can also be supplied with a packed lever lifting device, limit

switch to indicate opening and closing of the valve, governing ring to

limit adjustment of the spring to the set point, for ease of re-setting.

To overhaul the valve the following procedure should be followed:

remove the cap, mark the position of the adjusting screw relevant to

the locknut, so the correct position may be found during re-setting.

Loosen the adjusting screw and locknut to relax the spring, remove

the lockscrew from the body, to free the blowdown ring. Unscrew

the nozzle from the body and remove the complete assembly from

the inside of the body. Check the contact faces of the seat and disc,

should any scratching or pitting be present the surfaces will need to

be relapped. Replace all of the joints then assemble the valve in

reverse order. To prevent damage to the disc and nozzle faces,

place a screwdriver in the spindle slot. This will stop the spindle

turning whilst re-setting the valve.

Installation

During installation of the valve avoid bumping or shaking to prevent

damaging the flange faces and misalignment of the trim. Blow

through the circuit line on which the valve is to be installed, this is to

remove any foreign bodies. Clean the valve and nozzle connections

thoroughly; foreign bodies on the nozzle may damage the valve

seat during popping. Install the valve in a vertical position only, with

the inlet downwards. After the valve has been installed make it pop

at least twice to allow automatic alignment of the trim. Misalignment

may be caused accidentally during transport or during installation.

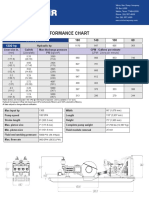

Typical Flanged Type 2600

1

2

3

4

5

6

18

9

10

11

19

12

13

20

14

15

21

16

Item

1

2

3

4

5

6

8

9

10

11

12

13

14

15

16

18

19

20

21

22

Description

Cap Plug/Gag

Joint (Plug/Gag)

Cap

Adjusting Screw

Locknut

Joint (Cap)

Spring

Spindle

Disc Holder

Ball

Disc

Lockscrew

Joint (Lockscrew)

Blowdown Ring

Joint (Body)

Spring Carrier

Grubscrew

Circlip

Body

Nozzle

Material (S2)

Stainless Steel

Non Asbestos

Carbon Steel

Stainless Steel

Carbon Steel

Non Asbestos

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Non Asbestos

Stainless Steel

Non Asbestos

Stainless Steel

Stainless Steel

Stainless Steel

Carbon Steel

Stainless Steel

Material (S3)

Stainless Steel

Non Asbestos

Stainless Steel

Stainless Steel

Stainless Steel

Non Asbestos

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Non Asbestos

Stainless Steel

Non Asbestos

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

22

Valve Size

B

Screwed Valves

Weight

44.5

85.5

219

3.0 kg

231*

6.0 kg

x 1

x 1

1 x 1

Flanged Valves

A

These Items are recommended spares.

x 1

x 1

1 x 1

81*

97*

* Dimensions given are only for ANSI150 RF flanges

TYPE 2600 RELIEF/SAFETY RELIEF VALVE

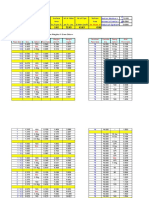

Saturated Steam Capacities

In pounds per hour

(10% Accumulation)

Water Capacities

In U. S. Gallons per minute

(25% Accumulation)

0.04

0.06

Set Pressure

Psi

Gauge

10

45

68

30

59

50

Set Pressure

Psi

Gauge

Orifice Area (sq. in.)

Air Capacities in cubic feet

Free air per hour

(10% Accumulation)

Orifice Area (sq. in.)

0.04

0.06

Set Pressure

Psi

Gauge

10

3.3

89

30

5.8

122

184

50

70

161

242

100

219

150

Orifice Area (sq. in.)

0.04

0.06

10

15

23

8.6

30

29

43

7.5

11.2

50

42

63

70

8.8

13.2

70

55

82

328

100

10.5

16

100

75

112

315

473

150

13

19.4

150

108

162

200

412

618

200

15

22.4

200

141

211

250

508

763

250

16.7

25

250

174

261

300

605

907

300

18.3

27.4

300

207

310

350

700

1052

350

20

29.6

350

240

360

400

798

1197

400

21

31.6

400

273

409

450

895

1342

450

22.3

33.6

450

306

458

500

990

1487

500

23.6

35.4

500

339

508

600

1185

1776

600

26

38.7

600

405

607

700

1377

2066

700

28

42

700

470

706

800

1570

2356

800

30

44.7

800

537

805

900

1764

2645

900

31.7

47.5

900

603

904

1000

1957

2935

1000

33.4

50

1000

669

1003

1200

2343

3515

1200

36.5

55

1200

800

1200

1500

2922

4383

1500

41

61

1500

1000

1500

1700

3310

4963

1700

43.5

65

1700

1130

1700

2000

3900

5830

2000

47

71

2000

1330

1995

Disclaimer

The information, specifications and technical data contained in this catalogue are subject to change without notice. The user should verify

all technical data and specifications prior to use. Broady Valves does not warrant that the material and information contained herein is

current or correct and assumes no responsibility for the use or misuse of any such material and information by the user.

BROADY FLOW CONTROL LIMITED

English Street, Kingston-Upon-Hull,

East Yorkshire, HU3 2DU.

Telephone: 01482 619601 Fax: 01482 619701

Email: sales@broady.co.uk Website: www.broady.co.uk

Potrebbero piacerti anche

- Valves HandbookDocumento51 pagineValves Handbookedhy_0367% (3)

- Stripping and Servicing The Theoben Rapid 7111Documento8 pagineStripping and Servicing The Theoben Rapid 7111graham487775% (4)

- Valves Details and UsageDocumento72 pagineValves Details and UsageKagira Drawing Soltuion100% (1)

- Piper's BrainDocumento291 paginePiper's BrainKevin BrownNessuna valutazione finora

- Valves General For DummiesDocumento42 pagineValves General For Dummiesdito100% (7)

- New Microsoft Word DocumentDocumento24 pagineNew Microsoft Word DocumentGaurav TripathiNessuna valutazione finora

- ValvesDocumento44 pagineValvesأحمد محمد قدريNessuna valutazione finora

- Valves 1660544940Documento141 pagineValves 1660544940richardNessuna valutazione finora

- GIW Slurry ManualDocumento14 pagineGIW Slurry ManualMehrdad AminkazemiNessuna valutazione finora

- Soportes STDDocumento119 pagineSoportes STDFabian Sepulveda100% (2)

- Control Valves BasicsDocumento203 pagineControl Valves Basicszeeshansuboor100% (1)

- ValvesDocumento141 pagineValvesSabith Mohammed100% (1)

- Gate ValvesDocumento13 pagineGate Valvesyessa gamuedaNessuna valutazione finora

- Airtower 26 CompressorDocumento4 pagineAirtower 26 CompressorJonson Cao0% (1)

- Compressed Air Source BookDocumento128 pagineCompressed Air Source Bookgfollert100% (1)

- Zurn Aquaflush z6000 ManualDocumento8 pagineZurn Aquaflush z6000 ManualrosaearlNessuna valutazione finora

- BALON Floating Valve - Installation and Repair Manual 2Documento13 pagineBALON Floating Valve - Installation and Repair Manual 2Rudi Syarif Hidayat HarahapNessuna valutazione finora

- Francis Turbine Laboratory ReportDocumento6 pagineFrancis Turbine Laboratory ReportMichael Adrian60% (5)

- The Range and Level of Impurities in CO2 Streams From CCSDocumento47 pagineThe Range and Level of Impurities in CO2 Streams From CCSJonson CaoNessuna valutazione finora

- Calculation of Wall Thickness MAWP API 5l x52 (Rev-2)Documento21 pagineCalculation of Wall Thickness MAWP API 5l x52 (Rev-2)YusepSúarðiNessuna valutazione finora

- CCUS in Steel IndustryDocumento52 pagineCCUS in Steel IndustryJonson CaoNessuna valutazione finora

- Heat Loss Insulated PipeDocumento14 pagineHeat Loss Insulated PipeJonson CaoNessuna valutazione finora

- Presentation of ValvesDocumento183 paginePresentation of ValvesfazarbadhushaNessuna valutazione finora

- Valves 110722053925 Phpapp01Documento77 pagineValves 110722053925 Phpapp01Jogi Oscar SinagaNessuna valutazione finora

- Es Acv M115F M1115FDocumento4 pagineEs Acv M115F M1115FWattsNessuna valutazione finora

- Safey & SOP (Hydraulic)Documento3 pagineSafey & SOP (Hydraulic)afiqzeroNessuna valutazione finora

- Steam Systems PDFDocumento20 pagineSteam Systems PDFchristian vergaray gonzales100% (1)

- Deployment of CCS in The Cement IndustryDocumento139 pagineDeployment of CCS in The Cement IndustryJonson CaoNessuna valutazione finora

- Acorn BEIS Update 051020 FINALDocumento23 pagineAcorn BEIS Update 051020 FINALJonson CaoNessuna valutazione finora

- D75KS Manual Partes PDFDocumento806 pagineD75KS Manual Partes PDFSara100% (3)

- Blowdown TankDocumento1 paginaBlowdown TankShameer Majeed0% (1)

- FEED-Study-Report-DG3 - Redacted - Version - 03-2 EFWDocumento266 pagineFEED-Study-Report-DG3 - Redacted - Version - 03-2 EFWJonson Cao100% (1)

- Valves Gate DamperDocumento54 pagineValves Gate DamperLalit MeenaNessuna valutazione finora

- Inlet ValveDocumento5 pagineInlet Valveujwol_phaijuNessuna valutazione finora

- Grantham Briefing Paper - Carbon Capture Technology - November 2010Documento20 pagineGrantham Briefing Paper - Carbon Capture Technology - November 2010Jonson CaoNessuna valutazione finora

- The Costs of CO2 TransportDocumento53 pagineThe Costs of CO2 TransportJonson CaoNessuna valutazione finora

- Callide Oxyfuel With CCS ProjectDocumento61 pagineCallide Oxyfuel With CCS ProjectJonson CaoNessuna valutazione finora

- Global Technology Roadmap For CCS in RefineriesDocumento44 pagineGlobal Technology Roadmap For CCS in RefineriesJonson CaoNessuna valutazione finora

- Farris Valve ManualDocumento11 pagineFarris Valve ManualsumsolcaggNessuna valutazione finora

- Energy From Waste Plants With Carbon Capture FinalDocumento34 pagineEnergy From Waste Plants With Carbon Capture FinalJonson CaoNessuna valutazione finora

- PLTU Nagan Raya NAD 2X110MW: Boiler Operation Manual (Startup Boiler Operation Manual) Vol.1 - 4ADocumento27 paginePLTU Nagan Raya NAD 2X110MW: Boiler Operation Manual (Startup Boiler Operation Manual) Vol.1 - 4AWahyuda IckyNessuna valutazione finora

- Pipe Flow Expert User GuideDocumento182 paginePipe Flow Expert User Guidelilbie100% (1)

- Isolation Valve - Watts E3243Documento4 pagineIsolation Valve - Watts E3243AHMAD ISLAHINessuna valutazione finora

- Weflo Nrs Gate Op and MaintDocumento5 pagineWeflo Nrs Gate Op and MaintyusufNessuna valutazione finora

- Type 2600 FlowstarDocumento2 pagineType 2600 FlowstartakenoveraccountNessuna valutazione finora

- Wafer Check Valves - O&MDocumento4 pagineWafer Check Valves - O&MjayakumarNessuna valutazione finora

- Condensate Collection (CCA/CCAF/CCM) and Steam Distribution (MSD/SMSD) Manifolds Installation, Operation and Maintenance InstructionsDocumento4 pagineCondensate Collection (CCA/CCAF/CCM) and Steam Distribution (MSD/SMSD) Manifolds Installation, Operation and Maintenance InstructionsMarcial NuñezNessuna valutazione finora

- Forged Steel Valves Manual-AllDocumento7 pagineForged Steel Valves Manual-Allshganesh81gmailcomNessuna valutazione finora

- Types of ValvesDocumento6 pagineTypes of ValvesersgdNessuna valutazione finora

- Stainless Series S115-43 or S6115-43 (Globe), S1115-43 or S61115-43 (Angle) Specification SheetDocumento1 paginaStainless Series S115-43 or S6115-43 (Globe), S1115-43 or S61115-43 (Angle) Specification SheetWattsNessuna valutazione finora

- Instruction Manual: Bharat Heavy Electricals Limited TiruchirapalliDocumento7 pagineInstruction Manual: Bharat Heavy Electricals Limited TiruchirapalliUJJAL KUMAR BHATTACHARYAYNessuna valutazione finora

- Ex Reg2ndDocumento57 pagineEx Reg2nddaviddealbaNessuna valutazione finora

- WNCO Valve's WN-1 Valve MaintenanceDocumento5 pagineWNCO Valve's WN-1 Valve MaintenancethritaNessuna valutazione finora

- N-583 Foot ValveDocumento1 paginaN-583 Foot ValveSầu ĐờiNessuna valutazione finora

- Manual Mantenimiento Cuadradas Rev.1Documento10 pagineManual Mantenimiento Cuadradas Rev.1pelaeztemplarioNessuna valutazione finora

- Stainless Series S118-4 or S6118-4 (Globe), S1118-4 or S61118-4 (Angle) Specification SheetDocumento1 paginaStainless Series S118-4 or S6118-4 (Globe), S1118-4 or S61118-4 (Angle) Specification SheetWattsNessuna valutazione finora

- Stainless Series S110-14 or S6110-14 (Globe), S1110-14 or S61110-14 (Angle) Specification SheetDocumento1 paginaStainless Series S110-14 or S6110-14 (Globe), S1110-14 or S61110-14 (Angle) Specification SheetWattsNessuna valutazione finora

- Stainless Series S110-14 or S6110-14 (Globe), S1110-14 or S61110-14 (Angle) Specification SheetDocumento1 paginaStainless Series S110-14 or S6110-14 (Globe), S1110-14 or S61110-14 (Angle) Specification SheetWattsNessuna valutazione finora

- 8in Wafer Ball Vale IMODocumento2 pagine8in Wafer Ball Vale IMOw4uengineerNessuna valutazione finora

- Stainless Series S113-19 or S6113-19 (Globe), S1113-19 or S61113-19 (Angle) Specification SheetDocumento1 paginaStainless Series S113-19 or S6113-19 (Globe), S1113-19 or S61113-19 (Angle) Specification SheetWattsNessuna valutazione finora

- AAP S19 Check Valves & Strainers SDocumento13 pagineAAP S19 Check Valves & Strainers SAppleuk SudarNessuna valutazione finora

- Butterfly Valves Waferdesign Manual O&mDocumento17 pagineButterfly Valves Waferdesign Manual O&mMilu OberoiNessuna valutazione finora

- Series V100 Ball ValveDocumento20 pagineSeries V100 Ball ValvejenniferNessuna valutazione finora

- Stainless Steel S110-10 or S6110-10 (Globe), S1110-10 or S61110-10 (Angle) Specification SheetDocumento1 paginaStainless Steel S110-10 or S6110-10 (Globe), S1110-10 or S61110-10 (Angle) Specification SheetWattsNessuna valutazione finora

- Classic Series F113-12 (Globe), F1113-12 (Angle) Specification SheetDocumento1 paginaClassic Series F113-12 (Globe), F1113-12 (Angle) Specification SheetWattsNessuna valutazione finora

- Stainless Series S113-12 or S6113-12 (Globe), S1113-12 or S61113-12 (Angle) Specification SheetDocumento1 paginaStainless Series S113-12 or S6113-12 (Globe), S1113-12 or S61113-12 (Angle) Specification SheetWattsNessuna valutazione finora

- Angle Type Blowdown ValveDocumento7 pagineAngle Type Blowdown ValverikumohanNessuna valutazione finora

- Classic Series F118-3 (Globe), F1118-3 (Angle) Specification SheetDocumento1 paginaClassic Series F118-3 (Globe), F1118-3 (Angle) Specification SheetWattsNessuna valutazione finora

- Classic Series F110-10 (Globe), F1110-10 (Angle) Specification SheetDocumento1 paginaClassic Series F110-10 (Globe), F1110-10 (Angle) Specification SheetWattsNessuna valutazione finora

- Fw750 Operation ManualDocumento20 pagineFw750 Operation ManualHamza BenchabiNessuna valutazione finora

- Series 13 Dir-Act 3-Piece Ball Valve Installation, Operation, and Maintenance InstructionsDocumento3 pagineSeries 13 Dir-Act 3-Piece Ball Valve Installation, Operation, and Maintenance InstructionsluchitocapoNessuna valutazione finora

- Val-Matic Rubber-Seated Ball Valve: Operation, Maintenance and Installation ManualDocumento12 pagineVal-Matic Rubber-Seated Ball Valve: Operation, Maintenance and Installation ManualDhim131267Nessuna valutazione finora

- Introduction To Valves - Butterfly ValvesDocumento9 pagineIntroduction To Valves - Butterfly Valvesangelufc99Nessuna valutazione finora

- Valvs FBVDocumento10 pagineValvs FBVgabi_nanaNessuna valutazione finora

- Double Disc Check Valve: Job NameDocumento10 pagineDouble Disc Check Valve: Job NameAditya RochmansyahNessuna valutazione finora

- Swing-Flex Check Valve: Operation, Maintenance and Installation ManualDocumento8 pagineSwing-Flex Check Valve: Operation, Maintenance and Installation ManualAhmed ShawkyNessuna valutazione finora

- Mustang Series M115-11 or M6115-11 (Globe), M1115-11 or M61115-11 (Angle) Specification SheetDocumento1 paginaMustang Series M115-11 or M6115-11 (Globe), M1115-11 or M61115-11 (Angle) Specification SheetWattsNessuna valutazione finora

- Failure Analysis of Ball ValvesDocumento12 pagineFailure Analysis of Ball ValvesGhiyat FarisNessuna valutazione finora

- Failure Analysis of Ball Valves WorcesterDocumento12 pagineFailure Analysis of Ball Valves Worcestercvishwas1159Nessuna valutazione finora

- IOM Manual For Air Cylinder Operated ValvesDocumento21 pagineIOM Manual For Air Cylinder Operated Valvesjhon riosNessuna valutazione finora

- Classic Series F115-58 (Globe), F1115-58 (Angle) Specification SheetDocumento1 paginaClassic Series F115-58 (Globe), F1115-58 (Angle) Specification SheetWattsNessuna valutazione finora

- Sherwood Valves Cylinder ValvesDocumento17 pagineSherwood Valves Cylinder Valvesklr_sean100% (1)

- Simple Plumbing Repairs for the Home and FarmsteadDa EverandSimple Plumbing Repairs for the Home and FarmsteadNessuna valutazione finora

- CCS in PPLDocumento11 pagineCCS in PPLJonson CaoNessuna valutazione finora

- Potential For Carbon Dioxide EOR in The Cooper and Eromanga BasinsDocumento73 paginePotential For Carbon Dioxide EOR in The Cooper and Eromanga BasinsJonson CaoNessuna valutazione finora

- Energy Consumption and Energy Analysis of MEA-Based CCSDocumento8 pagineEnergy Consumption and Energy Analysis of MEA-Based CCSJonson CaoNessuna valutazione finora

- Towards A Transport Infrastructure For Large-Scale CCS in EuropeDocumento51 pagineTowards A Transport Infrastructure For Large-Scale CCS in EuropeJonson CaoNessuna valutazione finora

- Heat Conduction Pipe InsulationDocumento1 paginaHeat Conduction Pipe InsulationJonson CaoNessuna valutazione finora

- Increase in Global Electricity Generation by 2040: 770 Million PeopleDocumento21 pagineIncrease in Global Electricity Generation by 2040: 770 Million PeopleJonson CaoNessuna valutazione finora

- Humber Hydrogen NetworkDocumento11 pagineHumber Hydrogen NetworkJonson CaoNessuna valutazione finora

- SaskPower CCSDocumento62 pagineSaskPower CCSJonson CaoNessuna valutazione finora

- BS 5266-6-1999Documento12 pagineBS 5266-6-1999Jonson CaoNessuna valutazione finora

- BS 5266-4-1999Documento28 pagineBS 5266-4-1999Jonson CaoNessuna valutazione finora

- Air Compressor ASK-27TDocumento5 pagineAir Compressor ASK-27TJonson CaoNessuna valutazione finora

- Operating and Maintenance Instructions For: Air Valve For Waste Water and Potable WaterDocumento3 pagineOperating and Maintenance Instructions For: Air Valve For Waste Water and Potable WaterhoseyliauNessuna valutazione finora

- Chapter6 Giacomini CatalogueDocumento8 pagineChapter6 Giacomini CataloguecristyryeNessuna valutazione finora

- Full Floating Clapper Assembly: Swing Check ValveDocumento2 pagineFull Floating Clapper Assembly: Swing Check Valvemubarak aliNessuna valutazione finora

- Online TRG CourseDocumento12 pagineOnline TRG Coursegreyphen greyNessuna valutazione finora

- Water SystemDocumento9 pagineWater SystemArun GuptaNessuna valutazione finora

- NEW Atlanta PPR - TRI FOLD - 2021Documento2 pagineNEW Atlanta PPR - TRI FOLD - 2021Aldrex ValerosNessuna valutazione finora

- Modul Puskesmas BLUD 2019 - Keuda - Kemendagri - CompressedDocumento183 pagineModul Puskesmas BLUD 2019 - Keuda - Kemendagri - CompressedeliaNessuna valutazione finora

- Compressed Air Piping AluminiumDocumento16 pagineCompressed Air Piping AluminiumVinay MalikNessuna valutazione finora

- Instructions For UGS 43Documento2 pagineInstructions For UGS 43rıdvan duranNessuna valutazione finora

- ENVIRO GUARD - Pipe End CoversDocumento2 pagineENVIRO GUARD - Pipe End CoversadalghusaNessuna valutazione finora

- ATT Stop and Control Valves-WriteupDocumento3 pagineATT Stop and Control Valves-WriteupErwin Fernandes GurningNessuna valutazione finora

- User Instructions: Installation Operation Maintenance Serck Audco Pressure Balanced Plug ValveDocumento16 pagineUser Instructions: Installation Operation Maintenance Serck Audco Pressure Balanced Plug ValveApoorv GoenkaNessuna valutazione finora

- White Star Quatro 1300HP Performance ChartDocumento1 paginaWhite Star Quatro 1300HP Performance ChartMo SafNessuna valutazione finora

- 760 Oil SeparatorDocumento10 pagine760 Oil SeparatorrazvanNessuna valutazione finora

- Outdoor Units: EDUS 39 - 606A - R1Documento31 pagineOutdoor Units: EDUS 39 - 606A - R1msn20091Nessuna valutazione finora

- Pneumatic HammerDocumento45 paginePneumatic HammerKarthi KeyanNessuna valutazione finora

- Longest Path in SNDC ProjectDocumento1 paginaLongest Path in SNDC ProjectJun UrbanoNessuna valutazione finora

- Sar695 Cy05 000303Documento18 pagineSar695 Cy05 000303Mohammad RizwanNessuna valutazione finora

- User & Installation Manual: Intarblock IntartopDocumento44 pagineUser & Installation Manual: Intarblock IntartopAlex LaraNessuna valutazione finora