Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

W Composite

Caricato da

Sudhakar KarnanDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

W Composite

Caricato da

Sudhakar KarnanCopyright:

Formati disponibili

1496T_c16_577-620 12/31/05 14:08 Page 578

2nd REVISE PAGES

Learning Objectives

After careful study of this chapter you should be able to do the following:

1. Name the three main divisions of composite

5. Compute longitudinal strengths for discontinumaterials, and cite the distinguishing feature of

ous and aligned fibrous composite materials.

each.

6. Note the three common fiber reinforcements

2. Cite the difference in strengthening mechanism

used in polymer-matrix composites, and, for

for large-particle and dispersion-strengthened

each, cite both desirable characteristics and

particle-reinforced composites.

limitations.

3. Distinguish the three different types of fiber7. Cite the desirable features of metal-matrix

reinforced composites on the basis of fiber length

composites.

and orientation; comment on the distinctive me8. Note the primary reason for the creation of

chanical characteristics for each type.

ceramic-matrix composites.

4. Calculate longitudinal modulus and longitudinal

9. Name and briefly describe the two subclassificastrength for an aligned and continuous fibertions of structural composites.

reinforced composite.

16.1 INTRODUCTION

principle of

combined action

Many of our modern technologies require materials with unusual combinations of

properties that cannot be met by the conventional metal alloys, ceramics, and polymeric

materials. This is especially true for materials that are needed for aerospace, underwater, and transportation applications. For example, aircraft engineers are increasingly

searching for structural materials that have low densities, are strong, stiff, and abrasion

and impact resistant, and are not easily corroded. This is a rather formidable combination of characteristics. Frequently, strong materials are relatively dense; also, increasing

the strength or stiffness generally results in a decrease in impact strength.

Material property combinations and ranges have been, and are yet being, extended by the development of composite materials. Generally speaking, a composite

is considered to be any multiphase material that exhibits a significant proportion

of the properties of both constituent phases such that a better combination of properties is realized. According to this principle of combined action, better property

combinations are fashioned by the judicious combination of two or more distinct

materials. Property trade-offs are also made for many composites.

Composites of sorts have already been discussed; these include multiphase

metal alloys, ceramics, and polymers. For example, pearlitic steels (Section 9.19)

have a microstructure consisting of alternating layers of a ferrite and cementite

(Figure 9.27). The ferrite phase is soft and ductile, whereas cementite is hard and

very brittle. The combined mechanical characteristics of the pearlite (reasonably

high ductility and strength) are superior to those of either of the constituent phases.

There are also a number of composites that occur in nature. For example, wood

consists of strong and flexible cellulose fibers surrounded and held together by a

stiffer material called lignin. Also, bone is a composite of the strong yet soft protein collagen and the hard, brittle mineral apatite.

A composite, in the present context, is a multiphase material that is artificially

made, as opposed to one that occurs or forms naturally. In addition, the constituent

phases must be chemically dissimilar and separated by a distinct interface. Thus,

most metallic alloys and many ceramics do not fit this definition because their multiple phases are formed as a consequence of natural phenomena.

In designing composite materials, scientists and engineers have ingeniously

combined various metals, ceramics, and polymers to produce a new generation of

Potrebbero piacerti anche

- Material Engineering ResearchDocumento34 pagineMaterial Engineering ResearchJhoven De CastroNessuna valutazione finora

- Lightweight Strong Materials: Composite MaterialsDocumento36 pagineLightweight Strong Materials: Composite MaterialsCarlo TorresNessuna valutazione finora

- Composites Mini ProjectDocumento44 pagineComposites Mini ProjectRajaReddyNessuna valutazione finora

- Introduction to Composites Materials ClassificationDocumento44 pagineIntroduction to Composites Materials ClassificationVj Aditya100% (1)

- Composites Innit ButtDocumento21 pagineComposites Innit ButtRyan DelaCourtNessuna valutazione finora

- Unit - I Introduction of Composites: Figure (1) : Composite Korean BowDocumento61 pagineUnit - I Introduction of Composites: Figure (1) : Composite Korean Bowu2b11517Nessuna valutazione finora

- Composites and Applications 2Documento21 pagineComposites and Applications 2Dasrat KumarNessuna valutazione finora

- Composite+Materials I IIDocumento24 pagineComposite+Materials I IIcorleoneeeNessuna valutazione finora

- LECTURE NO. 10. Composite MaterialsDocumento10 pagineLECTURE NO. 10. Composite MaterialsBizuayehu Tadesse AzeneNessuna valutazione finora

- Composite Materials1Documento11 pagineComposite Materials1Govind JhaNessuna valutazione finora

- Netaji Subhash University of Technology: Home Assignment OnDocumento27 pagineNetaji Subhash University of Technology: Home Assignment OnParshant YadavNessuna valutazione finora

- Composite Material 1 1Documento1 paginaComposite Material 1 1Sudhakar KarnanNessuna valutazione finora

- Chapter 1 IntroductionDocumento25 pagineChapter 1 IntroductionRandy VidsNessuna valutazione finora

- Composite Materials Part 1Documento300 pagineComposite Materials Part 1PethurajNessuna valutazione finora

- Composite MaterialDocumento67 pagineComposite MaterialQs 19Nessuna valutazione finora

- General Introduction Introduction of Composites: Historical Development / Historical Overview: PastDocumento514 pagineGeneral Introduction Introduction of Composites: Historical Development / Historical Overview: PastMuthuvel MNessuna valutazione finora

- CompositeDocumento4 pagineCompositeAshok PradhanNessuna valutazione finora

- 08 Chapter1Documento63 pagine08 Chapter1Inam Ul Haq100% (1)

- Module 1Documento50 pagineModule 1chris_m_germain100% (1)

- Composite Materials GuideDocumento3 pagineComposite Materials GuiderkNessuna valutazione finora

- 17 - Composite MaterialsDocumento22 pagine17 - Composite MaterialsNoman Shah100% (1)

- AbstractDocumento11 pagineAbstractDHRUV SINGHALNessuna valutazione finora

- Composite Materials 2 Marks All 5 UnitsDocumento31 pagineComposite Materials 2 Marks All 5 UnitsM.ThirunavukkarasuNessuna valutazione finora

- Basic CompositesDocumento65 pagineBasic Compositessuba vNessuna valutazione finora

- Unit-I TO Composite MaterialsDocumento40 pagineUnit-I TO Composite MaterialsSaisurendra VeerlaNessuna valutazione finora

- Composite Materials GuideDocumento174 pagineComposite Materials GuideAbhishekVerma100% (1)

- Metal - Matrix Composites: $ M Haghshenas, University of Waterloo, Waterloo, ON, CanadaDocumento28 pagineMetal - Matrix Composites: $ M Haghshenas, University of Waterloo, Waterloo, ON, CanadaFocșa SergiuNessuna valutazione finora

- Mechanics of Composite MaterialsDocumento4 pagineMechanics of Composite MaterialsDwi Antoro100% (1)

- Composite Materials - 2 Marks - All 5 UnitsDocumento31 pagineComposite Materials - 2 Marks - All 5 UnitsMohan Prasad.M84% (19)

- Classification of Composite MaterialsDocumento4 pagineClassification of Composite Materialsthasarathanr1993_939Nessuna valutazione finora

- Composite Material GuideDocumento34 pagineComposite Material GuideAISHWARYANessuna valutazione finora

- Material Science: Properties and Classification of Composite MaterialsDocumento1 paginaMaterial Science: Properties and Classification of Composite MaterialsRollysa MelaniasariNessuna valutazione finora

- Study of Mechanical Properties of Hybrid Natural Fiber CompositeDocumento5 pagineStudy of Mechanical Properties of Hybrid Natural Fiber CompositeMir Aqib HussainNessuna valutazione finora

- Berthelot SF 98 99 175 181 PDFDocumento620 pagineBerthelot SF 98 99 175 181 PDFferroburakNessuna valutazione finora

- Module-1: General Introduction M1: General Introduction M1.1 Introduction of CompositesDocumento35 pagineModule-1: General Introduction M1: General Introduction M1.1 Introduction of CompositesANessuna valutazione finora

- Walnut Shell A ReviewDocumento11 pagineWalnut Shell A ReviewGaneshNessuna valutazione finora

- Metal-Matrix Composites: October 2015Documento29 pagineMetal-Matrix Composites: October 2015AKHIL C SUNNYNessuna valutazione finora

- Textile_Structural_Composite_and_Its_AppDocumento5 pagineTextile_Structural_Composite_and_Its_Appptlimaproject92Nessuna valutazione finora

- MMC PDFDocumento29 pagineMMC PDFAadelNessuna valutazione finora

- SP Guide To CompositesDocumento69 pagineSP Guide To CompositesCefirel_grifonNessuna valutazione finora

- Composite Materials: 1.2 Characteristics of A Composite MaterialDocumento5 pagineComposite Materials: 1.2 Characteristics of A Composite Materialashok pradhanNessuna valutazione finora

- Lecture NotesDocumento44 pagineLecture NotesRaj KumarNessuna valutazione finora

- Composites Materials. 15me32Documento47 pagineComposites Materials. 15me32subba reddy100% (1)

- Introduction to Composite MaterialsDocumento42 pagineIntroduction to Composite Materials062 NITHEESH KUMAR .CNessuna valutazione finora

- Composite Materials: Nurul Farahin BT MusaDocumento30 pagineComposite Materials: Nurul Farahin BT MusaAhmad Faiz ShahidinNessuna valutazione finora

- Composite Materials GuideDocumento23 pagineComposite Materials Guidenasuha batrishahNessuna valutazione finora

- TOPIC 11 Composite Materials (Notes)Documento16 pagineTOPIC 11 Composite Materials (Notes)Kaynine KikoNessuna valutazione finora

- Composite MaterialsDocumento4 pagineComposite MaterialsFatmaNessuna valutazione finora

- CM NotesDocumento136 pagineCM NotesFayaz KhanNessuna valutazione finora

- Avinash Document ProjectDocumento90 pagineAvinash Document ProjectBajibabu IndurthiNessuna valutazione finora

- Project Report PDFDocumento38 pagineProject Report PDFLogic Manju71% (14)

- CompositesDocumento11 pagineCompositesTrupti KalamdaniNessuna valutazione finora

- Chapter 1 To 5Documento47 pagineChapter 1 To 5Somanathan SubashNessuna valutazione finora

- ProjectDocumento53 pagineProjectKHALEEL PASHA SHAIKNessuna valutazione finora

- Composite Materials: A Guide to Properties and ApplicationsDocumento47 pagineComposite Materials: A Guide to Properties and ApplicationsNarkedamilli Tulasi RadhaNessuna valutazione finora

- Manganese Metal Composites Properties ExplorationDa EverandManganese Metal Composites Properties ExplorationNessuna valutazione finora

- Elastic, Plastic and Yield Design of Reinforced StructuresDa EverandElastic, Plastic and Yield Design of Reinforced StructuresNessuna valutazione finora

- Composite Steel and Concrete Structural Members: Composite Steel and Concrete Structures: Fundamental Behaviour (Second Edition)Da EverandComposite Steel and Concrete Structural Members: Composite Steel and Concrete Structures: Fundamental Behaviour (Second Edition)Valutazione: 4 su 5 stelle4/5 (10)

- DFMA Introduction 3Documento1 paginaDFMA Introduction 3Sudhakar KarnanNessuna valutazione finora

- DFMA Introduction 2Documento1 paginaDFMA Introduction 2Sudhakar KarnanNessuna valutazione finora

- Module Learning Objectives: M.S Ramaiah School of Advanced Studies - BangaloreDocumento1 paginaModule Learning Objectives: M.S Ramaiah School of Advanced Studies - BangaloreSudhakar KarnanNessuna valutazione finora

- Lean OverviewDocumento29 pagineLean OverviewSudhakar KarnanNessuna valutazione finora

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 37Documento1 paginaEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 37Sudhakar KarnanNessuna valutazione finora

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 43Documento1 paginaEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 43Sudhakar KarnanNessuna valutazione finora

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 40Documento1 paginaEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 40Sudhakar KarnanNessuna valutazione finora

- Module Syllabus: M.S Ramaiah School of Advanced Studies - BangaloreDocumento1 paginaModule Syllabus: M.S Ramaiah School of Advanced Studies - BangaloreSudhakar KarnanNessuna valutazione finora

- Autodesk® Inventor™ and Sheet Metal Manufacturing: From Drawing To FabricationDocumento15 pagineAutodesk® Inventor™ and Sheet Metal Manufacturing: From Drawing To FabricationSudhakar KarnanNessuna valutazione finora

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 45Documento1 paginaEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 45Sudhakar KarnanNessuna valutazione finora

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 38Documento1 paginaEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 38Sudhakar KarnanNessuna valutazione finora

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 35Documento1 paginaEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 35Sudhakar KarnanNessuna valutazione finora

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 44Documento1 paginaEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 44Sudhakar KarnanNessuna valutazione finora

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 39Documento1 paginaEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 39Sudhakar KarnanNessuna valutazione finora

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 42Documento1 paginaEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 42Sudhakar KarnanNessuna valutazione finora

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 33Documento1 paginaEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 33Sudhakar KarnanNessuna valutazione finora

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 34Documento1 paginaEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 34Sudhakar KarnanNessuna valutazione finora

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 34Documento1 paginaEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 34Sudhakar KarnanNessuna valutazione finora

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 35Documento1 paginaEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 35Sudhakar KarnanNessuna valutazione finora

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 29Documento1 paginaEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 29Sudhakar KarnanNessuna valutazione finora

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 30Documento1 paginaEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 30Sudhakar KarnanNessuna valutazione finora

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 32Documento1 paginaEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 32Sudhakar KarnanNessuna valutazione finora

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 28Documento1 paginaEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 28Sudhakar KarnanNessuna valutazione finora

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 31Documento1 paginaEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 31Sudhakar KarnanNessuna valutazione finora

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 24Documento1 paginaEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 24Sudhakar KarnanNessuna valutazione finora

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 25Documento1 paginaEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 25Sudhakar KarnanNessuna valutazione finora

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 27Documento1 paginaEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 27Sudhakar KarnanNessuna valutazione finora

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 26Documento1 paginaEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 26Sudhakar KarnanNessuna valutazione finora

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 22Documento1 paginaEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 22Sudhakar KarnanNessuna valutazione finora

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 23Documento1 paginaEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 23Sudhakar KarnanNessuna valutazione finora

- DJI Matrice 300 RTK SpecsDocumento6 pagineDJI Matrice 300 RTK SpecsHoai Nam NguyenNessuna valutazione finora

- Airbus Family CCQMMF JOEB Report (120304)Documento36 pagineAirbus Family CCQMMF JOEB Report (120304)pedatiNessuna valutazione finora

- Shibukumar Interview Aviation Update PDFDocumento36 pagineShibukumar Interview Aviation Update PDFshibuNessuna valutazione finora

- Mi-24 CWAM POHDocumento103 pagineMi-24 CWAM POHpscwps29hrNessuna valutazione finora

- Gmail - WHY JOIN THE BOMBAY FLYING CLUBDocumento4 pagineGmail - WHY JOIN THE BOMBAY FLYING CLUBAkash SharmaNessuna valutazione finora

- Formularul REAC 01: Air Safety ReportDocumento15 pagineFormularul REAC 01: Air Safety ReportRazvan AzamfireiNessuna valutazione finora

- Gaitonde ProgAeroSci 2015 (SWBLI Review)Documento20 pagineGaitonde ProgAeroSci 2015 (SWBLI Review)Taro YamadaNessuna valutazione finora

- SKRGDocumento16 pagineSKRGbrailibNessuna valutazione finora

- How airlines use big data to improve operations and customer serviceDocumento6 pagineHow airlines use big data to improve operations and customer serviceAngelica RoblesNessuna valutazione finora

- Demag 180T AC435Documento20 pagineDemag 180T AC435sidhuaraviiNessuna valutazione finora

- Complete The Passage: Trư NG THPT Tân BìnhDocumento4 pagineComplete The Passage: Trư NG THPT Tân BìnhBích NguyễnNessuna valutazione finora

- Certification-memoranda-import-'Final' EASA CM-As-002 Issue 01 - Revision 01 - Clarifications To AMC 20-27 - PUBLDocumento17 pagineCertification-memoranda-import-'Final' EASA CM-As-002 Issue 01 - Revision 01 - Clarifications To AMC 20-27 - PUBLmicheldaNessuna valutazione finora

- Vept Atc SmacDocumento1 paginaVept Atc Smaczxcvbn,kuiNessuna valutazione finora

- MECH 430 Assignment 4 F2018Documento9 pagineMECH 430 Assignment 4 F2018Апцгдк Ьфш БгднчллNessuna valutazione finora

- Pub - Italian Civil and Military Aircraft 1930 1945 PDFDocumento153 paginePub - Italian Civil and Military Aircraft 1930 1945 PDFBepis100% (2)

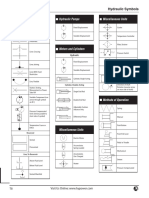

- Fluid Power Symbols PDFDocumento4 pagineFluid Power Symbols PDFsanisah1245100% (1)

- Lab 1a Wind Tunnel Testing Principles & Lift and Drag Coefficients On An AirfoilDocumento6 pagineLab 1a Wind Tunnel Testing Principles & Lift and Drag Coefficients On An Airfoilzeeshan khanNessuna valutazione finora

- c-130 Index Service NewDocumento16 paginec-130 Index Service Newangelo marra100% (1)

- Framework Structural SystemDocumento24 pagineFramework Structural SystemAmirrudin Samsudin50% (2)

- Horizontal and Vertical PlaneDocumento13 pagineHorizontal and Vertical PlaneUlanNessuna valutazione finora

- Semper ViperDocumento100 pagineSemper ViperJDoe DoesonNessuna valutazione finora

- Problem A1 Study of Bernoulli'S Theorem I. AbstractDocumento9 pagineProblem A1 Study of Bernoulli'S Theorem I. AbstractpjrapanutNessuna valutazione finora

- Airworthiness Directive Schedule: Helicopters Bell 47 Series & Kawasaki Bell 47 Series 25 June 2009Documento12 pagineAirworthiness Directive Schedule: Helicopters Bell 47 Series & Kawasaki Bell 47 Series 25 June 2009Cristian PugaNessuna valutazione finora

- Cessna C208B ChecklistDocumento123 pagineCessna C208B ChecklistCarlos ZablahNessuna valutazione finora

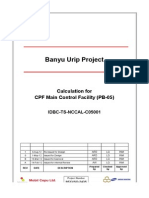

- IDBC-TS-NCCAL-C05001 Rev 1 - Calculation For CPF Main Control Facility (PB-05)Documento243 pagineIDBC-TS-NCCAL-C05001 Rev 1 - Calculation For CPF Main Control Facility (PB-05)Daniel Silva100% (1)

- Doc.9683 Oaci PDFDocumento335 pagineDoc.9683 Oaci PDFefigue01100% (1)

- Adhiparasakthi College of EngineeringDocumento6 pagineAdhiparasakthi College of EngineeringrishinathnehruNessuna valutazione finora

- Venezuela Cycle 2111Documento145 pagineVenezuela Cycle 2111Jose Francisco Colina100% (2)

- Subject: Weight and Balance Control of AircraftDocumento5 pagineSubject: Weight and Balance Control of AircraftjanhaviNessuna valutazione finora

- Wired For War Book Review by Chong Shi HaoDocumento4 pagineWired For War Book Review by Chong Shi HaogeorgegimNessuna valutazione finora