Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Block and Bleed Valves (140221)

Caricato da

Nilesh MistryCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Block and Bleed Valves (140221)

Caricato da

Nilesh MistryCopyright:

Formati disponibili

Block and Bleed Valves

MBB, MD, MB , MDB and VB3 , VB4 Series

Instrumentation Solutions

www.finelok.com

www.fitokgroup.com

1 Block and Bleed Valves

Block and Bleed Valves 2

Features

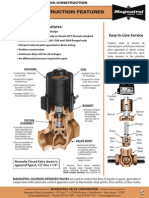

Needle Type Valve Model

Features

Maximum working pressure: 10000 psig (689 bar)

o

o

Working temperature up to 850 F (454 C) with Graphite packing

Maximum working pressure is 10000 psig (689 bar).

Colour coded valve function identification

Working temperature are as follows:

Every design is hydraulic pressure tested in accordance and API 598 with EN 12266-1. Every set is

Set Screw

Gland

tested with nitrogen for leak-tight performance at 6000 psig

Fire-tested design in accordance with API 607 and BS 6755 part 2

Lock Nut

Flanged connections comply with ANSI B16.5 RF and RTJ

Packing

Washer

Pressure ratings in accordance with ANSI B16.34

Lower

Stem

Stem

Actuator

Bonnet

Packing

Stop Pin

PTFE: -65oF to 450oF (-54oC to 232oC )

Graphite: -65oF to 850oF (-54oC to 454oC )

Two-stem design: thread hardened upper stem and smooth surface

hardened lower stem.

Upper stem thread lubricant is isolated from system fluid.

The nonrotating lower stem, linearly instead of helical movement,

avoids galling damage to the seat and tip, as well as reduces the

total friction area between the packing and the lower stem.

Stem back seating seals in fully open position.

Panel mounting is available as an option.

Double lock-pins enable steady and durable fastening of the handle.

Handle with different colors are available.

Ball Valve Model

OS&Y Needle Type Valve Model

Features

Maximum working pressure is 10000 psig (689 bar).

Lock N ut

Stop Pin

Stem

Packing

Stem

Bearing

Seat

Stainless

Steel Handle

PTFE: -65 F to 400 F (-54 C to 204 C )

PEEK: -65 F to 450 F (-54 C to 232 C )

Actuate at quarter-turn.

Blowout-proof

Stem

Set Screw

Working temperature are as follows:

Anodized

Aluminum

Investment

Case Yoke

Directional stem flats show open or closed position.

Bottom-loaded stem prevents stem blowout and enhances

system safety.

Maximum working pressure is 10000 psig (689 bar).

Rolled Stem Thread

Flange

Packing Gland

eliminates galling between valve stem and body.

It may be required to adjust the packing during the service

life of the valve.

Graphite: -65oF to 850oF (-54oC to 454oC )

Two-stem design: thread hardened upper stem and smooth surface

hardened lower stem.

Upper stem thread lubricant is isolated from system fluid.

High-strength stem bearing provides smooth actuation and

Ball

Working temperature are as follows:

PTFE: -65oF to 450oF (-54oC to 232oC )

Adjustable Gland

Bolted

Bonnet

Features

Back Seat

Design

Nonrotating

Lower Stem

The nonrotating lower stem, linearly instead of helical movement,

avoids galling damage to the seat and tip, as well as reduces the

total friction area between the packing and the lower stem.

Bolted bonnet enhance strength and reliability.

FINELOK ball valves are designed to be operated in a fully open

Back seat design provides secondary stem sealing and prevents stem

or fully closed position.

blowout.

Adjustable gland flange allows easy access to the packing gland and

packing adjustment for an effective stem seal.

Investment case yoke is formed by precision casting which enhances

strength and perfect stem alignment.

Two handle pins make the handle fixed firmly and lastingly.

Handle colors indicate functions:

Needle and OS&Y valves:

BLACK = Isolate/Block RED = Vent/Bleed

Ball valves:

YELLOW = Isolate/Block RED = Vent/Bleed

Instrumentation Solutions

Instrumentation Solutions

3 Block and Bleed Valves

Block and Bleed Valves 4

Monoflange Single Block and Bleed Valves

Standard Materials of Construction

MBB Series

Body Material

Component

Carbon

Steel

Stainless Steel

Features

Duplex

Stainless Steel

Piping and instrument valves in one body

Weight, space and cost savingover traditional designs

Material Grade/Specification

316 SS,

316L SS

/A182

Body/End

connector

316 SS,

316L SS

/A479

Blowout-proof valve stems and needles

LF2/A350 F51/A182 S31803/A479

Complete traceability of materials

1/4 female NPT standard vent with plug

Ball

1/2 female NPT standard outlet with plug

Stem

316 SS, 316L SS/A479

Ball

Valve

Retainer

Needle

Type

Globe

Valve

Stem Tip

Block: OS&Y

Bleed: needle (ON)

Socket

Reinforced PTFE, PEEK

Seat

OS&Y

Needle

Type

Globe

Valve

S31803/A479

316 SS, 316L SS/A479

Stem

S31803/A479

Bonnet

Stem Tip

Process

316 SS, 316L SS/A479

Stem

Vent

Bonnet

CF8M/A351 or 316 SS/A182

Yoke

L (RF)

L (RTJ)

L (RF)

L (RTJ)

Stainless steel is standard material, others are available upon request.

Flange Size

Pressure vs. Temperature

Bore Size

in. (mm)

ANSI

Class

L

in. (mm)

L'

in. (mm)

150

Ball Valve module

Needle and OS&Y Needle

Temperature ( C)

-54

260

10000

689

9000

620

8000

552

7000

PTFE

6000

482

414

345

5000

4000

275

3000

207

38

149

260

371

482

593

704

11000

758

10000

689

3/4

9000

620

(DN 20)

8000

552

482

7000

6000

414

PT

FE

Sta

nd

ard

5000

4000

345

Gra

phi

te

276

2000

138

3000

207

1000

69

2000

138

1000

69

-65

100

200

300

400

500

0

o

Temperature ( F)

100

300

500

700

Temperature (oF)

1

(DN 25)

3.25 (82.5)

5.25 (133.4)

3.50 (88.9)

150

3.88 (98.6)

2.75 (69.8)

4.62 (117.3)

3.25 (82.6)

5.13 (130.3)

3.50 (88.9)

5.50 (139.7)

3.75 (95.2)

4.25 (108.0)

3.12 (79.2)

4.88 (124.0)

3.50 (88.9)

5.88 (149.4)

4.00 (101.6)

900

1100

300

2.03 (51.6)

2.03 (51.6)

600

2.03 (51.6)

2.11 (53.5)

2.11 (53.5)

0.157 (4.0)

300

2.03 (51.6)

2.03 (51.6)

600

2.11 (53.5)

2.11 (53.5)

6.25 (158.8)

4.25 (108.0)

2.03 (51.6)

2.03 (51.6)

5.00 (127.0)

3.88 (98.6)

2.11 (53.5)

2.11 (53.5)

6.12 (155.5)

4.50 (114.3)

900/1500

2.19 (55.5)

2.19 (55.5)

7.00 (177.8)

4.88 (124.0)

2500

2.67 (67.9)

2.67 (67.9)

8.00 (203.2)

5.75 (146.1)

150

2.11 (53.5)

2.11 (53.5)

6.00 (152.4)

4.75 (120.7)

2.19 (55.5)

2.19 (55.5)

6.50 (165.1)

5.00 (127.0)

900/1500

2.42 (61.5)

2.42 (61.5)

8.50 (215.9)

6.50 (165.1)

2500

2.88 (73.4)

2.88 (73.4)

9.25 (235.0)

6.75 (171.5)

2500

150

1300

11/2

Process interface valves for sour gas service are

representative or FINELOK if any request.

4.75 (120.7)

2500

900/1500

Sour Gas Service/NACE Compliant

available. Materials are selected in accordance with

900/1500

150

(DN 40)

NACE MR0175/ISO 15156. Contact the authorized

2.62 (66.5)

2500

0

-65

3.75 (95.2)

2.03 (51.6)

900/1500

Pressure (bar)

204

Pressure (psig)

149

Pressure (bar)

93

EK

PE

Pressure (psig)

38

Temperature ( C)

2

(DN 50)

B

in. (mm)

2.38 (60.5)

600

A

in. (mm)

3.50 (88.9)

300

Type Valve

-54 -18

Outlet

S31803/A479

300

600

300

600

Dimensions are for reference only and are subject to change.

Instrumentation Solutions

Instrumentation Solutions

Block and Bleed Valves 6

5 Block and Bleed Valves

Monoflange Double Block Valves

Monoflange Single Block Valve

MD Series

MB Series

Features

Features

Piping and instrument valves in one body

Piping and instrument valves in one body

Weight, space and cost saving over traditional designs

Weight, space and cost saving over traditional designs

Blowout-proof valve stems and needles

Blowout-proof valve stems and needles

Complete traceability of materials

Complete traceability of materials

1/2 female NPT standard outlet with plug

1/2 female NPT standard outlet with plug

Primary: OS&Y

Secondary: needle (ON)

Primary: needle

Secondary: needle (NN)

Block: needle (N)

Block: OS&Y (O)

A

A

A

B

A

B

Process

Outlet

Process

L (RF)

L' (RTJ)

L (RF)

L' (RTJ)

Flange Size

Bore Size

in. (mm)

ANSI

Class

L

in. (mm)

L'

in. (mm)

300

(DN 50)

L'

in. (mm)

150

300

A

in. (mm)

B

in. (mm)

3.50 (88.9)

2.38 (60.5)

3.75 (95.2)

2.62 (66.5)

3.50 (88.9)

900/1500

4.75 (120.7)

3.25 (82.5)

150

3.88 (98.6)

2.75 (69.8)

2500

5.25 (133.4)

3.50 (88.9)

150

3.88 (98.6)

2.75 (69.8)

4.62 (117.3)

3.25 (82.6)

5.13 (130.3)

3.50 (88.9)

5.50 (139.7)

3.75 (95.2)

4.25 (108.0)

3.12 (79.2)

4.88 (124.0)

3.50 (88.9)

5.88 (149.4)

4.00 (101.6)

6.25 (158.8)

4.25 (108.0)

300

2.03 (51.6)

4.62 (117.3)

3.25 (82.6)

2.03 (51.6)

2.11 (53.5)

2.11 (53.5)

2.03 (51.6)

2.03 (51.6)

2.11 (53.5)

3.50 (88.9)

5.50 (139.7)

3.75 (95.2)

900/1500

4.25 (108.0)

3.12 (79.2)

2500

300

(DN 20)

3.50 (88.9)

5.88 (149.4)

4.00 (101.6)

6.25 (158.8)

4.25 (108.0)

900/1500

2500

2.03 (51.6)

5.00 (127.0)

3.88 (98.6)

2.11 (53.5)

2.11 (53.5)

6.12 (155.5)

4.50 (114.3)

600

2.03 (51.6)

2.03 (51.6)

2.03 (51.6)

2.11 (53.5)

2.11 (53.5)

150

4.88 (124.0)

2.03 (51.6)

2.03 (51.6)

600

5.13 (130.3)

1

2.11 (53.5)

300

3/4

600

150

L

in. (mm)

5.25 (133.4)

2500

(DN 40)

ANSI

Class

2500

900/1500

11/2

2.62 (66.5)

Bore Size

in. (mm)

600

150

(DN 25)

3.75 (95.2)

Flange Size

3.25 (82.5)

2500

0.157 (4.0)

2.38 (60.5)

2.03 (51.6)

900/1500

3.50 (88.9)

4.75 (120.7)

600

(DN 20)

B

in. (mm)

900/1500

300

3/4

2.03 (51.6)

A

in. (mm)

(DN 25)

0.157 (4.0)

300

2.03 (51.6)

2.03 (51.6)

600

150

11/2

300

2.11 (53.5)

2.11 (53.5)

2.03 (51.6)

2.03 (51.6)

5.00 (127.0)

3.88 (98.6)

2.11 (53.5)

2.11 (53.5)

6.12 (155.5)

4.50 (114.3)

600

900/1500

2.19 (55.5)

2.19 (55.5)

7.00 (177.8)

4.88 (124.0)

2500

2.67 (67.9)

2.67 (67.9)

8.00 (203.2)

5.75 (146.1)

900/1500

2.19 (55.5)

2.19 (55.5)

7.00 (177.8)

4.88 (124.0)

150

2.11 (53.5)

2.11 (53.5)

6.00 (152.4)

4.75 (120.7)

2500

2.67 (67.9)

2.67 (67.9)

8.00 (203.2)

5.75 (146.1)

2.19 (55.5)

2.19 (55.5)

6.50 (165.1)

5.00 (127.0)

150

2.11 (53.5)

2.11 (53.5)

6.00 (152.4)

4.75 (120.7)

2.19 (55.5)

2.19 (55.5)

6.50 (165.1)

5.00 (127.0)

900/1500

2.42 (61.5)

2.42 (61.5)

8.50 (215.9)

6.50 (165.1)

2500

2.88 (73.4)

2.88 (73.4)

9.25 (235.0)

6.75 (171.5)

300

600

(DN 40)

900/1500

2.42 (61.5)

2.42 (61.5)

8.50 (215.9)

6.50 (165.1)

2500

2.88 (73.4)

2.88 (73.4)

9.25 (235.0)

6.75 (171.5)

Dimensions are for reference only and are subject to change.

(DN 50)

Outlet

L (RF)

L' (RTJ)

L (RF)

L' (RTJ)

150

600

Process

Outlet

300

600

Dimensions are for reference only and are subject to change.

Instrumentation Solutions

Instrumentation Solutions

Block and Bleed Valves 8

7 Block and Bleed Valves

Monoflange Double Block & Bleed Valves

Flange Double Block and Bleed Valves

MDB Series

VB3 Series:

Features

Features

Piping and instrument valves in one body

Weight, space and cost saving over traditional designs

One piece forged body, minimize potential leak point

Blowout-proof valve stems and needles

Piping and instrument valves in one design

Complete traceability of materials

Weight, space and cost saving over traditional designs

1/4 female NPT standard vent with plug

Blowout-proof valve stems and needles

1/ 2female NPT standard outlet with plug

Secondary: needle

Complete traceability of materials

Bleed: needle (ONN)

Primary: ball

Secondary: ball

Bleed: needle (BBN)

Outlet

Process

B

C

B

Process

Primary: OS&Y

Outlet

Vent

Vent

A (RF to RF Flange)

A' (RTJ to RTJ Flange)

L (RF)

L (RTJ)

L (RF)

L (RTJ)

Flange Size

Flange Size

Bore Size

in. (mm)

ANSI

Class

L

in. (mm)

L'

in. (mm)

150

3.75 (95.2)

2.03 (51.6)

2500

5.25 (133.4)

3.50 (88.9)

150

2.75 (69.8)

300

300

3.88 (98.6)

2.03 (51.6)

4.62 (117.3)

150

300

2

(DN 50)

Instrumentation Solutions

(DN 20)

900/1500

3.50 (88.9)

2500

5.50 (139.7)

3.75 (95.2)

150

4.25 (108.0)

3.12 (79.2)

4.88 (124.0)

3.50 (88.9)

(DN 25)

5.88 (149.4)

4.00 (101.6)

2500

6.25 (158.8)

4.25 (108.0)

150

5.00 (127.0)

3.88 (98.6)

5.13 (130.3)

2.11 (53.5)

2.11 (53.5)

2.03 (51.6)

2.03 (51.6)

2.11 (53.5)

2.11 (53.5)

2.03 (51.6)

2.11 (53.5)

2.03 (51.6)

2.11 (53.5)

6.12 (155.5)

4.50 (114.3)

3/8 (9.5)

300

A'

in. (mm)

6.41 (162.8)

5.91 (150.1)

5.91 (150.1)

6.81 (173.0)

6.81 (173.0)

11/2

6.69 (170.0)

7.99 (202.9)

7.99 (202.9)

B

in. (mm)

C

in. (mm)

3.50 (88.9)

2.38 (60.5)

3.75 (95.3)

2.62 (66.5)

4.75 (120.7)

3.25 (82.6)

5.25 (133.4)

3.50 (88.9)

3.88 (98.6)

2.75 (69.9)

4.62 (117.3)

3.25 (82.6)

5.13 (130.3)

3.50 (88.9)

(DN 40)

2.19 (55.5)

7.00 (177.8)

4.88 (124.0)

2500

2500

2.67 (67.9)

2.67 (67.9)

8.00 (203.2)

5.75 (146.1)

150

2.19 (55.5)

2.19 (55.5)

6.00 (152.4)

6.50 (165.1)

4.75 (120.7)

5.00 (127.0)

5.91 (150.1)

6.81 (173.0)

6.81 (173.0)

6.69 (170.0)

6.69 (170.0)

7.99 (202.9)

7.99 (202.9)

5.50 (139.7)

3.75 (95.3)

6.41 (162.8)

6.61 (167.9)

4.25 (108.0)

3.12 (79.2)

5.91 (150.1)

7.00 (177.8)

7.00 (177.8)

4.88 (124.0)

3.50 (88.9)

10.30 (261.6)

10.30 (261.6)

5.88 (149.4)

4.00 (101.6)

10.70 (271.8)

10.70 (271.8)

6.25 (158.8)

4.25 (108.0)

8.90 (226.1)

9.49 (241.0)

5.00 (127.0)

3.88 (98.6)

9.89 (251.2)

9.89 (251.2)

6.12 (155.4)

4.50 (114.3)

11.50 (292.1)

11.50 (292.1)

7.00 (177.8)

4.88 (124.0)

12.40 (315.0)

12.40 (315.0)

8.00 (203.2)

5.75 (146.1)

9.09 (230.9)

9.49 (241.0)

6.00 (152.4)

4.75 (120.7)

10.10 (256.5)

10.30 (261.6)

6.50 (165.1)

5.00 (127.0)

5.91 (150.1)

2

(DN 50)

7.00 (177.8)

7.00 (177.8)

600

2.19 (55.5)

2.11 (53.5)

6.41 (162.8)

5.91 (150.1)

300

900/1500

2.11 (53.5)

6.69 (170.0)

900/1500

900/1500

300

A

in. (mm)

600

600

150

L'

in. (mm)

600

2.03 (51.6)

2500

(DN 40)

3.25 (82.6)

3/4

600

900/1500

11/2

900/1500

3.25 (82.5)

150

(DN 25)

2.62 (66.5)

4.75 (120.7)

600

0.157 (4.0)

300

2.38 (60.5)

900/1500

2500

L

in. (mm)

150

2.03 (51.6)

900/1500

ANSI

Class

2500

300

(DN 20)

B

in. (mm)

Bore Size

in. (mm)

600

150

3/4

A

in. (mm)

3.50 (88.9)

300

600

L (RF to NPT Connection)

L' (RTJ to NPT Connection)

300

7.64 (194.1)

7.00 (177.8)

7.64 (194.1)

7.00 (177.8)

600

600

900/1500

7.64 (194.1)

7.64 (194.1)

12.00 (304.8)

12.00 (304.8)

8.50 (215.9)

6.50 (165.1)

900/1500

2.42 (61.5)

2.42 (61.5)

8.50 (215.9)

6.50 (165.1)

2500

8.03 (204.0)

8.03 (204.0)

13.60 (345.4)

13.60 (345.4)

9.25 (235.0)

6.75 (171.5)

2500

2.88 (73.4)

2.88 (73.4)

9.25 (235.0)

6.75 (171.5)

Instrumentation Solutions

9 Block and Bleed Valves

Block and Bleed Valves 10

Large-bore Bolted Double Block and Bleed Valves

Injection Double Block & Bleed Valves

VB4 Series

Function - injection

Injection of chemicals and other media into the process stream can be accomplished with this design. A check valve is installed to

prevent process fluid from reaching the inlet injection position. There is a 0.125" (3 mm) hole in the injection nozzle orifice. The

Features

length of the injection nozzle orifice can be manufactured to meet customer requirements and needs to be specified. The injection

orifice can also be rotated. Injection valves can be provided in most of the styles and options offered for the DBB ranges.

Complementing the existing one-piece range, flange to

flange bolted construction DBB valves available in sizes

from 1/2 to 2.

Designed according to ASME SI B16.34

Weight, space and cost saving over traditional designs.

FLOW

Complete traceability of materials

Process

Outlet

1 Hole 3 mm Dia.

Full-bore Series

Check Valve

Vent

Reduced-bore Series

Injection Quill

The injection quill length (L) is manufactured to meet customer requirements.

The injection nozzle is a 3 mm diameter hole (standard).

Integral Check Valve

This poppet type spring return valve has a FKM soft seal (standard).

L

Overall Length

L

Overall Length

Process

Process

Outlet

Outlet

Sampling Double Block & Bleed Valves

Vent

Vent

Dimensions

Function - sampling

Dimensions

This design is developed to remove a sample directly from process stream at full system pressure. The customised sampling probe

extends from the pipe flange connection for correct sample removal. Sampling valves can be provided without a probe and valves

Flange Size

Bore Size

in. (mm)

ANSI

Class

150

(25.4)

Bore Size

in. (mm)

ANSI

Class

150

10.7 (272)

L

in. (mm)

11.0 (279)

300

11.2 (285)

600

11.9 (301)

14.3 (364)

900/1500

14.6 (370)

14.8 (377)

2500

15.6 (396)

300

11.0 (279)

600

11.5 (292)

900/1500

2500

11/2

(DN 40)

(25.4)

can be provided in most of the styles and options offered for the DBB ranges.

(DN25)

Flange Size

45

L

in. (mm)

FLOW

Process

11/2

11/2

(DN 40)

(38.1)

(DN 50)

(50.8)

150

14.2 (361)

150

14.3 (364)

300

14.4 (367)

300

14.6 (372)

11/2

(DN 50)

(38.1)

600

15.1 (384)

600

15.4 (390)

900/1500

15.8 (402)

900/1500

16.3 (415)

2500

18.2 (463)

2500

18.7 (475)

150

15.7 (400)

300

16.1 (410)

150

15.4 (390)

300

15.7 (398)

600

16.4 (416)

(DN 80)

(50.8)

900/1500

18.9 (481)

Dimensions are for reference only and are subject to change

Instrumentation Solutions

600

16.9 (428)

900

17.4 (441)

1500

19.7 (500)

Outlet

Vent

Sampling Probe

The sampling probe length (L) is manufactured to meet customer requirements.

Instrumentation Solutions

Instrumentation Solutions

Integral

screwed-bonnet

needle valve

(primary block) MBB

MD

MB

OS&Y

MDB

bolted-bonnet Series

Y needle valve

(primary block)

Bore size is

2 Std. 20 mm

Bore size is

1 Std. 14 mm

RJ

RTJ Flange

RF Serrated

RFA Flange

(6.3 to 12.5 m)

RF Smooth

Flange

(3.2 to 6.3 m)

RF

Bore size is

Std. 9.5 mm

VB3

VB4

Series

Inlet Type

VB3

Configuration

SS

Inlet Size

RF16B

16 1" (DN25)

24 1 1/2"(DN40)

32 2" (DN50)

8 1/2" (DN15)

12 3/4" (DN20)

1.Options of ball valve bore:

3/8 " (9.5 mm) bore (all process connection sizes);

1/2 " (14 mm) bore (1, 1 1/2, or 2 process connections; select size DN25, DN40 or DN50)

3/4 " (20 mm) bore (1 1/2 or 2 process connections; select size DN40 or DN50)

Large-bore Bolted

VB4 Double Block

and Bleed

Flange Double

VB3 Block and Bleed

Monoflange

MDB Double Block

and Bleed

Monoflange

MB Single Block

D5 F51

CS A105

SS 316 SS

6L 316L SS

Series

Monoflange

MBB Single Block and

Bleed Valves

Monoflange

MD Double Block

Body

Material

Ordering Information

G Class 2500

F Class 1500

E Class 900

C Class 600

B Class 300

Same as

inlet

Outlet ANSI

Size Class

PS

1/ 2 Female

FNT8 NPT

Outlet

Type

V8

A Class 150

ANSI Class

FNT8

1/2 Female

V8 NPT

with plug

1/4 Female

V4 NPT

with plug

Vent Type

and Size

G Graphite

P PEEK

PTFE

Packing/Sealing

Material

IN Injection

application

NACE

MR0175

Sampling

SA application

S

No

Special

Application

11 Block and Bleed Valves

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- Chronic Pain GuidelinesDocumento56 pagineChronic Pain GuidelinesOporadhBiggan100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Supplier Quality Assurance ManualDocumento29 pagineSupplier Quality Assurance ManualNilesh Mistry0% (1)

- Physical Security Audit Checklist PDFDocumento3 paginePhysical Security Audit Checklist PDFHendrawan StbNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Binac Ao STR EET: Vicinity Map & Street View, Source Google MapsDocumento17 pagineBinac Ao STR EET: Vicinity Map & Street View, Source Google MapsBee AnquilianoNessuna valutazione finora

- Save and share GZCL training spreadsheets onlineDocumento263 pagineSave and share GZCL training spreadsheets onlinejohn wick100% (1)

- Physical Therpay Protocols For Conditions of Neck RegionDocumento74 paginePhysical Therpay Protocols For Conditions of Neck Regionjrpsaavedra4599Nessuna valutazione finora

- Effects of Limited Face-to-Face Classes on Grade 11 TVL Students and TeachersDocumento45 pagineEffects of Limited Face-to-Face Classes on Grade 11 TVL Students and TeachersJoseph Xyrel Malacad100% (1)

- Project Report On Biodegradable Plates, Glasses, Food Container, Spoon Etc.Documento6 pagineProject Report On Biodegradable Plates, Glasses, Food Container, Spoon Etc.EIRI Board of Consultants and Publishers0% (1)

- What It Is and The Six Steps Necessary To Achieve ItDocumento40 pagineWhat It Is and The Six Steps Necessary To Achieve ItMalory RobayoNessuna valutazione finora

- Bray Characterized Control Valve Engineering SpecDocumento1 paginaBray Characterized Control Valve Engineering SpecNilesh MistryNessuna valutazione finora

- TruFit CatalogDocumento32 pagineTruFit CatalogNilesh MistryNessuna valutazione finora

- Data Sheet  " Design Conformance Standards.Documento2 pagineData Sheet  " Design Conformance Standards.Nilesh MistryNessuna valutazione finora

- Install Instruations STMDocumento6 pagineInstall Instruations STMNilesh MistryNessuna valutazione finora

- TruFit 10K CatalogDocumento20 pagineTruFit 10K CatalogNilesh MistryNessuna valutazione finora

- Resources Industrial Thomson ValveLineCard OnlineversionDocumento4 pagineResources Industrial Thomson ValveLineCard OnlineversionNilesh MistryNessuna valutazione finora

- 2015 Q1 - Intertek - MalaysiaDocumento1 pagina2015 Q1 - Intertek - MalaysiaNilesh MistryNessuna valutazione finora

- Aeroquip Fittings2Documento0 pagineAeroquip Fittings2conmatporNessuna valutazione finora

- Cat GGC9000Documento28 pagineCat GGC9000Nilesh MistryNessuna valutazione finora

- Info PED eDocumento1 paginaInfo PED eNilesh MistryNessuna valutazione finora

- FloLok Catalog - AshxDocumento40 pagineFloLok Catalog - Ashxaromero888Nessuna valutazione finora

- AVK Waterloss BrochureDocumento12 pagineAVK Waterloss BrochureNilesh MistryNessuna valutazione finora

- Cat Acvbr9000Documento16 pagineCat Acvbr9000Nilesh MistryNessuna valutazione finora

- Instrumentation Tube: Tube and Tube AccessoriesDocumento4 pagineInstrumentation Tube: Tube and Tube AccessoriesNilesh MistryNessuna valutazione finora

- Rainbird - Installation and Maintaining of ValvesDocumento16 pagineRainbird - Installation and Maintaining of Valvesstef11_127571Nessuna valutazione finora

- AKI Quick Release Couplings for Fluid LinesDocumento3 pagineAKI Quick Release Couplings for Fluid LinesNilesh MistryNessuna valutazione finora

- Insert Selection For Turning Operation On CNC Turning Centre Using MADM MethodsDocumento11 pagineInsert Selection For Turning Operation On CNC Turning Centre Using MADM Methodsprince duhanNessuna valutazione finora

- Valve Con STR FeaturesDocumento1 paginaValve Con STR FeaturesNilesh MistryNessuna valutazione finora

- VS3 VS6 Instrumentation ValvesDocumento2 pagineVS3 VS6 Instrumentation ValvesNilesh MistryNessuna valutazione finora

- WWW - Ventile.cz 7. Instrument Manifold Amp Gauge ValvesDocumento10 pagineWWW - Ventile.cz 7. Instrument Manifold Amp Gauge ValvesNilesh MistryNessuna valutazione finora

- Valves For Shtokman Field (Instrumentation)Documento10 pagineValves For Shtokman Field (Instrumentation)Nilesh MistryNessuna valutazione finora

- CNCDocumento13 pagineCNCvarathapandianNessuna valutazione finora

- Tech Ascend CNC Student ManualDocumento42 pagineTech Ascend CNC Student ManualabyzenNessuna valutazione finora

- Toolsetting 101871Documento8 pagineToolsetting 101871Nilesh MistryNessuna valutazione finora

- Cat Acvbr9000Documento16 pagineCat Acvbr9000Nilesh MistryNessuna valutazione finora

- AKI Quick Release Couplings for Fluid LinesDocumento3 pagineAKI Quick Release Couplings for Fluid LinesNilesh MistryNessuna valutazione finora

- Instrumentation Tube: Tube and Tube AccessoriesDocumento4 pagineInstrumentation Tube: Tube and Tube AccessoriesNilesh MistryNessuna valutazione finora

- Valves For PowerDocumento3 pagineValves For Powershashikanth79Nessuna valutazione finora

- Adrv9008 1Documento68 pagineAdrv9008 1doubleNessuna valutazione finora

- TLC Analysis of Siling Labuyo Extract ComponentsDocumento3 pagineTLC Analysis of Siling Labuyo Extract ComponentsJan Eric Balete0% (1)

- Abel Rosario Marte Resume1Documento2 pagineAbel Rosario Marte Resume1abelNessuna valutazione finora

- Laccase Mediator Pretreatment of Wheat StrawDocumento15 pagineLaccase Mediator Pretreatment of Wheat StrawMeyerling RandfordNessuna valutazione finora

- MicrosystemDocumento5 pagineMicrosystembabalalaNessuna valutazione finora

- Coa Polivinilpirrolidona K-90 (PVP K-90) Lote 20221019Documento1 paginaCoa Polivinilpirrolidona K-90 (PVP K-90) Lote 20221019Ives AlbarracinNessuna valutazione finora

- Bill 192: An Act To Ensure Student Health and Safety in The Classroom by Regulating Ambient Air Quality in SchoolsDocumento8 pagineBill 192: An Act To Ensure Student Health and Safety in The Classroom by Regulating Ambient Air Quality in SchoolsCtv MontrealNessuna valutazione finora

- Book 1Documento100 pagineBook 1Devasyruc100% (1)

- Prof Educ 2: Foundation of Special and Inclusive EducationDocumento12 pagineProf Educ 2: Foundation of Special and Inclusive EducationNerissa Custosa BastoNessuna valutazione finora

- 2013 - Sara E. TraceDocumento35 pagine2013 - Sara E. TraceDewi WulandariNessuna valutazione finora

- Tabata Its A HIITDocumento8 pagineTabata Its A HIITbertabastionniNessuna valutazione finora

- Review of Literature Review of LiteratureDocumento31 pagineReview of Literature Review of LiteratureeswariNessuna valutazione finora

- Computed Tomography (CT) - BodyDocumento7 pagineComputed Tomography (CT) - Bodyfery oktoraNessuna valutazione finora

- AMGG-S - 1 - Environmental Safeguard Monitoring - 25.03.2021Documento48 pagineAMGG-S - 1 - Environmental Safeguard Monitoring - 25.03.2021Mahidul Islam RatulNessuna valutazione finora

- Prac - 2Documento3 paginePrac - 2nv471646Nessuna valutazione finora

- Atlas Tool Specs SummaryDocumento3 pagineAtlas Tool Specs SummaryWaleed Barakat MariaNessuna valutazione finora

- Technical Information Bulletins Ajax # 010717Documento28 pagineTechnical Information Bulletins Ajax # 010717harley florezNessuna valutazione finora

- Tata Bluescope Steel Limited, Jamshedpur.: Liquefied Petroleum Gas Material Safety Data SheetDocumento6 pagineTata Bluescope Steel Limited, Jamshedpur.: Liquefied Petroleum Gas Material Safety Data Sheetsujit5584Nessuna valutazione finora

- Q 400 SYSTEM BestDocumento9 pagineQ 400 SYSTEM BestTeddy EshteNessuna valutazione finora

- Greenhouse Effect: Greenhouse Gases and Their Impact On Global WarmingDocumento9 pagineGreenhouse Effect: Greenhouse Gases and Their Impact On Global WarmingrabiulNessuna valutazione finora

- SPR MAN 4 14 ET Operating ManualDocumento24 pagineSPR MAN 4 14 ET Operating ManualJason WeeksNessuna valutazione finora

- 1154ec108nanoelectronics PDFDocumento3 pagine1154ec108nanoelectronics PDFLordwin CecilNessuna valutazione finora