Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

PD-0100-0034 - Rev - A Hogen H Eng

Caricato da

geofaxxxxxxTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

PD-0100-0034 - Rev - A Hogen H Eng

Caricato da

geofaxxxxxxCopyright:

Formati disponibili

PD-0100-0034

REVISION A

HOGEN H SERIES

HYDROGEN GENERATOR

Installation & Operation Manual

==================== Hydrogen By Wire ======================

PROTON, HOGEN, Hydrogen by Wire, and Transforming EnergyTM are trademarks or registered trademarks of Proton Energy Systems, Inc.

2003 Proton Energy Systems, All Rights Reserved

HOGEN H Series Hydrogen Generator

Installation & Operation Manual

HOGEN H Series Hydrogen Generator

Installation & Operation Manual

Output:

2, 4, 6 NM3/Hour

Serial Number: ___________________

January 2007

Proton Energy Systems, Inc.

10 Technology Drive

Wallingford, CT 06492

(203) 949-8697

www.protonenergy.com

customerservice@protonenergy.com

SIC 3569-901

NAICS 333-999-8556

Gas Generating Equipment

Gas Generating Equipment

This document is the property of Proton Energy Systems, Inc. and is delivered on the express condition that it is

not to be disclosed, reproduced in whole or in part, or used for any purpose other than the operation and

servicing of the HOGEN H Series hydrogen generator without Proton Energy Systems, Inc written consent and

that no right is granted to disclose or so use any information contained in said document. This restriction does

not limit the right to use information obtained from another source.

PD-0100-0034 REV A

CONFIDENTIAL Do not copy

Page 2 of 90

HOGEN H Series Hydrogen Generator

Installation & Operation Manual

HOGEN H Series Hydrogen Generator

INSTALLATION & OPERATION MANUAL

Prepared by

PROTON ENERGY SYSTEMS, INC.

CONTENTS

1

Introduction .......................................................................................................................................... 8

1.1

Key Definitions, Acronyms, and Abbreviations Used in this Document .................................. 10

1.2

General Description................................................................................................................... 11

1.3

Classification of the HOGEN Hydrogen Generator .................................................................. 12

1.4

Subsystems ................................................................................................................................ 13

1.4.1

Water and Oxygen Management Subsystem ................................................................... 13

1.4.2

Hydrogen Gas Management Subsystem .......................................................................... 14

1.4.3

Control and Power Distribution ....................................................................................... 14

1.5

Enclosure................................................................................................................................... 15

1.5.1

Fluids Enclosure .............................................................................................................. 15

1.5.2

Electrical Enclosure ......................................................................................................... 15

1.5.3

Enclosure Integrity........................................................................................................... 16

1.6

2

Product Specification ................................................................................................................ 17

Safety................................................................................................................................................... 19

2.1

General Information .................................................................................................................. 19

2.2

Using Hydrogen Gas ................................................................................................................. 19

2.3

References ................................................................................................................................. 20

Installation .......................................................................................................................................... 21

3.1

Top-Level Steps of Installation ................................................................................................. 22

3.2

Facility Air Ventilation Requirements ...................................................................................... 22

3.3

Operating Environment ............................................................................................................. 25

3.4

Site Preparation ......................................................................................................................... 25

3.5

Instructions on Unpacking the HOGEN Hydrogen Generator .................................................. 27

3.6

Lifting and Moving ................................................................................................................... 28

3.7

Anchoring Instructions .............................................................................................................. 30

3.8

Electrical Interfaces................................................................................................................... 31

3.8.1

Cabling Procedure............................................................................................................ 31

3.8.2

Remote Alarm Contact and Shutdown Connections........................................................ 34

3.9

Mechanical Interfaces................................................................................................................ 35

PD-0100-0034 REV A

CONFIDENTIAL Do not copy

Page 3 of 90

HOGEN H Series Hydrogen Generator

Installation & Operation Manual

3.9.1

3.9.2

3.9.3

3.9.4

3.9.5

3.9.6

3.9.7

Physical Layout, Connections and Dimensions ............................................................... 36

Hydrogen Vent Interface.................................................................................................. 38

Vent Line Installation ...................................................................................................... 39

Product Hydrogen Interface ............................................................................................. 39

Air Dilution Interface and Integrated Oxygen Disposal .................................................. 40

Coolant Water Interfaces ................................................................................................. 41

Feed Water Interfaces ...................................................................................................... 43

3.10

Connecting the Cell Stack(s) ..................................................................................................... 46

3.11

Calibration Gas Cylinder Installation ........................................................................................ 51

3.12

Inlet and Exit (Optional) Air Filter Housing Installation .......................................................... 51

3.13

External Shroud Installation (Optional) .................................................................................... 55

3.14

Guard Bed Installation Instructions........................................................................................... 57

3.15

First Time Startup Instructions .................................................................................................. 58

3.15.1

High-Powered Connection Torque Requirements ........................................................... 58

3.16

Remote Monitoring Software Installation ................................................................................. 59

3.16.1

Network Specifications.................................................................................................... 62

3.16.2

Cabling............................................................................................................................. 62

3.17

Configuring the System for Network Interface ......................................................................... 63

3.17.1

Resetting Network Settings.............................................................................................. 63

3.18

LAN Installation........................................................................................................................ 66

3.18.1

PC Parameters.................................................................................................................. 66

3.18.2

LAN Configuration Instructions ...................................................................................... 67

3.18.3

Electrical Connections for LAN Installation.................................................................... 69

3.19

Remote Monitoring Setup ......................................................................................................... 69

3.19.1

Remote Software Monitoring Feature.............................................................................. 69

3.19.2

Data Logging Feature ...................................................................................................... 70

3.20

4

Remote Monitoring Upgrade Instructions ................................................................................. 72

Operation ............................................................................................................................................ 74

4.1

Operating Modes ....................................................................................................................... 74

4.1.1

Normal Mode................................................................................................................... 74

4.1.2

Service Mode ................................................................................................................... 74

4.1.3

Keys ................................................................................................................................. 74

4.2

Pre-Start Startup Instructions .................................................................................................... 75

4.3

Applying Power......................................................................................................................... 75

4.4

Control Panel............................................................................................................................. 76

4.5

Generating Hydrogen ................................................................................................................ 77

4.6

Manual Shutdown...................................................................................................................... 78

4.7

Automatic Shutdown................................................................................................................. 79

User Interface ..................................................................................................................................... 82

5.1.1

LCD Display Areas.......................................................................................................... 82

5.1.2

Display Screens................................................................................................................ 82

APPENDIX A: Options ....................................................................................................................... 83

PD-0100-0034 REV A

CONFIDENTIAL Do not copy

Page 4 of 90

HOGEN H Series Hydrogen Generator

Installation & Operation Manual

6.1

Pressure Reducing Regulator Option ........................................................................................ 83

6.2

Coolant Isolation Kit Option (Installed) .................................................................................... 84

6.3

Dewpoint Transmitter Option.................................................................................................... 84

6.4

Backup Manifold Auto Crossover Option................................................................................. 85

6.5

Combustible Gas Sensor Assembly Option............................................................................... 85

6.6

Lab Purity Option...................................................................................................................... 86

6.7

StableFlowTM Performance Optimization Option...................................................................... 86

APPENDIX B: Installation Checklist.................................................................................................. 88

LIST OF FIGURES

Figure 1 HOGEN H Series Hydrogen Generator .......................................................................................... 8

Figure 2 HOGEN H Series Interface Connections....................................................................................... 11

Figure 3 HOGEN H Series Hydrogen Generator WOMS Piping and Instrumentation Document (P&ID). 13

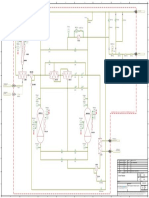

Figure 4 HOGEN H Series Hydrogen Generator HGMS P&ID.................................................................. 14

Figure 5 HOGEN H Series Hydrogen Generator Interface Connections .................................................... 21

Figure 6 HOGEN H Series Hydrogen Generator Plan View for Installation .............................................. 26

Figure 7 Removing Bolt from the Shipping Beam ........................................................................................ 27

Figure 8 Additional Beam Location ............................................................................................................. 28

Figure 9 Removing Screws from Bottom Front Panel.................................................................................. 28

Figure 10 Removing Base Fastener Cover Plate ......................................................................................... 29

Figure 11 Lifting the Unit using a Forklift................................................................................................... 29

Figure 12 Anchoring Diagram ..................................................................................................................... 30

Figure 13 Anchoring Holes .......................................................................................................................... 30

Figure 14 Electrical Interface Locations ..................................................................................................... 31

Figure 15 Internal Power and Ground Connections.................................................................................... 32

Figure 16 HOGEN H Series Hydrogen Generator Electrical Interface Locations...................................... 33

Figure 17 Remote Alarm Relay Location ..................................................................................................... 34

Figure 18 Terminals to Wire External Contacts .......................................................................................... 35

Figure 19 TB 3 Location .............................................................................................................................. 35

Figure 20 Left Side View

Figure 22 Front View

Figure 21 Right Side View............................................................................. 36

Figure 23 3-D View .............................................................................. 36

Figure 24 HOGEN H Series Hydrogen Generator Interface Connections .................................................. 37

Figure 25 Condensate Drain Trap Flow ...................................................................................................... 39

Figure 26 Product Hydrogen Interfaces....................................................................................................... 40

Figure 27 Coolant Water Interfaces............................................................................................................. 41

Figure 28 TB 4 Location .............................................................................................................................. 42

PD-0100-0034 REV A

CONFIDENTIAL Do not copy

Page 5 of 90

HOGEN H Series Hydrogen Generator

Installation & Operation Manual

Figure 29 TB4 Wiring Locations.................................................................................................................. 42

Figure 30 DI Water Feed Port ..................................................................................................................... 43

Figure 31 Water Feed Valve on Bulkhead ................................................................................................... 45

Figure 32 A200 Tank with Bungee Cord...................................................................................................... 46

Figure 33 Removing the Tie Wrap from the Cell Stack Outlet Fitting ......................................................... 47

Figure 34 Removing the Cap from the Cell Stack Outlet Fitting ................................................................. 47

Figure 35 Tightening the Outlet Fitting on Cell Stack A.............................................................................. 48

Figure 36 Cell Stack and Connection Locations .......................................................................................... 49

Figure 37 Calibration Gas Cylinder Installation ......................................................................................... 51

Figure 38 Filter Element .............................................................................................................................. 52

Figure 39 Removing the Screws ................................................................................................................... 52

Figure 40 Removing the Filter Retaining Clip ............................................................................................. 53

Figure 41 Filter Housing Installed on the HOGEN H Series Hydrogen Generator .................................... 53

Figure 42 Sliding Air Filter into Filter Housing .......................................................................................... 54

Figure 43 Reinstalling Filter Retaining Clip................................................................................................ 54

Figure 44 Installing Screws.......................................................................................................................... 55

Figure 45 Sliding External Shroud over Filter Housing .............................................................................. 55

Figure 46 Tightening Screw on Top of External Shroud.............................................................................. 56

Figure 47 Guard Bed Filter Cartridge and Housing ................................................................................... 57

Figure 48 Guard Bed Cartridge inside Guard Bed Housing ....................................................................... 57

Figure 49 Tightening the Filter Housing...................................................................................................... 58

Figure 50 First Screen in Installation Wizard.............................................................................................. 60

Figure 51 Second Screen in Installation Wizard .......................................................................................... 60

Figure 52 Installation of Software Screen.................................................................................................... 61

Figure 53 Installation Initializing Screen..................................................................................................... 61

Figure 54 Installation Completed Screen..................................................................................................... 62

Figure 55 Ethernet Cable Pinout ................................................................................................................. 63

Figure 56 Server IP Address Location ......................................................................................................... 64

Figure 57 Choosing Settings ........................................................................................................................ 64

Figure 58 Select Set Config Params............................................................................................................. 65

Figure 59 Configuration Parameters Menu ................................................................................................. 65

Figure 60 Remote Monitoring Wiring .......................................................................................................... 66

Figure 61 HCS Monitoring Folder Location................................................................................................ 67

Figure 62 Support Files Folder Location..................................................................................................... 68

Figure 63 MODBUS TCP Configuration.ini Location................................................................................. 68

PD-0100-0034 REV A

CONFIDENTIAL Do not copy

Page 6 of 90

HOGEN H Series Hydrogen Generator

Installation & Operation Manual

Figure 64 IP Address Location .................................................................................................................... 69

Figure 65 Default Screen ............................................................................................................................. 70

Figure 66 Enable/Disable Switch for Data Logging Feature ...................................................................... 71

Figure 67 .CSV File Example....................................................................................................................... 71

Figure 68 Data Log Example in Excel ......................................................................................................... 71

Figure 69 Uninstall Wizard.......................................................................................................................... 72

Figure 70 System Uninstalling Software ...................................................................................................... 73

Figure 71 Uninstall Process Completed....................................................................................................... 73

Figure 72 Control Panel Overview .............................................................................................................. 74

Figure 73 LCD Display Areas...................................................................................................................... 82

Figure 74 Example Schematic of the Pressure Reducing Regulator ............................................................ 83

Figure 75 Coolant Isolation Option Installed .............................................................................................. 84

Figure 76 Dewpoint Transmitter.................................................................................................................. 84

Figure 77 Backup Manifold Auto Crossover................................................................................................ 85

Figure 78 Combustible Gas Sensor Assembly.............................................................................................. 85

Figure 79 Lab Purity Kit .............................................................................................................................. 86

Figure 80 StableFlow Process ..................................................................................................................... 87

LIST OF TABLES

Table 1 HOGEN H Series Specifications ..................................................................................................... 18

Table 2 HOGEN H Series Hydrogen Generator Interface Connections ...................................................... 21

Table 3 Electrical Interface Connections Reference Dimensions ................................................................ 33

Table 4 Materials to Avoid Contact with DI Water Feed............................................................................. 44

Table 5 Preferred Materials in Contact with DI Water Feed....................................................................... 44

Table 6 High-Powered Connection Torque Requirements........................................................................... 59

Table 7 Network Specifications .................................................................................................................... 62

Table 8 Standard Ethernet Cable Wiring Connections for Normal and Crossover Cables ......................... 62

Table 9 Controller Default Network Settings ............................................................................................... 63

Table 10 Recommended Computer Network Settings................................................................................... 63

Table 11 Error and Warning Codes ............................................................................................................. 81

Table 12 Pressure Drop Data for Pressure Reducing Regulator................................................................. 83

PD-0100-0034 REV A

CONFIDENTIAL Do not copy

Page 7 of 90

HOGEN H Series Hydrogen Generator

Installation & Operation Manual

1 INTRODUCTION

The HOGEN H Series industrial hydrogen generator (see Figure 1) is a Proton Exchange

Membrane, or PEM, water electrolysis system packaged for rapid onsite installation and

ease of use. Configured with up to three PEM stacks, the HOGEN H Series hydrogen

generator is designed to deliver up to 6 NM3/h (228 SCFH) of 99.9995 percent pure

hydrogen at a maximum pressure of 15 barg (225 psig). The HOGEN H Series hydrogen

generator may be configured with one, two, or three cell stacks to meet customer

hydrogen need through the range of 0 to 6 NM3/h. Hydrogen generation is continuously

available and follows customer demand as long as power and deionized, or DI, water are

available. The HOGEN H Series hydrogen generator is designed to operate in a wellventilated, non-classified, indoor environment.

Proton Energy Systems, Inc. (PROTON) has provided these instructions to guide the

installation and operation of a HOGEN H Series hydrogen generator. These instructions

provide technical product information, installation requirements, detailed mechanical and

electrical interface specifications, and operating instructions. Important safety

information is also included in this manual. Please take time to familiarize yourself with

the system and the manual.

IT IS THE CUSTOMERS RESPONSIBILITY TO CONSULT WITH THE

LOCAL AUTHORITY HAVING JURISDICTION (AHJ) REGARDING LOCAL

CODE REQUIREMENTS FOR INSTALLATION AND OPERATION OF THIS

EQUIPMENT.

DO NOT USE THE HOGEN H SERIES HYDROGEN GENERATOR IN A

MANNER NOT SPECIFIED BY PROTON ENERGY SYSTEMS.

Fluids

Compartment

Electronics

Compartment

Figure 1 HOGEN H Series Hydrogen Generator

PD-0100-0034 REV A

CONFIDENTIAL Do not copy

Page 8 of 90

HOGEN H Series Hydrogen Generator

Installation & Operation Manual

This manual attempts to answer most of the frequently asked questions with regards to

the installation and operation of the unit. However, should you have any questions, the

PROTON technical staff stands ready to answer them and support the successful

deployment of this equipment. Please call (203) 949-8697 and ask for technical service

support or email customerservice@protonenergy.com. Please have the model number

and serial number of your unit available.

PROTON offers a full range of installation and training services. Contact PROTON

Customer Service at 203-949-8697 or your local service provider/supplier for more

information.

If freezing conditions exist at your site, you must take measures to prevent

condensation from freezing and obstructing the H2 vent line and freezing the water

supply and drain lines.

After performing any service or maintenance work, make sure the doors to the

enclosure are completely closed prior to the startup operation of your generator.

Do not remove or install the flash card provided with the unit while the unit is

powered.

It is the customers responsibility to organize a backup hydrogen supply to bridge critical

times during maintenance and service.

PD-0100-0034 REV A

CONFIDENTIAL Do not copy

Page 9 of 90

HOGEN H Series Hydrogen Generator

Installation & Operation Manual

1.1 Key Definitions, Acronyms, and Abbreviations Used in this

Document

PROTON Proton Energy Systems, Inc.

ASME American Society of Mechanical Engineers

NM3/h - Normal cubic meter per hour (International Normal conditions are 1.01325 bar

and 0 Celsius)

SCFH - Standard cubic foot per hour (US Standard conditions for air are 14.7 psia and

70F)

Bar - 14.5 PSI or 100 KPa (KiloPascals or Newton/cm), a unit of system pressure.

Standard atmosphere = 1.01325 bar = 14.696 psi

PSI - Pounds force per square inch (lbf /in2=6894.7 Pa), a unit of pressure

L/m - Liters per minute flow (for hydrogen, calculated at normal conditions)

cc - Cubic centimeter

KW - Kilowatt;

KVA - Kilovolt-ampere

S/cm - MicroSiemen per centimeter, a measure of water conductivity

HOGEN - Registered TM of Proton Energy Systems Inc. for packaged water

electrolysis based hydrogen generators

FNPT Female National Pipe Thread

NPT National Pipe Thread

NFPA National Fire Protection Association, a Standards Organization

CPI Chemical Process Instrumentation

VDC Volts Direct Current

VAC Volts Alternating Current

NEC National Electric Code, NFPA 70

LAN Local Area Network

HGMS Hydrogen Gas Management Subsystem

WOMS Water/Oxygen Management Subsystem

UI User Interface

HCS H Series Control System

PSU Power Supply Unit

- Notes contain helpful suggestions or references.

- Indicates a potentially hazardous situation, which, if not avoided, may result in minor or

moderate injury. It may also be used to alert against unsafe practices. This could result

in equipment damage or loss of data.

- Indicates a potentially hazardous situation, which, if not avoided, could result in death

or serious injury.

PD-0100-0034 REV A

CONFIDENTIAL Do not copy

Page 10 of 90

HOGEN H Series Hydrogen Generator

Installation & Operation Manual

1.2 General Description

The HOGEN H Series hydrogen generator is a fully integrated, packaged

electrolysis system that produces high purity hydrogen from water and electricity.

The system includes up to three electrolyzer cell stacks, as well as the support

systems necessary for regulating electrolyzing operations and pressurizing

hydrogen. The support systems are used to aid in the functions of the system:

circulating water, drying hydrogen, cabinet dilution, liquid cooling and shutting

down the system. The unit contains all of the required sensors and controls to aid

in monitoring the safety, performance and automatic operation of the system and

to allow for optional remote monitoring and diagnostics. The unit is designed to

operate in a well-ventilated, non-hazardous (non-classified), indoor environment.

The recommended customer supplied interfaces are outlined in Figure 2.

Figure 2 HOGEN H Series Interface Connections

PD-0100-0034 REV A

CONFIDENTIAL Do not copy

Page 11 of 90

HOGEN H Series Hydrogen Generator

Installation & Operation Manual

1.3 Classification of the HOGEN Hydrogen Generator

The HOGEN H Series hydrogen generator is a source of hydrogen, a combustible

gas. When the unit is running, it can convert water to hydrogen and oxygen.

When it is not running, the production of the combustible gas, hydrogen, stops.

Protection against the ignition of a potentially explosive atmosphere inside the

generator is accomplished using basic protection techniques described in NFPA

69, Standard on Explosion Prevention Systems and EN 1127-1, Explosive

atmospheres Explosion prevention and protection Part 1: Basic concepts and

methodology.

The primary protection used is containment of the hydrogen. It is contained as

much as possible inside the plumbing in the generator and is not allowed to mix

with air to form a potentially explosive atmosphere.

Dilution is the second protection. A blower moves air through the section of the

enclosure where the hydrogen is generated at a rate sufficient to dilute the largest

credible hydrogen leak to a level below the lower flammable limit (LFL) of

hydrogen. The dilution rate is enough to reduce the area classification inside this

section of the enclosure to non-hazardous (Zone 2 NE [negligible extent]). This is

confirmed using analysis and testing per IEC 60079-10. Additionally, the power

source that drives hydrogen generation is interlocked by sensor(s) that confirm the

operation of the dilution blower.

The third protection that is provided is the elimination of ignition sources in any

potentially explosive atmospheres inside the generator. All of the internal power

distribution equipment and as many other electrical components as possible are

located in a separate section of the enclosure that is sealed from the section where

the hydrogen is generated. The electrical components that remain in the hydrogen

generation section are located outside any dilution zones. Again, this is

confirmed using analysis and testing per IEC 60079-10.

TUV Rheinland, an independent third party testing agency that is both an NRTL

for the U.S. and Canada (like UL and CSA) and a Notified Body for the European

Union, reviewed this approach to protection against potentially explosive

atmospheres. The agency expressed their opinion stating that the H Series

hydrogen generator employs primary protection means against potentially

explosive atmospheres in the generator and that, since the generator is not

designed to be placed inside a (existing) potentially explosive atmosphere, no

additional certification or approval is required.

As noted above, one of the primary protections against possible explosion is

dilution with air. For this to be effective it is essential that the source of the air be

non-hazardous (non-classified). Consequently, if fresh (non-hazardous) air is

PD-0100-0034 REV A

CONFIDENTIAL Do not copy

Page 12 of 90

HOGEN H Series Hydrogen Generator

Installation & Operation Manual

supplied as required, the exhaust from the generator is non-hazardous as any

hydrogen is diluted below the LFL. Therefore, due to the extent of the previously

mentioned protection and prevention of explosive atmospheres, the hydrogen

generator does not change the area classification of the area it is installed.

1.4 Subsystems

1.4.1 Water and Oxygen Management Subsystem

The Water and Oxygen Management Subsystem (WOMS) (see Figure 3)

separates a two-phase mixture of oxygen gas and water from the electrolysis cell

stacks. The oxygen may normally contain up to 0.5 percent hydrogen by volume.

A combustible gas sensor (P&ID Tag CG220) monitors percent LEL of hydrogen

in oxygen. In the event of a failure, the system shuts down if 50 percent LEL is

detected. The WOMS subsystem:

Minimizes Evaporation

Allows Draining of Water

Maintains and Monitors Water Quality

Manages Water Inventory

Prevents/Accommodates Hazard from Cell Stack Failure

Accepts Two-Phase Water and Hydrogen Stream from the Hydrogen

Management System (HGMS)

Delivers Cooled and Filtered Water Streams to the Three Cell Stacks

Rejects Heat via a Process Water Interface

Vents Oxygen

Figure 3 HOGEN H Series Hydrogen Generator WOMS Piping and Instrumentation Document

(P&ID)

PD-0100-0034 REV A

CONFIDENTIAL Do not copy

Page 13 of 90

HOGEN H Series Hydrogen Generator

Installation & Operation Manual

1.4.2 Hydrogen Gas Management Subsystem

The Hydrogen Gas Management Subsystem (HGMS) (see

Figure 4) separates product hydrogen from water and delivers high purity dry

hydrogen product at pressure. The HGMS subsystem:

Accepts a Two-Phase Pressurized Hydrogen/Water Stream

Delivers a Single-Phase Hydrogen Gas Stream of at Least 99.999 Percent

Purity

Delivers a Liquid Water Stream (Which typically includes Dissolved

Hydrogen Gas) to the WOMS

Figure 4 HOGEN H Series Hydrogen Generator HGMS P&ID

1.4.3 Control and Power Distribution

The controls affect the automatic startup, product delivery rate, safety monitoring,

and operational control for all modes of operation. The control system:

Provides an Easy-to-Use User Interface for Equipment Operators, Service,

and Maintenance Personnel

Provides Optional Remote Monitoring, Diagnostics, Service, and Remote

Operation Functions

Provides a Safety Circuit, Including Pressure Monitoring and Cutoff

Switches such as E-Stop, Flood, and Main Disconnect, to De-Energize

Circuits in Process Enclosure for Type X Pressurization Per NFPA 496

PD-0100-0034 REV A

CONFIDENTIAL Do not copy

Page 14 of 90

HOGEN H Series Hydrogen Generator

Installation & Operation Manual

1.5 Enclosure

The enclosure element of the HOGEN H Series hydrogen generator:

Protects the Internal Elements of the Generator from Shipment Damage

and the Environment

Provides Structural Mounting and Support

Consists of both Fluids and Electrical Enclosures and Optional Filter

Housing and Shrouds

Prevents Unauthorized Access

1.5.1 Fluids Enclosure

The fluids enclosure largely contains the following elements and provides the

listed functions:

Dilution Blower, Cell Stacks, WOMS, and HGMS

Bulkhead with Requisite Fluid Interconnect Locations

Dilutes and Disposes Vents of Waste Oxygen via Air Flow

Provides Dilution to Reduce Internal Environment to Non-Hazardous

(Non-Classified) Per IEC 60079-10

CONTACT WITH HIGH VOLTAGE MAY RESULT IN DEATH OR SERIOUS

INJURY.

1.5.2 Electrical Enclosure

The electrical enclosure provides the necessary input and output electrical

connections and top-level control.

The electrical enclosure contains elements that:

Provide DC Power to the Cell Stacks based upon Hydrogen Requirements

Include Test Points for Diagnostic Purposes

Provide Control to the Various Subsystems

Provide a User Interface Panel for Unit Operation

Provide 380-480 VAC Power to Pump, Blower and 24 VDC Power

Supply

Provide 24 VDC to Control Circuits and Cell Stack Power Supply Fans

CONTACT WITH HIGH VOLTAGE MAY RESULT IN DEATH OR SERIOUS

INJURY.

PD-0100-0034 REV A

CONFIDENTIAL Do not copy

Page 15 of 90

HOGEN H Series Hydrogen Generator

Installation & Operation Manual

1.5.3 Enclosure Integrity

Visually inspect the enclosure element for any signs of damage, particularly if it is

subject to direct impact or wet conditions. Please keep water, dust and other

foreign particles out of the enclosure area. Also, verify that the seals on the doors

and panels are not compromised or damaged. Contact PROTON or your local

service provider/supplier with questions.

PD-0100-0034 REV A

CONFIDENTIAL Do not copy

Page 16 of 90

HOGEN H Series Hydrogen Generator

Installation & Operation Manual

1.6 Product Specification

Hydrogen Production

Net Production Rate

Delivery Pressure Nominal

Power Consumed/Volume of Hydrogen

Gas Produced

Purity

Concentration of Impurities:

Turndown Range

Upgradeability

DI Water Requirement

Rate at Max Consumption Rate

1.83 L/hr

3.66 L/hr

5.50 L/hr

.50 gal/hr

.96 gal/hr

1.42 gal/hr

5 C to 50 C

41 F to 122 F

1.5 to 4 barg

21.8 to 58.0 PSIG

ASTM Type II Deionized Water Required (< 1 micro Siemen/CM)

ASTM Type I Deionized Water Preferred (< 0.1 micro Siemen/CM)

Temperature

Pressure

Input Water Quality

Heat Load and Coolant Requirement

Cooling

Heat Load from System

Coolant

Electrical Specifications

Recommended Breaker Rating

Electrical Specification

Interface Connections

H2 Product Port

H2/H2O Vent Port

DI Water Port

Calibration-Gas Port

Cooling Supply Port

Cooling Return Port

Drain Port

Electrical

Communications

PD-0100-0034 REV A

H 2m

H 4m

H 6m

3

3

2 Nm /h

4 Nm /h

6 Nm3/h

76 SCF/hr

152 SCF/hr

228 SCF/hr

15 barg

225 PSIG

8.3 kWh/Nm3

7.0 kWh/Nm3

6.8 kWh/Nm3

3

3

21.2 kWh/100 ft

18.5 kWh/100 ft

17.8 kWh/100 ft3

99.9995 Percent

Water Vapor < 5 PPM Water (-65 C/ -85 F Dewpoint)

N2 < 2 PPM, O2 < 1 PPM, All Others Undetectable

0 to 100 Percent Net Product Delivery

N/A

Field Upgradeable to Field Upgradeable to

a Max of 6 Nm3/h

a Max of 6 Nm3/h

(228 SCF/hr)

(228 SCF/hr)

Liquid-Cooled

8.1 kW Max

16.1 kW Max

23.7 kW Max

0 to 50 Percent Anti-Freeze, Non-Fouling

1.4 to 6.9 barg (20 to 100 PSIG)

5 C to 35 C (41 F to 95 F)

15 to 87 L/min (4 to 23 GPM), Depends on Model and Coolant

Temperature

22 kVA

40 kVA

380 - 480 VAC, 3 Phase, 50 - 60 Hz

58 kVA

CPI Compression Tube Fitting, SS

FNPT, SS

FNPT, SS

1/8 FNPT, Brass

1 FNPT, Brass

1 FNPT, Brass

3/8 FNPT, Brass

Connect to On-Board Circuit Breaker

Ethernet

CONFIDENTIAL Do not copy

Page 17 of 90

HOGEN H Series Hydrogen Generator

Installation & Operation Manual

Control Systems

Standard Features

H 2m

H 4m

H 6m

Fully Automated, Push Button Start/Stop, E-Stop. On-Board H2

Detection. Automatic Fault Detection and System Depressurization.

Form C Relay (5A, 250V, 150W Max Rated Switching)

Safety Circuit Trip

Remote Alarm

Remote Shutdown

Enclosure Characteristics

Dimensions (L x D x H)

180 cm x 80 cm x 180 cm

71 x 32 x 71

700 kg

747 kg

794 kg

1500 lbs

1600 lbs

1700 lbs

IP43 for Fluids Compartment; Upgradeable to IP55; IP66 for

Electronics Compartment.

Weight

Rating

Environmental Considerations

Standard Siting Location

Storage/Transport Temperature

Ambient Temperature Range

Altitude Range Sea Level to:

Ventilation

Safety and Regulatory Conformity

Cabinet Ventilation with Environment

Noise

dB(A) at 1 Meter

Approvals

Options

Indoor, Level 1, 0 to 90 Percent RH Non-Condensing, NonHazardous/Non-Classified Environment

5 C to 60 C

41 F to 140 F

5 C to 50 C

41 F to 122 F

2400 m

7874 ft

Proper Ventilation must be Provided from a Non-Hazardous Area at

a Rate in Accordance with IEC60079-10, Zone 2 NE

NFPA 69 and EN 1127-1, Clause 6.2

Vent Fan Draws Fresh Air up to 28 Nm3/min

1000 ft3/min

< 83

NYFD Approval Pending

PROTON offers a wide range of options to tailor your HOGEN

hydrogen generation system to meet your specific operational

requirements. Please contact your local Proton Energy

representative to discuss the current list of options available to best

fit your needs.

Table 1 HOGEN H Series Specifications

Specifications are subject to change. Consult factory for latest spec and tolerances on

figures specified without ranges.

PD-0100-0034 REV A

CONFIDENTIAL Do not copy

Page 18 of 90

HOGEN H Series Hydrogen Generator

Installation & Operation Manual

2 SAFETY

The safety guidelines below may not cover all situations. If there are concerns or

questions, please call PROTON or check with local authorities.

2.1 General Information

This system produces hydrogen and dilutes oxygen into the ventilation air stream.

It is important for users to be aware, understand, and comply with all local safety

requirements related to the handling of hydrogen and compressed gases. It is

important to operate the HOGEN in a ventilated, non-hazardous (non-classified)

area. (The HOGEN complies with NFPA 70, NFPA 79, and NFPA 496.)

2.2 Using Hydrogen Gas

Hydrogen is odorless, tasteless, colorless, and highly flammable. It is highly

combustible in the presence of oxygen and burns with a colorless flame.

If you are not in danger, stop the flow of gas and use water to cool the area. The

lower flammability limit of hydrogen is 4 percent hydrogen in air by volume. If

fire occurs, do not attempt to extinguish flames, allow the fire to burn out.

Hydrogen gas is lighter than air.

Prevent overexposure to hydrogen. Hydrogen is non-toxic, but it can act as a

simple asphyxiant by displacing the oxygen in the air. Effects of oxygen

deficiency, resulting from simple asphyxiants, include rapid breathing, diminished

mental alertness, impaired muscular coordination, faulty judgment, depression of

all sensations, emotional instability, and fatigue. As asphyxiation progresses,

nausea, vomiting, prostration, and loss of consciousness may result.

The HOGEN H Series hydrogen generator is equipped with a pressure relief valve

(P&ID Tags RV308 and RV351). If the system experiences an over-pressure

condition, the relief valve opens and allows the system to depressurize by

allowing hydrogen to flow out the H2/H2O vent. (Refer to Section 3.9.2 for

Pressure Relief Valves and Vent Lines.)

FIRE OR EXPLOSION! KEEP ALL SOURCES OF IGNITION AWAY FROM

HYDROGEN.

IT IS ESSENTIAL THAT THE SAFETY SYSTEM IS NOT BYPASSED.

CONTINUED OPERATION COULD RESULT IN SERIOUS INJURY AND/OR

DAMAGE TO THE GENERATOR.

PD-0100-0034 REV A

CONFIDENTIAL Do not copy

Page 19 of 90

HOGEN H Series Hydrogen Generator

Installation & Operation Manual

2.3 References

Refer to Section 3.2 for Ventilation Requirements.

Refer to Section 3.5 for Lifting and Moving.

Refer to Section 3.8.2 for Remote E-Stop and Remote Alarm

Refer to the Maintenance Manual for Lock Out/Tag Out Procedure.

PD-0100-0034 REV A

CONFIDENTIAL Do not copy

Page 20 of 90

HOGEN H Series Hydrogen Generator

Installation & Operation Manual

3 INSTALLATION

The HOGEN H Series hydrogen generator is a fully integrated system. To install the

HOGEN generator, mechanical, electrical, fluid, and communication interface

requirements must be met. This section describes the interface and installation

requirements. Figure 5 illustrates the hardware, mounting points and connections for

system integration and packaging.

L

A

B

C

D

JK

E

F

G

H

Figure 5 HOGEN H Series Hydrogen Generator Interface Connections

Reference

A

B

C

D

Interface Connection

Calibration Gas Port

H2/H2OV Vent Port

H2 Product Port

Air Inlet Filter

Reference

H

I

J

K

E

F

G

DI Water Feed Port

Cooling Water Inlet Port

Cooling Water Outlet Port

Interface Connection

Drain DI H20 Port

AC Power Feed in this Area

Communications in this Area

Remote Alarm & Shutdown in

this Area

Lifting Eyebolts

Table 2 HOGEN H Series Hydrogen Generator Interface Connections

PD-0100-0034 REV A

CONFIDENTIAL Do not copy

Page 21 of 90

HOGEN H Series Hydrogen Generator

Installation & Operation Manual

3.1 Top-Level Steps of Installation

The top-level steps of installation are as follows:

1. Installing proper ventilating schemes within the area the HOGEN generator is to

occupy.

2. Verifying the proper environmental conditions the HOGEN generator is to be

exposed.

3. Siting the unit.

4. Connecting electrical interfaces.

5. Connecting mechanical interfaces.

6. Calibrating the combustible gas detector.

Each of these steps is described in further detail in their sub-sections within this

section.

3.2 Facility Air Ventilation Requirements

The HOGEN H Series hydrogen generator design implements ventilation in

accordance with NFPA 496, Type Z pressurized ventilation scheme. A blower at

the inlet air filter forces 400 to 1000 cubic feet per minute (CFM) of fresh purge

air through the fluids compartment. The blower is of sufficient power to maintain

an internal positive static air pressure in excess of 0.25 in (5.08 mm) of water

column. A pressure switch within the cabinet detects any loss of ventilation

pressure and will produce a safety shutdown of the generator upon loss of

pressure. Further, the air purge rate is such that it dilutes any internal hydrogen

leakage to a concentration below 1 percent hydrogen in air (25 percent of the

lower flammable limit (LFL)).

Although the unit will not be able to make hydrogen when the safety circuit is

triggered, the safety circuit does not shutdown the system entirely. Fans and other

areas of the safety circuit will remain engaged.

As an additional benefit, this air ventilation rate excessively dilutes byproduct

oxygen to a safe concentration below 23.5 percent, precluding any hazards

associated with enriched oxygen atmospheres.

PROTON recommends an installation area air change rate of several hundred

times the maximum generation rate of the HOGEN H Series hydrogen generator

to preclude any possible build up of hydrogen or enriched air concentrations in

the facility. In the event the ventilation system fails or the air inlet is restricted,

the HOGEN H Series hydrogen generator is equipped with a safety circuit to

detect the loss of ventilation and stop any further generation of hydrogen by

automatically shutting down. The small amount of hydrogen left on-board is

PD-0100-0034 REV A

CONFIDENTIAL Do not copy

Page 22 of 90

HOGEN H Series Hydrogen Generator

Installation & Operation Manual

automatically vented through the vent stack port; however some residual

hydrogen remains in the system. The circuit also disconnects power to all

electrical equipment in the process (fluids) enclosure, though the fans and other

areas of the safety circuit remain energized.

Additionally, an internal hydrogen detector produces an automatic alarm if

excessive hydrogen is detected. If required, the HOGEN H Series system can

interface with facility fire detection systems, combustible gas sensor or other

external facility alarms as required.

THE HOGEN H SERIES HYDROGEN GENERATORS ARE DESIGNED TO

OPERATE IN NON-EXPLOSIVE, NON-HAZARDOUS, NON-CLASSIFIED

ENVIRONMENTS. THE EQUIPMENT CABINET IS VENTILATED WITH

FRESH AIR TO MAINTAIN A SAFE, NON-EXPLOSIVE INTERNAL

OPERATING ENVIRONMENT (US PATENT 5980726).

Coal dust environments require an optional external filter and shroud kit from PROTON

(KT-1000-0037).

Always refer to local code requirements to determine minimum facility ventilation

requirements. A worksheet for estimating minimum ventilation at your facility is

given below.

How to calculate the ventilation requirements for your site:

1. Record net hydrogen generation rate (P) for your selected generator.

(Refer to Table 1):

P = ________ NM3/h (SCFH)

If there is a plan to have multiple hydrogen generators in the room, P must be the

sum of all generators.

2. Calculate the gross hydrogen generation rate (G). (Add 10 percent):

G =P x 1.1 = ________ NM3/h (SCFH)

3. Calculate recommended ventilation rate (F). (Several hundred times gross

generation rate):

F > 100 x G/60 = ________ NM3/min (SCFm)

4. Confirm if actual room ventilation (FA) is adequate, FA =_______________:

a. Is actual room ventilation (FA) greater than or equal to F?

YES/NO

PD-0100-0034 REV A

CONFIDENTIAL Do not copy

Page 23 of 90

HOGEN H Series Hydrogen Generator

Installation & Operation Manual

If you answered YES for 4a, then you may install the unit in the room. If you

answered NO for 4a, then you may not site the unit in the room until improvements

are made to the ventilation system.

Example Calculation:

1. Record net hydrogen generation rate (P) for your selected generator. (Refer

to Table 1):

P = 228 (SCFH)

2. Calculate the gross hydrogen generation rate (G). (Add 10 percent):

G = 1.1 x P = 250.8 (SCFH)

3. Calculate recommended ventilation rate (F). (Several hundred times gross

generation rate):

F > 100 x G/60 = 25080 (SCFH) / 60 = 418 SCFM

4. Confirm if actual room ventilation (FA) is adequate, FA = 950 cfm

a. Is actual room ventilation (FA) greater than or equal to F? YES

PD-0100-0034 REV A

CONFIDENTIAL Do not copy

Page 24 of 90

HOGEN H Series Hydrogen Generator

Installation & Operation Manual

3.3 Operating Environment

The HOGEN H Series hydrogen generator is designed for indoor use. It shall be

situated on a grade of no more than 1 degrees. The area that the system

occupies shall have the ventilation schemes described in Section 3.2.

The standard HOGEN H Series hydrogen generator is rated for ambient

temperatures and is not designed for freezing conditions (per H Series

Specifications discussed in Table 1). If the system is introduced to freezing

conditions, damage to the system occurs.

Consult PROTON for information on placing the unit in a freezing environment.

The HOGEN H Series hydrogen generator contains a systems thermocouple that

monitors the water temperature in the process water circulation loop of the

system. The unit runs 100 percent hydrogen output at 59C. If the system water

temperature reaches 60C, the unit begins reducing the maximum hydrogen

output and triggers a warning. If the warning is undetected, the unit continues

reducing hydrogen output until it shuts down at 65C. If the cooling feed water

temperature exceeds 35C, the unit may overheat and shutdown.

The HOGEN H Series hydrogen generator can be stored and transported in certain

environments (per H Series Specifications discussed in Table 1). In the event that

the unit is to be transported in a freezing environment, water must be drained

from the system and the cell stack(s) must be taken out of the system and

transported separately. Instructions for the decommissioning of the system are

detailed in the Service Manual).

THE GENERATOR IS TYPICALLY SHIPPED WITH THE PEM CELL STACK

(S) ALREADY INSTALLED. FOR THIS REASON, DO NOT EXPOSE THE

STACK (S) TO FREEZING CONDITIONS WHEN THE UNIT IS NOT

RUNNING. PLEASE CONSULT THE FACTORY FOR SPECIAL STORAGE

AND HANDLING INSTRUCTIONS IF THE UNIT WILL BE EXPOSED TO

FREEZING CONDITIONS PRIOR TO INITIAL START UP.

3.4 Site Preparation

The HOGEN H Series hydrogen generator is designed for indoor installation on a

level concrete pad. AC power, deionized water and cooling water that meets the

specifications outlined in Table 1 are the key utilities required. Ensure the

generator is located so that it is safe from vehicle traffic and is in compliance with

local safety regulations. PROTON recommends the use of barriers if placing the

unit near a vehicle traffic area.

PD-0100-0034 REV A

CONFIDENTIAL Do not copy

Page 25 of 90

HOGEN H Series Hydrogen Generator

Installation & Operation Manual

A level floor, 1 degrees, capable of supporting the generator is required. The

minimum clearance requirements of the area around the generator are shown in

Figure 6. There is a zero minimum clearance requirement on the back of the

generator. The minimum clearance requirement on the front, left and right panels

of the generator is 1 meter or 3.3 ft. It is the customers responsibility to verify

that the local code requirements for this type of equipment are met when

installing this equipment.

All facility connections are identified in Figure 5. Leave sufficient clearance to

permit adequate air movement in and out of the generator from the front and the

left side of the unit.

Front access is very important for operation, ventilation and maintenance. The

generator is controlled from the front control panel, which has start and stop

switches, E-Stop, main disconnect, keypad, and service bypass key switch.

Opening the door of the fluid compartment permits access for routine

maintenance.

Figure 6 HOGEN H Series Hydrogen Generator Plan View for Installation

PD-0100-0034 REV A

CONFIDENTIAL Do not copy

Page 26 of 90

HOGEN H Series Hydrogen Generator

Installation & Operation Manual

3.5 Instructions on Unpacking the HOGEN Hydrogen Generator

The HOGEN hydrogen generator arrives with shipping beams used to support the

unit during shipment. Please use the following instructions to unpack the

hydrogen generator:

1. Using a 9/16 wrench with a socket and a ratchet, unscrew the four (4) nuts

from the beam in the front of the unit.

2. Using a 9/16 wrench with a socket and a ratchet, unscrew the two (2) nuts

from the beam on the right side of the unit. Repeat this step for the two (2)

nuts located on the left side of the unit.

3. Once all nuts are unscrewed, push down on each bolt (there are eight {8} bolts

total) and take each bolt from the bottom. (Refer to Figure 7.)

Figure 7 Removing Bolt from the Shipping Beam

4. Remove the shipping beams from the unit.

5. Remove the additional shipping beam from the unit, which is located behind

the bolted beam in the front of the unit.

PD-0100-0034 REV A

CONFIDENTIAL Do not copy

Page 27 of 90

HOGEN H Series Hydrogen Generator

Installation & Operation Manual

Shipping Beam

Figure 8 Additional Beam Location

3.6 Lifting and Moving

The HOGEN H Series hydrogen generator is delivered on a pallet and weighs

approximately 1750 lbs. (794 kg). The generator can be transported on a pallet

using a forklift or by a hoist or overhead crane.

To lift and move the generator using a forklift, refer to the following instructions:

1. Using a Number 30 TORX bit, remove the four (4) screws on the bottom front

panels at the base of the unit (see Figure 9).

Base Fastener

Cover Plate

Figure 9 Removing Screws from Bottom Front Panel

2. Press down and remove the four (4) black, base fastener cover plates.

PD-0100-0034 REV A

CONFIDENTIAL Do not copy

Page 28 of 90

HOGEN H Series Hydrogen Generator

Installation & Operation Manual

Figure 10 Removing Base Fastener Cover Plate

3. Using a screwdriver, pry out the bottom front panels.

4. Repeat Steps 1 4 for the rear of the unit.

5. Using a forklift/hand truck, lift the unit from under the floor. Make sure the

forks extend passed the back of the unit.

Forks Extending

Beyond the Rear

Figure 11 Lifting the Unit using a Forklift

6. Once the unit is in final position, re-install the base panels and the base

fastener cover plates.

If transporting by hoist, align all eyebolts (Item L in Figure 5) down both sides of

the unit. Place solid (appropriately sized) bar stock inside the eyebolts to run the

entire length of the unit. Lift the enclosure from the bars, as they facilitate an

even weight distribution. Attach appropriately sized harness, chain or sling for a

more even weight distribution.

PD-0100-0034 REV A

CONFIDENTIAL Do not copy

Page 29 of 90

HOGEN H Series Hydrogen Generator

Installation & Operation Manual

3.7 Anchoring Instructions

It is required to properly secure an H Series hydrogen generator to a concrete pad

when siting the equipment outdoors. The drawing provided below should be used

to locate the anchor points needed to perform the installation. All materials and

methods used should be appropriate for anchoring the H Series hydrogen

generator in the intended environment.

Figure 12 Anchoring Diagram

Anchoring Holes

Figure 13 Anchoring Holes

If the HOGEN H Series hydrogen generator is placed in a freezing environment and

there is a loss of power, take necessary provisions to keep the unit from freezing.

PD-0100-0034 REV A

CONFIDENTIAL Do not copy

Page 30 of 90

HOGEN H Series Hydrogen Generator

Installation & Operation Manual

3.8 Electrical Interfaces

Once the HOGEN H Series Hydrogen Generator is properly located, electrical

connections can be made. All user supplied I/O cables that interface with this

system must not exceed 30 meters (98.4 feet) in length.

3.8.1 Cabling Procedure

Ensure that the electrical connections

conform to IP66/NEMA4 and are

compliant with the local electrical

codes. The electrical power

connection and data communications

connections must be weather-tight to

keep out water and dust for reliable

and safe operation. The electrical

and data connections can be installed

on the right side of the generator, in

the approximate location indicated by

the red arrows in Figure 14. The

reference dimensions are listed in

Table 3.

Electrical

Data

Figure 14 Electrical Interface Locations

It is important to verify that the input voltage to the generator maintains stability between

380 to 480 VAC to sustain reliable operation. If the input voltage falls below 360 VAC or

rises above 500 VAC, an on board voltage monitoring relay trips the HOGEN hydrogen

generator to the OFF position.

PD-0100-0034 REV A

CONFIDENTIAL Do not copy

Page 31 of 90

HOGEN H Series Hydrogen Generator

Installation & Operation Manual

The cabling procedure is as follows:

1. Size the AC power conductors according to the service rating listed on the

nameplate (Refer to Table 1).

2. Ensure that connections conform to IP66/NEMA 4 standards and are

compliant with the local electrical codes.

3. Remove the right side panel from the unit if required.

4. Verify that the selected connectors are appropriately sized for the pre-drilled

holes.

5. Install the appropriate IP66/NEMA 4 connector into the hole drilled in the

side of the panel.

6. Feed the power and ground conductors through the AC power feed connector.

7. Connect the power conductors to the top of the main circuit

breaker/disconnect in side the unit.

8. Bring the protective earth ground conductor into the unit along with power to

the conductors.

3-Phase

Input

Protective

Earth Ground

Figure 15 Internal Power and Ground Connections

PD-0100-0034 REV A

CONFIDENTIAL Do not copy

Page 32 of 90

HOGEN H Series Hydrogen Generator

Installation & Operation Manual

Figure 16 HOGEN H Series Hydrogen Generator Electrical Interface Locations

Reference

Dimension

A

B

C

D

Main Power Feed

Units

Inches

mm

5.50

139.70

13.00

330.20

6.14

155.90

8.50

215.90

Data Communications

Reference

Units

Dimension Inches

mm

E

8.50

215.90

21.00

533.40

F

5.50

139.70

G

43.03

1903.10

H

Table 3 Electrical Interface Connections Reference Dimensions

PD-0100-0034 REV A

CONFIDENTIAL Do not copy

Page 33 of 90

HOGEN H Series Hydrogen Generator

Installation & Operation Manual

3.8.2 Remote Alarm Contact and Shutdown Connections

An external alarm from the HOGEN H Series hydrogen generator may be

connected to announce system availability status. Only Normally Open (NO)

contacts are available on the remote alarm relay, located on the right side of the

controller assembly, as shown in Figure 17. The form C alarm relay contacts are

rated for 1 230V, 5 amps max. DO NOT exceed this rating.

Remote

Alarm

Figure 17 Remote Alarm Relay Location

A normally open contact is available for the remote alarm relay. The contact is

rated for 230V, 5 Amp max. DO NOT EXCEED this rating.

The remote alarm contact must be wired to 4TB terminals seven (7) and eight (8).

The user may shut down the system remotely by connecting an external contact

closure to terminal block 3TB. (Reference XPE2544.) This feature permits the

user to interconnect facility alarms to cause the generator to stop operation.

Contacts must be rated to 50 W, 1 amp min. Multiple switches can be wired in

series to form a user-safety circuit. For installation of all electrical connections to

the unit follow the general guidelines as outlined Section 3.8.1.

External contacts must be wired across 3TB terminals 17 and 18. A second external

contact can be wired across 3TB terminals 16 and 19.

PD-0100-0034 REV A

CONFIDENTIAL Do not copy

Page 34 of 90

HOGEN H Series Hydrogen Generator

Installation & Operation Manual

Figure 18 Terminals to Wire External Contacts

The two jumpers (wired across TB 3 on terminals 16/19 and 17/18) installed in

the unit represent customer remote E-Stop switches. To install a remote E-Stop,

simply remove one of the jumpers, 5-6 or 37-38, and replace it with remote e-stop

wiring. Terminal block TB 3 is located in the upper right area of the power panel

(see Figure 19).

Figure 19 TB 3 Location

3.9 Mechanical Interfaces

This section provides a detailed description of the mechanical interface

requirements. The physical layout and dimensions of the HOGEN H Series

hydrogen generator are shown. Detailed interface connections for the hydrogen

outlet, DI feed water and cooling water supply are also supplied.

PD-0100-0034 REV A

CONFIDENTIAL Do not copy

Page 35 of 90

HOGEN H Series Hydrogen Generator

Installation & Operation Manual

3.9.1 Physical Layout, Connections and Dimensions

The physical layout of the HOGEN H Series hydrogen generator is shown in the

following figures (Refer to Section 3.1).

Figure 20 Left Side View

Figure 21 Right Side View

Figure 22 Front View

PD-0100-0034 REV A

CONFIDENTIAL Do not copy

Figure 23 3-D View

Page 36 of 90

HOGEN H Series Hydrogen Generator

Installation & Operation Manual

Figure 24 HOGEN H Series Hydrogen Generator Interface Connections

PD-0100-0034 REV A

CONFIDENTIAL Do not copy

Page 37 of 90

HOGEN H Series Hydrogen Generator

Installation & Operation Manual

3.9.2 Hydrogen Vent Interface

The HOGEN H Series hydrogen generator vents hydrogen during startup, system

depressurization, dryer purging cycles, and overpressure relief. The HOGEN H

Series hydrogen generator vents up to 12.3 liters of hydrogen per minute to purge

and condition the Hydrogen Gas Management Subsystem (HGMS).

In the GENERATE-VENT mode, the H Series hydrogen generator shall operate at

approximately 6 percent generation while discharging generated hydrogen to vent. This

operation purges the phase separation portions of the HGMS with hydrogen to eliminate

any air gases that may be present.

At the end of GENERATE-VENT (130 seconds min/10 minutes max), the vent

valve (P&ID Tag SV329) closes and the system begins to pressurize. During

system shutdown, the on-board inventory hydrogen (< 1.4 SCF/0.036 Nm3) is

vented to atmospheric pressure, leaving some residual hydrogen in the system.

Depressurization occurs when gas generation stops and the vent valve (P&ID Tag

SV329) is opened, allowing hydrogen to flow out of the H2/H2O vent.

The internal dryer of the HOGEN H Series hydrogen generator is a pressureswing dryer. Each bed operates alternately in two half-cycles of equal duration:

pressurization followed by adsorption and depressurization, followed by a purge

with product hydrogen from the alternate bed. It is during this purge that

desorbed water vapor with hydrogen is blown out of the non-operating bed and

directed out the H2/H2O vent. During these purge cycles, approximately 13.8

liters per minute (max) of hydrogen exits the H2/H2O vent port with desorbed

moisture.

The H2/H2O vent port uses FNPT connection. Figure 5 shows the connection

location. The vent line to be attached to the port should be installed per best

practice for hydrogen vent lines and must not be reduced or restricted. Refer to

local standards, NFPA 50A, CGA G5.5, and ASME B31.3.

DO NOT ALLOW HYDROGEN TO VENT INDOORS, NEAR VENTILATION

INTAKES, WORK AREAS, OR ANY SOURCE OF IGNITION.

THE HYDROGEN VENT LINE AND VENT STACK TO ATMOSPHERE MUST

REMAIN FREE FROM OBSTRUCTIONS AND KEPT FROM FREEZING.

A condensate drain trap (As shown in Figure 25) is recommended to remove condensate

from the vent stack and can be purchased from PROTON (Part Number 02-2000-0002).

PD-0100-0034 REV A

CONFIDENTIAL Do not copy

Page 38 of 90

HOGEN H Series Hydrogen Generator

Installation & Operation Manual

Figure 25 Condensate Drain Trap Flow

3.9.3 Vent Line Installation

The connection for the hydrogen vent is FNPT. The vent port is located at the

top of the bulkhead panel and is clearly labeled. For proper hydrogen dryer

operation and compliance with pressure safety codes, 3/8 tubing (10mm) or

larger is required.

The vent line shall not be restricted by excessive length of tubing or by the use of check

valves. Vent backpressure adversely affects the moisture content of the hydrogen

produced.

In applications operating below freezing, precautions must be taken to prevent

freezing of the vent lines.

The vent line must be installed to minimize the possibility of restriction or blockage

due to animals, insects, dirt, rust, etc

3.9.4 Product Hydrogen Interface

The HOGEN H Series hydrogen generator is designed to produce hydrogen that

contains no more than < 5 PPM of water and <1 PPM of other contaminants.

Hydrogen is delivered at a maximum pressure of 15 barg (225 psig) and up to the

units rated flow rate.

PD-0100-0034 REV A

CONFIDENTIAL Do not copy

Page 39 of 90

HOGEN H Series Hydrogen Generator

Installation & Operation Manual

The product hydrogen port uses a Parker CPITM compression tube fitting for

OD stainless steel tubing with .035 wall. Figure 5 shows the connection location.

Figure 26 Product Hydrogen Interfaces

Parker CPITM is a trademark of the Parker Hannifin Company

3.9.5 Air Dilution Interface and Integrated Oxygen Disposal

The HOGEN H Series generator is shipped with an air inlet grill on the left side of

the unit and air dilution discharge grills on the front face of the unit. This

configuration is designed to IP 43. An optional outlet filter housing and shroud kit

is available and is designed to IP 56. The installation area (the source of the

HOGEN ventilation air) must be non-hazardous (non-classified) and well

ventilated. It is very important that the inlet and exhaust dilution grills are not

blocked or restricted in any way. Section 3.2 describes the air dilution protection

scheme inside the HOGEN H Series hydrogen generator, which recommends the

minimum facility air dilution requirements.

Byproduct oxygen is diluted and disposed into the HOGEN H series air dilution

stream, so there is no need for an oxygen port on the HOGEN H series. During

maximum operation, the oxygen concentration increase is only 0.5 percent.

The air inlet grill needs to be replaced with an air filter housing at installation. Refer to

Section 3.11 for instructions.

ADEQUATE DILUTION AND INDOOR AIR EXCHANGES MUST BE

PROVIDED TO ASSURE THAT OXYGEN AND HYDROGEN

CONCENTRATIONS DO NOT BUILD TO UNSAFE LEVELS (REFER TO

SECTION 3.2).

PD-0100-0034 REV A

CONFIDENTIAL Do not copy

Page 40 of 90

HOGEN H Series Hydrogen Generator

Installation & Operation Manual

3.9.6 Coolant Water Interfaces

The coolant water supply and return are 1 FNPT connections. Figure 5 shows

the connection locations of these ports. It is recommended that the user provide

isolation valves to permit maintenance and servicing of the coolant loop. Proton

has an Automatic Coolant Isolation Kit (KT-1000-0017) available. The following

instructions guide the wiring of the automatic valve. Complete instructions are in

PD-0101-0019, which are included in the kit.

A strainer must be installed on the fluid inlet to prevent clogging of the system

with particulate. Typically, strainers have low holding capacities and are only

designed for a low numbers of particles. Facilities with high particle counts in the

cooling water may require additional filtration to prevent frequent clogging of this

strainer. PROTON recommends a 50 mesh filter element.

Figure 27 Coolant Water Interfaces

PROTON also recommends using pressure gauges to monitor filter/strainer

pressure drops and available facility cooling water.

Never operate the unit without the inlet strainer installed!

PD-0100-0034 REV A

CONFIDENTIAL Do not copy

Page 41 of 90

HOGEN H Series Hydrogen Generator

Installation & Operation Manual

To wire the automatic isolation valve, use the following instructions:

1. Use a minimum14 AWG cable suited for the environment (600V, 90 C,

UL/CE Approved).

2. Lockout/Tagout the unit.

3. Route the cable the unit through the right hand panel of the electrical

enclosure (see Figure 5).

All connections through the electrical panels must be made with an IP66-rated strain

relief to maintain the integrity of the electrical enclosures environmental rating.

4. With the solenoid valve in position, make an electrical connection to terminal

7 and 8 on terminal strip block TB4, which is located on the right hand side of

the electrical enclosure door (see Figure 28).

Figure 28 TB 4 Location

The positive wire should be connected to unused terminal 2 and the negative wire

to unused terminal 5. Refer to Figure 29.

Figure 29 TB4 Wiring Locations

PD-0100-0034 REV A

CONFIDENTIAL Do not copy

Page 42 of 90

HOGEN H Series Hydrogen Generator

Installation & Operation Manual

3.9.7 Feed Water Interfaces

The DI water Feed port is a FNPT connection. Figure 5 shows the connection