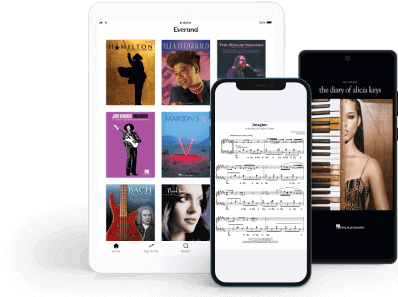

Enjoy popular sheet music when you subscribe

Sheet music

Get instant access to 70,000+ pieces of sheet music with our digital subscription. From classical powerhouses like Bach and Beethoven to today’s best selling artists like Beyoncé and Bruno Mars, our digital library of sheet music hits all the right notes. Sign up today to start playing your favorite tunes.

Top 20 Songbooks Trending

Piano Calm: 15 Reflective Solos Composed by Phillip Keveren Rating: 5 out of 5 stars5/5Clair de Lune: Piano Solo Rating: 4 out of 5 stars4/5Hallelujah Rating: 4 out of 5 stars4/5Primer Level - Lesson Book, 2nd Edition: Piano Adventures® Rating: 4 out of 5 stars4/5Shallow (from A Star Is Born) Rating: 4 out of 5 stars4/5The Greatest Showman: Music from the Motion Picture Soundtrack Rating: 5 out of 5 stars5/5Mean Girls Rating: 4 out of 5 stars4/5The Phantom of the Opera - Movie Selections Rating: 5 out of 5 stars5/5Tiny Dancer Rating: 4 out of 5 stars4/5The Hunchback of Notre Dame: The Stage Musical: Vocal Selections Rating: 5 out of 5 stars5/5Speechless (from Aladdin) Rating: 4 out of 5 stars4/5Frozen 2 Piano/Vocal/Guitar Songbook: Music from the Motion Picture Soundtrack Rating: 4 out of 5 stars4/5Tangled: Music from the Motion Picture Soundtrack Rating: 4 out of 5 stars4/5Level 3A - Lesson Book - 2nd Edition: Piano Adventures® Rating: 5 out of 5 stars5/5Level 2A - Lesson Book - 2nd Edition: Piano Adventures® Rating: 4 out of 5 stars4/5Colors of the Wind: From Disney's Pocahontas Rating: 5 out of 5 stars5/5Reflection Rating: 5 out of 5 stars5/5Disney Favorites: Jazz Piano Solos Series Volume 51 Rating: 5 out of 5 stars5/5Disney Peaceful Piano Solos Rating: 4 out of 5 stars4/5Level 1 - Lesson Book - 2nd Edition: Piano Adventures® Rating: 4 out of 5 stars4/5Willy Wonka & the Chocolate Factory Rating: 4 out of 5 stars4/5Love Story Rating: 5 out of 5 stars5/5Someone You Loved Rating: 4 out of 5 stars4/5A Whole New World Sheet Music Rating: 5 out of 5 stars5/5How Far I'll Go (from Moana) Rating: 4 out of 5 stars4/5

Currently Charting

Trolls: Music from the Motion Picture Soundtrack Rating: 4 out of 5 stars4/5Taylor Swift - Lover Rating: 4 out of 5 stars4/5Olivia Rodrigo - Sour Rating: 4 out of 5 stars4/5Billie Eilish - Happier Than Ever Rating: 4 out of 5 stars4/5Taylor Swift - Midnights Rating: 4 out of 5 stars4/5Encanto: Music from the Motion Picture Soundtrack Rating: 5 out of 5 stars5/5Chart Hits of 2021-2022 Rating: 4 out of 5 stars4/5Top Hits of 2022: P/V/G Rating: 5 out of 5 stars5/5Best of Adele Rating: 4 out of 5 stars4/5Adele - 30 Rating: 5 out of 5 stars5/5Ariana Grande - Thank U, Next Rating: 5 out of 5 stars5/5Million Reasons Rating: 5 out of 5 stars5/5Today's Hits: 30 Streaming Favorites Rating: 5 out of 5 stars5/5Justin Bieber - Justice Rating: 5 out of 5 stars5/5Frank Ocean - Channel Orange Rating: 4 out of 5 stars4/5Sam Smith - Love Goes Rating: 5 out of 5 stars5/5Shawn Mendes - Wonder Rating: 0 out of 5 stars0 ratingsHarry Styles - Harry's House Rating: 5 out of 5 stars5/5Lorde - Melodrama Rating: 5 out of 5 stars5/5Dua Lipa Rating: 5 out of 5 stars5/5Coldplay - A Head Full of Dreams Rating: 5 out of 5 stars5/5Maroon 5 - Red Pill Blues Rating: 0 out of 5 stars0 ratings

Grammy Award-Winning Artists

The Beatles - Sgt. Pepper's Lonely Hearts Club Band - Updated Edition Rating: 4 out of 5 stars4/5Dolly Parton - Greatest Hits Rating: 5 out of 5 stars5/5The Stevie Wonder Anthology Rating: 5 out of 5 stars5/5Encanto: Music from the Motion Picture Soundtrack Rating: 5 out of 5 stars5/5Coldplay - Viva La Vida Rating: 4 out of 5 stars4/5Taylor Swift - Fearless Rating: 5 out of 5 stars5/5Taylor Swift - 1989 Rating: 4 out of 5 stars4/5Bruno Mars - 24K Magic Rating: 5 out of 5 stars5/5Billie Eilish - When We All Fall Asleep, Where Do We Go? Rating: 4 out of 5 stars4/5Adele - 21: Easy Piano Rating: 4 out of 5 stars4/5Taylor Swift - Midnights Rating: 4 out of 5 stars4/5The Diary of Alicia Keys (Songbook) Rating: 4 out of 5 stars4/5Sting - The Best of 25 Years Rating: 4 out of 5 stars4/5Lizzo - Cuz I Love You Rating: 5 out of 5 stars5/5Frank Sinatra Anthology (Songbook) Rating: 4 out of 5 stars4/5Rihanna - Loud Rating: 5 out of 5 stars5/5La La Land: Music from the Motion Picture Soundtrack Rating: 4 out of 5 stars4/5Beyoncé - I Am ... Sasha Fierce Rating: 4 out of 5 stars4/5The Grammy Awards Record of the Year 1958-2011: E-Z Play Today Volume 160 Rating: 4 out of 5 stars4/5Ed Sheeran - Divide Rating: 5 out of 5 stars5/5The Police Anthology (Songbook) Rating: 4 out of 5 stars4/5Foo Fighters - Greatest Hits Rating: 3 out of 5 stars3/5Lady Gaga Rating: 4 out of 5 stars4/5Best of Santana Rating: 4 out of 5 stars4/5Eric Clapton - Unplugged - Deluxe Edition Rating: 5 out of 5 stars5/5U2 - The Piano Collection Rating: 4 out of 5 stars4/5Metallica: Classic Songs for Guitar: Note-for-Note Transcriptions with DVD Rating: 3 out of 5 stars3/5Mumford & Sons - Sigh No More Rating: 4 out of 5 stars4/5Ariana Grande - Sweetener Rating: 5 out of 5 stars5/5The Henry Mancini Collection Rating: 4 out of 5 stars4/5

About Sheet music

Your favorite titles in sheet music, all in one place. From today’s chart-topping hits to nostalgic pieces from a bygone era, our sheet music app has something for every person, skill level, and instrument. If you want to play like the best, our selection of pieces from Grammy Award-winning artists — like Adele, Frank Sinatra, U2, and more — are sure to inspire your artistry. For the classical fans among us, our wide selection of classical sheet music will give you Lisztomania. Relive the good old times with chart-topping jams from years past or, better yet, discover new favorites that you haven’t played yet. For fans of the stage and screen, our extensive selection of sheet music for movies and musicals will have you belting out your favorite songs in no time. Learn the foundations with our jazz and blues sheet music. A sheet music subscription lets you choose your own musical adventure so that you can access inspiration whenever the mood strikes.

Your favorite titles in sheet music, all in one place. From today’s chart-topping hits to nostalgic pieces from a bygone era, our sheet music app has something for every person, skill level, and instrument. If you want to play like the best, our selection of pieces from Grammy Award-winning artists — like Adele, Frank Sinatra, U2, and more — are sure to inspire your artistry. For the classical fans among us, our wide selection of classical sheet music will give you Lisztomania. Relive the good old times with chart-topping jams from years past or, better yet, discover new favorites that you haven’t played yet. For fans of the stage and screen, our extensive selection of sheet music for movies and musicals will have you belting out your favorite songs in no time. Learn the foundations with our jazz and blues sheet music. A sheet music subscription lets you choose your own musical adventure so that you can access inspiration whenever the mood strikes.