Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

4EATDiagServ PDF

Caricato da

Йордан ВасилевDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

4EATDiagServ PDF

Caricato da

Йордан ВасилевCopyright:

Formati disponibili

Subaru

4EAT Diagnosis

and Service

Changing the engine oil would seem to

be such a simple procedure. Yet a mistake can yield catastrophic results. The

transmission in the photo above was

being replaced due to a differential failure. The differential failure was not

caused by a part failure, but rather by

operator error. The differential fluid had

been drained during an oil service, rather

than the engine oil. The drained fluid

was not replaced, and a few hundred

miles later, the differential was

destroyed.

This error may have been caused by

unfamiliarity with Subaru vehicles or simple inattentiveness. In any case, its not a

mistake any of us would want to make.

Although we ran this information in an

earlier End Wrench, seeing the destroyed

transaxle drove home the fact that some

technicians still need to be reminded of the

correct service procedures.

When performing an oil change service

on Subaru vehicles, dont confuse the

drain plugs and filters located under the

vehicle. Subaru models produced over the

past several years feature an under-engine

cover. This cover greatly reduces the accumulation of dirt and grime on the engine

and also reduces the overall coefficient of

drag of the vehicle. However, it does limit

the access to the engine oil drain plug and

engine oil filter.

Items to remember when performing

services on Subaru vehicles:

The engine oil filter is located at the

front of the engine.

The engine oil pan and 17 mm oil drain

plug are painted black and are located

directly under the engine above the

under-engine cover.

The engine oil dipstick is located

under the hood, on the front drivers

corner of the engine.

The transmission front differential is

bright aluminum with a gold-colored

21 mm drain plug. This housing is

bolted directly behind the engine and

is filled with GL-5 gear oil.

The differential dipstick is located

under the hood near the firewall, on

the passenger side of the differential

housing.

The transmission pan is black. Its 17

mm drain plug is located on the drivers side of the pan. The drain plug is

normally silver in color, but black

drain plugs have also been installed on

occasion. The transmission is filled

with Genuine Subaru factory

fill AT/PS Fluid P/N SOA868V9240.

1999 and later Subaru vehicles

Continued on page 16.

14

4EAT Diagnosis and Service

Continued on page 18.

equipped with automatic transmissions have a screw-on filter on the drivers side of the transmission. Do not

confuse this with the engine oil filter.

The transmission filter does not

require service under normal conditions.

The automatic transmission fluid dipstick is under the hood, on the drivers

side of the car near the firewall.

All three dipsticks have yellow handles for easy identification.

Always confirm proper lubricant levels

in each unit after performing any service.

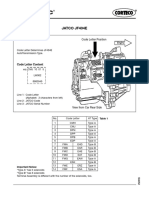

Transmission drain and filter

Engine oil drain plug (engine undercover in place)

Transmission dipstick

End Wrench

Differential drain plug

The

Differential dipstick (4EAT)

16

4EAT Diagnosis and Service

ATF and Differential

Level Inspection

ATF Level

1) Raise the ATF temperature to 60 to

80 degrees C (140 to 176 degrees F)

from 40 to 60 degrees C (104 to 140

degrees F) (when cold) by driving a distance of 5 to 10 km (3 to 6 miles).

Note: The ATF level

varies with fluid temperature. Pay attention

to the fluid temperature

when checking oil level.

Level Gauge

Measuring ATF level

2) Make sure the vehicle is level. After selecting all positions (P, R,

N, D, 3, 2,1), set the

selector lever in P

range. Measure fluid

level with the engine

idling.

Note: After running, idle the engine for

one or two minutes before measurement.

3) If the fluid level is below the center

between upper and lower marks, add

Genuine Subaru factory fill AT/PS Fluid

P/N SOA868V9240 until the fluid level

is found within the specified range

(above the center between upper and

lower marks). When the transmission is

hot, the level should be above the center of upper and lower marks, and when

it is cold, the level should be found

below the center of these two marks.

(32 degrees F is more than 25 minutes).

The time required for the transmission

fluid temperature to rise to 30 degrees C

(86 degrees F) when the atmospheric

temperature is 0 degrees C (32 degrees

F) is approximately eight minutes.

By running the vehicle

The time for the transmission fluid

temperature to rise to 60 degrees C (140

degrees F) with atmospheric temperature of 0 degrees C (32 degrees F) is

more than 10 minutes.

5) Method for checking fluid level upon

delivery or at periodic inspection:

Check fluid level after a warm-up run

of approximately 10 minutes. During

the warm-up period, the automatic

transmission functions can also be

checked.

Differential Gear Oil Level

1) Ensure the vehicle is on a level surface and the parking brake is set.

Note: Do not check the oil level nor add

oil to the case with the front end of the

vehicle raised; this will result in an

incorrect reading of the oil level.

2) Check whether the oil level is

between the upper (FF) and lower (LF)

marks. If it is below the lower limit

mark, add oil until the level reaches the

upper mark.

Oil Level Gauge

4) Time Required to Reach Proper Operating Temperature

By idling the engine

The time required for the transmission fluid temperature to rise to 60

degrees C (140 degrees F) when the

atmospheric temperature is 0 degrees C

Upper

Level

Lower

Level

Measuring differential gear oil level

Oil Leakage

It is difficult to accurately determine the precise position of an oil

leak, since the surrounding area

also becomes wet with oil. The

points listed below should be

checked for fluid leakage. Checking

Continued on page 20.

The

End Wrench

Caution:

Use care not to exceed the upper limit

level.

ATF level varies with temperature.

Remember that the addition of fluid to

the upper limit mark when the transmission is cold will result in the overfilling of fluid.

18

4EAT Diagnosis and Service

method is as follows:

(1) Place the vehicle on a lift, and

check whether the leaking oil is ATF

or not. The ATF is wine red in color,

and can be discriminated easily from

engine oil and gear oil.

(2) Wipe clean the leaking oil and

dust from a suspected area, using a

noninflammable organic solvent such

as carbon tetrachloride.

(3) Run the engine to raise the fluid

temperature, and set the selector

lever to D in order to increase the

fluid pressure and quickly detect a

leaking point. Also check for fluid

leaks while shifting select lever to

R, 2, and 1.

The places where oil seals and gaskets are applied are:

1) Jointing portion of the case

Transmission

case and oil pump

housing jointing

portion

Torque converter clutch case and

oil pump housing

jointing portion

Transmission

case and extension case jointing

portion

Differential gear breather

4) Automatic transmission case

Transmission case (defective casting)

Mating surface of oil pan

O-ring on the test plugs

Oil supply pipe connector

ATF cooler pipe connector and gasket

Oil pan drain plug

O-ring on the transmission harness

holder

Oil pump plugs

ATF breather

Shift lever oil seal

O-ring on the vehicle speed sensor 2

(Front)

O-ring on the turbine revolution sensor

ATF filter oil seal

5) Extension case

Potential mating surface leakage areas

Extension case

3) Oil pump housing

Oil pump housing (defective casting)

O-ring on the test plugs

The

End Wrench

2) Torque converter clutch case

Engine crankshaft oil seal

Torque converter clutch impeller

sleeve oil seal

ATF cooler pipe

connector

Torque converter clutch

Torque converter clutch case

Axle shaft oil

Torque converter clutch case seal

O-ring on the

outside diameter of axle shaft oil seal

holder

O-ring on the differential oil gauge

Differential oil drain plug

Location of steel balls

20

Extension case (defective casting)

O-ring on the vehicle speed sensor 1

(Rear)

Rear drive shaft oil seal

O-ring on the test plugs

Self-Diagnostics

Abnormal Display On AT

Oil Temp Indicator

When any on-board diagnostics

item is malfunctioning, the display on

the AT OIL TEMP indicator light blinks

from the time the malfunction is detected after starting the engine until the

ignition switch is turned OFF. The malfunctioning part or unit can be determined by a trouble code during onboard diagnostics operation. Problems

which occurred previously can also be

identified through the memory function. If the AT OIL TEMP indicator

does not show a problem (although a

problem is occurring), the problem can

be determined by checking the performance characteristics of each sensor

using the Select Monitor. The indicator

signal is as shown in the figure below.

Reading Trouble Codes Using the

Indicator Light

The AT OIL TEMP indicator light

flashes the code corresponding to the

faulty part.

The long segment (1.2 sec on) indicates a ten, and the short segment

(0.2 sec on) signifies a one

Clear Memory

The current trouble codes shown on

the display are cleared by turning the

ignition switch OFF after conducting

on-board diagnostics operation. Previous trouble codes, however, cannot be

cleared since they are stored in the

TCM memory, which is operating on

the back-up power supply. These trouble codes can be cleared by removing

the specified fuse (located under the

right or left lower position of the

instrument panel).

Clear Memory: Removal of No. 4 fuse

(for at least one minute)

The No. 4 fuse is located in the line

to the memory back-up power supply

of the TCM. Removal of this fuse clears

the previous trouble codes stored in the

TCM memory.

Be sure to remove the No. 4 fuse for

at least the specified length of time.

Otherwise, trouble codes may not be

cleared.

Trouble Code Flash Sequence

Trouble Code

Item

Content of Diagnosis

11

Engine speed signal

Detects open or shorted input signal circuit

27

ATF temperature sensor

Detects open or shorted input signal circuit

31

Throttle position sensor

Detects open or shorted input signal circuit

33

Vehicle speed sensor 2 (front)

Detects open or shorted input signal circuit

36

Torque converter turbine

Detects open or shorted input signal circuit

speed sensor

38

Torque control signal

45

Intake manifold pressure signal

Detects open or shorted input signal circuit

Detects open or shorted input signal circuit

71

Shift solenoid 1

Detects open or shorted output signal circuit

72

Shift solenoid 2

Detects open or shorted output signal circuit

73

Low clutch timing solenoid

Detects open or shorted output signal circuit

74

2-4 brake timing solenoid

Detects open or shorted output signal circuit

75

Line pressure duty solenoid

Detects open or shorted output signal circuit

76

2-4 brake duty solenoid

Detects open or shorted output signal circuit

77

Lock-up duty solenoid

Detects open or shorted output signal circuit

79

Transfer duty solenoid

Detects open or shorted output signal circuit

93

Vehicle speed sensor 1 (rear)

Detects open or shorted input signal circuit

21

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- AC Catalogue80Documento859 pagineAC Catalogue80Йордан ВасилевNessuna valutazione finora

- BMW Mini FWD CVTDocumento2 pagineBMW Mini FWD CVTЙордан ВасилевNessuna valutazione finora

- Derale CatalogDocumento32 pagineDerale CatalogЙордан ВасилевNessuna valutazione finora

- Automatic Choice: Filter CatalogueDocumento44 pagineAutomatic Choice: Filter CatalogueЙордан ВасилевNessuna valutazione finora

- 5HP30Documento43 pagine5HP30David Rosado100% (1)

- AC Vehicle IndexDocumento73 pagineAC Vehicle IndexЙордан ВасилевNessuna valutazione finora

- Mercedes Trans 7G Tronic PlusDocumento6 pagineMercedes Trans 7G Tronic PlusEdwin C. Walke100% (1)

- Dorsoduro 1200 ABS-ATC - SM - 2010 - GB - 897263 PDFDocumento408 pagineDorsoduro 1200 ABS-ATC - SM - 2010 - GB - 897263 PDFЙордан ВасилевNessuna valutazione finora

- Blz. 346-349 62TEDocumento4 pagineBlz. 346-349 62TEcmtassoNessuna valutazione finora

- Yamaha FJR 1300 - Service Manual (06) - Inglés PDFDocumento586 pagineYamaha FJR 1300 - Service Manual (06) - Inglés PDFЙордан Василев100% (2)

- AB60E Transmission OperationDocumento1 paginaAB60E Transmission OperationЙордан ВасилевNessuna valutazione finora

- 5HP30 Spare Parts CatalogDocumento46 pagine5HP30 Spare Parts CatalogAlberto VicenteNessuna valutazione finora

- Manual Cambio Automatico SorentoDocumento8 pagineManual Cambio Automatico SorentoDione FreireNessuna valutazione finora

- 54 Mitsubishi 2 R4A51 V4A51 R5A51Documento8 pagine54 Mitsubishi 2 R4A51 V4A51 R5A51Йордан ВасилевNessuna valutazione finora

- 01J & 0AN (Multitronic) : in Line FWD CVT (Electronic Control)Documento3 pagine01J & 0AN (Multitronic) : in Line FWD CVT (Electronic Control)Йордан Василев0% (1)

- 2012 GTR ManualDocumento21 pagine2012 GTR ManualAkrae Acr0% (1)

- JF404EDocumento8 pagineJF404EЙордан Василев50% (6)

- 4eat Late PDFDocumento4 pagine4eat Late PDFЙордан Василев100% (1)

- 04CVT 57Documento11 pagine04CVT 57mklimesh2600Nessuna valutazione finora

- Valve Body and Mechatronic Service PDFDocumento44 pagineValve Body and Mechatronic Service PDFSamuel Zuniga100% (1)

- 04CVT 57Documento11 pagine04CVT 57mklimesh2600Nessuna valutazione finora

- 04CVT 57Documento11 pagine04CVT 57mklimesh2600Nessuna valutazione finora

- 4HP24ADocumento4 pagine4HP24Aruss-porter-7077Nessuna valutazione finora

- 4at Auto Trans PDFDocumento60 pagine4at Auto Trans PDFЙордан ВасилевNessuna valutazione finora

- Transmision Automatica AW 60-40LE Manual de Despiece y ReparacionDocumento3 pagineTransmision Automatica AW 60-40LE Manual de Despiece y ReparacionJose Francisco79% (28)

- 5 L 40 eDocumento2 pagine5 L 40 eLiviu NedaNessuna valutazione finora

- ZF 5hp24Documento46 pagineZF 5hp24Davidoff Red100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Armadio Presentation-2019Documento45 pagineArmadio Presentation-2019Subhash Singh TomarNessuna valutazione finora

- Investigation of Skew Curved Bridges in Combination With Skewed Abutments Under Seismic ResponseDocumento5 pagineInvestigation of Skew Curved Bridges in Combination With Skewed Abutments Under Seismic ResponseEditor IJTSRDNessuna valutazione finora

- Synthesis Essay Coming To Grips With GenesisDocumento11 pagineSynthesis Essay Coming To Grips With Genesisapi-259381516Nessuna valutazione finora

- Adriano Costa Sampaio: Electrical EngineerDocumento3 pagineAdriano Costa Sampaio: Electrical EngineeradrianorexNessuna valutazione finora

- Dairy Products Theory XIIDocumento152 pagineDairy Products Theory XIIDskNessuna valutazione finora

- Raneem AlbazazDocumento33 pagineRaneem AlbazazGordana PuzovicNessuna valutazione finora

- Us Navy To Evaluate Anti Submarine Warfare Training SystemDocumento2 pagineUs Navy To Evaluate Anti Submarine Warfare Training SystemVictor PileggiNessuna valutazione finora

- Course Code:TEX3021 Course Title: Wet Processing Technology-IIDocumento20 pagineCourse Code:TEX3021 Course Title: Wet Processing Technology-IINakib Ibna BasharNessuna valutazione finora

- Tabla de Avances de AcesoriosDocumento3 pagineTabla de Avances de AcesoriosPedro Diaz UzcateguiNessuna valutazione finora

- Test09 Eoc Algebra2 ReducedDocumento33 pagineTest09 Eoc Algebra2 ReducedkristymadimikeNessuna valutazione finora

- Quartile1 PDFDocumento2 pagineQuartile1 PDFHanifah Edres DalumaNessuna valutazione finora

- Lima Indiana Oil FieldDocumento32 pagineLima Indiana Oil FieldCHARLES PATULAYNessuna valutazione finora

- Rectifier 5G High Density Embedded Power (3U Power Rack, Three Phase Four Wire) E...Documento4 pagineRectifier 5G High Density Embedded Power (3U Power Rack, Three Phase Four Wire) E...Lintas LtiNessuna valutazione finora

- 15 Benefits of CyclingDocumento8 pagine15 Benefits of CyclingJoycs PintoNessuna valutazione finora

- Tokyo Guidelines 2018Documento115 pagineTokyo Guidelines 2018Alik Razi100% (1)

- Wcdma Idle Mode (Ericsson)Documento29 pagineWcdma Idle Mode (Ericsson)Hosein ShahbaziNessuna valutazione finora

- Valdez, Shenny RoseDocumento3 pagineValdez, Shenny Roseyeng botzNessuna valutazione finora

- SOPDocumento16 pagineSOPjerome marquezNessuna valutazione finora

- Coffee Quality Manual by Abra Rand Nig Use IDocumento25 pagineCoffee Quality Manual by Abra Rand Nig Use IIpungNessuna valutazione finora

- Iodide and Bromide Ions in Brackish Water, Seawater, and Brines D 3869 - 04Documento12 pagineIodide and Bromide Ions in Brackish Water, Seawater, and Brines D 3869 - 04stevgonNessuna valutazione finora

- B737-3 ATA 23 CommunicationsDocumento112 pagineB737-3 ATA 23 CommunicationsPaul RizlNessuna valutazione finora

- Atomic St. Package PDFDocumento28 pagineAtomic St. Package PDFSatvik RaoNessuna valutazione finora

- Diagnostic Imaging of The Pharynx and Esophagus: Key PointsDocumento33 pagineDiagnostic Imaging of The Pharynx and Esophagus: Key PointsChutcharwan JintasoponNessuna valutazione finora

- 9A02502 Transmission of Electric PowerDocumento6 pagine9A02502 Transmission of Electric PowersivabharathamurthyNessuna valutazione finora

- Region 1 - Concreting Works Materials Prices - PHILCON PRICESDocumento9 pagineRegion 1 - Concreting Works Materials Prices - PHILCON PRICESMark Gregory RimandoNessuna valutazione finora

- EDS-A-0101: Automotive Restricted Hazardous Substances For PartsDocumento14 pagineEDS-A-0101: Automotive Restricted Hazardous Substances For PartsMuthu GaneshNessuna valutazione finora

- 500 TransDocumento5 pagine500 TransRodney WellsNessuna valutazione finora

- Chapter 7 Dopant Diffusion - IDocumento32 pagineChapter 7 Dopant Diffusion - I강준호Nessuna valutazione finora

- Ujian 1 THN 4Documento13 pagineUjian 1 THN 4Che Shuk ShukaNessuna valutazione finora

- Indoor Air Quality Standard Procedures - 2014 RevDocumento12 pagineIndoor Air Quality Standard Procedures - 2014 RevFioriAmeliaHathawayNessuna valutazione finora