Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

MCE 439 Assignment 3

Caricato da

Ammar1994Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

MCE 439 Assignment 3

Caricato da

Ammar1994Copyright:

Formati disponibili

MCE 439 Computer Integrated

Manufacturing

Assignment # 3

1. Prepare an NC part program for the part shown. The dimensions given in the

figure are in mm. The tool diameter is 20 mm. (3 pts)

2. The positioning table for a component insertion machine uses a stepping motor and lead screw

mechanism. The design specifications require a table speed of 0.4 m/s and an accuracy = 0.02 mm.

The pitch of the lead screw = 5.0 mm, and the gear ratio = 2:1 (2 turns of the motor for each turn of

the lead screw). The mechanical errors in the motor, gear box, lead screw, and table connection are

characterized by a normal distribution with standard deviation = 0.0025 mm. Determine (a) the

minimum number of step angles in the stepping motor and (b) frequency of the pulse train required

to drive the table at the desired maximum speed.

3. Using the notation scheme for defining manipulator configurations , draw diagram of the following

robot: (a) TRT:R,

4. The linear joint (type L) of a certain industrial robot is actuated by a piston mechanism. The length

of the joint when fully retracted is 600 mm and when fully extended is 1000 mm. If the robot's

controller has an 8-bit storage capacity, determine the control resolution for this robot.

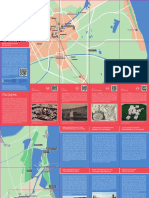

5. A flexible manufacturing system is being planned. It has a ladder layout as pictured in Figure P10.1

and uses a rail guided vehicle system to move parts between stations in the layout. All workparts are

loaded into the system at station 1, moved to one of three processing stations (2, 3, or 4), and then

brought back to station 1 for unloading. Once loaded onto its RGV, each workpart stays onboard the

vehicle throughout its time in the FMS. Load and unload times at station 1 are each 1.0 min.

Processing times at other stations are: 5.0 min at station 2, 7.0 min at station 3, and 9.0 min at

station 4. Hourly production of parts through the system is: 7 parts through station 2, 6 parts through

station 3, and 5 parts through station 4. (a) Develop the from-to Chart for trips and distances using

1

MCE 439 Computer Integrated

Manufacturing

Assignment # 3

the same format as Table 10.5. (b) Develop the network diagram for this data similar to Figure

10.13. (c) Determine the number of rail guided vehicles that are needed to meet the requirements of

the flexible manufacturing system, if vehicle speed = 60 m/min and the anticipated traffic factor =

0.85. Assume reliability = 100%.

6. An automated guided vehicle system is being planned for a warehouse complex. The AGVS will be

a driverless train system, and each train will consist of the towing vehicle plus four carts. Speed of

the trains will be 160 ft/min. Only the pulled carts carry loads. The average loaded travel distance

per delivery cycle is 2000 ft and empty travel distance is the same. Anticipated travel factor = 0.95.

Assume reliability = 1.0. The load handling time per train per delivery is expected to be 10 min. If

the requirements on the AGVS are 25 cart loads per hour, determine the number of trains required.

7. A closed loop overhead conveyor must be designed to deliver parts from one load station to one

unload station. The specified flow rate of parts that must be delivered between the two stations is

300 parts per hour. The conveyor has carriers spaced at a center-to-center distance that is to be

determined. Each carrier holds one part. Forward and return loops will each be 90 m long.

Conveyor speed = 0.5 m/s. Times to load and unload parts at the respective stations are each = 12 s.

Is the system feasible and if so, what is the appropriate number of carriers and spacing between

carriers that will achieve the specified flow rate?

8. An AS/RS is used for work-in-process storage in a manufacturing facility. The AS/RS has five

aisles, each aisle being 120 ft long and 40 ft high. The horizontal and vertical speeds of the S/R

machine are 400 ft/min and 50 ft/min, respectively. The S/R machine requires 12 sec to accomplish

a pick and deposit operation. The number of single command cycles equals the number of dual

command cycles. If the requirement is that the AS/RS must have a throughput rate of 200 S/R

transactions per hour during periods of peak activity, will the AS/RS satisfy this requirement? If so,

what is the utilization of the AS/RS during peak hours.

Potrebbero piacerti anche

- Bài Tập Tiểu LuậnDocumento5 pagineBài Tập Tiểu LuậnToy and MeNessuna valutazione finora

- Assignment FMSDocumento2 pagineAssignment FMSAnuragShrivastavNessuna valutazione finora

- AGV Problems: Calculating Vehicle RequirementsDocumento1 paginaAGV Problems: Calculating Vehicle RequirementsLương Bảo HânNessuna valutazione finora

- Sheet 2 2017-2018Documento7 pagineSheet 2 2017-2018Yahya Abdelhameed AamerNessuna valutazione finora

- MANDALAY TECHNOLOGICAL UNIVERSITY MECHATRONIC ENGINEERING TUTORIAL PROBLEMSDocumento2 pagineMANDALAY TECHNOLOGICAL UNIVERSITY MECHATRONIC ENGINEERING TUTORIAL PROBLEMSTher Htet AungNessuna valutazione finora

- Model Paper 18ME7G3Documento4 pagineModel Paper 18ME7G3Xaf FarNessuna valutazione finora

- 07a81402 Flexible Manufacturing SystemsDocumento4 pagine07a81402 Flexible Manufacturing SystemsSharanya ThirichinapalliNessuna valutazione finora

- Exercises 15 10Documento1 paginaExercises 15 10Hiền Trang Lê ThiênNessuna valutazione finora

- Industrial Engineering: Tutorials ForDocumento18 pagineIndustrial Engineering: Tutorials ForYahya Abdelhameed AamerNessuna valutazione finora

- 04 FMSDocumento6 pagine04 FMSz8699Nessuna valutazione finora

- Features and Working Principles: 2.1 Types of MachinesDocumento33 pagineFeatures and Working Principles: 2.1 Types of Machinessp48888Nessuna valutazione finora

- DIFFERENT TAMPING MODES AND TRACK ALIGNMENTDocumento13 pagineDIFFERENT TAMPING MODES AND TRACK ALIGNMENTIrwan Joe100% (1)

- IEEE TRANSACTIONS ON ROBOTICS AND AUTOMATION, VOL. 7 , NO. 2, APRIL I991Documento12 pagineIEEE TRANSACTIONS ON ROBOTICS AND AUTOMATION, VOL. 7 , NO. 2, APRIL I991maysamshNessuna valutazione finora

- 15 Integrated Manufacturing Systems Lecture #15 HandoutDocumento2 pagine15 Integrated Manufacturing Systems Lecture #15 HandoutFelipeNessuna valutazione finora

- Assignment No.: 02: Take This Assignment From Mr. Pai and Give That Assignment To StudentsDocumento1 paginaAssignment No.: 02: Take This Assignment From Mr. Pai and Give That Assignment To StudentsjcspaiNessuna valutazione finora

- Tractor performance monitoring systemDocumento11 pagineTractor performance monitoring systemengineair007Nessuna valutazione finora

- PUC 3114 Project Assignment Work Aug 2023Documento8 paginePUC 3114 Project Assignment Work Aug 2023SKynet Movies Cyber PS4Nessuna valutazione finora

- Eazc 4121Documento1 paginaEazc 4121Priyanka MahajanNessuna valutazione finora

- ME3301 End Sem PaperDocumento2 pagineME3301 End Sem PaperTejas RaoNessuna valutazione finora

- Automated Guided Vehicle System - Ref - Def PracticeDocumento1 paginaAutomated Guided Vehicle System - Ref - Def PracticeHamza MalikNessuna valutazione finora

- 15P701Documento4 pagine15P701rajakrishnanNessuna valutazione finora

- Multi-Motor DrivesDocumento6 pagineMulti-Motor DrivessriabolfazlNessuna valutazione finora

- A Study in Industrial Robot ProgrammingDocumento26 pagineA Study in Industrial Robot ProgrammingPatel Dhaval100% (1)

- Rev. SPC of Pts & Xing Draft 29.03.17 PDFDocumento21 pagineRev. SPC of Pts & Xing Draft 29.03.17 PDFSuryakant KumarNessuna valutazione finora

- Industrial Engineering Tutorials GuideDocumento17 pagineIndustrial Engineering Tutorials GuideYahya Abdelhameed AamerNessuna valutazione finora

- Automatic Assembly Transfer Systems OverviewDocumento12 pagineAutomatic Assembly Transfer Systems OverviewSwami Anu DevNessuna valutazione finora

- Manufacturing Technology - II (ME305) Quiz 1Documento2 pagineManufacturing Technology - II (ME305) Quiz 1Gokul SinghNessuna valutazione finora

- Reviews 1: International UniversityDocumento11 pagineReviews 1: International UniversityQuỳnh NguyễnNessuna valutazione finora

- Mechanism Final ProjectDocumento14 pagineMechanism Final Projectsundari_murali100% (2)

- Probs in AMP PDFDocumento3 pagineProbs in AMP PDFwilliam taloNessuna valutazione finora

- Dynamic Analys Is of Belt Conveyor Based On AMESimDocumento2 pagineDynamic Analys Is of Belt Conveyor Based On AMESimAmit BhaduriNessuna valutazione finora

- Advanced ManufacturingDocumento5 pagineAdvanced Manufacturingmukesh3021Nessuna valutazione finora

- Project 3: Software Based Finite State MachinesDocumento13 pagineProject 3: Software Based Finite State MachineselvagojpNessuna valutazione finora

- 5-Conveyor QuestionsDocumento4 pagine5-Conveyor QuestionsRania ElrifaiNessuna valutazione finora

- Sheet 3Documento6 pagineSheet 3Aladdin AdelNessuna valutazione finora

- MM 323 MAN SYS 2012 FALL 6 Automated Production Lines PART 2Documento38 pagineMM 323 MAN SYS 2012 FALL 6 Automated Production Lines PART 2ogulcan_aytacNessuna valutazione finora

- Distributed Motion ControlDocumento6 pagineDistributed Motion ControlzoltanskaNessuna valutazione finora

- Advanced Manufacturing Technology MECH4012 Module#3 Tutorial#8 Production LinesDocumento4 pagineAdvanced Manufacturing Technology MECH4012 Module#3 Tutorial#8 Production LinesahmedNessuna valutazione finora

- ATS Server and Client ModelDocumento8 pagineATS Server and Client ModelAbhijitNessuna valutazione finora

- Storage Devices and CAD Modelling TechniquesDocumento23 pagineStorage Devices and CAD Modelling TechniquesshunmugeshNessuna valutazione finora

- CNC-H4-T Numerical Control System for Vertical LatheDocumento8 pagineCNC-H4-T Numerical Control System for Vertical LatheRobert GiangNessuna valutazione finora

- 12 Marin Rares LucianDocumento8 pagine12 Marin Rares LuciansharunnizamNessuna valutazione finora

- Computer Numerical ControlDocumento28 pagineComputer Numerical ControlsaisenthNessuna valutazione finora

- 07a80307 AutomationinmanufacutringDocumento8 pagine07a80307 AutomationinmanufacutringSharanya ThirichinapalliNessuna valutazione finora

- Classification of CNC MachineDocumento11 pagineClassification of CNC Machineaqtu12fuc81% (16)

- 1cv50 Assignment 2021Documento8 pagine1cv50 Assignment 2021Jade BreukinkNessuna valutazione finora

- Flying ShearDocumento5 pagineFlying ShearCarlos RamirezNessuna valutazione finora

- Automation in Manufacturing Exam QuestionsDocumento8 pagineAutomation in Manufacturing Exam QuestionsPradeepkumarKatgiNessuna valutazione finora

- Open and Close Loop SystemDocumento27 pagineOpen and Close Loop Systemnagendrakushwaha007Nessuna valutazione finora

- Experiment No: 1: Aim: - To Study Automated Flow Line (AFL) & Transfer Line MechanismDocumento8 pagineExperiment No: 1: Aim: - To Study Automated Flow Line (AFL) & Transfer Line MechanismJust for funNessuna valutazione finora

- AN00122-003 - Rotary Axis Flying ShearDocumento6 pagineAN00122-003 - Rotary Axis Flying ShearamirixmNessuna valutazione finora

- Advanced Curve Machining Method For 5-AxisDocumento6 pagineAdvanced Curve Machining Method For 5-AxisKaran VaniyaNessuna valutazione finora

- Project DetailsDocumento6 pagineProject Detailskituno festo sundayNessuna valutazione finora

- IIT Kharagpur Design for Assembly and Automation End Semester ExamDocumento2 pagineIIT Kharagpur Design for Assembly and Automation End Semester Exambrahma2deen2chaudharNessuna valutazione finora

- 254464.1 Car Mikac VezaDocumento6 pagine254464.1 Car Mikac VezaengrodeNessuna valutazione finora

- 1 s2.0 S2212827116302992 MainDocumento4 pagine1 s2.0 S2212827116302992 MainEhsan AhmadiyanNessuna valutazione finora

- BETA1 AUTOMATION TEST 1 KEY CONCEPTSDocumento3 pagineBETA1 AUTOMATION TEST 1 KEY CONCEPTSrealeboga moneiNessuna valutazione finora

- Control of DC Motor Using Different Control StrategiesDa EverandControl of DC Motor Using Different Control StrategiesNessuna valutazione finora

- Neues verkehrswissenschaftliches Journal - Ausgabe 26: User-based Adaptable High Performance Simulation Modelling and Design for Railway Planning and OperationsDa EverandNeues verkehrswissenschaftliches Journal - Ausgabe 26: User-based Adaptable High Performance Simulation Modelling and Design for Railway Planning and OperationsNessuna valutazione finora

- Lecture 4 - Process ImprovementDocumento39 pagineLecture 4 - Process ImprovementAmmar1994Nessuna valutazione finora

- The Toyota Way, Liker, Chs. 1-7, SelectedDocumento39 pagineThe Toyota Way, Liker, Chs. 1-7, SelectedAmmar1994Nessuna valutazione finora

- The Last Planner System: AgendaDocumento17 pagineThe Last Planner System: AgendaYusef SobhiNessuna valutazione finora

- Lean Engineering Concepts ExplainedDocumento43 pagineLean Engineering Concepts ExplainedAmmar1994Nessuna valutazione finora

- Lean Engineering Concepts ENMG 642: Lecture 5-Process MappingDocumento59 pagineLean Engineering Concepts ENMG 642: Lecture 5-Process MappingAmmar1994Nessuna valutazione finora

- Meal Plan for 3000 CaloriesDocumento2 pagineMeal Plan for 3000 CaloriesDipendraNessuna valutazione finora

- Lecture 3 - The Foundations of Lean ConstructionDocumento28 pagineLecture 3 - The Foundations of Lean ConstructionAmmar1994Nessuna valutazione finora

- Meal Plan for 3000 CaloriesDocumento2 pagineMeal Plan for 3000 CaloriesDipendraNessuna valutazione finora

- Legion Spreadsheet (v5.1)Documento11 pagineLegion Spreadsheet (v5.1)Ammar1994Nessuna valutazione finora

- American University of Sharjah Department of Mechanical Engineering Assignment/Homework COVER SHEETDocumento1 paginaAmerican University of Sharjah Department of Mechanical Engineering Assignment/Homework COVER SHEETAmmar1994Nessuna valutazione finora

- Maketa Ravenna 11.7.2022 PDFDocumento2 pagineMaketa Ravenna 11.7.2022 PDFAntonio AmorosoNessuna valutazione finora

- Locations of engine and chassis numbers across vehicle brandsDocumento6 pagineLocations of engine and chassis numbers across vehicle brandscool47guy09100% (3)

- Curriculum Vitae: Personal DataDocumento2 pagineCurriculum Vitae: Personal Datamuh asriNessuna valutazione finora

- Joy18Hd: Load Haul Dump - Diesel Hybrid General SpecificationDocumento3 pagineJoy18Hd: Load Haul Dump - Diesel Hybrid General SpecificationEstyNessuna valutazione finora

- PDF qsk95 PDFDocumento24 paginePDF qsk95 PDFJorge BellidoNessuna valutazione finora

- Bahasa Inggris FixDocumento8 pagineBahasa Inggris FixDwi Prayogi100% (1)

- Research on Flat Slab, Ribbed Slab and Lift Slab Construction MethodsDocumento17 pagineResearch on Flat Slab, Ribbed Slab and Lift Slab Construction MethodsArgelita Alpuerto UnlayaoNessuna valutazione finora

- KTM Duke 250 Abs 2017 GST 0Documento1 paginaKTM Duke 250 Abs 2017 GST 0zaim nur hakimNessuna valutazione finora

- Live Load DispersionDocumento36 pagineLive Load Dispersionneeta rautelaNessuna valutazione finora

- 1 (B) Advance - Aansoekvorm - Application Form - MasterDocumento7 pagine1 (B) Advance - Aansoekvorm - Application Form - MasterbesterkailaNessuna valutazione finora

- Latihan Bab 3Documento12 pagineLatihan Bab 3Hasnah GhaniNessuna valutazione finora

- CAMC Trucks Service Manual PDFDocumento535 pagineCAMC Trucks Service Manual PDFchuck absulioNessuna valutazione finora

- Oceans Future To 2050Documento104 pagineOceans Future To 2050Carlos GarridoNessuna valutazione finora

- Sustainable TransportDocumento15 pagineSustainable TransportHardik ChhabraNessuna valutazione finora

- CHEVROLET AVEO 2005 ECU PINOUT JAZZ - Google SearchDocumento3 pagineCHEVROLET AVEO 2005 ECU PINOUT JAZZ - Google SearchNofriagara Davit HarnawanNessuna valutazione finora

- 1478509168446223172Documento9 pagine1478509168446223172علی چیواییNessuna valutazione finora

- Specification Model: V6-280-C-N: Application DataDocumento4 pagineSpecification Model: V6-280-C-N: Application DataMehdi Ben AbdelkaderNessuna valutazione finora

- Effects-Of-Oplan-Tokhang-To-Drug-Surrenderees-In-Sinacaban-1 FinalDocumento9 pagineEffects-Of-Oplan-Tokhang-To-Drug-Surrenderees-In-Sinacaban-1 FinalMatthew DuNessuna valutazione finora

- PT WBK 777e Kdp00831 Wht019 Smu 5217 Seal Yoke LeakDocumento1 paginaPT WBK 777e Kdp00831 Wht019 Smu 5217 Seal Yoke LeakNasirKodratNessuna valutazione finora

- Segway® SE Service ManualDocumento92 pagineSegway® SE Service ManualGustavo RodriguezNessuna valutazione finora

- Affidavit of LossDocumento95 pagineAffidavit of LossKenneth GarciaNessuna valutazione finora

- Airport Basic ComponentsDocumento5 pagineAirport Basic ComponentsCJ Laforteza100% (1)

- AMBREY Safety SecurityDocumento6 pagineAMBREY Safety SecuritynavalsilNessuna valutazione finora

- Typical Roof Beam Detail: Elevator SpecsDocumento1 paginaTypical Roof Beam Detail: Elevator SpecsPrince Winderic G. AclanNessuna valutazione finora

- Amritsar MailDocumento3 pagineAmritsar MailBubulKumar BaskeNessuna valutazione finora

- Aap Ki Unnati Ka Sachcha Saathi: Ficiency Fitability GressDocumento6 pagineAap Ki Unnati Ka Sachcha Saathi: Ficiency Fitability GressSubham BhartiNessuna valutazione finora

- SRN Oyo Name Alternate Name Cluster Short Address Plot No. Street City PincodeDocumento3 pagineSRN Oyo Name Alternate Name Cluster Short Address Plot No. Street City PincodeSushobhan SahaNessuna valutazione finora

- House Guide TemplateDocumento8 pagineHouse Guide TemplatewandolyNessuna valutazione finora

- Mercedes 722.9Documento56 pagineMercedes 722.9psuguy100% (2)

- Consumer Guide To Automobile Insurance Cau1Documento27 pagineConsumer Guide To Automobile Insurance Cau1Joseph OmodoNessuna valutazione finora