Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

CDA110 Specifaction Sheet

Caricato da

GendakensCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

CDA110 Specifaction Sheet

Caricato da

GendakensCopyright:

Formati disponibili

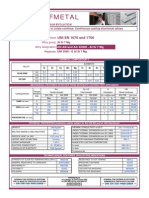

Specification Sheet

CDA110

0 (Electrolytic Tough Pitch)

US EPA Registered Antimicrobial

Chemical Composition

(%max., unless shown as range or min.)

(1)

Cu

O

Min. /Max. 99.90 min Nominal .04

(1) Cu value includes Ag.

Note: This is a high conductivity copper which has, in the annealed condition a minimum conductivity of 100% IACS except for

Alloy C10100 which has a minimum conductivity of 101% IACS.

Note: Oxygen and trace elements may vary depending on

o the process.

Applicable Specifications

Product

Bands, Projectile Rotating

Bar

Specification

MILITARY MIL-B-20292

MIL

ASME SB133

ASTM B152

SAE J463, J461

Bar, Bus

ASTM B187

Bar, Forging

ASTM B124

Bolts

ASTM F468

Brazing Filler Metal

FEDERAL QQ-B-650

QQ

Foil, Printed Circuits

ASTM B451

Forgings, Die

ASTM B283

Nuts

ASTM F467

Pipe, Bus

ASTM B188

Plate

AMS 4500

ASTM B152

SAE J463, J461

Rod

ASME SB133

MILITARY MIL-C-12166

MIL

SAE J463, J461

Rod, Bus

ASTM B187

Rod, Forging

ASTM B124

Screws

ASTM F468

Shapes

SAE J461, J463

Shapes, Bus

ASTM B187

Shapes, Forging

ASTM B124

Sheet

AMS 4500

ASTM B152, B694

SAE J461, J463

Sheet, Building Construction ASTM B370

Sheet, Clad

ASTM B506

Sheet, Lead Coated

ASTM B101

Sheet, Printed Circuits

ASTM B451

www.nfm.co.za

Specification Sheet

Strip

AMS 4500

ASTM B694, B152

SAE J463, J461

Strip, Building Construction ASTM B370

Strip, Clad

ASTM B506

Strip, Printed Circuits

ASTM B451

Studs

ASTM F468

Tube, Bus

ASTM B188

Tube, Welded

ASTM B447

Wire, Medium-Hard Drawn

ASTM B2

FEDERAL QQ-W-343

QQ

Wire, Coated With Lead Alloy ASTM B189

Wire, Coated With Nickel

ASTM B355

Wire, Coated With Silver

ASTM B298

Wire, Coated With Tin

ASTM B33, B246

Wire, Flat

AMS 4500

ASTM B272

Wire, Hard Drawn

ASTM B1

FEDERAL QQ-W-343

QQ

Wire, Metalizing

MILITARY MIL-W-6712

MIL

Wire, Soft

ASTM B3, B738, B48

FEDERAL QQ-W-343

QQ

SAE J461, J463

Wire, Stranded

ASTM B8, B496, B470, B286, B229, B226, B174, B173, B172

FEDERAL QQ-B-575

QQ

Wire, Trolley

ASTM B47, B116

Common Fabrication Processes

Blanking, Coining, Copper smithing, Drawing, Etching, Forming and Bending, Heading and Upsetting,

Hot Forging and Pressing, Piercing and Punching, Roll Threading and Knurling, Shearing, Spinning,

Squeezing and Swaging, Stamping

Fabrication Properties

Joining Technique

Suitability

Soldering

Excellent

Brazing

Good

Oxyacetylene Welding

Not Recommended

Gas Shielded Arc Welding

Fair

Coated Metal Arc Welding

Not Recommended

Spot Weld

Not Recommended

Seam Weld

Not Recommended

Butt Weld

Good

Capacity for Being Cold Worked Excellent

Capacity for Being Hot Formed Excellent

Forgeability Rating

65

Machinability Rating

20

www.nfm.co.za

Specification Sheet

Thermal Properties

Treatment

Temp./Time - US Temp./Time - SI

Stress Temperature

Solution Minimum

Solution Maximum

Solution Time

Solution Medium

None

Precipitation Value

Precipitation Time

Precipitation Medium None

Annealing Minimum 700

371

Annealing Maximum 1200

649

Annealing Time

Hot Works Minimum 1400

761

Hot Works Maximum 1600

872

Mechanical Properties (measured at room temperature, 68 F (20 C)

Yield

Yield

Yield

Izod

Section Cold Typ/

Tensile Strength StrengthStrength Rockwell Vickers Brinell Shear Fatigue

Temp

El

Impact

Size Work Min

Strength (0.5% ext. (0.2% (0.05%

Hardness Hard. Hard. StrengthStrength*

Strength

under load) offset) offset)

in.

%

F

ksi

ksi

ksi

ksi

% B CF 30T500

5003000ksi

ksi

ft-lb

mm.

C

MPa

MPa

MPa

MPa

MPa

MPa

J

Flat Products

H02

0.04

0

TYP 68

42

36

1440- 8450 - 26

13

0.0

1

20

290

248

1440- 8450 - 179

90

0.0

M20

0.025 0

TYP 68

32

10

50- - 40- - 22

0.0

0.64

20

221

69

- 152

50- - 40- 0.0

Rod

32

10

55- - 40- - 22

0.0

M20

1

0

TYP 68

25.4

20

221

69

55- - 40- - 152

0.0

Shapes

32

10

50- - 40- - 22

0.0

M30

0.5

0

TYP 68

12.7

20

221

69

50- - 40- - 152

0.0

0.0

M20

0.5

0

TYP 68

32

10

50- - 40- - 22

0.0

12.7

20

221

69

50- - 40- - 152

Flat Products

50

45

6 50- 9057 - 28

0.0

H04

0.04

0

TYP 68

1

20

345

310

6 50- 9057 - 193

0.0

Rod

H04

0.25

40 TYP 68

55

50

1060- 94- - 29

0.0

6.35

20

379

345

1060- 94- - 200

0.0

Wire

OS050 0.08

0

TYP 68

35

35- - - - - 24

0.0

2

20

241

35- - - - - 165

0.0

Flat Products

H08

0.04

0

TYP 68

55

50

4 60- 9463 - 29

14

0.0

1

20

379

345

4 60- 9463 - 200

97

0.0

H01

0.025 0

TYP 68

38

30

3525- 70- - 25

0.0

0.64

20

262

207

3525- 70- - 172

0.0

Rod

OS050 1

0

TYP 68

32

10

55- - 40- - 22

0.0

25.4

20

221

69

55- - 40- - 152

0.0

Wire

H08

0.08

0

TYP 68

66

1 - - - - - 33

0.0

2

20

455

1 - - - - - 228

0.0

Flat Products

H04

1

0

TYP 68

45

40

2045- 85- - 26

0.0

25.4

20

310

276

2045- 85- - 179

0.0

OS050 0.025 0

TYP 68

32

10

50- - 40- - 22

0.0

50- - 40- 0.64

20

221

69

- 152

0.0

H00

0.025 0

TYP 68

36

28

4010- 60- - 25

0.0

0.64

20

248

193

4010- 60- - 172

0.0

Rod

H04

2

16 TYP 68

45

40

2045- 85- - 26

0.0

51

20

310

276

2045- 85- - 179

0.0

H04

1

35 TYP 68

48

44

1647- 87- - 27

17

0.0

25.4

20

331

303

1647- 87- - 186

117

0.0

Tube

OS025 0.065 0

TYP 68

34

11

45- - 45- - 23

0.0

1.65

20

234

76

45- - 45- - 159

0.0

H80

0.065 40 TYP 68

8 60- 9563 0.0

55

50

- 29

Temper

www.nfm.co.za

Specification Sheet

1.65

0.065

1.65

Flat Products

M20

0.04

1

Shapes

OS050 0.5

12.7

Wire

H04

0.08

2

Flat Products

OS050 0.04

1

Shapes

H04

0.5

12.7

Tube

OS050 0.065

1.65

Flat Products

OS025 0.04

1

H10

0.04

1

H01

0.04

1

H00

0.04

1

H04

0.025

0.64

H55

20

TYP 68

20

379

40

276

345

32

221

8 60- 9563 2535- 7745 2535- 7745 -

200

26

179

0.0

0.0

0.0

TYP 68

20

34

234

10

69

45- - 4545- - 45-

23

159

0.0

0.0

TYP 68

20

32

221

10

69

50- - 4050- - 40-

22

152

0.0

0.0

TYP 68

20

55

379

1 - - - 1 - - - -

29

200

0.0

0.0

TYP 68

20

32

221

10

69

45- - 4045- - 40-

22

152

0.0

0.0

15

TYP 68

20

40

276

32

221

3035- - 3035- - -

26

179

0.0

0.0

TYP 68

20

32

221

10

69

45- - 4045- - 40-

22

152

0.0

0.0

TYP 68

20

TYP 68

20

TYP 68

20

TYP 68

20

TYP 68

20

34

234

57

393

38

262

36

248

50

345

11

76

53

365

30

207

28

193

45

310

45- 45- 4 624 62252525253010301012501250-

23

159

29

200

25

172

25

172

28

193

11

76

-

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

15

0

0

0

0

45459564

9564

7036

7036

6025

6025

9090-

*Fatigue Strength: 100 x 10 6cycles,

unless indicated as [N] X 106.

Physical Properties

US Customary

Metric

Melting Point - Liquidus

1981 F

1083 C

Melting Point - Solidus

1949 F

1065 C

3

3

Density*

0.322 lb/in at 68 F

8.91 gm/cm @ 20 C

Specific Gravity

8.910

8.91

Electrical Resistivity

10.30 ohms-cmil/ft @ 68 F 1.71 microhm-cm

cm @ 20 C

Electrical Conductivity**

101 %IACS @ 68 F

0.591 MegaSiemens/cm @ 20 C

o

o

Thermal Conductivity

226 Btu ft/(hr ft2 F)at 68F 391.1 W/m K at 20 C

-6

o

-6

o

Coefficient of Thermal Expansion 9.40 10 per F (68-212 F) 16.9 10 per C (20-100

(20

C)

-6

o

-6

o

Coefficient of Thermal Expansion 9.60 10 per F (68-392 F) 17.3 10 per C (20-200

(20

C)

-6

o

-6

o

Coefficient of Thermal Expansion 9.80 10 per F (68-572 F) 17.6 10 per C (20-300

(20

C)

o

o

Specific Heat Capacity

0.092 Btu/lb/ F at 68 F

393.5 J/kg K at 293 K

Modulus of Elasticity in Tension 17000 ksi

117000 MPa

Modulus of Rigidity

6400 ksi

44130 MPa

*Actual value .321 - .323.

**Volume and weight basis.

www.nfm.co.za

Specification Sheet

Tempers Most Commonly Used

Flat Products

BAR, DRAWN H01, H04, H06, O60

BAR, ROLLED H01, H04, H06, M20, O60

PLATE

H00, M20, O60

SHEET

H00, H02, M20, O60

STRIP, DRAWN H04, O60

STRIP, ROLLED H00, H01, H02, H04, H08, H10, M20, O60, OS025

WIRE, DRAWN H04, H06, O60

WIRE, ROLLED H04, O60

Other

ROD

H04, M20, O60

SHAPES H04, M20, M30, O60

TUBE

H55, H58, H80, O60, OS025

WIRE

H00, H01, H04, H08, O60

Typical Uses

Architecture

Building Fronts, Gutters, Skylight Frames, Roofing, Flashing, Downspouts, Spouting

Automotive

Radiators, Gaskets

Builders Hardware

Cotter Pins, Butts, Ball Floats, Nails, Tacks, Soldering Copper, Rivets

Building

Screening, Wire Screening

Consumer

Christmas Ornaments

Electrical

Switches, Terminals, Trolley Wire, Contacts, Radio Parts, Magnet Wire, Busbars, Terminal

Connectors, Conductors, Electrical, Stranded Conductors, Wire, Electrical

Fasteners

Fasteners

Industrial

Pressure Vessels, Chemical Process Equipment, Chlorine Cells, Chimney Cap Screens, Heat

Exchangers, Printing Rolls, Anodes, Rotating Bands, Kettles, Pans, Vats, Road Bed Expansion Plates

Casting Characteristics

No casting characteristics available for this

t

alloy.

www.nfm.co.za

Potrebbero piacerti anche

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDa EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsValutazione: 4.5 su 5 stelle4.5/5 (10)

- Materials Data for Cyclic Loading: Low-Alloy SteelsDa EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsValutazione: 5 su 5 stelle5/5 (2)

- A 447Documento27 pagineA 447superman3kNessuna valutazione finora

- POSCO Korea - Galvanized SheetDocumento27 paginePOSCO Korea - Galvanized SheetFrancis BoeyNessuna valutazione finora

- EN6114Documento14 pagineEN6114akayirNessuna valutazione finora

- Material Alloy KHR32CDocumento2 pagineMaterial Alloy KHR32CKHNessuna valutazione finora

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDa EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNessuna valutazione finora

- Weld Like a Pro: Beginning to Advanced TechniquesDa EverandWeld Like a Pro: Beginning to Advanced TechniquesValutazione: 4.5 su 5 stelle4.5/5 (6)

- Leaded Tin Bronze C54400Documento3 pagineLeaded Tin Bronze C54400nfcastingsNessuna valutazione finora

- Stainless steels - properties, classes, composition and applicationsDocumento24 pagineStainless steels - properties, classes, composition and applicationsdennykvgNessuna valutazione finora

- Userguide For SSDocumento26 pagineUserguide For SSehsan4uNessuna valutazione finora

- Stainless AISI 3XXDocumento3 pagineStainless AISI 3XXThitaphol HuyananNessuna valutazione finora

- Material SpecificationDocumento50 pagineMaterial SpecificationSangyt Karna0% (2)

- Steel UserguideDocumento50 pagineSteel UserguideBhanu Pratap ChoudhuryNessuna valutazione finora

- Standards R M Salem - UserguideDocumento49 pagineStandards R M Salem - Userguidearunas1081Nessuna valutazione finora

- Sandvik SAF 2205: Duplex Stainless SteelDocumento8 pagineSandvik SAF 2205: Duplex Stainless SteelIuliu HurducaciNessuna valutazione finora

- Inconel - Alloy 330 - UNS N08330Documento8 pagineInconel - Alloy 330 - UNS N08330Javeed A. KhanNessuna valutazione finora

- 42crmo4 - HardnessDocumento8 pagine42crmo4 - HardnessavijayakumarsamyNessuna valutazione finora

- Cold Rolled 2010 DUNAFER HungriaDocumento12 pagineCold Rolled 2010 DUNAFER HungriaBeatriz RizzoNessuna valutazione finora

- Columbus Stainless Pocket GuideDocumento29 pagineColumbus Stainless Pocket Guidebruteforce2000Nessuna valutazione finora

- Tubular Products From Special MetalsDocumento26 pagineTubular Products From Special Metalskaveh-bahiraeeNessuna valutazione finora

- Brass Material Property Data Sheet for Custom FastenersDocumento2 pagineBrass Material Property Data Sheet for Custom FastenersMuzammil Ali KhanNessuna valutazione finora

- Aisi 200 SeriesDocumento19 pagineAisi 200 Seriessgupta_192494Nessuna valutazione finora

- Spec 4140 & 4130Documento7 pagineSpec 4140 & 4130Nisa_nisheNessuna valutazione finora

- URB25Documento4 pagineURB25malika_00Nessuna valutazione finora

- Sandvik 254 SMO Datasheet for Seamless Tube and PipeDocumento9 pagineSandvik 254 SMO Datasheet for Seamless Tube and PipeReadersmoNessuna valutazione finora

- Uns C51000Documento2 pagineUns C51000nazgulNessuna valutazione finora

- Wire Mesh Steel Reinforcement BarsDocumento6 pagineWire Mesh Steel Reinforcement Barssattar12345Nessuna valutazione finora

- C83600 PDFDocumento2 pagineC83600 PDFboccareddyNessuna valutazione finora

- Data SAF2205 04Documento8 pagineData SAF2205 04il_yoo_1Nessuna valutazione finora

- MaterialData - Aço 1045Documento2 pagineMaterialData - Aço 1045Victhor AraujoNessuna valutazione finora

- AISI/SAE 4130 bars and rings for sour serviceDocumento2 pagineAISI/SAE 4130 bars and rings for sour serviceEDWIN M.PNessuna valutazione finora

- Alloy: C95800: Typical UsesDocumento2 pagineAlloy: C95800: Typical UsesJarbas MoraesNessuna valutazione finora

- Datasheet Sandvik 3r65 For Medical Applications en v2020!12!10 06 - 47 Version 1Documento6 pagineDatasheet Sandvik 3r65 For Medical Applications en v2020!12!10 06 - 47 Version 1Mohammed Saleem Syed KhaderNessuna valutazione finora

- Stainless Steel 304 Material Property Data SheetDocumento2 pagineStainless Steel 304 Material Property Data SheetRahul SrivastavaNessuna valutazione finora

- Jis C3771Documento2 pagineJis C3771bkprodhNessuna valutazione finora

- ASM Material Data SheetDocumento3 pagineASM Material Data SheetAscanio BarbosaNessuna valutazione finora

- API 5L Line Pipe 24 Inch SCH 40 ERW PipeDocumento14 pagineAPI 5L Line Pipe 24 Inch SCH 40 ERW PipeJuan CilloNessuna valutazione finora

- Cuzr0,15: Uns:C15100 En:Cw120CDocumento17 pagineCuzr0,15: Uns:C15100 En:Cw120CNut AssanaiNessuna valutazione finora

- Catalogo - Cilindros Hidraulicos VEGADocumento24 pagineCatalogo - Cilindros Hidraulicos VEGARaul Izquierdo MoralesNessuna valutazione finora

- Industeel Tableau Nuances Special Carbon and Low AlloyDocumento1 paginaIndusteel Tableau Nuances Special Carbon and Low AlloyPravin VisputeNessuna valutazione finora

- Copper and Copper Alloy Ingots and CastingsDocumento2 pagineCopper and Copper Alloy Ingots and CastingspoopNessuna valutazione finora

- Raffmetal: UNI EN 1676 and 1706Documento2 pagineRaffmetal: UNI EN 1676 and 1706Anshuman RoyNessuna valutazione finora

- AISI 1035 Steel, Cold Drawn, High Temperature, Stress Relieved, 16-22 MM (0.625-0.875 In) RoundDocumento2 pagineAISI 1035 Steel, Cold Drawn, High Temperature, Stress Relieved, 16-22 MM (0.625-0.875 In) RoundJakJhonNessuna valutazione finora

- Aluminum Alloy EvolutionDocumento2 pagineAluminum Alloy Evolutionc4pp3ll410_m4tt0Nessuna valutazione finora

- PIPE SpecificationDocumento6 paginePIPE SpecificationNamta GeorgeNessuna valutazione finora

- Norma Aws Er70s6Documento2 pagineNorma Aws Er70s6Nathan CantelliNessuna valutazione finora

- Dunaferr Cold Rolled Product catalogueDocumento12 pagineDunaferr Cold Rolled Product catalogueMihály PálffyNessuna valutazione finora

- 5 - Duplex Stainless Steels and Nickel AlloysDocumento44 pagine5 - Duplex Stainless Steels and Nickel AlloysdennykvgNessuna valutazione finora

- Piping Equipment SpecificationsDocumento4 paginePiping Equipment Specificationsmabrouk2013Nessuna valutazione finora

- HASTELLOY® C-22HS™alloyDocumento16 pagineHASTELLOY® C-22HS™alloyYudha SatriaNessuna valutazione finora

- ARTY - Aubert Et Duval - Produits - Longs - GB PDFDocumento6 pagineARTY - Aubert Et Duval - Produits - Longs - GB PDFScott_B4UNessuna valutazione finora

- PC WireDocumento7 paginePC Wirejupe01Nessuna valutazione finora

- Material Inconel 600Documento16 pagineMaterial Inconel 600arvindgupta_2005100% (1)

- ThyssenKrupp Steel Data Sheet P235GHDocumento4 pagineThyssenKrupp Steel Data Sheet P235GHjaseerkannothNessuna valutazione finora

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopDa EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopValutazione: 4.5 su 5 stelle4.5/5 (2)

- Guidelines - Foreign Bank AccountDocumento4 pagineGuidelines - Foreign Bank AccountGendakensNessuna valutazione finora

- Guidelines For New Applicants - PortfolioDocumento1 paginaGuidelines For New Applicants - PortfolioGendakensNessuna valutazione finora

- FemDocumento106 pagineFemConstantin DorinelNessuna valutazione finora

- 2D Box Falling into WaterDocumento22 pagine2D Box Falling into Waterclimax1364Nessuna valutazione finora