Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Ball Mill Loading - Dry Milling

Caricato da

mladen lakicCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Ball Mill Loading - Dry Milling

Caricato da

mladen lakicCopyright:

Formati disponibili

Ball Mill Loading - Dry Milling

1 of 3

http://www.pauloabbe.com/size-reduction/resources/ball-mill-loading-d...

Talk with the Experts at Paul O. Abbe about your process requirements

About Us

Service

Parts

Vacuum Drying

Size Reduction

Mixing & Blending

Home

Request A Quote

Request A Call

Home | Size Reduction Resource Center | Ball Mill Loading - Dry Milling

Ball Mill Loading - Dry Milling

Size Reduction

Steel Ball Mills

Ceramic Lined Ball Mills

Slice Mill

One Piece Ceramic Mill

Pivoting Jar Mills

Jar Rolling Mills

Milling Jars

Size Reduction Resource Center

Size Reduction Links

Milling Discharging

Mill Loading Guidelines

Scaling Up

Milling Capacities

Ball Mill Loading (dry milling)

When charging a ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar u

rolling mill it is important to have the correct amount of media and correct amount o

Charging a Dry Mill The general operation of a grinding mill is to have the produc

between the balls as they tumble. If there are insufficient solids in the mill then the

itself and generate excessive media wear. If too much product then the solid may b

too much. As with most of the independent variable in ball milling it is best to do so

testing and then adjust your parameters. The starting point for ball mill media and s

generally starts as follows:

50% media charge

Assuming 26% void space between spherical balls (non-spherical, irregularl

mixed-size media will increase or decrease the free space)

50% x 26% = 13% free space

Add to this another 10%-15% above the ball charge for total of 23% to 25%

So as a rule of thumb we use 25% solid loading.

Empirical Check: Once the mill has been loaded and run for a few minutes, o

and look down into the mill. You should see some discernible layer of produc

media. If you can actually see the media then is too little solids charge. Most

decrease in volume as the particle size is reduced, so you may have to add m

check the solids volume again after a few hours. Once the quantity is finally

you can simply load the mill with the total amount of solids during the initial

Milling Application Form

Mixing Application Page

Milling Applications

Ceramic Mill Relining and

Refurbishing

Rebuilding and Refurbishing

Downloadable Applications

Help us understand your application

parameters.

20-Feb-15 09:41

Ball Mill Loading - Dry Milling

2 of 3

http://www.pauloabbe.com/size-reduction/resources/ball-mill-loading-d...

Paul O. Abbe | Home | Terms and Conditions | Privacy Policy | Products| Site Map

Member of Process Equipment Manufacturers Association

Member of Process Equipment Manufacturers Association

Members of the International Fine Partical Research Institute

20-Feb-15 09:41

Ball Mill Loading - Dry Milling

3 of 3

http://www.pauloabbe.com/size-reduction/resources/ball-mill-loading-d...

20-Feb-15 09:41

Potrebbero piacerti anche

- Method For Ultra High Purity Gold - Gold Refining ForumDocumento11 pagineMethod For Ultra High Purity Gold - Gold Refining Forummladen lakicNessuna valutazione finora

- Review of Laser-Matter InteractionDocumento29 pagineReview of Laser-Matter Interactionmladen lakicNessuna valutazione finora

- Technical Glass ProductsDocumento3 pagineTechnical Glass Productsmladen lakicNessuna valutazione finora

- Zone Refining. - Gold Refining ForumDocumento4 pagineZone Refining. - Gold Refining Forummladen lakicNessuna valutazione finora

- Optics Communications: Shengli Pu, Min Dai, Guoqing SunDocumento5 pagineOptics Communications: Shengli Pu, Min Dai, Guoqing Sunmladen lakicNessuna valutazione finora

- Dealing With WasteDocumento6 pagineDealing With Wastemladen lakicNessuna valutazione finora

- DocCopper's Copper Electrorefining PageDocumento2 pagineDocCopper's Copper Electrorefining Pagemladen lakicNessuna valutazione finora

- Silver Chloride Dissolution in ARDocumento5 pagineSilver Chloride Dissolution in ARAFLAC ............Nessuna valutazione finora

- Gamma Energy (KeV)Documento4 pagineGamma Energy (KeV)mladen lakicNessuna valutazione finora

- PFA Coating PFA Film - Teflon ™ PFADocumento7 paginePFA Coating PFA Film - Teflon ™ PFAmladen lakicNessuna valutazione finora

- GNS - E-Scrap Yield List v1.0Documento13 pagineGNS - E-Scrap Yield List v1.0Gustavo Cabrera100% (1)

- Contrast Agents TutorialDocumento32 pagineContrast Agents Tutorialmladen lakicNessuna valutazione finora

- X-Ray Fluorescence - WikipediaDocumento10 pagineX-Ray Fluorescence - Wikipediamladen lakicNessuna valutazione finora

- Dealing With WasteDocumento6 pagineDealing With Wastemladen lakicNessuna valutazione finora

- Oxidations With Nickel Peroxide (NICL2 + NAOCL)Documento5 pagineOxidations With Nickel Peroxide (NICL2 + NAOCL)mladen lakicNessuna valutazione finora

- TEMPO Catalyst SystemsDocumento1 paginaTEMPO Catalyst Systemsmladen lakicNessuna valutazione finora

- Carbohydrates: Occurrence, Structures and Chemistry: Rieder IchtenthalerDocumento30 pagineCarbohydrates: Occurrence, Structures and Chemistry: Rieder IchtenthalerAdriano Schindler Freire100% (1)

- Molecules 18 03206Documento21 pagineMolecules 18 03206mladen lakicNessuna valutazione finora

- Urushibara Nickel Eros - Ru003Documento1 paginaUrushibara Nickel Eros - Ru003mladen lakic100% (1)

- Biocinjugate Chemistry Rad Sa KarbonilomDocumento10 pagineBiocinjugate Chemistry Rad Sa Karbonilommladen lakicNessuna valutazione finora

- 4.1. Interaction Light-Matter 2-7-08Documento10 pagine4.1. Interaction Light-Matter 2-7-08mladen lakicNessuna valutazione finora

- Torulaspora Delbrueckii and Conversion To Ephedrine byDocumento4 pagineTorulaspora Delbrueckii and Conversion To Ephedrine bysalvia1025100% (1)

- Electronic Components - NoviteraDocumento2 pagineElectronic Components - Noviteramladen lakicNessuna valutazione finora

- Extraction of Silver From Waste X-Ray Films by Thiosulphate Leaching - IMPS2010-LibreDocumento9 pagineExtraction of Silver From Waste X-Ray Films by Thiosulphate Leaching - IMPS2010-LibredorutzuNessuna valutazione finora

- 1 s2.0 S0304885311007256 MainDocumento13 pagine1 s2.0 S0304885311007256 Mainmladen lakicNessuna valutazione finora

- Recovery of Tin and CopperDocumento9 pagineRecovery of Tin and Coppermladen lakicNessuna valutazione finora

- 04 Juten 19Documento2 pagine04 Juten 19mladen lakicNessuna valutazione finora

- The Manufacture of Chemicals by ElectrolysisDocumento92 pagineThe Manufacture of Chemicals by ElectrolysisJimNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Forging a SwordDocumento3 pagineForging a Swordglen biazonNessuna valutazione finora

- Rotary Kiln Plant: Operating Manual en-D000091-4C-4VDocumento129 pagineRotary Kiln Plant: Operating Manual en-D000091-4C-4Vnima mazaheriNessuna valutazione finora

- Candles 101 BrochureDocumento2 pagineCandles 101 BrochurebroomclosetsacNessuna valutazione finora

- SSPC News Bulletin - July 2020Documento26 pagineSSPC News Bulletin - July 2020JlkKumarNessuna valutazione finora

- Mathematical Model and Factors of Paste Thickener Rake TorqueDocumento5 pagineMathematical Model and Factors of Paste Thickener Rake TorquesaidNessuna valutazione finora

- Ageing Phenomena of CelluloseDocumento9 pagineAgeing Phenomena of CellulosedchyNessuna valutazione finora

- Astm F 442-99Documento7 pagineAstm F 442-99JORGE ARTURO TORIBIO HUERTA100% (2)

- (ENG) Journal-Paint Sludge On IndiaDocumento10 pagine(ENG) Journal-Paint Sludge On IndiaSoebowo AdjinegoroNessuna valutazione finora

- 1 Brain Storm Chemistry Med FinalDocumento7 pagine1 Brain Storm Chemistry Med FinalShudhanshu KumarNessuna valutazione finora

- Tanginl SeawallDocumento12 pagineTanginl SeawallKing LemuelNessuna valutazione finora

- Unistrut Uniper Pipe Support SystemsDocumento24 pagineUnistrut Uniper Pipe Support SystemsmolinachNessuna valutazione finora

- Viscosity of c5h802 - 19Documento1 paginaViscosity of c5h802 - 19CharlesNessuna valutazione finora

- Cooling TowerDocumento12 pagineCooling Towernhalieza1067Nessuna valutazione finora

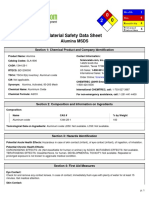

- Msds AluminaDocumento6 pagineMsds AluminayaderNessuna valutazione finora

- Morphology of PolymersDocumento7 pagineMorphology of PolymersYounis Muhsin100% (1)

- Fire Retardant Spray ComparisonDocumento11 pagineFire Retardant Spray Comparisonsteve4goshel100% (1)

- Is Slipperiness: Lubricity LubricationDocumento5 pagineIs Slipperiness: Lubricity LubricationRitik KaushalNessuna valutazione finora

- Org Chem LabDocumento7 pagineOrg Chem LabCriselda CarinoNessuna valutazione finora

- Tribological Analysis of Thin Films by Pin-On-Disc Evaluation of Friction PDFDocumento10 pagineTribological Analysis of Thin Films by Pin-On-Disc Evaluation of Friction PDFDavid Rafael RamírezNessuna valutazione finora

- Praktikum Metal 1Documento27 paginePraktikum Metal 1Muhammad Aldi Luthfi FauzanNessuna valutazione finora

- Miscellaneous Treatment MethodsDocumento25 pagineMiscellaneous Treatment Methodsjong LacNessuna valutazione finora

- Hazardous Waste Board For Outside GateDocumento4 pagineHazardous Waste Board For Outside GateJayant Kumar Jha100% (1)

- Module Outline 2011: Architects Need To Know But Can Never Find. Rockport: MassDocumento5 pagineModule Outline 2011: Architects Need To Know But Can Never Find. Rockport: Massapi-115534435Nessuna valutazione finora

- Block B Drawings (As Built & Retrofitted)Documento20 pagineBlock B Drawings (As Built & Retrofitted)hamapa4070Nessuna valutazione finora

- Effects of Heat Treatments On Steels For Bearing ApplicationsDocumento7 pagineEffects of Heat Treatments On Steels For Bearing ApplicationsAshwani KansaraNessuna valutazione finora

- Fosroc Nitoflor EU5: Constructive SolutionsDocumento3 pagineFosroc Nitoflor EU5: Constructive SolutionsVincent JavateNessuna valutazione finora

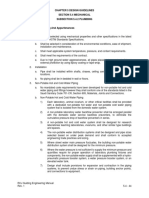

- Chapter 5 Design Guidelines Section 5.4 Mechanical Subsection 5.4.2 PlumbingDocumento4 pagineChapter 5 Design Guidelines Section 5.4 Mechanical Subsection 5.4.2 PlumbingkapsarcNessuna valutazione finora

- 31380112Documento5 pagine31380112Pedro Luis Choque MamaniNessuna valutazione finora

- Lithos: Lan-Chun Huang, Shao-Yong JiangDocumento20 pagineLithos: Lan-Chun Huang, Shao-Yong JiangNguyen tiendungNessuna valutazione finora

- Bremer and Leguil GMBH - RIVOLTA FLG GT-2 - 000000000600663025 - 08!16!2017 - EnglishDocumento9 pagineBremer and Leguil GMBH - RIVOLTA FLG GT-2 - 000000000600663025 - 08!16!2017 - EnglishUsama SaeedNessuna valutazione finora