Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Petrom OMV Norm DEF 2001 Rom Eng Rev.2 2009-06-01

Caricato da

lucianduCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Petrom OMV Norm DEF 2001 Rom Eng Rev.2 2009-06-01

Caricato da

lucianduCopyright:

Formati disponibili

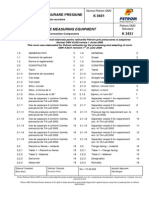

Norma Petrom OMV

RECIPIENTI SUB PRESIUNE

DEF 2001

Proiectare si constructie

Pag. 1

PRESSURE VESSELS

Petrom OMV Standard

Design and Construction

DEF 2001

Aceasta norma a fost elaborata pentru rafinariile Petrom prin prelucrarea si adaptarea normei

OMV DEF 2001 rev.05.12.2008. In caz de contradictii continutul versiunii originale germane are prioritate.

This norm was elaborated for Petrom refineries by the processing and adapting of norm

OMV DEF 2001 rev. 05.12.2008.In case of contradiction the content of German Version has priority.

Pct.

Cuprins

Pag.

Item

1.0

1.1

1.2

1.3

INFORMATII GENERALE

Domeniul de aplicare

Norme si reglementari

Principii de proiectare si constructie

3

3

3

4

1.0

1.1

1.2

1.3

1.4

2.0

3.0

3.1

3.2

3.3

3.4

Desene

MATERIALE

PROIECTARE SI CONSTRUCTIE

Informatii generale

Calcul

Constructie

Constructia specifica componentelorRecipienti uz general

Constructia specifica componentelor

Schimbatoare de caldura tubulare

Constructia specifica componentelor

Racitoare de aer

Fabricatie

VERIFICARI SI RECEPTII

DOCUMENTATIE

Documente pe care ofertantul trebuie sa

le prezinte inainte de incheierea

contractului

Documentatia de receptie

LIVRARE SI EXPEDIERE

Volum de livrare

Piese de rezerva

Neinclus in volumul de livrare

Starea marfii livrate

Ambalare

Documente ce se livreaza cu marfa

6

8

10

10

12

14

18

1.4

2.0

3.0

3.1

3.2

3.3

3.4

28

3.5

33

3.6

37

39

41

41

3.7

4.0

5.0

5.1

41

43

43

44

44

44

44

46

5.2

6.0

6.1

6.2

6.3

6.4

6.5

6.6

3.5

3.6

3.7

4.0

5.0

5.1

5.2

6.0

6.1

6.2

6.3

6.4

6.5

6.6

Elaborat / Compiled:

Verificat / Checked:

Parvu Mihai

Decusara Felicia

Content

Pag.

General

Scope

Standards and regulations

Design and

construction principles

Drawings

MATERIALS

DESIGN AND CONSTRUCTION

General

Calculation

Design

Component specific design

Vessels, general use

Component specific design

Tubular heat exchangers

Component specific design

Air-cooled heat exchangers

Manufacturing

TESTING AND ACCEPTANCE

DOCUMENTATION

Documents to be handed over by the

bidder before contract award

3

3

3

4

Acceptance documentation

DELIVERY AND DISPATCH

Scope of delivery

Spare parts

Not in scope of delivery

Condition of delivered goods

Packing

Documents to be attached to vessel

41

43

43

44

44

44

44

46

Rev: 2/01.06.2009

6

8

10

10

12

14

18

28

33

37

39

41

41

Aprobat / Approved:

Neil Morgan

Lazarescu Valerian

Divizia Rafinare Petrom OMV isi rezerva toate drepturile asupra acestei documentatii si va da in judecata pe orice persoana neautorizata sa o utilizeze sau sa o

transmita la terti

Petrom OMV Refining Division reserves all its rights to these documents and will take legal action against anyone

using them or passing them on without authorization

Pag./Page 2 Norma Petrom OMV DEF 2001 / Petrom OMV Standard DEF 2001

Pct.

Anexa 1

Anexa 2

Cuprins

Pag.

Item

47

51

Annex 1

Annex 2

52

Annex 3

53

54

Annex 4

Anexa 5

Norme si reglementari

Punctele ce trebuie sa fie clarificate

inainte de contractare

Valori minime pentru grosime

nominala perete

Incarcarea racordurilor

Flansa sudata cu gat lung

Anexa 6

Conceptul general de etansare

Anexa 7

Anexa 3

Anexa 4

Anexa 8

Content

Pag.

Standards and regulations

List of agreements to be made

prior to contract award

Minimum nominal wall thicknesses

47

51

52

Annex 5

Nozzle loads

Long welding neck flanges

53

54

55

Annex 6

General gasket guideline

55

Elemente de imbinare pentru

impamantare

Placarea prin sudare

57

Annex 7

Grounding lugs

57

58

Annex 8

Weld overlay cladding

58

Revizuiri

61

Revisions

61

Pag./Page 3 Norma Petrom OMV DEF 2001 / Petrom OMV Standard DEF 2001

1.0. INFORMATII GENERALE

1.0. GENERAL

Prezenta norma cuprinde cerintele impuse pentru

This standard contains requirements for

recipienti care intra sub incidenta HG 584/2004

recipienti care intra sub incidenta Prescriptiilor

Tehnice ISCIR -PT ISCIR C4/2003,C1/2003

recipientii pentru o presiune maxima admisa de

pana la 0,5 bar

recipienti pentru exploatare in vid

recipienti fara presiune

vessels that are subject to HG 584/2004

vessels that are subject to the ISCIR Technical

Prescriptions- PT ISCIR C4/2003,C1/2003

vessels for maximum allowable pressure of

up to 0.5 bar

vessels for vacuum operation

unpressurized vessels

din urmatoarele Grupe principale de componente :

of the following Construction Main Groups:

D Coloane, reactoare

E Schimbatoare de caldura, racitoare cu aer

F Vase, separatoare, filtre

D Columns, reactors

E Heat exchangers, coolers

F Vessels, separators, filters

Observatie:

Coloanele, reactoarele, schimbatoarele de caldura, racitoarele cu aer,

separatoarele si filtrele vor fi mentionate cu denumirea generica

recipiente.

Notes:

In the following, columns, reactors, heat exchangers, coolers,

separators and filters are all referred to as vessels.

Abaterile de la cerintele prezentei norme sau exceptiile

specifice unui proiect necesita acordul in scris din

partea managerului de proiect Petrom OMV si al

operatorului instalatiei.

Deviations from or project-related exceptions to the

requirements of this standard require the written

authorization of the Petrom OMV project manager and

the plant operator.

Sunt dorite in mod special abateri care ofera solutii

generatoare de avantaje economice si care sunt

superioare restrictiilor de calitate.

Deviations that bring economic advantage and exceed

quality cutbacks are especially welcome.

1.1.

1.1.

Domeniul de aplicare

Scope

Prezenta norma se aplica pentru Rafinariile Petrom

OMV. Prezenta norma poate fi aplicata si in alte locatii.

This standard is valid for Petrom OMV Refineries.

Denumirile functiilor mentionate in prezenta norma vor

fi intelese la genul neutru.

The function descriptions in this standard are to be

regarded as gender-neutral.

1.2.

1.2.

Norme si reglementari

This standard can also be applied by other subsidiaries.

Standards and regulations

In coroborare cu prezenta norma se vor respecta

dispozitiile legale, reglementarile si directivele

mentionate in Anexa 1 si care sunt valabile in Romania,

fiecare in varianta in vigoare.

In conjunction with this standard, the respective current

versions of the legal regulations, standards, and

directives valid in Romania and stated in 0 shall be

taken into account.

Nu consideram ca enumerarea prezentata este

completa.

This listing does not claim to be complete.

Daca intre diferitele dispozitii, reglementari, norme si

directive apar diferente sau contradictii, iar aspectele

respective nu sunt in mod expres clarificate prin

prezenta norma, se va aplica reglementarea cu

formularea cea mai restrictiva. In cazul in care

prevederile se exclud reciproc, atunci se va aplica

reglementarea prevazuta de legislatia romaneasca.

In the event of deviations or conflicts arising between

the various legal regulations, standards, and directives

and there is no explicit specification in this standard,

then the strictest formulation is to be applied. Where

they are mutually exclusive, in any case the Romanian

statutory regulations are to be applied.

Intra in responsabilitatea executantului sa verifice daca

prevederile prezentei norme sunt adecvate scopului

lucrarii respective. Aplicarea normei nu il exonereaza

pe executant de raspunderea pe care o are in calitate

de antreprenor profesionist si responsabil.

The contractor is responsible for checking the

appropriateness of this standard for the intended

purpose. The application does not relieve the contractor

of his responsibility as specialist and independent

entrepreneur.

Pag./Page 4 Norma Petrom OMV DEF 2001 / Petrom OMV Standard DEF 2001

Daca executantul are obiectii cu privire la una dintre

prevederile stabilite, el il va informa imediat in scris pe

angajator despre acest lucru.

If the contractor has reservations concerning a

specification stipulated, then he shall notify the client

about this in written form immediately.

1.3.

1.3.

Principii de proiectare si constructie

Design and construction principles

Se aplica reglementarile cuprinse in

The following regulations apply:

PT ISCIR in vigoare

PT ISCIR in force

Directiva privind echipamentele sub presiune

97/23/EU (PED)transpusa la nivel national prin HG

584/2004 privind stabilirea condiiilor de introducere

pe pia a echipamentelor sub presiune

Pressure Equipment Directive 97/23/EC

(PED),transposed at the national level through HG

584/2004 concerning establishment of conditions

for bringing equipment on the market

Directivei privind recipientii simpli sub presiune

87/404/EU transpusa la nivel national prin HG

454/2003 privind stabilirea condiiilor de introducere

pe pia a recipientelor simple sub presiune

Simple Pressure Vessels Directive 87/404/EEC

transposed at the national level through HG

454/2003 concerning establishment of conditions

for bringing simple pressure vessels on the market.

Standarde armonizate sub incidenta directivelor de

mai sus

Armonisated standards connected with the above

mentionated directives

Proiectarea trebuie sa indeplineasca standardele

tehnice actuale.

Design shall correspond to the latest state of the art.

Recipientele, componentele si accesoriile care nu

intra sub incidenta Prescriptiilor tehnice ISCIR

trebuie sa indeplineasca reglementarile mentionate

in Directiva privind echipamentele sub presiune

97/23/EU ( PED) transpusa la nivel national prin

HG 584/2004 precum si standardele SR EN

armonizate sub incidenta acestei directive.

Vessels, assemblies, and accessories that are not

within the scope of the Technical ISCIR

Prescriptions shall nevertheless satisfy Pressure

Equipment Directive 97/23/EC (PED) ransposed at

the national level through HG 584/2004 as well as

the armonisated standards connected with the

above mentionated directive.

Nota:

Cap.III art 10 din HG 584/2004 corespunde Articolului 3,

paragraph (3) si Annex I din PED.

Note:

Cap.III point 10 from HG 584/2004 correspond to Art.3,

paragraph (3) and Annex I in PED.

In proiectare se vor respecta cerintele impuse de

legislatia corespunzatoare privind controlul calitatii

mediului.

When designing, the requirements of national

regulations on environment quality control are to be

taken into account.

Se aplica normele Petrom OMV de referinta.

(de exemplu si normele Petrom OMV referitoare la

echipamentele de masurare AMC sau alte accesorii.)

The relevant Petrom OMV Standards shall apply (e.g.

also those Petrom OMV Standards for M & C

equipment or other accessories).

Contractorul trebuie sa ia masuri pentru ca normele

Petrom OMV sa fie aplicate si pentru componentele

livrate de terti sau pentru Package Units.

The contractor shall ensure that the Petrom OMV

Standards are also applied in the case of parts from

third parties and for package units.

Pag./Page 5 Norma Petrom OMV DEF 2001 / Petrom OMV Standard DEF 2001

1.3.1. Formulare pentru specificatie

1.3.1

La Specificatia tehnica se vor anexa formulare

corespunzatoare completate de catre firma partenera:

Appropiate standard forms are to be filled in by the

customers engineer and appended to the technical

specification:

Formulare pentru recipiente, reactoare si coloane

Formulare pentru schimbatoare de caldura tubulare

Formulare pentru racitoare de aer

Standard forms for specification

For vessels, reactors and columns

For tubular heat exchangers

For air-cooled heat exchangers

Pag./Page 6 Norma Petrom OMV DEF 2001 / Petrom OMV Standard DEF 2001

1.4.

Desene

1.4.

Drawings

1.4.1. Intocmirea desenelor

1.4.1. Drawing details

Desenele vor fi predate managerului de proiect Petrom

OMV pe suport de hartie si suport electronic.

Drawings shall be given to the Petrom OMV project

manager in paper and electronic form.

In cadrul documentatiei, se vor preda desene as-built.

"As-built" drawings shall be submitted within the context

of the documentation.

Norme Petrom/ OMV

Se aplica urmatoarele norme OMV / Concern:

301 Planuri si desene; Executie

350 ff Intocmirea planurilor in sistem electronic;

Generalitati

Petrom /OMV Standards

OMV Standards/Group Standards are to be applied:

301 Plans and drawings; generation

350 ff Electronic plan generation; general

Formatul datelor

Formatul fisierelor si al suportului de stocare date vor fi

convenite cu managerul de proiect Petrom OMV.

Data format

Data formats and data medium format are to be agreed

on with the Petrom OMV project manager.

Modificari

Modificarile vor fi marcate in desene prin triunghiuri,

impreuna cu numarul de revizuire aferent.

Amendments

Amendments are to be indicated on the drawings by

triangles containing the revision number.

Continutul

Desenele impreuna cu documentele aferente trebuie sa

contina urmatoarele date, daca este necesar, pentru

fiecare incinta (camera) de presiune:

Contents

The drawings together with the associated documents

shall contain the following data; if applicable, per

pressurized chamber:

Bloc-titlu (cartusul) completat conform

Normei Petrom OMV 310-1

Document header filled out acc. to

Petrom OMV Standard 310-1

Numarul echipamentului si denumirea, in rubrica

Denumire din bloc-titlu (cartus)

Equipment number and name in the Benennung

field of the header

Pag./Page 7 Norma Petrom OMV DEF 2001 / Petrom OMV Standard DEF 2001

dimensiuni

Dimensions

tolerante

Tolerances

calitatea suprafetelor prelucrate

Surface Quality

rezerva de coroziune

Corrosion Allowance

coeficientul cordonului de sudura

Weld joint coefficient

presiunea maxima admisa PS

Maximum allowable pressure PS

temperatura minima/maxima admisa TS

Maximum/minimum allowable temperature TS

presiunea de proba PT

Test pressure

volum

Volume

greutate proprie

Dead weight

categoria si modulul de evaluare conform

ISCIR/PED

categoria si modulul de evaluare conform

ISCIR/PED

placuta cu date de constructie completata si, dupa

caz, placuta indicatoare de momente de strangere,

pe desenul de ansamblu

Filled out manufacturers name plate and if

applicable the tightening torques plate on the

general layout drawing

lista de piese

Part list

materiale

Materials

tipul de certificate de inspectie pentru materiale

Types of inspection documents for materials

date complete privind sudurile

(planul de suduri, instructiuni de sudare (WPS))

Complete details on welding work

(welding plan, welding procedure sheets (WPS))

date complete privind verificarile si inspectiile

(planul de verificari si inspectii)

Complete details on testing and inspection

(Inspection and test plan (ITP))

planul tratamentelor termice

Annealing plan

date complete privind etapele de executie, cu

termenele planificate (planul de fabricatie)

Complete details on manufacturing steps and

planned target dates (manufacturing plan)

tipul si grosimea izolatiei

Type and thickness of insulation

tipul de acoperire

Type of coating

instructiuni de montaj si de ridicare

(exemple vezi Punct 6.5

Mounting and lifting instructions

(examples see item 6.5)

ordinea operatiilor de asamblare

Order of assembly

Garnituri de etansare

Pentru garniturile care nu sunt circulare, se vor intocmi

desene separate, de exemplu garnituri cu nervuri sau

garnituri rectangulare.

Gaskets

Separate drawings shall be produced for gaskets that

do not have a circular ring shape, e.g. for gaskets with

ribs or for rectangular gaskets.

Fascicul tubular

Desenul fascicului trebuie sa indice numarul de tevi pe

fiecare rand si numarul total de tevi.

Tube bundles

The drawing of the tube sheet shall contain the number

of tubes per row and the total number of tubes.

Fascicul tubular cu tevi in forma de U

Desenul fascicului tubular cu tevi in forma de U trebuie

sa contina un tabel cu lungimea liniara (desfasurata) a

tevilor.

U-tube bundles

The representation of the U-tubes shall contain a table

with the linear length of the tubes.

Pag./Page 8 Norma Petrom OMV DEF 2001 / Petrom OMV Standard DEF 2001

Stuturi,racorduri,guri de vizitare, decupaje

Desenele trebuie sa contina un tabel cu stuturi si un

tabel cu sarcinile admise de incarcare a stuturilor.

Tabelul cu stuturi trebuie sa includa si datele referitoare

la gurile de vizitare si la decupajele din rame.

Exemple de denumiri: S1, S2A, S2B, M1, A1

Pentru mai multe informatii privind denumirea, vezi

punctele specifice componentelor: 3.4.6,3.4.7,3.4.11.

Nozzles, manholes, openings

Drawings shall contain a nozzle table and a table with

the allowable nozzle loads. The nozzle table shall also

contain the data for the manholes and the openings in

skirts.

Designation examples: S1, S2A, S2B, M1, A1

For more detailed information on designation see the

component-specific items 3.4.6, 3.4.7, 3.4.11.

1.4.2. Verificarea desenelor

1.4.2. Drawing review

Contractorul trebuie sa prezinte managerului de proiect

Petrom OMV toate desenele si documentele aferente,

spre verificare. Daca nu se specifica altfel, pentru

prezentare se prevad urmatoarele termene, totusi, cel

mai tarziu cu o saptamana inainte de inceperea

fabricatiei:

The contractor shall submit all drawings and associated

documents to the Petrom OMV project manager for

reviewing. If not otherwise specified, the submission

shall be made until following due dates; however, at the

latest, 1 week before start of fabrication:

Desene, liste de piese, documente de sudura, plan

de derulare a procesului de fabricatie:

4 saptamani de la incredintarea contractului

Drawings, parts list, welding documents,

manufacturing plan:

4 weeks after contract award

Planul de verificari si inspectii:

6 saptamani de la incredintarea contractului

Inspection and Test plan:

6 weeks after contract award

Avizarea documentelor nu il exonereaza pe contractor

de responsabilitatea integrala care ii revine pentru

constructie, corectitudinea dimensiunilor si a datelor de

toleranta, precum si pentru respectarea tuturor

dispozitiilor legale si a cerintelor stipulate in Specificatia

tehnica.

The approval of the documents does not absolve the

contractor from his full responsibility for design,

dimensional correctness and tolerance statements as

well as observing all statutory regulations and the

requirements stated in the technical specification.

Abaterile de la documentele tehnice verificate de catre

organismul notificat sau abaterile de la cerintele

stipulate in Specificatia tehnica sunt admise numai

dupa o reverificare efectuata de organismul notificat si

cu aprobarea in scris a managerului de proiect Petrom

OMV.

Deviations from the technical documents reviewed by

the notified body or deviations from the requirements

stated in the technical specification are only possible

after renewed reviewing by the notified body and with

the written agreement of the Petrom OMV project

manager.

2.0.

2.0.

MATERIALE

MATERIALS

Alegerea materialelor va fi facuta inainte de incheierea

contractului, de comun acord cu managerul de proiect

Petrom OMV.

The choice of materials shall be made prior to contract

award and in agreement with the Petrom OMV project

manager.

Alegerea si utilizarea materialelor se realizeaza:

Choice and usage of materials is made:

in acceptiunea Directivei privind echipamentele sub

presiune 97/23/EC (PED),transpusa prin HG

584/2004 in legislatia romaneasca si prescriptii

tehnice ISCIR

in conformitate cu Specificatia tehnica,

in the sense of Pressure Equipment Directive

97/23/EC (PED),transposed at the national level

through HG 584/2004 and ISCIR Technical

Prescriptions

according to the technical specification,

in conformitate cu Normele Petrom OMV,

according to the Petrom OMV Standards,

in conformitate cu normativul tehnic aplicabil,

pe baza experientei in exploatare.

according to the technical design code to be

applied,

based on operational experience.

Pag./Page 9 Norma Petrom OMV DEF 2001 / Petrom OMV Standard DEF 2001

Tratamentele termice

Heat treatment

Pentru un recipient pentru care este prevazut un

tratament termic, vor fi comandate piese cu aceeasi

temperatura de revenire. Se va prevedea ca

temperatura de revenire sa fie indicata in certificatul de

material.

Parts for a vessel for which heat treatment is intended

are to be ordered with the same

tempering temperature. It is to be specified that

the tempering temperature is to be shown in the

material certificate.

Pag./Page 10 Norma Petrom OMV DEF 2001 / Petrom OMV Standard DEF 2001

3.0.

PROIECTARE SI CONSTRUCTIE

3.0.

DESIGN AND CONSTRUCTION

3.1 Informatii generale

3.1.

General

3.1.1. Intretinere si deservire

3.1.1

Maintenance and operation

Echipamentele vor fi astfel planificate si realizate, incat

Equipment shall be planned and erected so that

operatiile de intretinere sa poata fi efectuate fara un

mare efort tehnic suplimentar

the maintenance can be effected without any great

additional technical effort

sa fie posibila operarea in teren, in timpul

functionarii, de catre un singur operator.

the operation in the field during operation can be

carried out by a single person.

3.1.2

Durata de viata,

durata de functionare continua

3.1.2. Life time,

continuous operation period

Se va porni de la o durata de utilizare de 30 de ani, in

conditiile respectarii criteriilor tehnico-economice.

A lifetime of 30 years under technical-economical

criteria is to be assumed.

Solutiile tehnice vor fi astfel alese incat, in conditiile

unei utilizari conform scopului, sa se faciliteze o

functionare neintrerupta a recipientului de minimum 6

ani. Instructiunile de exploatare nu trebuie sa prevada

date contrare.

Technical solutions are to be selected such that when

operated as intended, uninterrupted operation of the

vessels for at least 6 years is possible. The operating

instructions may not require anything to the contrary.

Observatie: ca si in HG 584/2004, prin recipiente se inteleg si

reactorii, coloanele si schimbatoarele de caldura (deci si fasciculele

tubulare de tevi).

Note: As in the HG 584/2004, reactors, columns, and heat

exchangers (therefore also tube bundles) are also understood to be

"vessels".

3.1.3. Module pentru evaluarea conformitatii

3.1.3

Conformity assessment

Alegerea organismului notificat va fi facuta inainte de

incheierea contractului, de comun acord cu managerul

de proiect Petrom OMV.

The choice of the notified body is to be agreed on with

the Petrom OMV project manager prior to contract

award.

Pentru proiectarea, fabricarea si verificarea recipientilor

care intra sub incidenta HG 584/2004, se vor aplica

modulele specificate in tabelul de mai jos, in functie de

categorie.

For the design, manufacture and testing of vessels that

are in the scope of HG 584/2004,, the modules

according to the following table are to be used,

depending on the category.

Pot fi aplicate si acele module, specificate in tabelul de

mai jos, aferente unei categorii superioare.

Those modules from the table may also be used that

are assigned to a higher category.

Categorie

Modul

Category

Module

Cap.III,art.10

I

II

III

IV

A (fara marcaj CE)

A1

A1

G sau B+F sau B1+F

G sau B+F

Cap.III,art.10

I

II

III

IV

A (no CE-Marking)

A1

A1

G or B+F or B1+F

G or B+F

Tabel 1: Module pentru procedura de evaluare a conformitatii

Table 1: Conformity Assessment Modules

Pag./Page 11 Norma Petrom OMV DEF 2001 / Petrom OMV Standard DEF 2001

3.1.4

Normativ tehnic de proiectare

3.1.4. Technical design code

Alegerea normativului tehnic de proiectare va fi facuta

inainte de incheierea contractului, de comun acord cu

managerul de proiect Petrom OMV.

The choice of the technical design code is to be agreed

on with the Petrom OMV project manager prior to

contract award.

Pot fi aplicate urmatoarele reglementari tehnice:

The following technical design codes may be applied:

Reglementarea AD 2000

AD 2000 Codes

EN 13445 Recipienti sub presiune neexpusi la foc

EN 13445 Unfired pressure vessels

EN 286-1 Recipienti simpli sub presiune

neexpusi la foc pentru aer sau azot; Recipienti sub

presiune pentru uz general

TRD completata cu Directivele VGB

EN 286-1 Simple unfired pressure vessels

designed to contain air or nitrogen;

Pressure vessels for general

purposes

ASME Cod 2004 Boilere si Vase sub presiune,

Sectiunea VIII

TRD supplemented with the VGB-Guidelines

ASME Boiler and Pressure Vessel Code 2004,

Section VIII

TEMA Standards, Class R

API 661

TEMA Standarde, Class R

API 661

Racitoare de aer pentru aplicatii

generale in rafinarii

Air-Cooled Heat Exchangers for

General Refinery Service

3.1.5. Detalii nespecificate

3.1.5

Not specified details

Componentele pentru care datele nu sunt specificate

complet, chiar si dupa aplicarea prezentei norme, vor fi

proiectate de catre contractor, cu conditia respectarii

reglementarilor tehnice, si vor fi prezentate

managerului de proiect Petrom OMV, spre aprobare,

cel mai tarziu in etapa de verificare a desenelor.

Components that remain not completely specified even

after application of this Petrom OMV Standard are to be

designed by the contractor himself, observing generally

accepted rules of technology, and submitted to the

Petrom OMV project manager for approval within the

context of the drawing review.

Detaliile referitoare la pozitia exacta sau la pozitia de

montaj a componentelor, care nu au putut fi indicate in

momentul incheierii contractului, vor fi solicitate de

managerul de proiect Petrom OMV respectiv vor fi

transmise acestuia, inainte de inceperea fabricatiei.

Details of exact position or mounting orientation of

components that still could not be given at the

conclusion of contract are to be queried from the

Petrom OMV project manager or made known to him

before the start of fabrication.

Acest lucru vizeaza, de exemplu, stuturile, podestele,

suporturile pentru scari, placute indicatoare, marcaje de

instalare.

That concerns e.g. nozzles, platforms, supports for

ladders, signs and setting-up markings.

Pag./Page 12 Norma Petrom OMV DEF 2001 / Petrom OMV Standard DEF 2001

3.2 Calcul

3.2.

3.2.1. Informatii generale

3.2.1. General

Producatorul raspunde de proiectarea corecta a

componentelor.

Calculele vor fi realizate pentru toate conditiile de

functionare stabilite in Specificatia tehnica, pentru stare

de montaj si stare de testare.

The manufacturer is responsible for the proper design

of the components.

Calculations are to be carried out for all operational

conditions defined in the technical specification, the

assembly condition and the test condition.

Vor fi prezentate atestate de verificare a elementelor

portante si a elementelor de ridicare.

Proofs are to be provided for carrying and lifting

elements.

Rezervele de grosime a peretilor, rezultate din calculele

de stabilitate, nu trebuie sa fie utilizate pentru a obtine

aprobarea pentru decupaje sau pentru ranforsarea

decupajelor.

Wall thickness allowances from stability proof

calculations may not be used to get approval for

openings or opening reinforcements.

Fiecare recipient trebuie sa fie astfel conceput incat sa

poata sa absoarba incarcarile provenite din accesoriile

sau conductele racordate la el. Valorile pentru

incarcarea stuturilor: vezi Anexa 4

Every vessel shall be designed such that it can absorb

induced loads from equipment or piping attached to it.

Values for nozzle loads: see Annex 4

Metodele de calcul, coeficientii de siguranta, valorile

limita pentru deformari si ipotezele de incarcare sunt

abordate si la urmatoarele puncte:

Calculation methods, safety factors, limits for

deformation and load assumptions are also given in the

following items:

3.2.2 Caracteristici materiale

3.4.4 Capace plane

3.4.5 Flanse de aparate

3.4.12 Suporti articulati pentru aparate

3.6.7 Obloane de protectie la racitoare de aer

Calculation

3.2.2

3.4.4

3.4.5

3.4.12

3.6.7

Material properties

Flat covers

Girth flanges

Saddle supports

Louvers

3.2.2. Caracteristici materiale

3.2.2. Material properties

Valorile caracteristice ale materialelor pentru recipienti

vor fi luate din:

Numerical values of properties of materials for vessels

are to be taken from:

Normele europene armonizate referitoare la

materiale

Avizele europene de materiale

Avizele individuale de omologare

Harmonised European Standards

European Approvals of Material

Particular Material Appraisals

Observatie: valorile din certificatele de receptie, certificatele de

materiale etc. nu pot fi folosite in calculele de stabilitate.

Note: Values from acceptance certificates, inspection certificates etc.

shall not be used in strength calculations.

Domeniul de fluaj

In proiectarea in domeniul de fluaj se vor utiliza valorile

medii ale rezistentei, relevante pentru exploatarea

recipientului, respectiv colectivul de incarcare convenit

pentru 200000 de ore, si se va aplica un coeficient de

siguranta de minimum 1,25. Daca astfel de valori nu

exista, alegerea caracteristicilor materialelor si a

coeficientilor de siguranta va fi convenita cu managerul

de proiect Petrom OMV si va fi documentata.

Creep range

For the design in the creep range, average values of

the creep strength for 200,000 hours relevant for

operation of the vessel or the agreed load spectrum

shall be used and a safety factor of at least 1.25 is to be

applied. If such values are not available, the choice of

material property values and safety factors are to be

agreed on with the Petrom OMV project manager and

to be documented.

Se vor stabili masurile care asigura o durata de viata

acceptabila.

Measures are to be defined that ensure an acceptable

lifetime.

Daca este necesar, inspectia periodica va fi completata

cu masuri suplimentare.

If necessary, periodic inspection is to be extended by

additional measures.

Pag./Page 13 Norma Petrom OMV DEF 2001 / Petrom OMV Standard DEF 2001

3.2.3. Coeficient pentru cordon de sudura

3.2.3. Weld joint coefficient

Coeficientul minim aplicat pentru cordonul de sudura va

fi indicat de Petrom OMV in Specificatia tehnica.

The lowest applicable weld joint coefficient is given by

Petrom OMV in the technical specification.

Sunt exceptate de la aceasta prevedere cusaturile de

colt, Simbol .

Pentru aceste cusaturi se va considera un coeficient de

maximum 0,65.

Exceptions are fillet welds,

symbol.

A maximum weld joint coefficient of 0.65 is to be

applied for these welds.

Observatie:

Evitati cusaturile de colt (conform Punct Forme de cordoane de

sudura).pct.3.3.4

Note:

Avoid fillet welds, see item 3.3.4 (Type of welded joints)

3.2.4. Valori minime ale grosimii nominale a

peretelui

3.2.4. Minimum values of

nominal wall thickness

Grosimea nominala a peretelui urmatoarelor

componente nu trebuie sa se situeze sub valorile

mentionate in tabelele din Anexa 3:

The nominal wall thickness of the following parts may

not fall below the values in the Annex 3 tables:

cylindrical shells of heat exchangers with

removable bundles

cylindrical shells for general use including bonnets

and stationary head-channels

virole conice

conical shells

calote curbate

dished heads

rame verticale(virole suport,fuste)

skirts

alte parti componente similare ale recipientului

other similar vessel parts

stuturi de legatura

nozzle pipes

virolele cilindrice pentru schimbatoare de caldura

cu fascicule de tevi demontabile

virolele cilindrice in general, inclusiv pentru calote si

camere de distributie

3.2.5. Adaosuri (rezerva)de coroziune

3.2.5. Corrosion allowance

Adaosuri de coroziune se aplica pentru piesele si

cordoanele de sudura care vin in contact cu mediul de

stocare.

Corrosion allowances apply for parts and weld seams in

contact with the medium.

Pentru piesele din materiale rezistente la coroziune nu

se va lua in calcul o rezerva de coroziune.

La piesele din otel nerezistent la coroziune, rezerva

este de minimum 3 mm.

A corrosion allowance is not required for parts made of

corrosion-proof materials.

The corrosion allowance shall be at least 3 mm for noncorrosion-resistant steels.

Pentru componentele interne care sunt montate fix cu

recipientul sau a caror demontare presupune un efort

mare, rezerva de coroziune va fi prevazuta pentru toate

suprafetele care vin in contact cu mediul de stocare (de

exemplu inelele de sustinere).

For internals that are fixed permanently to the vessel or

are difficult to replace, the corrosion allowance shall be

applied to all surfaces in contact with the medium (e.g.

supporting rings).

Pentru componentele interne demontabile, care pot fi

inlocuite cu un efort rezonabil, va fi prevazuta jumatate

din rezerva de coroziune, pentru toate suprafetele care

vin in contact cu mediul de stocare.

For removable internals that can be replaced using

justifiable effort, the half of the corrosion allowance

shall be applied to all surfaces in contact with the

medium.

Adaosuri (rezerva) de coroziune specifice

componentelor:

Component specific corrosion allowances

Tevile din fascicule tubulare ale schimbatoarelor de

caldura si cordoanele de imbinare prin sudura a

acestora: fara rezerva de coroziune.

Tubes in heat exchanger bundles and the welding-in

seams for these: no corrosion allowance

Pag./Page 14 Norma Petrom OMV DEF 2001 / Petrom OMV Standard DEF 2001

3.3.

Constructie

3.3. Design

3.3.1. Protectia la coroziune

3.3.1. Corrosion protection

Tipul si modalitatea de executie a protectiei la

coroziune vor fi mentionate in Specificatia tehnica.

Type and design of corrosion protection is to be

specified in the technical specification.

Se aplica normele Concernului OMV:

P 1001 Protectia la coroziune; Proiectare

P 3001 Protectia la coroziune; Executie

The following OMV Group Standards apply:

P 1001 Corrosion protection; design

P 3001 Corrosion protection; implementation

Protectia la coroziune pentru livrare si expediere:

Vezi Punct 6.5

Corrosion protection for delivery and dispatch:

see item 6.5.

3.3.2. Acoperire pentru protectia la foc

3.3.2. Fire protection coating

Tipul si modalitatea de executie a acoperirii de protectie

la foc vor fi mentionate in Specificatia tehnica.

Type and design of fire protection coating is to be

specified in the technical specification.

Se aplica norma Petrom OMV:

M 3001 Acoperire de protectie la foc; Executie

The following Petrom OMV Standard applies:

M 3001 Fire protection coating; implementation

Pregatirea pentru acoperirea de protectie la foc

Preparation for fire protection coating

Suprafetele pentru care este prevazuta o acoperire de

protectie la foc vor fi acoperite cu un strat de grund, al

carui tip si a carui executie trebuie sa fie compatibile cu

tipul de acoperire de protectie la foc.

Surfaces which are to be fire protection coated are to

be provided with a primer coating whose type and

design are to be matched with those required for the

fire protection coating.

Detaliile referitoare la aceste lucrari vor fi convenite in

scris intre contractor si managerul de proiect Petrom

OMV.

Details concerning this are to be agreed on in writing

between the contractor and the Petrom OMV project

manager.

3.3.3. Piese imbinate prin sudare

3.3.3. Welded-on parts

Material

Material

Piesele care se sudeaza cu componente ale

recipientului care vin in contact cu mediul de stocare

vor fi din aceleasi material ca si respectivele

componente.

Parts to be welded on to vessel parts that come in

contact with the medium are to be manufactured from

the same material as these.

Orificii de inspectare

Inspection holes

Piesele care se sudeaza in asa fel incat alcatuiesc

spatii goale (cavitati) sau spatii de separare inchise, vor

fi prevazute cu cel putin un orificiu de inspectare cu filet

NPT si vor fi inchise cu un surub de inchidere

NPT . Orificiile de inspectare ( de control) nu trebuie

sa fie amplasate pe axele principale ale recipientului.

Parts which are welded on such that a closed cavity or

crevice occurs, are to be fitted with at least one

inspection hole NPT threaded and closed off with an

NPT plug. The inspection holes are not to be located

on vessel center lines.

Acest lucru vizeaza de exemplu ranforsarile

decupajelor, placile suport, toate tablele de ranforsare

pentru urechile de ridicare, gheare de apucare etc.

That applies to, e.g. set-on opening reinforcements,

saddle plates, all reinforcement plates for lifting lugs,

brackets, etc.

3.3.4. Forme de cordoane de sudura

3.3.4. Type of welded joints

Se vor evita cusaturile de colt (Simbol ) la

componentele expuse la presiune sau la cele incarcate

dinamic, cu exceptia tablele de ranforsare si a inelelor

sub vid.

Fillet welds ( symbol ) are to be avoided on

pressurized or dynamically loaded components

except for reinforcement plates and vacuum rings.

Pag./Page 15 Norma Petrom OMV DEF 2001 / Petrom OMV Standard DEF 2001

3.3.5. Suruburi exterioare si suruburi de inchidere

pentru orificiile de inspectare

Filetele suruburilor exterioare fabricate din otel-carbon,

exceptandu-le pe cele cadmiate, vor fi acoperite pe

toat lungimea cu un lubrifiant rezistent la temperatura.

Lubrifiantul trebuie sa fie pe baza de grafit si sa nu

contina cupru.

3.3.5. External bolts and plugs of inspection

holes

The threads of external carbon steel bolts, except when

cadmium-plated, are to be treated over the entire length

with a temperature-resistant lubricant.

The lubricant shall be based on graphite and shall not

contain copper.

3.3.6. Ranforsarile decupajelor

3.3.6. Opening reinforcement plates

In situatiile de mai jos nu este permisa utilizarea de

ranforsari circulare:

No ring-shaped opening reinforcements are to be used

in the following cases:

temperaturi normale de exploatare de peste 250 C

sau

normal operating temperatures above 250 C or

sour-gas environment or

mediul este acid sau

mediul este hidrogen

hydrogen environment

3.3.7. Elemente de ridicare,

puncte de suspendare

3.3.7. Lifting elements,

attachment points

Elementele de ridicare si punctele de suspendare vor fi

dimensionate dupa greutatea totala a unitatii de montaj

prevazute.

Lifting elements and attachment points are to be

dimensioned for the total weight of the planned

mounting unit.

In manualul de exploatare se va descrie si eventual se

va schita modul cum trebuie ridicat recipientul. In cazul

recipientilor verticali, acest lucru se va face si pentru

operatia de instalare a recipientului.

How the vessel is to be lifted shall be described, and

perhaps sketched, in the operation manual. This

applies also to the setting-up of vertical vessels.

3.3.8. Componente interne

3.3.8. Internal parts

Inspectarea pe interior a cordoanelor de sudura ale

recipientului trebuie sa fie posibila in ciuda prezentei

componentelor interne sudate.

The internal inspection of vessel welding seams shall

be possible in spite of welded internals.

Imbinarile cu surub vor fi asigurate.

Imbinarile cu surub nu trebuie sa fie zincate sau

cadmiate.

Piesele demontabile trebuie sa se potriveasca cu gura

de vizitare, sa poata trece prin aceasta.

Bolted connections are to be locked.

Bolted connections shall not be zinc-plated or

cadmium-plated.

Removable parts shall fit through the manhole.

Corrosion allowance: see item 3.2.5

Rezerva de coroziune: vezi Punct 3.2.5

3.3.9. Stuturi pentru manometre de control

3.3.9. Nozzles for test manometer

La fiecare incinta de presiune a unui recipient care

trebuie sa fie supus la probe de presiune trebuie sa

existe un stut (racord) in punctul cel mai inalt, care sa

fie adecvat pentru montarea unui manometru de

control.

A nozzle suitable for the connection of a test

manometer shall be available at the highest point of

each pressurized chamber of vessels which are subject

to pressure tests.

3.3.10. Stuturi pentru echipamente de masurare 3.3.10. Nozzles for measuring equipment

Pentru fiecare dispozitiv de masurare va fi prevazut un

stut propriu.

For each measuring device a fresh nozzle is to be

provided.

Pag./Page 16 Norma Petrom OMV DEF 2001 / Petrom OMV Standard DEF 2001

3.3.11. Recipienti verticali

3.3.11. Vertical vessels

Pozitia cordoanelor de sudura executate pe santier la

recipientii care se livreaza in componente individuale va

fi stabilita inainte de incheierea contractului.

The position of on-site welds on vessels that are

delivered as separate parts shall be defined prior to

contract award.

Piesele recipientilor verticali, care se monteaza pe

santier, vor fi prevazute cu dispozitive de ajustare si cu

suporti pentru platformele de montaj.

Parts of vertical vessels that are assembled on-site are

to be fitted with adjusting devices and supports for

movable platforms.

Axele principale, liniile de montaj si alte detalii

importante vor fi marcate bine vizibil.

Principal axes, setting-up lines and other important

details are to be marked clearly visible.

Pentru instalarea recipientilor verticali vor fi prevazute

urechi de ridicare sau alte sisteme asemanatoare.

Lifting lugs or similar devices are to be provided for the

setting-up of vertical vessels.

3.3.12. Recipienti pe constructii de beton

3.3.12. Vessels on concrete constructions

Pentru recipientii verticali se va prefera un sistem de

constructie cu ancorare.

Vertical vessels shall be preferably designed with

anchor cage.

Se vor lua masuri pentru ca elementele portante de la

recipient sa fie suficient de lungi pentru a se evita

incalzirea nepermisa a betonului. Acest lucru este

valabil, de exemplu, pentru recipientii amplasati pe

rame verticale, suporti, picioare sau grinzi portante.

It is to be ensured that the supporting elements of the

vessel are long enough that the concrete is not heated

up to a non-allowed level. That applies to e.g. vessels

on skirts, saddle supports, supporting legs, or bracket

supports.

3.3.13. Recipienti care trebuie sa fie izolati

3.3.13. Vessels which are to be insulated

Vor fi prevazuti suporti pentru izolatie. Detaliile privind

piesele care se sudeaza la recipient in acest scop vor fi

convenite cu producatorul izolatiei.

Supports for insulation shall be provided. Details of

parts to be welded on to the vessel are to be agreed on

with the insulation manufacturer.

Se aplica normele Petrom /OMV respectiv normele

Concernului:

The following Petrom/OMV or OMV Group Standards

apply:

L 1001 Izolatia la caldura; Proiectare

L 3001 Izolatia la caldura; Executie

L 3002 Izolatia la frig; Executie

L 3003 Izolatia la zgomot; Executie

L 1001 Thermal insulation; design

L 3001 Thermal insulation; implementation

L 3002 Cold insulation; design

L 3003 Sound insulation; Design

3.3.14. Recipienti in contact cu gaz acid

3.3.14. Vessels for sour-gas environment

Standardul de Rafinarie OMV RefStd_1010_v090209,

care inlocuieste Normele Petrom OMV H 1003 si H

3003, va fi aplicat in mod corespunzator pentru

recipienti in mediu cu gaz acid.

The OMV Refining Standard RefStd_1010_v090201,

which replaces Petrom OMV Standard H 1003 and

H 3003 ,are to be applied analogously to vessels for

sour-gas environment.

3.3.15. Recipienti pentru hidrogen, lesie sau

apa alcalina de alimentare cazane

3.3.15. Vessels for hydrogen, caustic solutions

or alkaline boiler feed water

Dupa sudare, recipientii din otel nealiat sau slab aliat,

care sunt alimentati cu hidrogen*, lesie sau apa alcalina

de alimentat cazane, incalzita la peste 80 C , vor fi

tratati termic (maleabilizati) fara tensiune.

Vessels made of unalloyed or low-alloy steel that is

impacted by hydrogen*, caustic solutions or alkaline

boiler feed water which is above 80 C are to be st ress

relief annealed after welding.

Se poate renunta la maleabilizarea fara tensiune a

recipientilor pentru apa alcalina de alimentat cazane,

daca se poate garanta ca temperatura apei nu va

depasi niciodata 80 C.

Stress relief annealing of vessels for alkaline boiler feed

water can be dispensed with if it can be guaranteed that

the water temperature will never exceed 80 C.

* presiune partiala H2 7 bar sau procent H2 50 vol%

* H2 partial pressure7 bar or H2 fraction50 vol%

Pag./Page 17 Norma Petrom OMV DEF 2001 / Petrom OMV Standard DEF 2001

3.3.16. Recipienti simpli sub presiune

3.3.16. Simple pressure vessels

Recipientii simpli sub presiune, neexpusi la foc, utilizati

pentru aer sau azot, conform EN 286-1, vor fi conceputi

pentru o presiune admisa PS de minimum 10 bar.

Simple unfired pressure vessels for air or nitrogen acc.

to EN 286-1 are to be designed for an allowable

pressure PS of at least 10 bar.

3.3.17. Recipienti cu presiune PS 0,5 bar

3.3.17. Vessels for pressure 0.5 bar

Urmatoarele puncte din prezenta norma nu se aplica

pentru recipientii cu o presiune maxima admisa PS de

pana la 0,5 bar:

The following sections of text in this standard do not

apply to vessels with a maximum allowable pressure

PS of up to 0.5 bar:

Punctul 3.3.4 Forme de cordoane de sudura

Item 3.3.4 Type of welded joints

Punctul 3.3.6Ranforsari pentru decupaje

Item 3.3.6 Opening reinforcement plates

Cerinta impusa pentru flansele presudate la Punctul

3.4.5Flanse pentru aparate

The demand for welding neck flanges

in item 3.4.5 Girth flanges

Cerinta impusa pentru declaratia de conformitate si

documentele organismului notificat, la Punctul 5.2.2

Volumul de documentatie.

The demand for the declaration of conformity and

documents from the notified body in item 5.2.2

Extent of documentation

Punctul 5.2.3 Manualul de inspectie si verificari

Item 5.2.3 Inspect and test log book

3.3.18. Marcarea

3.3.18. Marking

Recipientii montati vor fi marcati cu numarul de

echipament Petrom OMV, cu marcaj:

Set-up vessels are to be marked with the Petrom OMV

equipment number:

rezistent la conditiile meteo,

amplasat intr-un loc cu buna vizibilitate,

cu litere cu inaltime de 30 cm.

weatherproof

at an easily visible position

with 30 cm-high lettering

Recipientii orizontali vor fi marcati, daca este posibil, pe

partea cilindrica.

Horizontal cylindrical vessels are to be marked on the

cylindrical part, if possible.

Marcajul nu trebuie sa influenteze negativ materialul din

care este fabricat recipientul.

The marking shall not have any negative effect on the

vessel material.

La recipientii austenitici care se incalzesc la temperaturi

inalte, marcajul nu trebuie sa fie facut direct pe

recipient, ci pe izolatie.

With austenitic vessels that become hot, the marking

may not be made directly on the vessel, but on the

insulation.

Piesele detasabile vor fi stampilate cu numarul de

echipament. Acest lucru este valabil, de exemplu,

pentru capace de guri de vizitare, fascicule de tevi,

camere de distributie capace de camere de distributie.

La imbinari cu flanse, stampilele vor fi executate in parti

opuse (fata in fata).

Removable parts are to be stamped with the

equipment number. That applies to e.g. manhole

covers, tube bundles, stationary head-channels,

stationary head-channel covers. With flange

connections, the stampings shall be opposing.

3.3.19. Placute (panouri)de timbru si suporti

pentru placute

3.3.19. Data plates, data plate holders

Tipurile de placute de timbru ce trebuie montate la un

recipient, precum si detalii referitoare la placutele de

constructie si la suportii pentru placute sunt prezentate

in Norma Petrom OMV 220.

Placuta indicatoare de momente de strangere

Date privind aceste specificatii, vezi Punct 3.4.5 (Flanse

pentru aparate).

Which plates are to be attached to a vessel as well as

details about the plates and plate holders are described

in Petrom OMV Standard 220.

Tightening torques plate

For specifications about entries refer to item 3.4.5 (Girth

flanges).

Pag./Page 18 Norma Petrom OMV DEF 2001 / Petrom OMV Standard DEF 2001

3.4.

Constructia specifica componentelor

recipienti, uz general

3.4.

Component specific design

Vessels, general use

3.4.1. Virole cilindrice si conice

3.4.1. Cylindrical and conical shells

Tabla trebuie rulata pe directia de laminare.

The direction in which plate is rolled to shells shall be

the same direction as for rolling at manufacturing the

plate.

In cazul in care mantalele sunt realizate din tevi, se vor

folosi, de preferinta, tevi fara cusatura.

Valori minime ale grosimii nominale a peretelui: vezi

Anexa 3.

Cordoanele de sudura trebuie sa fie, pe cat posibil,

astfel amplasate, incat sa nu fie ascunse de alte piese.

If shells are made from tubes, seamless tubes shall be

preferred.Minimum nominal wall thicknesses: see Annex

3.

Wherever possible, welding seams shall be arranged

such that they are not covered by other parts.

3.4.2. Calote curbate

3.4.2. Dished heads

Calotele curbate trebuie sa fie executate de preferinta

sub forma de calote (capace) elipsoidale, conform DIN

28013.

Dished heads shall preferably be designed as ellipsoidal

heads acc. to DIN 28013.

Minimum nominal wall thicknesses: see Annex 3.

Valori minime ale grosimii nominale a peretelui: vezi

Anexa 3.

3.4.3. Funduri plane

3.4.3. Flat ends

Fundurile plane cu adaos de sudura vor fi realizate din

piese forjate.

Flat ends with a hub are to be manufactured from

forgings.

Tablele pentru fundurile plane, la care se sudeaza

stuturi, vor fi verificate in zona de sudura conform EN

10160 si trebuie sa indeplineasca Clasa de calitate E4.

Plates for flat ends to which nozzles are to be set on are

to be tested in the region of the weld acc. to EN 10160

and shall correspond to Class E4.

3.4.4. Capace plane

3.4.4. Flat covers

Tablele pentru capace plane, la care se sudeaza stuturi,

vor fi verificate in zona de sudura conform EN 10160 si

trebuie sa indeplineasca Clasa de calitate E4.

Plates for flat covers to which nozzles are to be set on

are to be tested in the region of the weld acc. to

EN 10160 and shall correspond to Class E4.

Pentru incarcarea de proba, incovoierea maxima admisa For the testing load case, the maximum allowable lateral

este:

buckling is:

in varianta cu tola de separare:

0,2 % din diametrul exterior,

for design with partition plate:

0.2 % of the outside diameter

in varianta fara tola de separare:

0,3 % din diametrul exterior.

for design without partition plate:

0.3 % of the outside diameter

Pag./Page 19 Norma Petrom OMV DEF 2001 / Petrom OMV Standard DEF 2001

3.4.5. Flanse circulare pentru aparate

3.4.5. Girth flanges

Se vor folosi de preferinta flanse presudate. Tipul de

constructie va fi specificat in oferta.

Preferably, welding neck flanges are to be used. The

design is to be stated in the tender.

In urmatoarele situatii trebuie sa se utilizeze flanse

presudate:

The use of welding neck flanges shall be obligatory in

the following cases:

contact cu gaz acid sau

sour-gas environment or

contact cu hidrogen

hydrogen environment

Ca flanse pentru aparate pot fi folosite flanse standard

mai mari de DN 600 respectiv 24.

Standard flanges larger than DN 600 or 24 may not be

used as girth flanges.

Daca flansele sunt fabricate din mai multe parti (bucati),

este necesar sa se obtina aprobarea managerului de

proiect Petrom OMV pentru metoda de fabricatie si

pentru volumul de operatii de verificare.

If flanges are fabricated from more than one part, the

approval of the Petrom OMV project manager is needed

for the fabrication method and the extent of testing.

Suprafete de contact piulite: rugozitate Rz pana la 40 m Nut contact faces: Roughness Rz up to 40 m

Suprafete de etansare:

Alegerea garniturii si valori de rugozitate:

Vezi Anexa 6 Conceptul general de etansare

Sealing faces:

Choice of gasket and specification of roughness:

see Annex 6 General gasket guideline

Calcul:

Calculul va fi realizat conform EN 1591-1.

Se vor indica gradele de incarcare pentru piesele

individuale.

Calculation:

Calculation shall be done acc. to EN 1591-1.

Load ratios of the individual parts are to be indicated.

Coeficienti de siguranta:

pentru conditii de exploatare: minimum S=2,0

pentru conditii de montaj si probe: min. S=1,5

Safety factors:

for operational conditions: minimum S=2.0

for assembly and test conditions: minimum S=1.5

The angle of flange rotation under operational conditions

Unghiul de rotire a flansei in conditii de exploatare poate shall not exceed 0.3.

fi de maximum 0,3.

La temperaturi maxime admise TS peste 300 C, pentr u

imbinarile cu flanse de aparate se vor efectua analize cu

elemente finite, cu exceptia cazului cand se utilizeaza

garnituri cu mansete sudate.

With maximum allowable temperatures TS of over

300 C, finite-element analyses shall be carried ou t for

girth flange connections, except when welded gaskets

are used.

Momente de strangere, placuta indicatoare de momente

de strangere

Tightening torques, tightening torques plate

Pe placuta indicatoare de momente de strangere, care

se monteaza la recipient, vor fi trecute urmatoarele date

referitoare la imbinarile cu flanse de aparate, conform

Normei Petrom OMV 220:

ANZ.MOM.MIN (MOMENT STRANGERE MINIM):

Moment de strangere pentru montare.

ANZ.MOM.MAX (MOMENT STRANGERE MAXIM):

Cea mai mica valoare din urmatoarele doua:

moment de strangere care genereaza tensionarea

maxima admisa a bolturilor filetate.

moment de strangere care genereaza incarcarea

maxima admisa (presiune pe suprafata) a garniturii.

LNGUNG MIN/MAX (ALUNGIRE MIN/MAX):

este necesara numai daca trebuie sa fie documentata

alungirea reala la strangere, de exemplu la bolturile cu

dilatatie.

Following data of girth flange connections are to be

entered into a tightening torques plate acc. to Petrom

OMV Standard 220 attached to the vessel:

ANZ.MOM.MIN (Minimum tightening torque):

Tightening torque for assembly.

ANZ.MOM.MAX (Maximum tightening torque):

the smaller of the following two values:

Tightening torque that leads to maximum allowable

tension in the stud bolts.

Tightening torque that leads to maximum allowable

load on the gasket (surface pressure).

LNGUNG MIN/MAX (Elongation min/max):

Is only required if the actual elongation on tightening is

to be documented, e.g. with necked-down bolts.

Pag./Page 20 Norma Petrom OMV DEF 2001 / Petrom OMV Standard DEF 2001

3.4.6. Racorduri

3.4.6. Nozzles

Se vor folosi flanse sudate cu gat sau flanse sudate cu

gat lung(LWN).

Welding neck flanges or long welding neck flanges are

to be used

In conditii de solicitare dinamica, generatoare de

oboseala, stuturile trebuie sa fie realizate ca stuturi cu

flanse sudate cu gat lung(LWN), de exemplu in cazul

solicitarii la oscilatii. Componentele expuse la solicitari

mari trebuie sa fie realizate pe cat posibil fara crestaturi.

Under fatiguing, dynamic loading, nozzles shall be

designed as long welding neck flanges, e.g. under

oscillating loads. Highly stressed components shall be

made without notches or grooves as far as possible.

Stuturile montate la piese plane trebuie sa fie sudate pe

aceste piese. Cele montate la virolele cilindrice, sferice

si conice, precum si la calote curbate, vor fi sudate cu

acestea (atasate prin sudura).

Nozzles on planar parts shall be set on. Nozzles on

cylindrical, spherical and conical shells and dished

heads shall be set in.

Stuturile sudate cu piesele (atasate prin sudura) trebuie

sa fie adaptate la suprafata interioara a recipientului.

Set-in nozzles are to be trimmed to match the vessel

inside surface.

Stuturile montate la o incinta de presiune trebuie sa fie

toate conform DIN respectiv EN sau toate conform

ASME.

The nozzles on a pressurized chamber shall either be all

according to DIN/EN or all according to ASME.

Denumire:

Pe desene, stuturile vor fi denumite astfel:

Designation:

In drawings nozzles are to be designated as follows:

cu litera S,

un numar curent,

iar in cazul a doua sau mai multor stuturi identice:

o litera curenta.

EXEMPLU: S1, S2, S3A, S3B

by the letter "S"

a sequential number

and, when there are two or more identical nozzles: a

sequential letter

e.g. S1, S2, S3A, S3B

Suprafete de etansare si garnituri: vezi Punct 3.4.9

Sealing faces and gaskets: see item 3.4.9

Suruburi: vezi Punct 3.4.10

Bolts: see item 3.4.10

Suprafete de contact piulite: Rugozitate Rz pana la 40

m

Nut contact faces: Roughness Rz up to 40 m

Gauri suruburi: Nu pe axele principale

Grosime nominala perete: valori minime vezi Anexa 3

Diametru exterior: Minimum 25 mm

Bolt holes: Not on center lines

Nominal wall thickness: see Annex 3 for min. values

Inside diameter: minimum 25 mm

Nominal size: minimum DN 25 or 1

Diametru nominal: Minimum DN 25 sau1

DN 25, DN 40, 1 si 1

Stuturile drepte cu diametre nominale DN 25, DN 40,

1 sau 1 ,cu o lungime de pana la 500 mm, vor fi

realizate ca flansa sudata cu gat lung (LWN). Ele vor fi

dimensionate de constructor si vor fi fabricate din piese

forjate. Schite cu detalii, vezi Anexa 5.

DN 25, DN 40, 1 and 1

Straight nozzles with nominal sizes DN 25, DN 40,

1 or 1 up to a length of 500 mm are to be designed

as long welding neck flanges. They are to be

dimensioned by the manufacturer and made of forgings.

See Annex 5 for drawings with details.

Pag./Page 21 Norma Petrom OMV DEF 2001 / Petrom OMV Standard DEF 2001

Incarcarea pe stut: incarcarile admise pe stuturi vor fi

indicate in forma de tabel, in desenul de fabricatie.

Valorile minime pentru incarcarile admise pe stut vor fi

calculate in baza Anexei 4.

Nozzle loads: The allowable nozzle loads shall be given

as a table in the fabrication drawing. Minimum values for

allowable nozzle loads are to be calculated according to

Annex 4.

Muchii interioare rotunjite:

Muchiile interioare vor fi

rotunjite cu R3 mm. Schita:

Rounded-off inner edges:

The inner edges are to

be rounded off with a

radius of R3 mm. Sketch:

Lungime stut

Lungimea stuturilor drepte este definita ca distanta,

masurata de-a lungul axei tevii stutului, dintre partea

exterioara a peretelui recipientului si suprafata de

etansare a flansei respectiv capatul tevii, in cazul

stuturilor fara flansa.

Nozzle length

The nozzle length of straight nozzles is defined as

the distance along the nozzle pipe axis between the

outside of the vessel wall and the flange sealing surface

or the end of the pipe at nozzles without flange.

Urmatoarele cerinte impuse in privinta lungimilor

minimale nu se aplica pentru stuturile de la gurile de

vizitare si stuturile cu coturile conductelor de legatura.

The following requirements for minimum lengths do not

apply to manhole nozzles and nozzles with pipe elbows.

Nozzles are to be designed with a minimum length

as given in the following table. With nozzles on insulated

Stuturile vor avea cel putin lungimea specificata in

vessels, these values apply as the minimum length that

tabelul de mai jos. Pentru stuturile de la recipientele cu

izolatie, aceste valori vor fi considerate ca fiind lungimea a nozzle protrudes beyond the insulation.

minima cu care un stut iese in afara izolatiei.

Nominal size

Diametru nominal

DN 25 / 1

DN 25 / 1

Minimum length

Lungime min.

pana la DN 80 / 3

150 mm

DN 100 / 4 pana la DN 200 / 8

200 mm

DN 250 / 10 si mai mare

250 mm

to DN 80 / 3

150 mm

DN 100 / 4 to DN 200 / 8

200 mm

DN 250 / 10 and over

250 mm

Table 2: Minimum nozzle lengths

Tabel 2: Lungimi minime stuturi

De asemenea, stuturile trebuie sa fie suficient de lungi

incat suruburile respectiv bolturile filetate ale armaturilor

racordate sa poata sa iasa in afara inspre peretele

recipientului respectiv inspre izolatie. Acest lucru este

valabil in mod special pentru stuturile amplasate neradial, care, eventual trebuie sa fie chiar mult mai lungi

decat valorile de mai sus.

Furthermore, nozzles shall be at least long enough so

that bolts or stud bolts of connected valves can be

withdrawn towards the vessel wall or the insulation. That

applies especially to non-radially aligned nozzles, which

might then be much longer than given above.

Recipiente cu virola suport (fusta):

Nu este permisa prezenta imbinarilor cu flansa in

interiorul virolei suport. Stuturile vor fi realizate in asa fel

incat sa iasa prin virola suport in afara.

Vessels with skirts:

Flange connections inside the skirt are not permitted.

Nozzles are to be led through and guided out of the

skirt.

Pag./Page 22 Norma Petrom OMV DEF 2001 / Petrom OMV Standard DEF 2001

3.4.7. Guri de vizitare

3.4.7. Manholes

Informatii generale:

General:

Diametru nominal DN 600 respectiv 24

Nominal size DN 600 or 24

Diametrul interior minim 585 mm

Smallest inside diameter minimum 585 mm

Capac cu doua manere unul langa altul

Covers with two handles besides each other

Cu brat rotativ

With davit

Cu manere pe partea interioara a recipientului,

deasupra gurii de vizitare

With handholds on the vessel inside

above the manhole

Cu trepte de siguranta pe partea interioara a

recipientului, sub gura de vizitare

With rungs on the vessel inside

below the manhole

Recipiente cu izolatie la frig:

Cold-insulated vessels

Cu balamale de rabatare

Daca la recipientele cu temperaturi extrem de

scazute (refrigerare) este absolut necesara o gura

de vizitare, ea va trebui sa fie amplasata in incinta

de gaz, acolo unde nu se intra niciodata in contact

cu suprafata de lichid rece, nici la pornirea, nici la

oprirea instalatiei.

With swivel hinges

If a manhole is absolutely necessary in lowtemperature vessels, it should be located in the

headspace where it will never come in contact with

cold liquid even during start-up and shutdown.

Tamburii de abur:

Steam drums:

Guri de vizitare ovale, cu margini catre interior sau

inele cu guri de vizitare cu deschidere de libera

trecere de minimum 320 x 420 mm.

Oval necked-in manholes or manhole rings with

minimum 320 x 420 mm clear opening.

Coloane si reactoare:

Columns and reactors:

Pe langa gura de vizitare, va fi prevazuta o gura de

suplimentara, cu diametrul de minimum DN 200

respectiv 8. Capacul acesteia va fi realizat astfel

incat sa fie etans cu peretele interior.

Denumire:

In desene, gurile de vizitare vor fi marcate cu litera M

si un numar curent, de exemplu M1, M2.

A service hole with nominal size minimum DN 200

or 8 is to be provided next to the manhole. Its cover

is to be such that it is flush with the inner wall

surface.

Designation:

In drawings manholes are to be designated by the letter

"M" and a sequential number, e.g. M1, M2.

Pag./Page 23 Norma Petrom OMV DEF 2001 / Petrom OMV Standard DEF 2001

3.4.8. Racorduri de aerisire (ventilatie)si golire

3.4.8. Vents and drains

vor fi prevazute la fiecare incinta sub presiune a

unui recipient, in punctul de inaltime maxima

respectiv de inaltime minima,

are to be provided for each pressurized chamber of

a vessel at the highest and the lowest point

are to be closed by blank flanges

vor fi inchise cu flanse oarbe,

trebuie sa aiba cel putin diametrele nominale

specificate in tabelul de mai jos:

shall have a minimum nominal size according to the

following table:

Incinta de presiune

Ventilatie

Golire

Racitor de aer

DN 25 / 1

DN 25 / 1

Recipient pana la 20 m

DN 25 / 1

DN 50 / 2

Recipient peste 20 m

DN 50 / 2

DN 80 / 3

Tabel 3: Diametre nominale minime pentru stuturi de ventilatie si

golire.

Pressurized chamber

Vent

Drain

Air-cooled

heat exchangers

DN 25 / 1

DN 25 / 1

Vessels up to 20 m

DN 25 / 1

DN 50 / 2

Vessels over 20 m

DN 50 / 2

DN 80 / 3

Table 3: Minimum nominal sizes for vent and drain nozzles

Grosimea nominala a peretelui stuturilor de

ventilatie si golire din oteluri neaustenitice trebuie sa

fie de minimum 5,5 mm.

The nominal wall thickness of vent and drain

nozzles of non-austenitic steel shall be minimum

5.5 mm.

Gurile de ventilatie si golire ale unui recipient pot sa fie

parti ale conductelor racordate la recipient, daca se

asigura faptul ca la probele de presiune, prin spatiile

dintre discurile de separare si flansele recipientului se

pot asigura ventilarea si golirea in conditii

corespunzatoare.

Vents and drains of a vessel may be part of the

connected piping if it is ensured that, in pressure tests,

venting and draining can be reliably carried out through

gaps between the blanking plates and the vessel

flanges.

3.4.9. Garnituri

3.4.9. Gaskets

In general, tipul de garnitura trebuie sa fie stabilit in

functie de Conceptul general de etansare din Anexa 6,

care reprezinta un standard pentru majoritatea

aplicatiilor care intra sub incidenta prezentei norme

OMV/Petrom.

In general, the type of gasket shall be taken from the

general gasket guideline in Annex 6 which represents a

standard for the most applications in the scope of this

OMV/Petrom Standard.

Intra in responsabilitatea contractorului sa verifice daca

garnitura este adecvata si, daca este nevoie, de comun

acord cu managerul de proiect , sa aplice o alta solutie

tehnica.

It falls within the responsibility of the contractor to verify

the suitability of the gasket and, if necessary and with

agreement of the project manager, to use a different

technical solution.

Normativ tehnic pentru controlul calitatii aerului

Garniturile pentru flanse de aparate, guri de vizitare,

capace ale camerelor racitoarelor de aer, stuturi si

conducte trebuie sa fie certificate ca fiind de inalta

calitate, in acceptiunea normativului tehnic pentru

controlul calitatii aerului( exp.TA-Luft 2002 si a Directivei

VDI 2440).

Technical Instruction on air Quality Control

Gaskets for girth flanges, manholes, covers of headers

of air-cooled heat exchangers, nozzles and piping shall

be highly suitable in the sense of Technical Instruction

on air Quality Control ( e.g TA-Luft 2002 and accordingly

certified according to the guideline VDI 2440).

Pag./Page 24 Norma Petrom OMV DEF 2001 / Petrom OMV Standard DEF 2001

Garnituri cu mansete sudate

vor fi prevazute daca sunt necesare din motive de

securitate, de siguranta in exploatare sau de tehnologie.

Utilizarea garniturilor cu mansete sudate, tipul acestora

si materialul din care sunt fabricate vor fi aprobate de

managerul de proiect Petrom OMV.

Welded gaskets

are to be provided when required for reasons of safety,

operational safety, or process engineering. The use of

welded gaskets, their type and material needs the

approval of the Petrom OMV project manager.

Clase de conducte:

Tipul de garnitura pentru imbinarea stuturilor si a

conductelor va fi luat din Clasa de conducte aferenta.

Pipe classes:

The type of gasket for the connection of nozzles and

piping is to be taken from the pipe classes.

Duritate:

Duritatea garniturilor de metal fara strat de incarcare

trebuie sa fie cu minimum 25 HB sub duritatea

suprafetei de etansare a flanselor.

Hardness:

The hardness of metal gaskets without layers shall be at

least 25 HB degrees of hardness below the hardness of

the sealing surface of the flanges.

Tolerante:

Pentru garniturile de la imbinarile cu flanse de aparate

se aplica urmatoarea regula:

pentru dimensiuni exterioare si pentru nervuri se va

aplica valoarea medie din toleranta minus, iar pentru

dimensiuni interioare, valoarea medie din toleranta plus

al domeniilor de toleranta conform ISO 2768-1.

Tolerances:

The following applies to gaskets for girth flange

connections:

for outside dimensions and ribs is the minus range, and

for inside dimensions is the plus range of the tolerance

zones acc. to ISO 2768-1 medium to be used.

3.4.10. Suruburi si piulite

3.4.10. Bolts and nuts

La flansele de aparate, flanse oarbe, capace de guri de

vizitare si racorduri / imbinari de racorduri se vor folosi

bolturi filetate ASME (inclusiv pentru imbinari cu flanse

conform DIN sau EN).

ASME stud bolts are to be used for girth flanges,

manhole covers, blank flanges, and nozzle/nozzle

connections (also for flange connections according

to DIN or EN).

Ca standard se vor utiliza Bolturi filetate standardizate

OMV definite astfel:

"OMV unified stud bolts", defined below, are to be used

as standard:

Standard pentru bolturi filetate,

Bolturi filetate standardizate OMV

Standard for stud bolts,

OMV unified stud bolt

- bolturi filetate conform ASME B16.5

- filet continuu conform ASME B1.1

- model roluit

- clasa filet 2A

- pana la 1: filet UNC / peste 1: filet 8UN

- material 21CrMoV5-7 (1.7709, Stampila GA)

- cu 2 buc. piulite hexagonale

conform ASME B18.2.2

- clasa filet piulite: 2B

- material piulite: 25CrMo4 (1.7218)

- stud bolt acc. to ASME B16.5

- continuous thread acc. to ASME B1.1

- rolled thread

- thread class 2A

- up to 1: UNC thread / over 1: 8UN thread

- material 21CrMoV5-7 (1.7709, stamp GA)

- with 2 heavy hex nuts

acc. to ASME B18.2.2

- thread class of nuts: 2B

- material of nuts: 25CrMo4 (1.7218)

Alte materiale pentru suruburi

Other bolt materials

Bolturi filetate: ca si bolturile filetate standardizate OMV,

dar dintr-un alt material.