Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Instruction Manual For DCP 9 KG

Caricato da

aliTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Instruction Manual For DCP 9 KG

Caricato da

aliCopyright:

Formati disponibili

USER HAND BOOK

CUM

ILLUSTRATED PART LIST

FOR 09 KG CAPACITY DRY POWDER PORTABLE

FIRE EXTINGUISHER FOR CLASS B&C FIRE.

TENDOR NO:-A043-00-MF-PR-8060/8060

PROJECT:-DEEN DAYAL FIELD DEVELOPMENT PROJECT,OGT

OWNER:-GUJRAT STATE PETROLEUM CORPORATION (GSPC)

PMC:-ENGINEERS INDIA LTD

TAG NO: - 308-MF-FE-001

DOCUMENT NO:-AEC/DCPSP09/2014-IB

ASHOKA ENGINEERING COMPANY

PLOT NO. 07 GALI NO. 7 ANAND PARBAT INDUSTRIAL ESTATE NEW

DELHI-110005

Sl No.11 Page 1 of 9

CHAPTER-I

GENERAL DESCRIPTION

SECTION 01:

Introduction

2. PURPOSE: The Extinguisher Fire Dry Powder 09 Kg. capacity is used to extinguish Class

B.C and Electric Fires, involving liquids or liquefiable solid, flammable and liquefied gases

and electric fires.

3. TECHANICAL DATA:

Type

Upright

Outside dia of Body

1755 mm

Clear opening dia of

neck ring

19 mm

Total Height

6205 mm

Capacity

9 Kg.

Weight

DOCNO. AEC/IB/DCPSP09/2014 -

5.410 Kg (Approx. Without charge)

REV.0

USER HAND BOOK CUM ILLUSTRATED PART LIST

1. GENERAL: This hand book covers descriptive instruction for operation maintenance and

storage of Extinguisher Fire Dry Powder 09 Kg. capacity. Before attempting to use this

Extinguisher, uses must go through this book carefully to get himself acquainted to ensure

best results.

Sl No.11 Page 2 of 9

SECTION-2

DESCRIPTION:

1. The Extinguisher unit consists of following assembling:

(a)Body,(b)Squeeze Grip Valve ,(c)Syphon pipe,(d)Hose pipe

2. MAIN ASSEMBLIES:

(a)BODY: The main body is fabricated out of M.S. Sheet of 1.6mm thk and its top dome is welded to a

neck-ring of M.S. pipe.

(c) SIPHON TUBE: This is made of ABS plastic and fitted to the Squeeze grip valve.

(d) HOSE PIPE: This consists of a rubber hose having 600 mm length & internal dia of

fitted with nozzle.

DOCNO. AEC/IB/DCPSP09/2014 -

REV.0

12.5mm and

USER HAND BOOK CUM ILLUSTRATED PART LIST

(b)SQUEEZE GRIP VALVE: Its made of Forged Brass Conforming FLB Grade of IS: 6932.

Sl No.11 Page 3 of 9

Chapter II

OPERATION AND USE

Section-1: PREPARATION FOR USE

INSTRUCTIONS

1. Clean the outer container of the fire extinguisher with a soft dry cloth properly.

2. Unscrew the squeeze grip valve.

3. Fill 9 kg of Dry Chemical Powder in the cylinder.

4. Check the squeeze grip valves washer is in the place.

5. Tighten the valve on the neck ring properly.

7. Check the discharge hole is not clogged.

8. Pressurize the extinguisher with dry nitrogen to a pressure of 15 bar.

9. Tighten the discharge hose to the valve body.

10. Put the safety clip in position.

11. Record the date of filling on the extinguisher.

NOW THE EXTINGUISHER IS READY TO USE

Section-2:-OPERATION AND USE

1. Before operation/use of extinguisher ,operator should be well trained /conversant with

handling/operation of subject extinguisher.

2. Keep/maintain sufficient distance during operation, to avoid any accident.

3. Minimum two persons should be involved during operation and proper safety measure

should be taken.

4. Remove the Fire Extinguisher from the wall bracket and carry to the fire place.

5. Remove the safety clip from the valve.

DOCNO. AEC/IB/DCPSP09/2014 -

REV.0

USER HAND BOOK CUM ILLUSTRATED PART LIST

6. Check the nozzle passage is clear.

Sl No.11 Page 4 of 9

6. Press the lever of squeeze grip valve

& extinguisher start to discharge the Dry

Chemical Powder.

7. Direct the jet on the seat of fire, with sweeping motion side to side.

8. When fire is out ,standby & watch for possible re-ignition .

9. Realize the lever of the valve to stop the discharge of powder.

CHAPTERCHAPTER-III

MAINTENANCE AND REPAIR

Section 01

MAINTENANCE

1. After the discharge ,the extinguisher must be cleaned with dry cloth or cotton waste

DO NOT USE WATER TO CLEAN THE FIRE EXTINGUISHER.

2. The Extinguisher must be recharged and the date of charging to be indicated on the

3. Clean the exterior of the extinguisher body once in a month.

4. Once in a month check the nozzle outlet for clogging.

5. At frequent intervals, it must be ensured that extinguisher is in proper condition with

safety clip in the position & it is not accidentally discharge.

6. Once in a month, check the pressure gauge for specified pressure in the cylinders. In

case pressure is low send the extinguisher for recharging.

7. Check the vent holes are not clogged.

8. Before recharging ,unscrew the valve slowly to release the pressure from the

extinguisher

9. Check the valve operating mechanism is working properly.

10. Empty the dry powder in a container & check the powder for caking, lumping and any

foreign material .It caking/lumping are found, replace the powder with fresh powder

charge.

11. Before replacing the powder, check the inner surface for any corrosion/damage .In

case inner surface is found to be corroded .The cylinder should be subjected to

hydraulic pressure of 35Kg/cm2 to check for any leakage/seepage etc. If cylinder is

DOCNO. AEC/IB/DCPSP09/2014 -

REV.0

USER HAND BOOK CUM ILLUSTRATED PART LIST

extinguisher body.

Sl No.11 Page 5 of 9

found to be acceptable it should be cleaned thoroughly and surface treatment is to be

carried out.

12. The Cylinder body shall be subjected to Hydrostatic pressure test after every three

years. If leakage/seepage, visible distortion is observed, the extinguisher shall be

USER HAND BOOK CUM ILLUSTRATED PART LIST

rejected and replace.

DOCNO. AEC/IB/DCPSP09/2014 -

REV.0

Sl No.11 Page 6 of 9

13. The cylinder which fails the hydrostatic pressure test shall be rejected and disposed of

to avoid subsequent use.

14. Some of the extinguisher (say 10% to25%) should be picked up randomly from the

extinguishers lot which are in continuous operation for the last 03 years for conduct of

performance test .Advantage of the test should be taken to give practical training to the

staff in handling and operation of extinguisher .In case where more than 25%

extinguisher fails the performance test, all the remaining extinguisher from the lot

should be used in imparting warning.

15. Once in a year, polish the painted portion with wax polish and brass parts with metal

polish.

16. Written records should be maintained for maintenance, inspection and testing of

extinguisher. One page shall be allocated to each extinguisher.

17. NOTE:

(a) Dry Powder extinguisher should be opened in a dry room and for a minimum

possible time to avoid effect of atmospheric moisture on powder.

18. The uncharged extinguisher stocked inside shall be maintained as given below:(b) Once in a year check the washer valve ,grease the threads and check the lever

mechanism and discharge control for free movement .Examine vent holes.

(c) Once in a year, examine the bodies of extinguisher externally and internally using

illuminating probe. Corroded or damaged extinguisher should be replaced.

(d) Once in a year, polish the painted portion with wax polish and brass parts with

metal polish.

(e) The extinguisher shall be subjected to a hydraulic pressure of 35kgf/cm2 for a

duration of 30 sec before issuing to the user subject to the last hydraulic test was

done before three years .In case extinguisher fails due to leakage or visible

distortion ,the same shall be replaced.

DOCNO. AEC/IB/DCPSP09/2014 -

REV.0

USER HAND BOOK CUM ILLUSTRATED PART LIST

(a) Once in six months, clean the exterior of extinguisher by soft & dry cloth.

Sl No.11 Page 7 of 9

Section -2: REPAIR

1. At the time of inspection any worn out part/parts should be replaced by new one. For

any major repair send the extinguisher to the manufacturer.

2. While assembling valve, all the parts should be properly cleaned to ensure correct

fitting.

CHAPTER-IV

TRANSPORTATION

(a) The extinguisher to be transported after proper packing as per specn,in empty condition

to avoid any mishap by Rail/Road.

(b) Any additional safeguard considered may be added by the contractor.

CHAPTER-V

PACKING AND PRESERVATION

The fire extinguisher is operated in the upright position. The design of the nozzle is such as

to ensure a throw of jet not less than 2 meters for a minimum period of more than 13 sec

& discharge of 90% minimum

of powder contents. The extinguisher should always be

transported in empty condition to avoid any mishap.

Section-2:

(a) PACKING

1. No packing is required during use.

2. Each extinguisher shall be packed in a polythene bag of 100 micron thickness &

thereafter in a corrugated box of 5 ply sheet with adequate polystyrene packing at

top and bottom of extinguisher to protect the valve and bottom skirt to avoid the

movement of extinguisher. The thickness of polystyrene at any point shall not be

less than 20 mm. The box shall be closed with self-adhesive tape strapped with

plastic/nylon strap.

(b) PRESERVATION

1. Keep the extinguisher in a cool & dry place.

2. Do not expose the extinguisher to direct sunlight.

DOCNO. AEC/IB/DCPSP09/2014 -

REV.0

USER HAND BOOK CUM ILLUSTRATED PART LIST

SECTION-1: SPECIAL FEATURE AND HAZARDS:

USER HAND BOOK CUM ILLUSTRATED PART LIST

Sl No.11 Page 8 of 9

DOCNO. AEC/IB/DCPSP09/2014 -

REV.0

Sl No.11 Page 9 of 9

ITEM NO.

DESCRIPTION

QTY.

PART NO.

VALVE ASSEMBLY

01

AEC\DCP09\01

COLLAR O RING

01

AEC\DCP09\02

DELIVERY PIPE WITH NOZZLE

01

AEC\DCP09\03

HOSE GASKET O-RING

01

AEC\DCP09\04

RING PIN

01

AEC\DCP09\05

5A

CHAIN(NYLON) FOR RING PIN

01

AEC\DCP09\54

LEVER

01

AEC\DCP09\06

HANDLE

01

AEC\DCP09\07

GAUGE

01

AEC\DCP09\08

VLAVE STEM O-RING

01

AEC\DCP09\09

10

VALVE STEM ASSEMBLY

01

AEC\DCP09\10

11

SPRING

01

AEC\DCP09\11

12

SIPHON PIPE

01

AEC\DCP09\12

13

STRAP AND HOSE ASSY

01

AEC\DCP09\13

DOCNO. AEC/IB/DCPSP09/2014 -

REV.0

USER HAND BOOK CUM ILLUSTRATED PART LIST

ILLUSTRATED PART LIST

Potrebbero piacerti anche

- Japan Epicon Finish HB Ex White HDocumento7 pagineJapan Epicon Finish HB Ex White HAbhijeet DasguptaNessuna valutazione finora

- Oisd STD 175Documento59 pagineOisd STD 175yandiNessuna valutazione finora

- Ammonia Unloading Sop ZaclDocumento2 pagineAmmonia Unloading Sop ZaclHARRY SINGHNessuna valutazione finora

- Foam InductorDocumento6 pagineFoam InductorDipanjan Chakrabarti100% (1)

- JSA For Hydrojetting (Gun With Rigid Lance) at Jetting YardDocumento23 pagineJSA For Hydrojetting (Gun With Rigid Lance) at Jetting YardSHAH NAWAZ SAEEDNessuna valutazione finora

- Decoding Manufacturing Dates For Regulators and Flashback ArrestorsDocumento5 pagineDecoding Manufacturing Dates For Regulators and Flashback Arrestorssatyendra kumarNessuna valutazione finora

- Hydrojetting SafetyDocumento5 pagineHydrojetting SafetyHeryNessuna valutazione finora

- Filling & Decanting SOP'sDocumento4 pagineFilling & Decanting SOP'sMian Abdul RehmanNessuna valutazione finora

- Is 11006 2011 PDFDocumento16 pagineIs 11006 2011 PDFAnantha NarayananNessuna valutazione finora

- Apcosil 605Documento1 paginaApcosil 605rihtak123Nessuna valutazione finora

- JSA #34 - N2 PurgingDocumento1 paginaJSA #34 - N2 PurgingHelza RahmanniaNessuna valutazione finora

- Standard Operating Procedure For HSDDocumento3 pagineStandard Operating Procedure For HSDisjglfdskNessuna valutazione finora

- Static and Mobile Pressure Vessels Rules OverviewDocumento22 pagineStatic and Mobile Pressure Vessels Rules Overviewsatnam1979100% (1)

- Project: Engineering, Procurement & Construction For Upgrade Uthmaniyah-Abqaiq Pipelines Systems Bi# 10-01196 CONTRACT# 6600049184Documento14 pagineProject: Engineering, Procurement & Construction For Upgrade Uthmaniyah-Abqaiq Pipelines Systems Bi# 10-01196 CONTRACT# 6600049184Mohamed Wasim ShaikhNessuna valutazione finora

- 200 Liter Foam TrolleyDocumento1 pagina200 Liter Foam Trolleyvivekvpsfe100% (1)

- Oisd STD 170Documento26 pagineOisd STD 170Nanu PatelNessuna valutazione finora

- Tank Lorry Safety & Security Check-Step 1Documento3 pagineTank Lorry Safety & Security Check-Step 1fawad haider100% (1)

- Quiz For TT DriverDocumento8 pagineQuiz For TT DriverGulbarga DepotNessuna valutazione finora

- Nitrogen Handling PurgingDocumento9 pagineNitrogen Handling PurgingJeet Singh100% (1)

- Safety Alert Space HeatersDocumento2 pagineSafety Alert Space HeatersRamadan KareemNessuna valutazione finora

- Penguard PrimerDocumento5 paginePenguard PrimerPutroedidohNessuna valutazione finora

- SHOT BLASTING SAFETYDocumento3 pagineSHOT BLASTING SAFETYAkhilesh KumarNessuna valutazione finora

- MSDS High Speed DieselDocumento3 pagineMSDS High Speed DieselK B ManoharanNessuna valutazione finora

- Saudi Aramco Inspection Checklist: Receiving Inspection of Centrifugal Pumps SAIC-G-2002 29-Dec-16 MechDocumento32 pagineSaudi Aramco Inspection Checklist: Receiving Inspection of Centrifugal Pumps SAIC-G-2002 29-Dec-16 MechAbdul Hafeez SoomroNessuna valutazione finora

- Conbextra EP120 TDS PDFDocumento3 pagineConbextra EP120 TDS PDFzulfikarNessuna valutazione finora

- Covering Holes Tailgate Safety TalkDocumento1 paginaCovering Holes Tailgate Safety TalkBalaji RajasekaranNessuna valutazione finora

- 2.0 Pressure TestingDocumento11 pagine2.0 Pressure TestingHATEMNessuna valutazione finora

- Tank TruckDocumento80 pagineTank Truckjacobpm2010Nessuna valutazione finora

- Fire Safety Checklist for Saudi Aramco CampsDocumento5 pagineFire Safety Checklist for Saudi Aramco CampsHaleem Ur Rashid BangashNessuna valutazione finora

- Hydraulic Jack SOPDocumento9 pagineHydraulic Jack SOPGyanendra Narayan NayakNessuna valutazione finora

- Sabic M80064SDocumento2 pagineSabic M80064STungdinh NguyenNessuna valutazione finora

- 9 Use of Hand Roller Compactor SafetyDocumento2 pagine9 Use of Hand Roller Compactor SafetyarchieNessuna valutazione finora

- 2.0 Windsock Wind SpeedsDocumento1 pagina2.0 Windsock Wind SpeedsSoham Mukherjee100% (2)

- HSD Unloading SopDocumento2 pagineHSD Unloading SopVikas Kumar100% (1)

- Monsoon Preparedness Plan, Infinity-HYD 111 Project 15-04-2021Documento3 pagineMonsoon Preparedness Plan, Infinity-HYD 111 Project 15-04-2021Md jawedNessuna valutazione finora

- Rim SealDocumento6 pagineRim SealVasant Kumar VarmaNessuna valutazione finora

- Maintenance Instructions For The Type Ces 3000 Hyperbaric Fire ExtinguisherDocumento16 pagineMaintenance Instructions For The Type Ces 3000 Hyperbaric Fire ExtinguisherBonar StepanusNessuna valutazione finora

- Report of Ultrasonic Flaw Detection Test of Weld JointDocumento1 paginaReport of Ultrasonic Flaw Detection Test of Weld Jointkevin desai100% (1)

- PT Bhaita Wire Rope Inspection ProcedureDocumento4 paginePT Bhaita Wire Rope Inspection ProcedureSugianto TanNessuna valutazione finora

- Confined Space - IntroductionDocumento23 pagineConfined Space - Introductionyogeshwaran NNessuna valutazione finora

- Painting ReportDocumento29 paginePainting ReportDimas Afiefan AmirNessuna valutazione finora

- Responsibilities of Rig Superintendent StudyDocumento7 pagineResponsibilities of Rig Superintendent StudyAnonymous VNu3ODGavNessuna valutazione finora

- Dacon Rescue Scoop Design GuidelinesDocumento4 pagineDacon Rescue Scoop Design GuidelinesJon LopezNessuna valutazione finora

- Sample: Please Do Not Write On TestDocumento9 pagineSample: Please Do Not Write On TestPrimelift Safety Resources Limited0% (1)

- Crane 3612 LoadChartDocumento6 pagineCrane 3612 LoadChartZura RamliNessuna valutazione finora

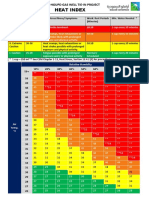

- Aramco Heat Index A4Documento1 paginaAramco Heat Index A4DLPS HSENessuna valutazione finora

- Buku IstighfarDocumento1 paginaBuku IstighfarAfif MudzakkirNessuna valutazione finora

- MM2000 - DatasheetDocumento2 pagineMM2000 - DatasheetABDUL GHAFOORNessuna valutazione finora

- Sec.2-61 Sky Climbers & Suspended Power PlatformsDocumento6 pagineSec.2-61 Sky Climbers & Suspended Power Platformsbravo2uniform2736Nessuna valutazione finora

- Method of Statement For Installation Procedure of DG SetDocumento15 pagineMethod of Statement For Installation Procedure of DG SetMohammaD ALINessuna valutazione finora

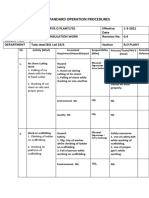

- New Sop InsulationDocumento4 pagineNew Sop InsulationBALAL AKRAM100% (2)

- Counter Weight DrawingDocumento1 paginaCounter Weight Drawingrajaguru20003Nessuna valutazione finora

- Bunker and Oil Transfer Checklist: ISM - Manual Developement of Plans For Shipboard ProceduresDocumento1 paginaBunker and Oil Transfer Checklist: ISM - Manual Developement of Plans For Shipboard ProceduresAleksandrNessuna valutazione finora

- MDPE Work ProcedureDocumento18 pagineMDPE Work ProcedureANURAG YADAVNessuna valutazione finora

- 3832 - 4-Chain Pulley BlockDocumento8 pagine3832 - 4-Chain Pulley BlockAshish PattanaikNessuna valutazione finora

- Hydra & Trailer ChecklistDocumento2 pagineHydra & Trailer ChecklistparthaNessuna valutazione finora

- Britannia Powder CartridgeDocumento5 pagineBritannia Powder Cartridgealfred.mathewsNessuna valutazione finora

- Field Engineering Bulletin: Long-Term Storage and Protection of Sundyne Pumps and CompressorsDocumento8 pagineField Engineering Bulletin: Long-Term Storage and Protection of Sundyne Pumps and CompressorsJoshua McAlisterNessuna valutazione finora

- Camisa de CilindroDocumento16 pagineCamisa de CilindroFelipe CarranzaNessuna valutazione finora

- Basf 9665 Conipur M 865 Z enDocumento3 pagineBasf 9665 Conipur M 865 Z enMarijana JukicNessuna valutazione finora

- MTBE Presintation For IMCODocumento26 pagineMTBE Presintation For IMCOMaryam AlqasimyNessuna valutazione finora

- Dont CryDocumento8 pagineDont CryIolanda Dolcet Ibars100% (1)

- SI Units in Geotechnical EngineeringDocumento7 pagineSI Units in Geotechnical EngineeringfaroeldrNessuna valutazione finora

- The hyperwall: A multiple display wall for visualizing high-dimensional dataDocumento4 pagineThe hyperwall: A multiple display wall for visualizing high-dimensional dataMahendra PututNessuna valutazione finora

- Stereoscopic Restitution Instruments: Materi Kuliah GD3204 Fotogrametri I, Semester I-2009/2010Documento50 pagineStereoscopic Restitution Instruments: Materi Kuliah GD3204 Fotogrametri I, Semester I-2009/2010ththaalNessuna valutazione finora

- DS450 Shop Manual (Prelim)Documento94 pagineDS450 Shop Manual (Prelim)GuruRacerNessuna valutazione finora

- BS 5896 2010Documento33 pagineBS 5896 2010shashiresh50% (2)

- Item No. Specification Requested Offered Specifications 1.1. 1.1 Law and CertificatesDocumento23 pagineItem No. Specification Requested Offered Specifications 1.1. 1.1 Law and CertificatesSaša StankovićNessuna valutazione finora

- Attachment To Division Memorandum No. - , S, 2020Documento3 pagineAttachment To Division Memorandum No. - , S, 2020Jasmin Move-RamirezNessuna valutazione finora

- Advanced Excel FormulasDocumento25 pagineAdvanced Excel Formulasskmohit singhalNessuna valutazione finora

- Ranking 4Documento34 pagineRanking 4Deepti BhatiaNessuna valutazione finora

- Siemens 1LE1 PDFDocumento308 pagineSiemens 1LE1 PDFharold100% (1)

- DSSSB 01 2017Documento9 pagineDSSSB 01 2017Praneeta KatdareNessuna valutazione finora

- ICT PresentationDocumento13 pagineICT PresentationThe Leo LoverNessuna valutazione finora

- OceanPixel Abundo Marine Renewable Energy An Emerging OptionDocumento96 pagineOceanPixel Abundo Marine Renewable Energy An Emerging OptionjopaypagasNessuna valutazione finora

- General Purpose Relay SpecsDocumento2 pagineGeneral Purpose Relay SpecsAndres DiazNessuna valutazione finora

- Axial Shortening of Column in Tall Structure.Documento9 pagineAxial Shortening of Column in Tall Structure.P.K.Mallick100% (1)

- P8B WS Memory Qualified Vendors List (QVL)Documento3 pagineP8B WS Memory Qualified Vendors List (QVL)bolpensmaierNessuna valutazione finora

- Battery Testing and MaintenanceDocumento23 pagineBattery Testing and MaintenanceMormor Omerta0% (1)

- Breaking Water Protection Paradigms: RTM Composite DomesDocumento52 pagineBreaking Water Protection Paradigms: RTM Composite DomesaerostressNessuna valutazione finora

- Assessment of Groundwater Quality Using GIS - A Case Study of The Churu District of RajasthanDocumento9 pagineAssessment of Groundwater Quality Using GIS - A Case Study of The Churu District of RajasthanSivaShankarNessuna valutazione finora

- Testing concrete and brick strengthDocumento2 pagineTesting concrete and brick strengthlolenlennNessuna valutazione finora

- A1.2.3 Method Statement 4a Redacted Version2Documento98 pagineA1.2.3 Method Statement 4a Redacted Version2ChanelNessuna valutazione finora

- Transmission ImpairmentsDocumento49 pagineTransmission ImpairmentsLaurentiuStanciuNessuna valutazione finora

- Aashto T19-Bulk Density (Unit Weight)Documento7 pagineAashto T19-Bulk Density (Unit Weight)Marc Anthony de Villa100% (1)

- DPWH Standard Specifications for ShotcreteDocumento12 pagineDPWH Standard Specifications for ShotcreteDino Garzon OcinoNessuna valutazione finora

- Product Portfolio ManagementDocumento10 pagineProduct Portfolio ManagementSandeep Singh RajawatNessuna valutazione finora

- Royal 3KW Solar System: Ref: RSE/SQ/804/2020 Date: 09-28-2020 Sale QuotationDocumento3 pagineRoyal 3KW Solar System: Ref: RSE/SQ/804/2020 Date: 09-28-2020 Sale Quotationmuhammad aliNessuna valutazione finora

- Selection ToolsDocumento13 pagineSelection ToolsDominador Gaduyon DadalNessuna valutazione finora