Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Purpose and Scope: Pipelines and Terminals Manual/Volume 3 - Maintenance

Caricato da

mahdi_gDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Purpose and Scope: Pipelines and Terminals Manual/Volume 3 - Maintenance

Caricato da

mahdi_gCopyright:

Formati disponibili

TITLE

SECTION 38:

SUBJECT 03:

Pipelines and Terminals Manual/Volume 3 - Maintenance

* Pipeline Construction and Repair

Mud Plug Installation

PURPOSE AND SCOPE

Mud (gel) plugs are installed at line-repair or tie-in locations to prevent residual water,

crude oil and hydrocarbon vapours from entering the work area through open-ended

piping.

Three types of mud plugs, or a combination of them are used:

Removable: for installing flanges or removable fittings.

Vented: for installing flanges or removable fittings.

Solid: for line repairs and joining two pipes.

REFERENCES

PDM 03-02-05: Critical Procedures: Lockouts and Forceful Removal of a Lock

PDM 03-08-20: Product Movement-Piping & Accessories: Blanking and Tagging &

Installation of Blanks and Blinds

ASSOCIATED DOCUMENTS

None

DEFINITIONS

None

PROCEDURE

Mud plugs must not be used as a replacement for isolation. The type of mud plug

selected is determined on a per site basis.

Notes and Cautions

A typical mud plug consists of a mixture of Wyoming bentonite clay and water or

windshield washer fluid. These are combined to form a stiff plastic mixture.

The impact of mud plug type and retrieval should be discussed with operations.

November 2004 - Rev 16

Ptm33803.doc

Page 38 .03-1 of 2

SECTION 38.03:

Pipeline Construction and Repair

Mud Plug Installation

A solid mud plug should always be used to supplement a mechanical seal plug.

To obtain maximum swelling capability, freshly prepared mud plug material should

always be used.

Pressure may build up when using non vented plugs. Provide relief through

venting.

Mud Plug Installation

1. Prepare the line for plug installation.

2. Hand file the sharp edges left by the cold-cutter wheels.

3. Clean the inside of the pipe before installing the plug.

4. Install the mud plug into the line.

Mix mud plugs using window-washer antifreeze in winter.

Provide a means to remove mud material after the work is complete if required

(e.g. backing plate and wire).

Install a vent hose in the line for vented mud plugs. Ensure the free end of the

hose is downwind of the repair and gas detection is performed at the vent area

as well as the repair site.

Installing Vented Mud Plugs

1. Install a vent hose in the line for vented mud plugs.

2. Cut two steel plates to a size smaller than the inside pipeline diameter.

Ensure the plates will pass back through the flange-neck root weld.

3. Cut a hole in the plates to allow the hose to pass through the plates.

4. Use retainer bolts to pull the plates together.

5. Ensure the free end of the hose is at least 20m downwind of the repair.

Ensure gas detection is performed at the vent areas well as the repair area when using

vented plugs.

v

Page 38.03-2 of 2

Ptm33803.doc

November 2004 - Rev 16

Potrebbero piacerti anche

- ATB 021 Flowtite Pipe Tapping PDFDocumento10 pagineATB 021 Flowtite Pipe Tapping PDFRajadurai SinghNessuna valutazione finora

- Rubber Lining ApplicationDocumento9 pagineRubber Lining ApplicationeyslNessuna valutazione finora

- Refrigerant Piping Work1Documento13 pagineRefrigerant Piping Work1Le Manh HieuNessuna valutazione finora

- PAL - Construction GuidelinesDocumento28 paginePAL - Construction GuidelinesCarew Mohammed AbayomiNessuna valutazione finora

- Report - Measuring, Cutting, Joining PipesDocumento54 pagineReport - Measuring, Cutting, Joining PipesStephen Tabiar100% (1)

- MOS For Water Supply Pipe Installation Inside ToiletDocumento3 pagineMOS For Water Supply Pipe Installation Inside ToiletSherif M. ElgebalyNessuna valutazione finora

- Fitters Guide 2017 Ver5Documento48 pagineFitters Guide 2017 Ver5Bogdan GeorgeNessuna valutazione finora

- Installation Guidelines For C&I Installation of Pneumatic LineDocumento6 pagineInstallation Guidelines For C&I Installation of Pneumatic LineCharu ChhabraNessuna valutazione finora

- Culvert SlipliningDocumento8 pagineCulvert SlipliningbetopagoadaNessuna valutazione finora

- Installation Guide For PVC PipeDocumento43 pagineInstallation Guide For PVC Pipeb1gm3nNessuna valutazione finora

- Fire Fighting Inside BuildingDocumento3 pagineFire Fighting Inside BuildingHamada ELarabyNessuna valutazione finora

- Condensate Discharge Pipe Installation: Installer GuideDocumento21 pagineCondensate Discharge Pipe Installation: Installer Guidealin76usNessuna valutazione finora

- Troubleshooting Defects Hot Runner SystemDocumento4 pagineTroubleshooting Defects Hot Runner SystemJorge MartinezNessuna valutazione finora

- Rubber Lining PrinciplesDocumento5 pagineRubber Lining PrinciplesTushar MangratiNessuna valutazione finora

- Fire Hydrant in ST Alation ManualDocumento13 pagineFire Hydrant in ST Alation ManualMohammad ElhedabyNessuna valutazione finora

- Measuring, Cutting and Joining Pipes: Cast Iron PipeDocumento5 pagineMeasuring, Cutting and Joining Pipes: Cast Iron PipeStanley Scott ArroyoNessuna valutazione finora

- Method Statement For GRP Pipe InstallationDocumento8 pagineMethod Statement For GRP Pipe Installationdj_holo100% (1)

- Jointing Instructions Dec 20123Documento2 pagineJointing Instructions Dec 20123Gabi CristacheNessuna valutazione finora

- Auya30lblu - Aoya30lbtl - InstallDocumento2 pagineAuya30lblu - Aoya30lbtl - InstallpepondeAvilesNessuna valutazione finora

- 6035 L2u204 PPT Outcome3Documento25 pagine6035 L2u204 PPT Outcome3shahin.noktehdan4102Nessuna valutazione finora

- 6035 L2u204 PPT Outcome3Documento25 pagine6035 L2u204 PPT Outcome3Adrian JugariuNessuna valutazione finora

- Refrigeration PipelinesDocumento2 pagineRefrigeration PipelinesDavidB1206Nessuna valutazione finora

- Cl20702 705 Manual Mup HiDocumento33 pagineCl20702 705 Manual Mup HiRamadan RashadNessuna valutazione finora

- Rubber Lining Application Manual Revision Date: September 1, 2009 Section 10: Pipe Lining Procedures Page: 10 - 1Documento15 pagineRubber Lining Application Manual Revision Date: September 1, 2009 Section 10: Pipe Lining Procedures Page: 10 - 1EdgarDavidDiazCamposNessuna valutazione finora

- Rubber Lining Application Manual Revision Date: September 1, 2009 Section 10: Pipe Lining Procedures Page: 10 - 1Documento15 pagineRubber Lining Application Manual Revision Date: September 1, 2009 Section 10: Pipe Lining Procedures Page: 10 - 1Haresh JoganiNessuna valutazione finora

- EO-2 Fitting InstallationDocumento4 pagineEO-2 Fitting InstallationMayank Kumar GuptaNessuna valutazione finora

- Method Statement For AC Units Pipe Installation and Drainage - CatDocumento8 pagineMethod Statement For AC Units Pipe Installation and Drainage - CatakerimtuzunNessuna valutazione finora

- Fiberstrong Piping System Above Ground Installation ManualDocumento32 pagineFiberstrong Piping System Above Ground Installation ManualIbrahim Habiba100% (1)

- Method Statement For Installation of PVC PipesDocumento13 pagineMethod Statement For Installation of PVC PipesChathura Dharmasena100% (3)

- Installation, Operation and Maintenance - LOK-FLANGE ® Multitube Heat ExchangersDocumento5 pagineInstallation, Operation and Maintenance - LOK-FLANGE ® Multitube Heat ExchangersCLIFFORDPANessuna valutazione finora

- Electrofusion WeldingDocumento4 pagineElectrofusion WeldingRajesh RadeNessuna valutazione finora

- Good Din FIRE FIGHTING SYSTEM DESCRIPTIONDocumento4 pagineGood Din FIRE FIGHTING SYSTEM DESCRIPTIONJan LerNessuna valutazione finora

- Rubber Lining Application PDFDocumento9 pagineRubber Lining Application PDFLasandu WanniarachchiNessuna valutazione finora

- Method Statement Duct InstallationDocumento5 pagineMethod Statement Duct Installationcharles dNessuna valutazione finora

- C 1541 - 04 Qze1ndeDocumento5 pagineC 1541 - 04 Qze1ndecarlosNessuna valutazione finora

- Inspection of The SystemsDocumento12 pagineInspection of The SystemsTulen CabuldinNessuna valutazione finora

- Installation Instructions: Plastic Pipe Industry AssociationDocumento27 pagineInstallation Instructions: Plastic Pipe Industry Associationahmedmohamed2014Nessuna valutazione finora

- Reformer Tube Replacement - RFQDocumento4 pagineReformer Tube Replacement - RFQChinmay FakeNessuna valutazione finora

- Proceso de Soldadura PVC George FisherDocumento10 pagineProceso de Soldadura PVC George FisherMarco Antonio Hernandez MotaNessuna valutazione finora

- Ms-Black Steel PipeDocumento4 pagineMs-Black Steel PipeYusufNessuna valutazione finora

- HYPRO™ PVC-O Pipes Installation Guide: Molecor (SEA) SDN BHDDocumento8 pagineHYPRO™ PVC-O Pipes Installation Guide: Molecor (SEA) SDN BHDmabj68Nessuna valutazione finora

- Assembly and Installation PVC To MEtal PipeDocumento11 pagineAssembly and Installation PVC To MEtal PipevuongNessuna valutazione finora

- Eu002 ReviewerDocumento6 pagineEu002 ReviewerjunalynnerosaNessuna valutazione finora

- Mechanical PlugsDocumento6 pagineMechanical Plugskategord0% (1)

- PVC-O Tecnical Spesification MolecorDocumento11 paginePVC-O Tecnical Spesification MolecorRusdy NugrahaNessuna valutazione finora

- See-Thru Potato Cannon: Featured GuideDocumento16 pagineSee-Thru Potato Cannon: Featured GuideJose De Tomas SanchezNessuna valutazione finora

- Feed Water Heater ManualDocumento16 pagineFeed Water Heater Manualfelix asadeNessuna valutazione finora

- MOS For Water Supply Pipe InstallationDocumento3 pagineMOS For Water Supply Pipe InstallationDon Roseller Dumaya100% (1)

- General Guidelines InsulationDocumento56 pagineGeneral Guidelines InsulationPadmanaban SoundirarajanNessuna valutazione finora

- Pipework Maintenance: 15.1 Maintenance-Key To Trouble-Free ServiceDocumento6 paginePipework Maintenance: 15.1 Maintenance-Key To Trouble-Free ServiceAde Sari TrianaNessuna valutazione finora

- BestPractices Thermoplastic Sep08Documento10 pagineBestPractices Thermoplastic Sep08geverett2765Nessuna valutazione finora

- Plugs and ProfilesDocumento43 paginePlugs and ProfilesTariq SaydawiNessuna valutazione finora

- Simple Plumbing Repairs for the Home and FarmsteadDa EverandSimple Plumbing Repairs for the Home and FarmsteadNessuna valutazione finora

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerDa EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerValutazione: 5 su 5 stelle5/5 (1)

- Plastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3Da EverandPlastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3Nessuna valutazione finora

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsDa Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsValutazione: 4 su 5 stelle4/5 (1)

- The Weir Direct-Acting Feed Pump - Working InstructionsDa EverandThe Weir Direct-Acting Feed Pump - Working InstructionsNessuna valutazione finora

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDa EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNessuna valutazione finora

- EKL-QC-F-0121 QC Monthly Report R 2.0Documento2 pagineEKL-QC-F-0121 QC Monthly Report R 2.0mahdi_gNessuna valutazione finora

- Satr-P-3101 Rev 3Documento8 pagineSatr-P-3101 Rev 3mahdi_gNessuna valutazione finora

- 03 11 4297Documento3 pagine03 11 4297mahdi_gNessuna valutazione finora

- EKL-QC-F-0106-C Post Weld Heat Treatment ReportDocumento1 paginaEKL-QC-F-0106-C Post Weld Heat Treatment Reportmahdi_gNessuna valutazione finora

- SATR-X-3101 Rev 3Documento3 pagineSATR-X-3101 Rev 3mahdi_gNessuna valutazione finora

- SATR-X-3201 Rev 3Documento4 pagineSATR-X-3201 Rev 3mahdi_gNessuna valutazione finora

- SAIC-X-3102 Rev 3Documento5 pagineSAIC-X-3102 Rev 3mahdi_gNessuna valutazione finora

- Sa P 070Documento3 pagineSa P 070mahdi_gNessuna valutazione finora

- Saudi Aramco Pre-Commissioning FormDocumento1 paginaSaudi Aramco Pre-Commissioning Formmahdi_gNessuna valutazione finora

- Satr B 4001Documento3 pagineSatr B 4001mahdi_gNessuna valutazione finora

- Saudi Aramco Test Report: On-Site Built-Up Shower Receptor Watertightness Test SATR-S-4006 15-Dec-09 PlumbDocumento1 paginaSaudi Aramco Test Report: On-Site Built-Up Shower Receptor Watertightness Test SATR-S-4006 15-Dec-09 Plumbmahdi_gNessuna valutazione finora

- Satr S 4001Documento1 paginaSatr S 4001mahdi_gNessuna valutazione finora

- Saic S 4006Documento2 pagineSaic S 4006mahdi_gNessuna valutazione finora

- Saudi Aramco Pre-Commissioning Form: Sapmt Inspection Operations Signature & DateDocumento2 pagineSaudi Aramco Pre-Commissioning Form: Sapmt Inspection Operations Signature & Datemahdi_gNessuna valutazione finora

- Saudi Aramco Test Report: Building Drainage and Vent Piping Hydrotest SATR-S-4003 15-Dec-09 PlumbDocumento2 pagineSaudi Aramco Test Report: Building Drainage and Vent Piping Hydrotest SATR-S-4003 15-Dec-09 Plumbmahdi_gNessuna valutazione finora

- Sa J 001Documento2 pagineSa J 001mahdi_gNessuna valutazione finora

- Saudi Aramco Pre-Commissioning Form: MeteringDocumento1 paginaSaudi Aramco Pre-Commissioning Form: Meteringmahdi_gNessuna valutazione finora

- Sa J 001Documento2 pagineSa J 001mahdi_gNessuna valutazione finora

- Saudi Aramco Pre-Commissioning FormDocumento2 pagineSaudi Aramco Pre-Commissioning Formmahdi_gNessuna valutazione finora

- Saudi Aramco Pre-Commissioning Form: Positive Displacement Pumps (Reciprocating)Documento1 paginaSaudi Aramco Pre-Commissioning Form: Positive Displacement Pumps (Reciprocating)mahdi_gNessuna valutazione finora

- Saudi Aramco Pre-Commissioning FormDocumento1 paginaSaudi Aramco Pre-Commissioning Formmahdi_gNessuna valutazione finora

- Saudi Aramco Pre-Commissioning Form: FORM # J-011 (5/19/15) SHT 1 of 2Documento2 pagineSaudi Aramco Pre-Commissioning Form: FORM # J-011 (5/19/15) SHT 1 of 2mahdi_gNessuna valutazione finora

- Saudi Aramco Pre-Commissioning FormDocumento1 paginaSaudi Aramco Pre-Commissioning Formmahdi_gNessuna valutazione finora

- Saudi Aramco Pre-Commissioning FormDocumento2 pagineSaudi Aramco Pre-Commissioning Formmahdi_gNessuna valutazione finora

- Saer 5895Documento18 pagineSaer 5895sethu1091Nessuna valutazione finora

- Sa F 001Documento13 pagineSa F 001mahdi_gNessuna valutazione finora

- Sa G 005Documento1 paginaSa G 005mahdi_gNessuna valutazione finora

- Saudi Aramco Pre-Commissioning FormDocumento2 pagineSaudi Aramco Pre-Commissioning Formmahdi_gNessuna valutazione finora

- Sa e 001aDocumento7 pagineSa e 001amahdi_gNessuna valutazione finora

- Saer 5711Documento161 pagineSaer 5711sethu1091100% (1)

- Solubility of Water in Hydrocarbons - Hibbard & SchallaDocumento27 pagineSolubility of Water in Hydrocarbons - Hibbard & SchallarschirtNessuna valutazione finora

- Hydril - GK Annular r2Documento2 pagineHydril - GK Annular r2Anonymous 48jYxR1CNessuna valutazione finora

- 5.0 - 5.13 - SummaryDocumento230 pagine5.0 - 5.13 - SummaryVea ValcorzaNessuna valutazione finora

- Manual For Copper Still by Rainier DistillersDocumento9 pagineManual For Copper Still by Rainier DistillersRainier DistillersNessuna valutazione finora

- M7 Safety PrecautionsDocumento10 pagineM7 Safety Precautionsketan SNessuna valutazione finora

- Parametric Optimization in Die Sinking Edm of Inconel 825 Using Copper ElectrodeDocumento9 pagineParametric Optimization in Die Sinking Edm of Inconel 825 Using Copper ElectrodeManishNessuna valutazione finora

- Matching Your Crucible To Your Application.Documento8 pagineMatching Your Crucible To Your Application.Richard.nlNessuna valutazione finora

- Chapter 7 - Lubricants and Lubrication SystemsDocumento34 pagineChapter 7 - Lubricants and Lubrication SystemsRi AlvesNessuna valutazione finora

- G3612 Schesematic RENR5911!01!01-ALLDocumento2 pagineG3612 Schesematic RENR5911!01!01-ALLAnonymous eii2XsNessuna valutazione finora

- FMEA BoilerDocumento2 pagineFMEA Boilerraito100% (1)

- Properties of Water: Table A.1Documento23 pagineProperties of Water: Table A.1Andrés Otero RojasNessuna valutazione finora

- Thermalysis-Converting Waste Plastic To DieselDocumento8 pagineThermalysis-Converting Waste Plastic To DieselRavi KumarNessuna valutazione finora

- Physical and Chemical PrinciplesDocumento7 paginePhysical and Chemical PrinciplesJr DocorNessuna valutazione finora

- Chapter 4 - Edible Oils, Fats and WaxesDocumento32 pagineChapter 4 - Edible Oils, Fats and WaxesIvy JoyceNessuna valutazione finora

- Combination DriveDocumento10 pagineCombination Driveadityasingh979Nessuna valutazione finora

- The Lease Pumper's HandbookDocumento4 pagineThe Lease Pumper's HandbookArun AhirwarNessuna valutazione finora

- NO: Sold To: Date: Terms: Business Style: Address: Osca/Pwd Id NoDocumento6 pagineNO: Sold To: Date: Terms: Business Style: Address: Osca/Pwd Id NoQueenie AlgireNessuna valutazione finora

- I. Introduction - CombustionDocumento6 pagineI. Introduction - CombustionNadeine GathercoleNessuna valutazione finora

- HP Bitumen HandbookDocumento53 pagineHP Bitumen HandbookAnuj Mathur100% (1)

- Hydrodealkylation 12Documento2 pagineHydrodealkylation 12khanh11h100% (1)

- Weishaupt Product Info Gas and Dual Fuel Burners Sizes 1-3Documento8 pagineWeishaupt Product Info Gas and Dual Fuel Burners Sizes 1-3AMIR MahmoodNessuna valutazione finora

- Abbreviations HydraulicDocumento1 paginaAbbreviations HydraulicAbdul Junaedi0% (1)

- Expt6 HeatofcombustionDocumento4 pagineExpt6 HeatofcombustionBo Marayag100% (1)

- Eye C GasDocumento3 pagineEye C GasLuis ReyesNessuna valutazione finora

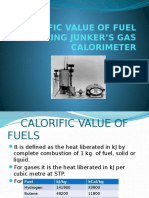

- Calorific Value of Fuel Using Junker S Gas CalorimeterDocumento12 pagineCalorific Value of Fuel Using Junker S Gas Calorimeterjishnu100% (1)

- 1.02 Introduction To HPI Sub-ConceptsDocumento38 pagine1.02 Introduction To HPI Sub-ConceptsNurmalinda SihombingNessuna valutazione finora

- 22 Mar 2018 121528120STS0QV2RAnnexurePreFeasibilityReportPFRDocumento61 pagine22 Mar 2018 121528120STS0QV2RAnnexurePreFeasibilityReportPFRKhoa TranNessuna valutazione finora

- The Nine Classes of Dangerous GoodsDocumento8 pagineThe Nine Classes of Dangerous GoodsJack PNessuna valutazione finora

- D Chemistry-For-Engineering-FinalDocumento12 pagineD Chemistry-For-Engineering-FinalCathy LevreNessuna valutazione finora

- Grade VIII-Notes (Chemistry) Chapter 4-Combustion and Flame.Documento10 pagineGrade VIII-Notes (Chemistry) Chapter 4-Combustion and Flame.kedar vatsNessuna valutazione finora