Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Fire Lite

Caricato da

Milos JelisavcicCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Fire Lite

Caricato da

Milos JelisavcicCopyright:

Formati disponibili

PROJECT NAME LINE 1

PROJECT HAME LINE 2

FIRM NAME PROJECT #

DATE

Technical Glass Products has included notes in this specification to assist you in tailoring the content to your

project. These comments will appear on your screen in blue. To hide them and view only the specification, do the

following: Click on Tools on your Microsoft Word toolbar. Under Tools, select Options. On the View tab,

under Formatting Marks, remove the check mark from the Hidden Text box. Then click OK. All blue text

will then be hidden. For assistance, call Technical Glass Products at 1-800-426-0279.

SECTION 08 81 17 - FIRE-RATED GLASS FIRELITE

PART 1 - GENERAL

0.1

SUMMARY

A.

Section Includes:

1

Fire-rated glazing materials installed as [transoms] [borrowed lites] [windows] in fire-rated

frames.

B.

Related Sections include the following:

1.

Section 06 40 00 Architectural Woodwork for wood frames for doors, sidelights, transoms,

borrowed lights.

2.

Section 08 11 00 Metal Doors and Frames for vision panels in interior doors and interior vision

panel (borrowed lites) frames.

3.

Section 08 14 16 Flush Wood Doors for vision panels in interior doors.

4.

Section 08 14 33 Stile and Rail Wood Doors for vision panels in interior doors.

5.

Section 08 51 23 Steel Windows.

0.2

REFERENCES

A.

American Society for Testing and Materials (ASTM):

1.

ASTM E2010-01: Standard Test Method for Positive Pressure Fire Tests of Window Assemblies.

B.

Glass Association of North America (GANA):

1.

GANA Glazing Manual.

2.

FGMA Sealant Manual.

C.

National Fire Protection Association (NFPA):

1.

NFPA 80: Fire Doors and Windows.

2.

NFPA 257 Fire Tests of Window Assemblies.

D.

Underwriters Laboratories, Inc. (UL):

1.

UL 9 Fire Tests of Window Assemblies.

E.

Standard Council of Canada:

1.

ULC Standard CAN4-S106: Fire Tests of Window Assemblies.

F.

<Insert building code name used by authority having jurisdiction>.

0.3

PERFORMANCE REQUIREMENTS

A.

Fire-rated glass ceramic clear and wireless glazing material listed for use in non-impact safety-rated

locations such as transoms and borrowed lites with fire rating requirements ranging from 20 to 90

minutes with required hose stream test.

FIRE RATED GLASS FIRELITE

Updated 6-12-12

08 81 17 -- 1

PROJECT NAME LINE 1

PROJECT HAME LINE 2

FIRM NAME PROJECT #

B.

0.4

DATE

Passes positive pressure test standards UBC 7-2 and UBC 7-4.

SUBMITTALS

A.

Comply with requirements of Section 01 33 00<Insert Section #>.

B.

Product data: Submit manufacturers technical data for each glazing material required, including

installation and maintenance instructions.

C.

Certificates of compliance from glass and glazing materials manufacturers attesting that glass and

glazing materials furnished for project comply with requirements. Separate certification will not be

required for glazing materials bearing manufacturers permanent label designating type and thickness of

glass, provided labels represent a quality control program involving a recognized certification agency or

independent testing laboratory acceptable to authority having jurisdiction.

D.

Product Test Listings: From UL indicating fire-rated glass complies with requirements, based on

comprehensive testing of current product.

E.

Samples: Submit, for verification purposes, approx. 8-inch by 10-inch sample for each type of glass

indicated.

0.5

QUALITY ASSURANCE

A.

Glazing Standards: GAMA Glazing Manual and FGMA Sealant Manual.

B.

Fire Protective Rated Glass: Each lite shall bear permanent, nonremovable label of UL certifying it for

use in tested and rated fire protective assemblies.

0.6

DELIVERY, STORAGE, AND HANDLING

A.

Deliver, store, and handle materials under provisions of Section 01 60 00<Insert Section #>.

B.

Deliver materials to specified destination in manufacturer or distributors packaging, undamaged,

complete with installation instructions.

C.

Store off ground, under cover, protected from weather and construction activities.

0.7

WARRANTY

A.

Provide manufacturer's limited warranty under provision of Section 01 78 00<Insert Section #>.

PART 2 - PRODUCTS

0.1

FIRE-RATED GLAZING MATERIALS

A.

Manufacturer: FireLite as manufactured by Nippon Electric Glass Company, Ltd., and distributed by

Technical Glass Products, 8107 Bracken Place SE, Snoqualmie, WA 98065, voice 1-800-426-0279, fax

1-800-451-9857, e-mail sales@fireglass.com, web site www.fireglass.com.

FIRE RATED GLASS FIRELITE

Updated 6-12-12

08 81 17 -- 2

PROJECT NAME LINE 1

PROJECT HAME LINE 2

FIRM NAME PROJECT #

B.

DATE

Properties:

1.

Thickness: 3/16 inch [5 mm].

2.

Weight: 2.4 lbs./sq. ft.

3.

Approximate Visible Transmission: 88 percent.

4.

Approximate Visible Reflection: 9 percent.

5.

Hardness (Vickers Scale): 700.

6.

Fire-rating: 20 minutes to 90 minutes.

7.

Impact Safety Resistance: None.

8.

Positive Pressure Test: UL 10C, UBC 7-2 and 7-4; passes.

9.

Surface Finish:

a.

Premium Grade-Ground and polished on both sides

b.

Standard Grade-Comparable to alternative fire-rated products marketed as Premium

c.

Obscure-Patterned surface

Positive Pressure Test: UL 10C, UBC 7-2 and 7-4; passes.

C.

Maximum sheet sizes based on surface finish:

1.

Premium: 48 inches by 96 inches.

2.

Standard: 48 inches by 96 inches.

3.

Obscure: 36 inches by 96 inches.

D.

Labeling: Permanently label each piece of FireLite with the FireLite logo, UL logo and fire rating in

sizes up to 3,325 sq. in., and with the FireLite label only for sizes that exceed the listing (as approved

by the local authority having jurisdiction).

E.

Fire Rating: Fire rating listed and labeled by UL for fire rating scheduled at opening locations on

drawings, when tested in accordance with [ASTM E2074-00 and ASTM E2010-01] [ULC Standards

CAN4 S-104 and CAN4 S-106] [NFPA 257] [UL 9 and UL 10B].

F.

Substitutions: No substitutions permitted.

0.2

0.3

GLAZING COMPOUND FOR FIRE-RATED GLAZING MATERIALS

A.

Glazing Tape: Closed cell polyvinyl chloride (PVC) foam, coiled on release paper over adhesive on two

sides, maximum water absorption by volume of 2 percent. Glass panels that exceed 1,393 sq. inches for

90-minute ratings must be glazed with fire-rated glazing tape supplied by manufacturer.

B.

[Glazing Compound: DAP 33 putty.]

C.

[Silicone Sealant: One-part neutral curing silicone, medium modulus sealant, Type S; Grade NS;

Class 25 with additional movement capability of 50 percent in both extension and compression (total

100 percent); Use (Exposure) NT; Uses (Substrates) G, A, and O as applicable. Available Products:

1.

Dow Corning 795 - Dow Corning Corp.

2.

Silglaze-II 2800 - General Electric Co.

3.

Spectrem 2 - Tremco Inc.

D.

Setting Blocks: Neoprene, EPDM, or silicone; tested for compatibility with glazing compound; of 70 to

90 Shore A hardness.

E.

Cleaners, Primers, and Sealers: Type recommended by manufacturer of glass and gaskets.

FABRICATION

FIRE RATED GLASS FIRELITE

Updated 6-12-12

08 81 17 -- 3

PROJECT NAME LINE 1

PROJECT HAME LINE 2

FIRM NAME PROJECT #

A.

DATE

Fabricate glass and other glazing products in sizes required to glaze openings indicated for Project, with

edge and face clearances, edge and surface conditions, and bite complying with recommendations of

product manufacturer and referenced glazing standard as required to comply with system performance

requirements.

PART 3 - EXECUTION

0.1

EXAMINATION

A.

Examine glass framing, with glazier present, for compliance with the following:

1.

Manufacturing and installation tolerances, including those for size, squareness, offsets at corners.

2.

Minimum required face or edge clearances.

3.

Observable edge damage or face imperfections.

B.

Do not proceed with glazing until unsatisfactory conditions have been corrected.

C.

Clean glazing channels and other framing members receiving glass immediately before glazing.

Remove coatings that are not firmly bonded to substrates.

0.2

INSTALLATION (GLAZING)

A.

Comply with referenced FGMA standards and instructions of manufacturers of glass, glazing sealants,

and glazing compounds.

B.

Protect glass from edge damage during handling and installation. Inspect glass during installation and

discard pieces with edge damage that could affect glass performance.

C.

Set units of glass in each series with uniformity of pattern, draw, bow, and similar characteristics.

D.

Cut glazing tape to length and set against permanent stops, flush with sight lines to fit openings exactly,

with stretch allowance during installation.

E.

Place setting blocks located at quarter points of glass with edge block no more than 6 inches from

corners.

F.

Glaze vertically into labeled fire-rated metal frames or partition walls with same fire rating as glass and

push against tape for full contact at perimeter of pane or unit.

G.

Place glazing tape on free perimeter of glazing in same manner described above.

H.

Install removable stop and secure without displacement of tape.

I.

[Use specified glazing compound, without adulteration; bed glazing material in glazing compound;

entirely fill all recess and spaces. Provide visible glazing compound with smooth and straight edges.]

J.

Install so that appropriate [UL] [FireLite] markings remain permanently visible.

0.3

PROTECTION AND CLEANING

A.

Protect glass from contact with contaminating substances resulting from construction operations.

Remove any such substances by method approved by glass manufacturer.

FIRE RATED GLASS FIRELITE

Updated 6-12-12

08 81 17 -- 4

PROJECT NAME LINE 1

PROJECT HAME LINE 2

FIRM NAME PROJECT #

B.

0.4

DATE

Wash glass on both faces not more than four days prior to date scheduled for inspections intended to

establish date of substantial completion. Wash glass by method recommended by glass manufacturer.

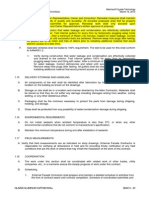

GLAZING SCHEDULE

Rating

20 to

60 min.

Assembly

Other than doors

HMS or wood*

Fireframes D.S.

90 min.

Other than doors

HMS

Fireframes D.S.

Max. Exposed

Area (Sq. In.)

Max. Width

Of Exposed

Glazing (In.)

Max. Height

Of Exposed

Glazing (In.)

Stop

Height

3,325

3,325

95

95

95

95

5/8

3/4"

2,627

2,627

56

56

56

56

5/8

3/4"

OR

* HMS indicates hollow metal steel framing. Fireframes D.S. indicates Designer Series narrow profile

framing available from TGP. For wood frames, check with manufacturer for maximum tested glass sizes.

END OF SECTION

FIRE RATED GLASS FIRELITE

Updated 6-12-12

08 81 17 -- 5

Potrebbero piacerti anche

- Divided States: Strategic Divisions in EU-Russia RelationsDa EverandDivided States: Strategic Divisions in EU-Russia RelationsNessuna valutazione finora

- Rajalakshmi Ansys Lab ManualDocumento98 pagineRajalakshmi Ansys Lab ManualSachi DhanandamNessuna valutazione finora

- Groundwater in Math Problems, Show All WorkDocumento4 pagineGroundwater in Math Problems, Show All Workprabhjotsingh592Nessuna valutazione finora

- Sashank KumarDocumento102 pagineSashank KumarAbninder SinghNessuna valutazione finora

- Theory of Metal CuttingTheory of Chip FormationDocumento13 pagineTheory of Metal CuttingTheory of Chip FormationLarry SmithNessuna valutazione finora

- Remote Notice Board Using GSMDocumento149 pagineRemote Notice Board Using GSMaksvinuNessuna valutazione finora

- Hsan Afar: Objective QualificationDocumento3 pagineHsan Afar: Objective QualificationAbdullah ChaudhryNessuna valutazione finora

- Exploration and Camparison of Different Technique To Measure The Particle Size of Tio PigmentDocumento15 pagineExploration and Camparison of Different Technique To Measure The Particle Size of Tio PigmentRESHMAMALEACKELNessuna valutazione finora

- De La La Salle University - Manila SyllabusDocumento4 pagineDe La La Salle University - Manila SyllabusAndrenel ReyesNessuna valutazione finora

- Vijaya KumarDocumento4 pagineVijaya KumarKarthik P MuraliNessuna valutazione finora

- Consequences Ind Rev Working ClassDocumento7 pagineConsequences Ind Rev Working ClassRajendra PersaudNessuna valutazione finora

- Lab 3 ReportDocumento8 pagineLab 3 ReportDoniPrasetyoNessuna valutazione finora

- PEJ1 Practice File Units 1 6Documento12 paginePEJ1 Practice File Units 1 6blagoje karovicNessuna valutazione finora

- Module I: Language As A System: Unit 3: Morphology and The Lexicon (Part 1)Documento8 pagineModule I: Language As A System: Unit 3: Morphology and The Lexicon (Part 1)Gildardo PalmaNessuna valutazione finora

- AMS Engagement Guidelines V2Documento24 pagineAMS Engagement Guidelines V2mohi4uNessuna valutazione finora

- Phraseology Theory, Analysis, and ApplicationsDocumento18 paginePhraseology Theory, Analysis, and ApplicationsJoshua WarrenNessuna valutazione finora

- Unit 2: The Organization of A COBOL ProgramDocumento24 pagineUnit 2: The Organization of A COBOL ProgramgauthamikNessuna valutazione finora

- 11 Acc P2 Memo Nov 2011Documento6 pagine11 Acc P2 Memo Nov 2011Ryno de BeerNessuna valutazione finora

- Curriculam Vitae: SynopsisDocumento3 pagineCurriculam Vitae: SynopsisKiranKumarNessuna valutazione finora

- Induction Motor: Fuzzy Logic Based Vector Control ofDocumento5 pagineInduction Motor: Fuzzy Logic Based Vector Control ofcoolrajeeeNessuna valutazione finora

- Chapter 15: Reflection and Refraction: Worksheet SolutionsDocumento4 pagineChapter 15: Reflection and Refraction: Worksheet SolutionsM Ravdi HirzanNessuna valutazione finora

- A Project Report On Solar Energy Based Automatic Street Light ControllerDocumento13 pagineA Project Report On Solar Energy Based Automatic Street Light ControllerJobert BartolayNessuna valutazione finora

- HVAC Guide Specifications Variable Speed Screw ChillerDocumento13 pagineHVAC Guide Specifications Variable Speed Screw ChillerNesken Frederico SiqueiraNessuna valutazione finora

- Mec281: Materials Science: Phase DiagramDocumento74 pagineMec281: Materials Science: Phase Diagrampatel ketan100% (1)

- Optical Wireless Comm.Documento8 pagineOptical Wireless Comm.malhiavtarsinghNessuna valutazione finora

- Department of Agriculture: DefinitionsDocumento13 pagineDepartment of Agriculture: DefinitionsSai AravindNessuna valutazione finora

- Abhishek Prakash: +1-7203979976/abpr7959@colorado - EduDocumento2 pagineAbhishek Prakash: +1-7203979976/abpr7959@colorado - EduAbhishek PrakashNessuna valutazione finora

- Strength of MaterialsDocumento5 pagineStrength of MaterialsSubbu SuniNessuna valutazione finora

- Rajiv Gandhi Aviation Academy Civil Airworthiness RequirementsDocumento5 pagineRajiv Gandhi Aviation Academy Civil Airworthiness RequirementsAamir Imam KhanNessuna valutazione finora

- Phantom of The Opera ScriptDocumento64 paginePhantom of The Opera ScriptYarmantoNessuna valutazione finora

- Gap Control For Socket Weld Back Welded Threaded FittingsDocumento12 pagineGap Control For Socket Weld Back Welded Threaded Fittingslaz_k100% (1)

- Locgo V: Naomi's Kitchen MakesDocumento3 pagineLocgo V: Naomi's Kitchen MakesColleen Fretzie Laguardia NavarroNessuna valutazione finora

- Structural Precast SpecificationsDocumento9 pagineStructural Precast SpecificationsMahmoud ShakerNessuna valutazione finora

- Professional Experience: Key Accomplishments (To Date)Documento3 pagineProfessional Experience: Key Accomplishments (To Date)Vaira ManickkamNessuna valutazione finora

- Alicias ResumeDocumento2 pagineAlicias Resumeapi-250867690Nessuna valutazione finora

- Automated Guided Vehicle: Line Tracer RobotDocumento25 pagineAutomated Guided Vehicle: Line Tracer Robotdillisingh85Nessuna valutazione finora

- Shop MGHTDocumento126 pagineShop MGHTGaurav SinghNessuna valutazione finora

- Questions Energy Flow PyramidsDocumento3 pagineQuestions Energy Flow PyramidsWagner OñaNessuna valutazione finora

- Clinical Profile of Tubercular Uveitis in A Tertiary Care Ophthalmic CentreDocumento3 pagineClinical Profile of Tubercular Uveitis in A Tertiary Care Ophthalmic CentreArif BudimanNessuna valutazione finora

- Project Mainly Based On KLT Tools: at HomeDocumento29 pagineProject Mainly Based On KLT Tools: at Homemzamor32Nessuna valutazione finora

- Verbals ExercisesDocumento43 pagineVerbals Exercisescoconut108Nessuna valutazione finora

- Shaping Grinding and Realated OperationsDocumento26 pagineShaping Grinding and Realated Operationspatel ketanNessuna valutazione finora

- Solutions For Construction Techniques and Technology: Iii.1 Structural SolutionDocumento10 pagineSolutions For Construction Techniques and Technology: Iii.1 Structural SolutionJennifer PearsonNessuna valutazione finora

- AD ART Forum KomiteDocumento4 pagineAD ART Forum KomitediazemilaNessuna valutazione finora

- SECTION 23 21 11 Boiler Plant Piping SystemsDocumento42 pagineSECTION 23 21 11 Boiler Plant Piping SystemsKarthick SamNessuna valutazione finora

- 2 - Friction Loss UnguidedDocumento7 pagine2 - Friction Loss UnguidedshaunyuNessuna valutazione finora

- Ip XiiDocumento141 pagineIp XiisaravkiruNessuna valutazione finora

- Motive:: Implementation of The Diffie-Hellman Key Exchange CS 603 - Fall 2005 Final Project Report Dr. Leszek LilienDocumento13 pagineMotive:: Implementation of The Diffie-Hellman Key Exchange CS 603 - Fall 2005 Final Project Report Dr. Leszek Lilienrodygo26Nessuna valutazione finora

- Assigned Cases For FinalsDocumento14 pagineAssigned Cases For FinalsDon SumiogNessuna valutazione finora

- Drama Games PDFDocumento11 pagineDrama Games PDFSnezana PoptesinNessuna valutazione finora

- Resume - Jerald MathisDocumento3 pagineResume - Jerald Mathisapi-250914759Nessuna valutazione finora

- Table of Content: S.No. Description Page NoDocumento82 pagineTable of Content: S.No. Description Page NoMazhar ZamanNessuna valutazione finora

- 1047-Suhartono-statistics-Paper Suhartono ITS Revision (Color Mark)Documento13 pagine1047-Suhartono-statistics-Paper Suhartono ITS Revision (Color Mark)Sagita SaraswatiNessuna valutazione finora

- Perangkat Lunak Pembelajaran Protokol Secret Sharing Dengan Algoritma Asmuth - BloomDocumento7 paginePerangkat Lunak Pembelajaran Protokol Secret Sharing Dengan Algoritma Asmuth - BloomAnwar EdogawaNessuna valutazione finora

- Exploratory Study OnDocumento75 pagineExploratory Study OnIkhlaasKaushalNessuna valutazione finora

- Teknologi Pengolahan Hasil PerkebunanDocumento8 pagineTeknologi Pengolahan Hasil PerkebunanDedi YushardiNessuna valutazione finora

- M.E. AeronauticalDocumento35 pagineM.E. AeronauticalVadivel AeroNessuna valutazione finora

- Orlando Disney Florida Holiday IdeaDocumento2 pagineOrlando Disney Florida Holiday IdeaSteven LondonNessuna valutazione finora

- v-Myb proteins and their oncogenic potential: A study on how two point mutations affect the interaction of v-Myb with other proteinsDa Everandv-Myb proteins and their oncogenic potential: A study on how two point mutations affect the interaction of v-Myb with other proteinsNessuna valutazione finora

- FOSG Quality StandardsDocumento1 paginaFOSG Quality Standardspandey008Nessuna valutazione finora

- Durability of Building and Construction Sealants and Adhesives Volume 2 Andreas T WolfDocumento132 pagineDurability of Building and Construction Sealants and Adhesives Volume 2 Andreas T Wolfpandey008100% (2)

- 498ADocumento8 pagine498Apandey008Nessuna valutazione finora

- HST HiltiDocumento4 pagineHST HiltimariuspiNessuna valutazione finora

- SFE RULEBOOK Issue 01 Board Approved 6 Nov 08Documento9 pagineSFE RULEBOOK Issue 01 Board Approved 6 Nov 08pandey008Nessuna valutazione finora

- TurkeyDocumento1 paginaTurkeypandey008Nessuna valutazione finora

- Astmc864 05Documento11 pagineAstmc864 05pandey0080% (1)

- ACP SpecDocumento1 paginaACP Specpandey008Nessuna valutazione finora

- Project SpecificationDocumento1 paginaProject Specificationpandey008Nessuna valutazione finora

- Job Description SHH502 Housing Repairs - Carpenter - Multi Trade OperativeDocumento5 pagineJob Description SHH502 Housing Repairs - Carpenter - Multi Trade Operativepandey008Nessuna valutazione finora

- SkyScape Design Installation Guide 2014Documento17 pagineSkyScape Design Installation Guide 2014pandey008Nessuna valutazione finora