Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Pseudomonas en Superficies de Acero Inoxidable

Caricato da

betokogTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Pseudomonas en Superficies de Acero Inoxidable

Caricato da

betokogCopyright:

Formati disponibili

POLISH JOURNAL OF FOOD AND NUTRITION SCIENCES

www.pan.olsztyn.pl/journal/

e-mail: joan@pan.olsztyn.pl

Pol. J. Food Nutr. Sci.

2007, Vol. 57, No. 2, pp. 167172

EFFECT OF BIOFILM FORMATION BY PSEUDOMONAS AERUGINOSA ON GAS

PERMEABILITY OF FOOD WRAPPING FOILS

Elbieta Bogusawska-Ws1, Sawomir Lisiecki2, Anna Drozdowska1, Katarzyna Ilczuk1

1

Department of Food Microbiology, 2Department of Packaging and Biopolymers; Faculty of Food Science and Fisheries,

Agricultural University of Szczecin, Szczecin

Key words: Pseudomonas aeruginosa, biofilm, food foils, gas permeability

The natural precedence of microorganisms growth on the damp surfaces is the formation of biofilm. The arising biolayer, stabilized by extracellular substances, is becoming hard to remove biological structure, the enzymatic activity of which can lead to violation of the packaging, and consequently to acceleration of the process of food spoilage.

The microorganisms of Pseudomonas species are widely spread in food products environment. In order to perform the analysis three types of food

wrapping foils from polyamide polyethylene (PA/PE), which were kept in Pseudomonas culture, were used in the study. Two strains were used the

standard ATCC 15442 (WZ) and the strain isolated from pork-beef minced meat (MB) airtight packaged. All cultures were run at the temperatures

4C and 20C. It was reported that on all types of food wrapping foils biofilms were developed, which were formed by Ps. aeruginosa. The biolayers

developed decreased permeability of foils, which was shown by restriction of permeability for gases. The changes of foils properties analysed here

were most of all dependent on the type of the foil.

INTRODUCTION

The utilization of foils in the food industry is the standard

in food technology nowadays. Proecological trends, together with more strict regulations concerning packaging waste,

promote the development of materials safe for environment.

Biodegradable food wrapping foils, available on the market, have attributes excluding them from the use as a packages for greasy or frozen food [Bartkowiak et al., 2004].

For these products use is made of packaging foils made of

artificial materials which protect easily spoilong food. The

requirement for their usage is proper binding of different

polymers with specified features [Michniewicz, 1999]. Polyamide (PA) and polyethylene (PE) or their derivatives are

commonly used materials with supplementing properties.

Good mechanical properties, attrition resistance and temperature stability of polyamide, and very low permeability for

gases and susceptibility for welding of polyethylene, predispose these synthetic foils (PA/PE) to be exploited in current

packaging methods. In vacuum packaging techniques, modified atmosphere packaging (MAP) and controlled atmosphere packaging (CAP), aseptic packaging and with oxygen

adsorbents, the proper choice of package has the influence

on the final quality and durability of a product [Czerniawski

& Stasiek, 2001]. Lowering oxygen contents and increasing

the amount of CO2, as a result of tissue and microbial respiration, limit the growth of facultative anaerobic microorgan-

ism, mostly Pseudomonas, Alteromonas and Moraxella, which

contributes to the extension of product durability.

An obvious result of growth of microorganisms on damp

surfaces is the formation of biofilm. Forming biolayer, stabilized by extracellular substances, becomes very hard to be

removed microbiological structure [Gilbert et al., 2003], the

enzymatic activity of which can lead to violation of packages

structure and, consequently, to speed up food spoilage processes. Improper usage of comestible foils as well as inappropriate microbiological quality of packaging product can contribute to the growth of spoilage microflora and pose danger

to the consumer.

Taking into consideration the above factors, the aim of

this work was to determine the effect of growing bacterial biofilm on the properties of food wrapping foils used.

MATERIALS AND METHODS

Food wrapping foils. In order to carry out the tests

three polyamide/polyethylene (PA/PE) food wrapping foils

were used (F1, F3, F5), admitted for use in the food industry. The foil F5 additionally contained vinyl-ethylene alcohol (EVOH). All of the foils used were produced with the coembossment method using chill roll. Properties of the foils

are given in Table 1.

Authors address for correspondence: Elbieta Bogusawska-Ws, Agricultural University of Szczecin, Faculty of Food Science and Fisheries,

Department of Food Microbiology, Papiea Pawa VI 3, 71-459 Szczecin, Poland; tel./fax: (48 91) 42 50 407; e-mail: ewas@tz.ar.szczecin.pl

Copyright by Institute of Animal Reproduction and Food Research of the Polish Academy of Sciences

168

Bogusawska-Ws E. et al.

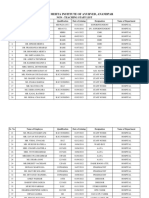

TABLE 1. Properties of foils used in testing.

Foil

labeling

Manufacturer

labeling

Chemical constitution

of foil

Foil thickness

(nm)

F1

GPM

PA/PE

90

F3

GPM

PA/PE

40

F5

GPP

EVOH

80

Ps. aeruginosa strains. The standard strain of Ps. aeruginosa ATCC 15442 (WZ), and the strain Ps. aeruginosa

(MB) isolated from hermetically-packaged pork-beef minced

meat were used for testing.

Isolation and identification of strains from minced

meat. Pseudomonas sp strains were isolated from meat according to Polish Norm [PN-85/A-82051]. The cultures were run in

three repetitions using the method of surface culture on Pseudomonas Agar base (Oxoid) with CFC Selective Agar Supplement (Oxoid). Plates were incubated for 3 days at room temperature. Blue and green fluorescent colonies were cultured on

Nutrient Agar (Oxoid) for further identification.

In order to establish which species the strains from 24-h

colony belong to, the Gram staining and oxidase tests were

carried out. For further identification G(-) and oxidase(+),

bacteria were taken into consideration. The affiliation of the

strains tested to species was confirmed with the use of API

ID 32 GN tests (bioMerieux), according to bioMerieux procedure.

Evaluation of hydrophobicity of Ps. aeruginosa

strains. Hydrophobicity of strains was estimated by adsorption to non-polar solvents (hexadecane) MATH (microbial

adhesion to hydrocarbons) according to Doyle & Rosenberg

[1990]. In order to perform the test, Ps. aeruginosa strains

WZ and MB, were cultured at two temperatures: 4C and

20C, on the BHI agar (OXOID). After overnight cultures,

the bacteria were washed by centrifugation in 0.85% NaCl.

The cell suspension was then standardized to OD600 0.1

and 0.3 (respectively to incubation temperature) in 0.1 mol/ L

phosphatic buffer (corresponding to 106 and 108 cells) using

a spectrophotometer. Then, 4.0 mL of the suspension were

supplemented with 1.5 mL of hexadecane. All the tests were

vortexed for 10 seconds and left intact for 10 min. The procedure was repeated until 60 sec vortexing was reached.

Changes in the absorbance of strain suspensions in relation

to the non-polar solvent were measured by using a Carlzeiss spectrophotometer at 600 nm. These bacterial strains

were incubated at 4oC and 20oC. According to the formula: At/Ao 100 (At preliminary extinction of suspension,

Ao extinction of suspension after defined time of vortexing measured in relation to a blank sample phosphorus

buffer), the results obtained enabled plotting a curve which

was a determinant of microorganism affinity to hexadecane

[Van der Mei et al., 1993]. Strains were considered hydrophilic when the decrease of suspension optical density after

a 60-sec vortexing was less than 30%. In the case of a decrease between 3070% the strains were considered medium

hydrophobic. The decrease higher than 70% suggested highly

hydrophobic strains.

Evaluation of ability to form biofilm by Ps. aeruginosa

strains. The ability to form biofilm was tested on Mineral Salt

Medium (MSM) base (0.1% KH2PO4, 0.1% Na2HPO4, 0.05%

NH4NO3, 0.05% (NH4)2SO4, 0.02% MgSO4 7H2O, 0.002%

CaCl2 2H2O, 0.0002% FeCl3, 0.00002% MnSO4) according

to Herman et al. [1997]. Bases were inoculated with the tested strains Ps. aeruginosa MB and WZ. The inoculum with

the final concentration of 102 CFU/mL was added to 100 mL

of base. Biofilms were formed on 1.0 cm2 strerile foils (F1, F3,

F5). In 3, 7 and 14-days intervals the ability to form biofilm on

different kinds of foils by chosen strains was tested.

To this end particular types of foils were taken from MSM

bases and rinsed three times in a physiological saline. Afterwards they were moved into liquid BHI base (Oxoid) with 1%

water solution of 2, 3, 5-triphenylotetrazolic chloride. After

24 h the growth of biofilm was checked, which was characterised by pink and reddish tint on the foil surface. Bacteria

were rinsed using a 0.5% saponine solution by 15-sec shaking

to estimate the number of cells adhered to the surface of the

foil [Ralska et al., 1998]. After that, quantitative cultures of

initial material were prepared on BHI Agar base (Oxoid) and

incubated for 72 h at a room temperature. Grown colonies

were then counted. The cultures were run in five repetitions.

The influence of Ps. aeruginosa strains on gas permeability of foils. Axenic MSM base was inoculated with

the tested MB and WZ strains at the final concentration of

102 CFU/mL. After that, standardised and axenic foils were

submerged in the cultures. The test was performed simultaneously at 4C and 20C. After incubation time (7 days), the

foils were taken out and rinsed in a 1% solution of sodium

azide, dried at a room temperature and taken for further testing. The foils kept in base without microorganisms but treated under the same conditions were used as controls.

The analysis of oxygen permeability (q) through tested foils

was performed according to ISO Standard 2556 [ISO, 1974],

DIN 53 380 using the OXTRAN 2/20 ML device (Mocon,

USA). The following mixture of gases was used: 98% N2 and

2% H2 as carrier gas, and oxygen (purity 3.5) as control gas.

Tests were carried out on samples having 50 cm2 of surface

area, at 23C, under standard conditions of relative humidity

0% and with 100% oxygen concentration. Measurement data

were compensated to atmospheric pressure. In order to obtain

credible results the samples were conditioned in measuring

compartments of the device for no shorter than 5 h.

Statistical analysis. A statistical analysis of the results

obtained was carried out using STATISTICA 6.0 PL software. The analysis of statistical significance of differences was performed with the Scheffe test, at a significance

level of p<0.05. Correlation was set at a significance level

of p<0.005. An analysis of concentrations of Ps. aeruginosa

strains depending on their hydrophobicity was performed by

the single-link method counted by Euclidean distance (Statistica PL).

RESULTS

Evaluation of hydrophobicity of Ps. aeruginosa

strains

Statistical record of results distinguished three groups of

169

Biofilm of Ps.aeruginosa on food foils

different hydrophobicity hydrophilic, medium hydrophobic and hydrophobic. Statistical evaluation of hydrophobicity variation of Ps. aeruginosa MB strains showed a lack of

the influence of culture temperature on the tested properties

of cell wall. It was demonstrated that in both instances, i.e. in

incubation at 4C and at 20C, the strain tested showed medium hydrophobic properties (Figure 1).

100

Taking into consideration Ps. aeruginosa WZ strain in the

culture run at 20 it was found that hydrophilic properties

had been kept. The lowering of temperature of the culture

to 4C resulted in the lowering of hydrophilicity of the strain

tested (Figure 1).

The ability of adhesion of Ps. aeruginosa strains to

the surface of the foil

The performed tests, determining the adhesive ability of

Ps. aeruginosa strains WZ and MB to chosen food wrapping foils F1, F3 and F5, showed a lack of significant differences in colonization of the surface by the bacteria (Figures

2, 3). For the tests performed with WZ strain at temperatures

of 4C and 20C, the assigned variation of function curve did

not show any statistically significant differences (p<0.05).

High resemblance between certain variants of the test was

reported (Figure 3). The statistical analysis based on tests

with MB strain proved the similarity between the colonization

of respective foils and certain temperature (Figure 2).

The intensity of growth of Ps. aeruginosa strains

MB and WZ was the highest during the first three days

of cultures. In the case of MB strain, the number of defined

microorganisms increased from 102 to 105 CFU/mL, whilst in

the case of WZ strain from 102 to 104 CFU/mL at 20C and

to 105 CFU/mL at 4C (Table 2). During the next days of tests

Hydrophobic

90

Hydrophobicity (%)

80

70

60

50

40

30

Medium hydrophobic

20

10

0

WZ-20C

WZ-4C

Hydrophilic

0

10

20

30

40

50

60

Time (s)

100

90

80

6.00E+06

60

5.00E+06

50

4.00E+06

40

30

CFU/cm2

Hydrophobicity (%)

70

Ps.aeruginosa MB

Hydrophobic

Medium hydrophobic

2.00E+06

20

10

0

3.00E+06

Hydrophilic

0

10

20

30

40

50

MB-20C

1.00E+06

MB-4C

0.00E+00

F1/20

60

F3/20

F5/20

F1/4

F3/4

F5/4

Kind of foils/temp.

Time (s)

FIGURE 2. The ability to form biofilm by Ps.aeruginosa MB.

FIGURE 1. Hydrophobicity of Ps.aeruginosa strains.

TABLE 2. Progress in the ability to form biofilm.

Foil

labeling

Temp.

o

(C)

F1

CFU/cm2 of Ps.aeruginosa WZ

CFU/ cm2 of Ps.aeruginosa MB

3 days

7 days

14 days

3 days

7 days

14 days

20

2.1E+04

(0.2)

4.7E+04

( 0.6)

1.7E+05

(0.12)

2.7E+05

(0.3)

9.5E+05

(0.9)

3.7E+06

(0.6)

F3

20

1.1E+04

(0.3)

1.6E+04

(0.4 )

2.9E+05

(0.2)

6.5E+05

(0.1)

1.4E+06

( 0.7)

5.2E+07

( 0.4)

F5

20

1.8E+04

(0.2)

2.6E+04

(0.5)

3.1E+05

(0.34)

4.2E+05

(0.3)

8.7E+05

(1.4)

1.9E+07

( 0.8)

3 days

7 days

14 days

3 days

7 days

14 days

F1

5.0E+05

(0.5)

1.6E+06

(1.0)

4.7E+04

(1.0)

3.2E+05

(0.4 )

1.8E+07

(0.9)

6.0E+05

(1.6)

F3

1.1E+05

(0.6)

5.7E+05

(0.9)

5.8E+06

(1.0)

5.7E+05

(0.4)

9.9E+06

(0.6)

4.0E+05

(1.6)

F5

1.1E+05

(0.6)

3.9E+06

(0.8)

2.0E+05

(1.0)

6.7E+05

( 0.5)

9.6E+06

(0.6)

6.3E+05

(1.1)

170

Bogusawska-Ws E. et al.

Ps.aeruginosa WZ

6.00E+05

WZ strain and by 31% for MB strain. At 4C in the case of

WZ strain the permeability was estimated to be 20% lower

than that of the control sample. No change was observed for

the MB strain (Figure 4).

4.00E+05

DISCUSSION

2.00E+05

Barrier and mechanical parameters used in food wrapping foils are due to polymers constructing them. Packaged

food is usually stored at low temperatures in order to limit

the growth of undesirable microflora. Moreover, refrigerating temperatures decrease oxygen permeability through foils

[Lisiecki, 2003]. Applied temperatures are not a barrier for

metabolic activity of psychrophilous microorganisms. The

result of growth of microorganisms is biofilm formation, the

enzymatic activity of which can lead to a change of conditions in microbial environment. Taking into consideration Ps.

aeruginosa, the chemical composition of the surface of this

G(-) bacteria directly contributes to colonization of both biological and abiotic surfaces. Particular role is attributed to the

three components forming not only the lipopolysaccharide

layer (LPS) of the cell but also its hydrophobic activity [Al-Tahan et al., 2000]. The base is oligosaccharide layer, which

has the unique 2-keto-3-deoxyoctonic acid (KDO), stabilized by Mg2+. An important role in bacterial adhesion is also

assigned to antigen O which is bound to irregular endings of

oligosaccharide. The process of colonization of abiotic environments by microorganisms, depending on the structure of

colonized surfaces, is related with changes in cell wall properties by transformation of proteins and lipids of the outer

membrane. The purpose of this process is to increase the

affinity to colonized surfaces. Cell wall then becomes more

hydrophobic. Bacterial adhesion to rough and matt surfaces is quicker and more intensive. However, the rate of adhesion to smooth and slippery surfaces is much slower at the

beginning.

In the food industry the possibilities of forming biofilm

are seen as a factor seriously dangerous to the production

[Poulsen, 1999; Sharma & Anand 2002b, Magrex-Debar et

al., 2000]. The most common reported reason for biofilm

formation is low hygiene during production and processing

process. It concerns mainly meat processing plants, mostly

raw packaged products, in which the presence of Salmonella, Campylobacter, Yersinia and Listeria is detected [Poulsen,

1999]. Food products packaged in polyethylene foils are also

not free from the presence of bacteria responsible for food

spoilage. The risks resulting from the presence of undesirable microflora, in the shape of biofilm in production environment, support suggestions to introduce the estimation of

biofilm as an important part of HACCP [Sharma & Anand,

2002a]. The control of biofilm formed by microorganisms

and its disposal is the greatest problem though [Gilbert et

al., 2003].

The biofilm formed by Ps. aeruginosa is a widely known

and commonly described phenomenon [Costerton et al.,

1999; Xu et al., 2001; Daveley & OToole, 2000]. The function of such a microbiological structure would not be possible without certain properties of cell wall. The ability to

adhere to the surface and its colonization are determined by

hydrophobicity of the cell whose activity, together with biofilm incubation, is modified by biosurfactant (surface active

1.00E+06

CFU/cm2

8.00E+05

0.00E+00

F1/20

F3/20

F5/20

F1/4

F3/4

F5/4

Kind of foils/temp.

FIGURE 3. The ability to form biofilm by Ps.aeruginosa WZ.

the growth rate of strains on the surface of tested foils was

not so intensive (Table 2).

Evaluation of gas permeability through food wrapping foils

Permeability of oxygen through foils submerged only in

the base (control sample) and kept under applied testing conditions depended on incubation temperature. It was proved

that the usage of cooling temperature changed the properties

of foils, which was observed in lower permeability for gases

(Figure 4).

As a result of running the culture it was determined that,

on the surface of the foils used there occurred a biolayer

which in all testing samples additionally reduced oxygen permeability. It was estimated that in cultures with foil F3 at

20C the average decrease in foil permeability equaled 40%

against the control sample. In the case of cultures run at 4C

the results were very close, i.e. 38% and 32% for WZ and MB

strains, respectively (Figure 4).

In the case of foil F1 such comparable results were not

Gas permeability (q*)

25.00

20.00

15.00

10.00

5.00

0.00

F1/4

F1/20

F3/4

F3/20

F5/4

F5/20

Foils/temp.

control

3

foils + Ps. aeruginosa WZ

foils + Ps. aeruginosa MB

*q = cm /m 24h bar

FIGURE 4. Evaluation of gas permeability through wrapping foils

obtained. The decrease in permeability of gases in all cultures

was shown, however it was observed that both strains WZ

and MB at 20 caused an increase in impenetrability by only

14% on average. For foils kept at 4C the results were higher

by 24% (Figure 4).

Slightly different results were obtained for foil F5. In this

case, at 20C the permeability barrier increased by 55% for

171

Biofilm of Ps.aeruginosa on food foils

agent) [Al-Tahan et al., 2000]. The hydrophobicity tests performed on strains of interest did not show any unequivocal

cell preferences. It was decided that at 20C the reference

strain WZ and the strain isolated from meat MB belonged

to the medium hydrophobic group (Figure 1). The temperature of 4C, used for the strain isolated from meat, did not

have any impact on the change of cell wall properties, whilst

it slightly weakened the lipophilic properties of the surface

of the cell of Ps. aeruginosa WZ strain (Figure 1). In many

works a correlation has been shown between the conditions

of culture, including incubation temperature, and hydrophobicity of Pseudomonas sp. [Szabo, 2003; Kumar et al., 2002;

Wolska et al., 2002]. The results of our statistical analysis are

not convergent with the above reports. The hydrophobicity of the cell is the result of many environmental factors and

the application of temperatures yet standard for psychrophilous microorganisms does not necessarily have the influence on the change of its properties. Quantitative assay from

cultures developing on the surfaces of tested food wrapping

foils suggest the correct interpretation of the results obtained

in hydrophobicity tests. Statistically confirmed differences

in the rate of foils colonization, in cultures at different temperatures (Table 2), were not observed. The intensive growth

of tested microorganisms WZ and MB strains, on tested

food wrapping foils, took place in the first three days of culture (Table 2). This situation has been confirmed by the work

of Auerbach et al. [2000], which shows that during the first

2 4 days of biofilm growth the cells divide in both upper and

lower layer of the biofilm, which is changing with the age

of biolayer. In further stages the rate of reproduction is lowering (Table 2) due to biofilm structure formation. According

to Tuleva et al. [2002], the biofilm formation, depending on

the strains of Pseudomonas, is observed between day 3 and 5

of incubation.

The strains analyzed in this work, i.e. WZ and MB, formed

biolayer on the surfaces of the foils used (Table 2). Pseudomonas sp. belong to the group of psychrotrophic microorganisms responsible for the spoilage of food kept in refrigerating

conditions. It is the result of the activity of potent proteolytic

and lipolytic enzymes, which leads to deterioration of product quality, and consequently to shortening its shelf life [Jay

et al., 2005; Doyle & Rosenberg, 1993]. In modern packaging techniques the wrapping foils should be characterised

by very low permeability for oxygen, steam, odorous substances and other gases CO2 and N2. According to Fik &

Leszczyska-Fik [1997], for materials used for vacuum packaging of meat the quotient of oxygen permeability should not

exceed 1 mL/ m2/24 h at 23C. According to Xu et al. [2001],

the presence and composition of gases, especially available

oxygen, used in packaging, is the factor determining the possibility to form bacterial biofilm [Xu et al., 1998, 2001].

Food wrapping foils, exposed to bacterial activity, and

their evaluation on account of gases permeability, showed

that permeability of foils became significantly lower except

one sample (Figure 4). Biolayers formed on the surfaces

of food wrapping foils caused the occurrence of additional

barrier limiting oxygen permeation (Figure 4). Biopolymers

which came into existence, as non-toxic biodegradable products, could be used for foil production. However, the main

problem would be the elimination of metabolically-active cell

from the biofilm formed by them. One of the major function

of microbiological biolayer is to protect bacterial structures

suspended in matrix against adverse environmental factors

[Daveley & OToole, 2000]. This is the reason of bacterial

resistance in biofilm, for example on antibiotics [Webb et al.,

2003] or unsuccessful application of some cleaners or purgatives in case of Pseudomonas sp. [Poulsen, 1999]. Recent

research on the mechanisms of regulation of physiological

processes of microorganisms point to the coordination of

bacterial behaviour including the activation of defence systems together with biofilm formation [Defoirdt et al., 2004;

Magrex-Debar et al., 2000].

CONCLUSIONS

In this work we wanted to determine the effect of the

growth of psychrophilous bacteria Ps. aeruginosa, on the

structure of food wrapping foils. The results obtained show

unequivocally that biofilm formed by the tested microorganisms became the additional barrier for gases. It should be

considered to abandon the usage of some synthetic components of foils in favour of natural products.

REFERENCES

1. Al-Tahan R.A., Sandrin T.R., Bodour A.A., Maier R.M.,

Rhamnolipid-induced removal of lipopolysaccharide from

Pseudomonas aeruginosa: effect on cell surface properties a interaction with hydrophobic substrates. Appl. Environ. Microbiol.,

2000, 66, 32623268.

2. Auerbach I.D., Sorensen C., Hansma H.G., Holden P.A., Physical

morphology and surface properties of unsaturated Pseudomonas

putida biofilm. J. Bacteriol., 2000, 183, 38093815.

3. Bartkowiak A., akowska Z., Lisiecki S., Szumigaj J., Permeability

for oxygen and susceptibility to microorganisms colonisation of

biodegradable and biodecomposing foils expected to be used

in food industry. 2004, in: Polymer Materials Pomerania-Plast,

Wyd. PS, pp. 5355 (in Polish).

4. Costerton J.W., Stewart P.S., Greenberg E.P., Bacterial biofilms:

a common cause of persistent infections. Science, 1999, 284,

13181322.

5. Czerniawski B., Stasiek J., The review of production systems of

multi layer foils. Plastics Rev., 2001, Sept., 3044.

6. Daveley M.E., OToole G.A., Microbial biofilms: from ecology

to molecular genetics. Microbiol. Molecul. Biol. Rev., 2000, 64,

847867.

7. Defoirdt T., Boon N., Bossier P., Verstraete W., Disruption of

bacterial quorum sensing: am unexplored strategy to fight infection in aquaculture. Aquaculture, 2004, 240, 6988.

8. Doyle R.J., Rosenberg M., Microbial Cell Surface Hydrophobicity,

1993, American Society for Microbiology, Washington D.C., pp.

1014.

9. Fik M., Leszczyska-Fik A., The influence of cooling preservation on the microbiological quality of vacum-packed pork

minced meat. Przem. Spo., 1997, 10, 4042 (in Polish).

10. Gilbert P., McBain A.J., Rickard A.H., Formation of microbial

biofilm in hygienic situations: a problem of control. Inter. Biodeter. Biodegr., 2003, 51, 245248.

11. Herman D.C., Zang Y., Miller R.M., Rhamnolipid (biosurfactant) effects on cell aggregation and biodegradation of residual hexadecane under saturated flow conditions. Appl. Environ.

Microbiol., 1997, 63, 36223627.

12. ISO 2556:1974, Plastics determination of gas transmission

rate of films and thin sheets under atmospheric pressure

Manometric methods.

13. Jay J.M., Loessner M.J., Golden D.A., Taxonomy, role, and sig-

172

14.

15.

16.

17.

18.

19.

20.

21.

22.

Bogusawska-Ws E. et al.

nificance of microorganisms in food. 2005, in: Modern Food

Microbiology (ed. D.R. Heldemann). Springer Inc., NY, USA,

pp. 1337.

Kumar G.S., Jagannadham M.V., Ray M.K., Low-temperature-induced changes in composition and fluidy of lipopolysaccharrides in the Antarctic psychrotrophic bacterium Pseudomonas

syringae. J. Bacteriol., 2002, 184, 67466749.

Lisiecki S., Permeability of oxygen and mechanical properties

of PA/PE laminates. 2003, in: Materials of the 36th Conference

of the Polish Academy of Sciences The quality of Polish food

shortly before the Poland integration with the European Union.

Elma Wroclaw, 1011 September 2003, p. 197.

Magrex-Debar E.L., Lemoine J., Gelle M.P., Jacquelin L.F,

Choisy C., Evaluation of biohazards in dehydrated biofilms

on foodstuff packaging. Int. J. Food Microbiol., 2000, 55,

239 243.

Michniewicz J., Packing and the quality of food products. 1999, in:

Materials of the5th Conference of Polish Society of Food Technologists Transport of food packages in food transport, 35 November 1999, Wyd. Nauk. PTT, Kiekrz k/Poznania, pp. 1825.

Polish Norm: PN-85/A-82051, Delicatessen products. Semi-finished and finished articles. Microbiological analyses (in Polish).

Poulsen L.V., Microbial biofilm in food processing. Lebensmittel

Wiss. Technol., 1999, 32, 321326.

Sharma M., Anand S.K., Characterization of constitutive microflora of biofilm dairy processing lines. Food Microbiol., 2002a,

19, 627636.

Sharma M., Anand S.K., Biofilm evaluation as an essential component of HACCP for food/dairy processing industry a case.

Food Control, 2002b, 13, 469477.

Szabo Z., Investigation of mechanism of cell membrane-active

23.

24.

25.

26.

27.

28.

cyclic lipodepsipeptides compounds. Acta Pharm. Hung., 2003,

73, 24956.

Tuleva B.K., Ivanov G.R., Christova N.E., Biosurfactant production by new Pseudomonas putida strain. Z. Naturforsch., 2002,

57c, 356360.

Van der Mei H.C., De Vries J., Busscher H.J., Hydrophobic and

electrostatic cell surface properties of thermophilic dairy streptococci. Appl. Environ. Microbiol., 1993, 59, 43054312.

Webb J.S., Givskov M., Kjelleberg S., Bacterial biofilm: adventures

in multicellularity. Cur. Opinion Microbiol., 2003, 6, 578585.

Wolska K., Pogorzelska S., Fijol E., Jakubczak A., Bukowski K.,

Influence of growth conditions on cell surface hydrophobicity of

Pseudomonas aeruginosa. Med. Dow. Mikrobiol., 2002, 54, 5661.

Xu K.D., Franklin M.J., Park C.H., McFeters G.A., Stewart P.S.,

Gene expression and protein levels of the stationary phase sigma

factor, RpoS, in continuously-fed Pseudomonas aeruginosa biofilms. FEMS Microbiol. Lett., 2001, 199, 6771.

Xu K.D, Stewart P.S., Xia F., Ching-Tsan H., McFeters G.A.,

Spatial physiological heterogenity in Pseudomonas aeruginosa. Biofilm is determined by oxygen availability. Appl. Environ.

Microbiol., 1998, 64, 40354039.

Received April 2006. Revision received July 2006 and accepted

March 2007.

WPYW TWORZENIA BIOFILMU PRZEZ PSEUDOMONAS AERUGINOSA NA PRZEPUSZCZALNO

GAZW PRZEZ FOLIE SPOYWCZE

Elbieta Bogusawska-Ws1, Sawomir Lisiecki2, Anna Drozdowska1, Katarzyna Ilczuk

1

Katedra Mikrobiologii ywnoci, 2Zakad Opakowalnictwa i Biopolimerw, Akademia Rolnicza w Szczecinie, Szczecin

Celem niniejszej pracy byo okrelenie wpywu rozwijajcego si biofilmu bakteryjnego na przepuszczalno gazw przez folie spoywcze

(PA/PE i EVOH) przy wykorzystaniu OX-TRAN 2/20 ML. W dowiadczeniu wykorzystano szczepy Ps. aeruginosa wyizolowane z prb

misa mielonego hermetycznie pakowanego oraz szczepu wzorcowego ATCC. We wszystkich wariantach dowiadczenia stwierdzono tworzenie biofilmu przez bakterie. Intensywno kolonizacji powierzchni folii przez testowane szczepy bya najwiksza w pierwszych trzech dniach

hodowli (tab. 2, 3). Nie stwierdzono korelacji pomidzy rodzajem folii, a intensywnoci tworzonej biofilmu (rys. 2, 3). Ustalono, e powstay

biofilm wpywa na podniesienie barierowoci wszystkich testowanych folii spoywczych.

Potrebbero piacerti anche

- Skowron2018 Article ComparisonOfSelectedDisinfectaDocumento11 pagineSkowron2018 Article ComparisonOfSelectedDisinfectaFlorentina BucurNessuna valutazione finora

- Effect of Pullulan Coating On Inhibition of Chosen Microorganisms' GrowthDocumento10 pagineEffect of Pullulan Coating On Inhibition of Chosen Microorganisms' GrowthChristmas ShineNessuna valutazione finora

- FDA Advanced Oxidation Technology With PhotohydroionizationDocumento6 pagineFDA Advanced Oxidation Technology With Photohydroionizationpattysaborio520Nessuna valutazione finora

- Dinaca - Final - Original Scientific PaperDocumento10 pagineDinaca - Final - Original Scientific PaperDaniela DiaconuNessuna valutazione finora

- Contrera Et Al 2013 NMRDocumento10 pagineContrera Et Al 2013 NMRSurajit BhattacharjeeNessuna valutazione finora

- Acidophilus ParticulaDocumento6 pagineAcidophilus ParticulaMay MolinaNessuna valutazione finora

- Asaff, Escobar, de La Torre - 2009 - Culture Medium Improvement For Isaria Fumosorosea Submerged Conidia ProductionDocumento6 pagineAsaff, Escobar, de La Torre - 2009 - Culture Medium Improvement For Isaria Fumosorosea Submerged Conidia ProductionJosé Matías ZapiolaNessuna valutazione finora

- Hao. 1998. Microbial Quality, C. Botulinum, Toxin Production, Fresh Cut Cabbage and LettuceDocumento6 pagineHao. 1998. Microbial Quality, C. Botulinum, Toxin Production, Fresh Cut Cabbage and LettucealecheverryNessuna valutazione finora

- Microbial Production of Polyhydroxybutyrate, A Biodegradable Plastic Using Agro-Industrial Waste ProductsDocumento11 pagineMicrobial Production of Polyhydroxybutyrate, A Biodegradable Plastic Using Agro-Industrial Waste Productsashuna249396Nessuna valutazione finora

- Jurnal PackagingDocumento6 pagineJurnal PackagingFarah Insan SalsabilaNessuna valutazione finora

- 230-Article Text-1391-1-10-20210106Documento4 pagine230-Article Text-1391-1-10-20210106khristinered455Nessuna valutazione finora

- Clostridium ButtirycumDocumento10 pagineClostridium ButtirycumJorge Luis Ortiz CarrilloNessuna valutazione finora

- Phenotyping Crop Plants for Physiological and Biochemical TraitsDa EverandPhenotyping Crop Plants for Physiological and Biochemical TraitsNessuna valutazione finora

- Criterios Microbiológicos - Temperas y PlastilinasDocumento3 pagineCriterios Microbiológicos - Temperas y PlastilinasJohanna JaraNessuna valutazione finora

- Gases MoldDocumento7 pagineGases MoldNadia TanniaNessuna valutazione finora

- Jurnal 5-Bio Waste KitosanDocumento12 pagineJurnal 5-Bio Waste KitosanNurhaliza YanuartiNessuna valutazione finora

- Isolation and Characterization of Starter Culture From Spontaneous Fermentation of SourdoughDocumento4 pagineIsolation and Characterization of Starter Culture From Spontaneous Fermentation of SourdoughHusna AdilaNessuna valutazione finora

- Tentative Title of ResearchDocumento4 pagineTentative Title of ResearchDerrickNessuna valutazione finora

- Journal of Dental Research: Validation of An in Vitro Biofilm Model of Supragingival PlaqueDocumento9 pagineJournal of Dental Research: Validation of An in Vitro Biofilm Model of Supragingival PlaqueJorge SaenzNessuna valutazione finora

- Toxins: Rapid Detection and Identification of Mycotoxigenic Fungi and Mycotoxins in Stored Wheat GrainDocumento17 pagineToxins: Rapid Detection and Identification of Mycotoxigenic Fungi and Mycotoxins in Stored Wheat GrainAlberto Galdino SparrowNessuna valutazione finora

- PHB Production in Azomonas, Acinteobacter and Bacillus Species: Isolation, Screening and IdentificationDocumento8 paginePHB Production in Azomonas, Acinteobacter and Bacillus Species: Isolation, Screening and IdentificationInternational Medical PublisherNessuna valutazione finora

- 13 - 15v5i2 - 4 Serratia Marcescens OU50TDocumento5 pagine13 - 15v5i2 - 4 Serratia Marcescens OU50TIsworo RukmiNessuna valutazione finora

- 1 s2.0 S0570178316300252 MainDocumento6 pagine1 s2.0 S0570178316300252 MainRizki Uhud NasofiNessuna valutazione finora

- 1 s2.0 S0570178316300252 MainDocumento6 pagine1 s2.0 S0570178316300252 MainRizki Uhud NasofiNessuna valutazione finora

- Bacillus PolyfermenticusDocumento6 pagineBacillus Polyfermenticussi275Nessuna valutazione finora

- In Situ: An Method For Cultivating Microorganisms Using A Double Encapsulation TechniqueDocumento9 pagineIn Situ: An Method For Cultivating Microorganisms Using A Double Encapsulation TechniqueBernard Louis MontemorNessuna valutazione finora

- Formatted MJM2 GehadDocumento10 pagineFormatted MJM2 GehadAbdel-Rahim HassanNessuna valutazione finora

- Antifungal Potential of Extracellular Metabolites Produced by StreptomyDocumento8 pagineAntifungal Potential of Extracellular Metabolites Produced by Streptomysiddhipurohit134586Nessuna valutazione finora

- Bioconversion of Cassava Starch By-Product Into Bacillus and Related Bacteria PolyhydroxyalkanoatesDocumento13 pagineBioconversion of Cassava Starch By-Product Into Bacillus and Related Bacteria PolyhydroxyalkanoatesMarelin Pereda SifuentesNessuna valutazione finora

- FM 25 (2008) 313-323Documento11 pagineFM 25 (2008) 313-323Antonia GounadakiNessuna valutazione finora

- 2020 JFoodProcessEng13436Documento12 pagine2020 JFoodProcessEng13436bayanikimashleymNessuna valutazione finora

- 2018 Mendoza MoralesetalDocumento9 pagine2018 Mendoza Moralesetallucia mendozaNessuna valutazione finora

- Volume: 04 Issue: 03 - May-Jun 2023Documento9 pagineVolume: 04 Issue: 03 - May-Jun 2023Central Asian StudiesNessuna valutazione finora

- 1 s2.0 S014181302302456X MainDocumento14 pagine1 s2.0 S014181302302456X MainkhwajaosamaNessuna valutazione finora

- Characterization of Bacillus Megaterium and Bacillus Mycoides Bacteria As Probiotic Bacteria in Fish and Shrimp FeedDocumento9 pagineCharacterization of Bacillus Megaterium and Bacillus Mycoides Bacteria As Probiotic Bacteria in Fish and Shrimp FeedAusteridad LopezNessuna valutazione finora

- Rapid and Mass Production of Biopesticide Trichoderma Brev T069 From Cassava Peels Using Solid-State Fermentation Bioreactor SystemDocumento37 pagineRapid and Mass Production of Biopesticide Trichoderma Brev T069 From Cassava Peels Using Solid-State Fermentation Bioreactor SystemLuis Chavez SantamarinaNessuna valutazione finora

- The Dynamics of Staphylococcus Epidermis Biofilm Formation in Relation To Nutrition, Temperature, and TimeDocumento6 pagineThe Dynamics of Staphylococcus Epidermis Biofilm Formation in Relation To Nutrition, Temperature, and TimeMohamed Amine MekniNessuna valutazione finora

- Optimization of Culture Condition in The Production of Bioenzymes by Bacteria Isolated From Poultry Waste in Sokoto State, NigeriaDocumento8 pagineOptimization of Culture Condition in The Production of Bioenzymes by Bacteria Isolated From Poultry Waste in Sokoto State, NigeriaUMYU Journal of Microbiology Research (UJMR)Nessuna valutazione finora

- Analysis of The Bacterial Strains Using Biolog Plates in The Contaminated Soil From Riyadh CommunityDocumento24 pagineAnalysis of The Bacterial Strains Using Biolog Plates in The Contaminated Soil From Riyadh CommunityFranky zNessuna valutazione finora

- Research Article: In-Package Air Cold Plasma Treatment of Chicken Breast Meat: Treatment Time EffectDocumento8 pagineResearch Article: In-Package Air Cold Plasma Treatment of Chicken Breast Meat: Treatment Time EffectedurapNessuna valutazione finora

- Effects of Nutritional and Environmental Conditions On Sinorhizobium Meliloti Biofilm FormationDocumento9 pagineEffects of Nutritional and Environmental Conditions On Sinorhizobium Meliloti Biofilm FormationMichael GatpatanNessuna valutazione finora

- Herrero Concepcion 2012 Flow Cytometric Physiological Alterations Herbicide MicroalgaeDocumento19 pagineHerrero Concepcion 2012 Flow Cytometric Physiological Alterations Herbicide MicroalgaeBrigita de BrillarNessuna valutazione finora

- Pichia Anomala J121 During Airtight Storage of Wheat: Nutrient Effects On Biocontrol of Penicillium Roqueforti byDocumento5 paginePichia Anomala J121 During Airtight Storage of Wheat: Nutrient Effects On Biocontrol of Penicillium Roqueforti byNurul FuadyNessuna valutazione finora

- The Bacteriocin Antimicrobial Test Activity of Probiotic Bacteria Isolated From Giant Prawns (Macrobrachium Rosenbergii)Documento10 pagineThe Bacteriocin Antimicrobial Test Activity of Probiotic Bacteria Isolated From Giant Prawns (Macrobrachium Rosenbergii)Reffy AdhaNessuna valutazione finora

- UJRRA - 22 - 22 (Research)Documento13 pagineUJRRA - 22 - 22 (Research)TMP Universal Journal of Research and Review ArchivesNessuna valutazione finora

- Protein BasedDocumento11 pagineProtein BasedBagja Malik SyakurNessuna valutazione finora

- Bacteria On SpongesDocumento6 pagineBacteria On SpongesJulius PanayoNessuna valutazione finora

- T Molitor PS Degrading BacteriaDocumento22 pagineT Molitor PS Degrading BacteriaDon GaboNessuna valutazione finora

- Soft RotDocumento9 pagineSoft RotHadeer AhmedNessuna valutazione finora

- Research Article: Fungal Diversity and Evaluation of Ochratoxin A Content of Coffee From Three Cameroonian RegionsDocumento10 pagineResearch Article: Fungal Diversity and Evaluation of Ochratoxin A Content of Coffee From Three Cameroonian RegionsNabilah RahmadifaNessuna valutazione finora

- An Endophytic Nodulisporium Sp. Producing Volatile Organic Compounds Having Bioactivity and Fuel PotentialDocumento3 pagineAn Endophytic Nodulisporium Sp. Producing Volatile Organic Compounds Having Bioactivity and Fuel PotentialIzza Cahya KamilaNessuna valutazione finora

- 18 Ijat2010 - 76FJRDocumento12 pagine18 Ijat2010 - 76FJRDenice ShyneNessuna valutazione finora

- Industrial Microbiology Lab 1 (BTC4205)Documento23 pagineIndustrial Microbiology Lab 1 (BTC4205)Jerry CaldwellNessuna valutazione finora

- Original Article Microencapsulation of Lactobacillus Acidophilus ATCC 43121 With Prebiotic Substrates Using A Hybridisation SystemDocumento9 pagineOriginal Article Microencapsulation of Lactobacillus Acidophilus ATCC 43121 With Prebiotic Substrates Using A Hybridisation SystemMay MolinaNessuna valutazione finora

- Artículo Microencapsulación Bacterias AcidolácticasDocumento5 pagineArtículo Microencapsulación Bacterias AcidolácticasDaniel HenaoNessuna valutazione finora

- Gamma Irradiation and Autoclave Sterilization Peat and Compost As The Carrier For Rhizobial Inoculant ProductionDocumento9 pagineGamma Irradiation and Autoclave Sterilization Peat and Compost As The Carrier For Rhizobial Inoculant ProductionSeptiana SariNessuna valutazione finora

- Microbiological Evaluation of An Edible Antimicrobial Coating PDFDocumento6 pagineMicrobiological Evaluation of An Edible Antimicrobial Coating PDFLuigi GonzálezNessuna valutazione finora

- 06-08 Pato-Yusuf (Revision)Documento8 pagine06-08 Pato-Yusuf (Revision)Fawwaz Muhammad AribNessuna valutazione finora

- Gonzles Ramrez2016Documento14 pagineGonzles Ramrez2016Paula GeorgianaNessuna valutazione finora

- 0362-028x-72 7 1419 PDFDocumento8 pagine0362-028x-72 7 1419 PDFnofriadyNessuna valutazione finora

- Hydration of Calcium Aluminate Cement Phase Ca and Ca2 in Refractory ApplicationsDocumento4 pagineHydration of Calcium Aluminate Cement Phase Ca and Ca2 in Refractory Applicationsakanksha.kumariNessuna valutazione finora

- SCR Control System, DIA - NE XT4: Technical InstructionDocumento48 pagineSCR Control System, DIA - NE XT4: Technical InstructionAli QaziNessuna valutazione finora

- Living in A Dream WorldDocumento8 pagineLiving in A Dream WorldTrọng Nguyễn DuyNessuna valutazione finora

- Polynomials Objectives:: element, is used. Thus, if a is an element of set A, we indicate this by writing "a ϵDocumento11 paginePolynomials Objectives:: element, is used. Thus, if a is an element of set A, we indicate this by writing "a ϵAlfredNessuna valutazione finora

- Brainware University: Practice Set ofDocumento4 pagineBrainware University: Practice Set ofDeep TarafdarNessuna valutazione finora

- SK Pradhan ObituaryDocumento1 paginaSK Pradhan Obituarysunil_vaman_joshiNessuna valutazione finora

- AQU3202 Amino Acid AnalysisDocumento8 pagineAQU3202 Amino Acid AnalysisWayMeen PangNessuna valutazione finora

- ITP - SewAage Water InstallationDocumento9 pagineITP - SewAage Water InstallationGultom Juliana LiliesNessuna valutazione finora

- Funding Request To Prospective DonorsDocumento6 pagineFunding Request To Prospective Donorspaulinus onovoNessuna valutazione finora

- Glucose Syrup Three-Effect Evaporation System: 1. Background & DescriptionDocumento2 pagineGlucose Syrup Three-Effect Evaporation System: 1. Background & DescriptionRushikesh uNessuna valutazione finora

- Raju ComparativePhilosophySpiritual 1963Documento16 pagineRaju ComparativePhilosophySpiritual 1963Kent Jerson CasianoNessuna valutazione finora

- How To Write Characters For ScreenplayDocumento4 pagineHow To Write Characters For ScreenplayfedorNessuna valutazione finora

- 2 VCA ETT 2017 Training v2 0 - EnglishDocumento129 pagine2 VCA ETT 2017 Training v2 0 - EnglishMassimo FumarolaNessuna valutazione finora

- GeneratorsDocumento2 pagineGeneratorsNoel GalangNessuna valutazione finora

- Richard Heck in MemoriamDocumento24 pagineRichard Heck in MemoriamTonie Jane SabadoNessuna valutazione finora

- Sizing and Selecting Pressure Relief ValvesDocumento70 pagineSizing and Selecting Pressure Relief ValvesSagar Naduvinamani100% (1)

- Anquamine 728: Curing AgentDocumento4 pagineAnquamine 728: Curing AgentGreg PanganNessuna valutazione finora

- Cable Spring PulleyDocumento6 pagineCable Spring PulleyDavid Olorato NgwakoNessuna valutazione finora

- International Journal of Fatigue: SciencedirectDocumento12 pagineInternational Journal of Fatigue: SciencedirectKurra SrikanthNessuna valutazione finora

- MELCS UnpackingDocumento2 pagineMELCS UnpackingTawagin Mo Akong Merts100% (5)

- Free Mechanical Aptitude Questions AnswersDocumento12 pagineFree Mechanical Aptitude Questions Answerswhriyj177Nessuna valutazione finora

- Microptic CatalogDocumento8 pagineMicroptic CatalogMhd DamNessuna valutazione finora

- Ga Verb Dictionary TemplatedDocumento179 pagineGa Verb Dictionary TemplatedKIMANINessuna valutazione finora

- QM For Business MIDTERM EXAMINATION REVIEW Apr 23 2020 BULLSHIT CONTENTDocumento10 pagineQM For Business MIDTERM EXAMINATION REVIEW Apr 23 2020 BULLSHIT CONTENTArgen GrzesiekNessuna valutazione finora

- Project ReportDocumento12 pagineProject ReportMuhammad SulemanNessuna valutazione finora

- ENDO Agar: Mode of Action LiteratureDocumento2 pagineENDO Agar: Mode of Action LiteratureadiazcalidadNessuna valutazione finora

- (Discontinued ) : ASTM A353 Alloy SteelDocumento1 pagina(Discontinued ) : ASTM A353 Alloy SteelDhanyajaNessuna valutazione finora

- Contoh Sterilefiltration Pada Viral Vaccine Live AtenuatedDocumento10 pagineContoh Sterilefiltration Pada Viral Vaccine Live Atenuatedkomang inggasNessuna valutazione finora

- Hospital Staff List To Be UpdatedDocumento4 pagineHospital Staff List To Be UpdatedHiteshNessuna valutazione finora

- Sound Wall Starter KitDocumento66 pagineSound Wall Starter KitMaxtron MoonNessuna valutazione finora