Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Special Slides - Heat Exchangers and Airfin Coolers

Caricato da

Mikee FelipeDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Special Slides - Heat Exchangers and Airfin Coolers

Caricato da

Mikee FelipeCopyright:

Formati disponibili

2/27/2015

Department of Chemical Engineering

College of Engineering

University of the Philippines Diliman

Second Semester, AY 2014-2015

ChE 142: Chemical

Engineering Plant Design

Detailed Design of

Static Equipment (HEx and AFC)

Heat Exchanger Types

Devore et al recommend the

following heat exchanger types:

Outline of Lecture

Introduction

Heat Exchanger Types

Design Calculations

P&ID Representation

Cost Estimation

Heat Exchanger Types

Spiral Heat Exchanger

Spiral heat exchanger if area is

less than 2 m2.

Double-pipe heat exchanger if

area is between 2 and 50 m2.

Shell-and-tube heat exchanger

if area is greater than 50 m2.

2/27/2015

Heat Exchanger Types

Heat Exchanger Types

Double Pipe Heat Exchanger

Shell and Tube Heat Exchanger

Shell and tube heat exchangers are

broadly classified into two: removable

and non-removable tube bundle.

Of the two classifications, the cheapest

options are the U-tube heat exchanger

and the fixed tubesheet heat exchanger

respectively.

Heat Exchanger Types

Heat Exchanger Types

Shell and Tube Heat Exchanger

Shell and Tube Heat Exchanger

2/27/2015

Heat Exchanger Types

Heat Exchanger Types

Shell and Tube Heat Exchanger

Shell and Tube Heat Exchanger

Heat Exchanger Types

Heat Exchanger Types

Shell and Tube Heat Exchanger

Shell and Tube Heat Exchanger

Costlier for the same heat transfer

area, but can clean shell side.

Cheaper for the same heat transfer

area, but cant clean shell side.

2/27/2015

Heat Exchanger Types

Heat Exchanger Types

Shell and Tube Heat Exchanger

Shell and Tube Heat Exchanger

Design Calculations

Design Calculations

Problem Statement

Design and draw the P&ID representation of

a shell-and-tube heat exchanger with the

following information:

2/27/2015

Design Calculations

Design Calculations

Initial Specifications

Initial Specifications

Fluid Placement

Place the fluid on the tube side if it is:

(arranged in order of priority)

1.

2.

3.

4.

5.

6.

Corrosive

Cooling water

More fouling

Less viscous

More pressurized

Hotter

Fluid Placement

Fouling factors (refer to Table 3.3)

Crude oil

= 0.004-0.005 hr-ft2-F/Btu

Kerosene

= 0.001-0.003 hr-ft2-F/Btu

Place the crude oil and kerosene in tube

side and shell side respectively.

Design Calculations

Design Calculations

Initial Specifications

Initial Specifications

Shell and Head Type

Tube and Tubing Layout

The following guidelines are

observed in the selection of tube

dimensions and layout:

14 BWG tubes with 1

triangular pitch for straight tubes

1 14 BWG tubes with 1

square pitch for U-tubes

What shell and tube heat exchanger type

is suitable for this service, BEU or BEM?

2/27/2015

Design Calculations

Design Calculations

Initial Specifications

Initial Specifications

Tube and Tubing Layout

Tube and Tubing Layout

The preferred straight tube lengths are 16 ft

and 20 ft. For the same heat transfer area,

which is more economical?

Longer but thinner

heat exchanger?

Shorter but fatter

heat exchanger?

What are the advantages and disadvantages

of triangular pitch over square pitch?

Design Calculations

Design Calculations

Initial Specifications

Initial Specifications

Baffle Dimensions

Baffle Dimensions

The baffle spacing is recommended to

be between 20% and 100% of the

shell diameter. The default is 20%.

The baffle cut is recommended to be

between 15% and 45%. The default is 20%.

2/27/2015

Design Calculations

Design Calculations

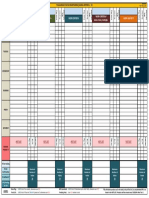

Maximum Pressure Drop

Maximum Pressure Drop

Allowable pressure drop for shell and tube

exchangers and air coolers in pumped liquid

service may be considered as follows:

Pressure (psig)

Allowable Pressure Drop (psi)

Shell Side

Tube Side

Up to 50

2.5 per shell

Less than 1.0

5.0

10

50 and above

5.0 per shell

1.0 to 5.0

7.5

10

Viscosity (cP)

Allowable Pressure Drop (psi)

Allowable pressure drop for shell and tube

exchangers and air coolers in condensing

service may be considered as follows:

5.0 to 15.0

10

15

15.0 to 25.0

15

20

25.0 to 50.0

15

25

Design Calculations

Design Calculations

Initial Specifications

Initial Specifications

The initial specifications are as follows:

Kerosene at shell, crude oil at tube

o Kerosene

= 0.003 hr-ft2-F/Btu

o Crude oil

= 0.005 hr-ft2-F/Btu

Heat exchanger type BEU

1 14 BWG tubes with 1 square pitch

o Outer diameter (Do) = 1.000 in

o Inner diameter (Di) = 0.834 in

o Tube pitch (PT)

= 1.250 in

o Clearance (C)

= 0.250 in

Tube length of 20 ft

Baffle spacing of 20% of shell diameter

Baffle cut of 20%

Maximum shell-side P

= 5.0 psi

Maximum tube-side P

= 10.0 psi

The initial specifications are as follows:

Kerosene at shell, crude oil at tube

o Kerosene

= 5.248 x 10-4 m2-K/W

o Crude oil

= 8.806 x 10-4 m2-K/W

Heat exchanger type BEU

1 14 BWG tubes with 1 square pitch

o Outer diameter (Do) = 0.02540 m

o Inner diameter (Di) = 0.02118 m

o Tube pitch (PT)

= 0.03175 m

o Clearance (C)

= 0.00635 m

Tube length of 6.096 m

Baffle spacing of 20% of shell diameter

Baffle cut of 20%

Maximum shell-side P

= 34.46 kPa

Maximum tube-side P

= 68.93 kPa

2/27/2015

Design Calculations

Design Calculations

Number of Shell Passes

Number of Shell Passes

Assume that only one shell pass will suffice.

Calculate the LMTD correction factor (F).

Assume that only one shell pass will suffice.

Calculate the LMTD correction factor (F).

Design Calculations

Design Calculations

Number of Shell Passes

Estimated Area

If calculated F is less than 0.80, set the

number of shell passes to two.

Calculate the area using the equation

Q = UAFTlm

Estimate the overall heat transfer

coefficient using the individual heat

transfer coefficients (should have been

done during ChE 141).

2/27/2015

Design Calculations

Design Calculations

Minimum Number of Tubes

Maximum Number of Tube Passes

The heat exchanger area is equal to the

surface area of each tube multiplied by

the number of tubes:

The tube-side fluid loses pressure as it

expands at the inlet nozzle, flows inside the

tubes, and contracts at the outlet nozzle.

A = nt x (DoL)

Assume that nozzle losses are negligible.

How can the maximum number of tube

passes be calculated using the equation

above?

Design Calculations

Design Calculations

Shell Diameter

Required Overall Heat Transfer Coefficient

Given the heat exchanger type and the tubeside details, a shell diameter can be selected:

Given the selected tube length and

the tube count on the selected shell

diameter, calculate the area available

for heat exchange:

A = nt x (DoL)

Calculate the required overall heat

transfer coefficient:

Ureq = Q/AFTlm

2/27/2015

Design Calculations

Design Calculations

Inside Heat Transfer Coefficient

Outside Heat Transfer Coefficient

The tube-side heat transfer coefficient is

calculated using the Seider-Tate and Hausen

equations. Viscosity correction is neglected:

The shell-side heat transfer coefficient is

calculated using the following correlation.

Viscosity correction is neglected:

Design Calculations

Design Calculations

Overall Heat Transfer Coefficient

Tube-Side Pressure Drop

Calculate the overall heat transfer coefficient

using the equation below. Metal resistance is

neglected:

The tube-side fluid loses pressure as it

expands at the inlet nozzle, flows inside the

tubes, and contracts at the outlet nozzle.

Assume that nozzle losses are negligible.

The magnitude of oversize is based on the

required overall heat transfer coefficient.

10

2/27/2015

Design Calculations

Design Calculations

Shell-Side Pressure Drop

Design Assessment

The shell-side fluid loses pressure as it

expands at the inlet nozzle, flows outside the

tubes, and contracts at the outlet nozzle.

Assume that nozzle losses are negligible.

P&ID Representation

What adjustments need to be done?

Case

Is overall HTC

greater than

required?

Is tube-side

P less than

maximum?

Is shell-side

P less than

maximum?

YES

YES

YES

YES

YES

NO

YES

NO

YES

NO

YES

YES

P&ID Representation

11

2/27/2015

P&ID Representation

P&ID Representation

P&ID Representation

Cost Estimation

Towler and Sinnott (2008) expressed the

January 2006 purchased cost of heat

exchangers as a function of area.

12

2/27/2015

Air Fin Coolers

Air Fin Coolers

Because of low heat

transfer coefficient on

the air side, the tubes

are finned to increase

the area available for

heat transfer.

Air Fin Coolers

Air fin coolers are second only to shelland-tube heat exchangers in frequency

of occurrence in chemical and

petroleum processing operations.

Air Fin Coolers

Forced Draft Air Fin Coolers

Assuming no process restrictions,

when is air cooling economically

advantageous over water cooling?

13

2/27/2015

Air Fin Coolers

Air Fin Coolers

Induced Draft Air Fin Coolers

Forced vs. Induced Draft Air Fin Coolers

Differentiate the two configurations in

terms of:

1. Accessibility of tubes and fan parts

2. Fan power consumption for the same

mass flowrate of air

3. Area for the same air fin cooler duty

Air Fin Coolers

Air Fin Coolers

Forced vs. Induced Draft Air Fin Coolers

Forced vs. Induced Draft Air Fin Coolers

14

2/27/2015

Air Fin Coolers

Air Fin Coolers

Forced vs. Induced Draft Air Fin Coolers

Tube Dimensions

For inlet process fluids above 350F,

use forced draft configuration.

Tube lengths are typically from 6 ft to 50 ft,

with 40 ft commonly used. Tubes are

typically stacked from three to eight rows,

with six rows commonly used.

Air Fin Coolers

Air Fin Coolers

Tube Dimensions

Bay Dimensions

Bay widths are typically from 4 ft to 30 ft, with

14 ft commonly used. Axial-flow fans with four

or six blades and diameters of 6 ft to 18 ft are

typically employed.

15

2/27/2015

Department of Chemical Engineering

College of Engineering

University of the Philippines Diliman

Second Semester, AY 2014-2015

ChE 142: Chemical

Engineering Plant Design

Detailed Design of

Static Equipment (HEx and AFC)

16

Potrebbero piacerti anche

- Lec#09 PHT - (04 Mar 2013 - Monday) - Design of Shell & Tube Heat ExchangerDocumento30 pagineLec#09 PHT - (04 Mar 2013 - Monday) - Design of Shell & Tube Heat ExchangerQamar AbbasNessuna valutazione finora

- Heat TransferDocumento9 pagineHeat TransferAjinkya MoreNessuna valutazione finora

- Project Heat and Mass TransferDocumento14 pagineProject Heat and Mass TransferAreen Emilia Faizlukman Jerry100% (1)

- Working Principle of Shell and Tube Heat ExchangerDocumento8 pagineWorking Principle of Shell and Tube Heat ExchangersanjayNessuna valutazione finora

- Shell and TubeDocumento66 pagineShell and TubeCachoNessuna valutazione finora

- 21 BCH 074Documento19 pagine21 BCH 074Anushka ChaudharyNessuna valutazione finora

- Basics of Shell and Tube Heat Exchangers With PDFDocumento12 pagineBasics of Shell and Tube Heat Exchangers With PDFSachin KumarNessuna valutazione finora

- New Microsoft Word Document 4.1Documento19 pagineNew Microsoft Word Document 4.1prashantmaukaNessuna valutazione finora

- Heat Exchanger Design: Table of ContentDocumento18 pagineHeat Exchanger Design: Table of ContenthellopaNessuna valutazione finora

- Hydraulic CalculationsDocumento4 pagineHydraulic Calculationskaramnia100% (1)

- Basics of Shell and Tube Heat Exchangers With PDFDocumento12 pagineBasics of Shell and Tube Heat Exchangers With PDFtruong cong truc100% (1)

- PED Ch2Documento30 paginePED Ch2Shubham KumarNessuna valutazione finora

- DesignDocumento36 pagineDesignvishal kumar mehtaNessuna valutazione finora

- Prepared By: Mr. Harsh PanchalDocumento46 paginePrepared By: Mr. Harsh PanchalKáûshàl PãtëlNessuna valutazione finora

- 06+shell+and+tube+hx SDocumento65 pagine06+shell+and+tube+hx SMuhammad HaidiNessuna valutazione finora

- Double Pipe Heat Exchanger: Open Ended Lab Lab Report NoDocumento10 pagineDouble Pipe Heat Exchanger: Open Ended Lab Lab Report NoAsad UllahNessuna valutazione finora

- Heat ExchangersDocumento14 pagineHeat ExchangersPrateek JainNessuna valutazione finora

- Chemical Design of Heat Exchanger TerdesakDocumento22 pagineChemical Design of Heat Exchanger TerdesakNor Ain100% (4)

- Design and Analysis of Boiler Pressure Vessels Based On IBR CodesDocumento9 pagineDesign and Analysis of Boiler Pressure Vessels Based On IBR Codesgermantoledo244596Nessuna valutazione finora

- Topsoe High Flux Steam ReformDocumento6 pagineTopsoe High Flux Steam ReformAnissa Nurul BadriyahNessuna valutazione finora

- Lva1 App6892Documento8 pagineLva1 App6892BRAHIMNessuna valutazione finora

- ME34 - ME Laboratory 2 - : Signature of Student Under Printed NameDocumento12 pagineME34 - ME Laboratory 2 - : Signature of Student Under Printed NameSky FallNessuna valutazione finora

- Shell and TubeDocumento66 pagineShell and TubeEdgar Enrique Diaz Marquina0% (1)

- Process Equipment Design-05Documento42 pagineProcess Equipment Design-05PARAG DAHARWAL 20CH10020Nessuna valutazione finora

- 3.1 Heat ExchangersDocumento76 pagine3.1 Heat Exchangersraghu_iictNessuna valutazione finora

- Lecture4-Example Shellandtubedesign PDFDocumento4 pagineLecture4-Example Shellandtubedesign PDFNassima Ghalem GharsaNessuna valutazione finora

- CH 311 HT Popstmid Lectures 2022-1Documento111 pagineCH 311 HT Popstmid Lectures 2022-1Shah WaleedNessuna valutazione finora

- Process Presentation Shell and Tube Heat Exchanger GalfarDocumento84 pagineProcess Presentation Shell and Tube Heat Exchanger GalfarKishore Sakhile100% (1)

- Heat TransferDocumento77 pagineHeat TransferSabariMechy50% (2)

- Heat ExchangersDocumento8 pagineHeat ExchangersLiyan Fajar GintaraNessuna valutazione finora

- Irjet V5i1308 PDFDocumento6 pagineIrjet V5i1308 PDFS. MarkNessuna valutazione finora

- PHT Unit-5 (THEORY)Documento81 paginePHT Unit-5 (THEORY)521 Balaji ONessuna valutazione finora

- GoedhartVCI P 2012 en Version1 IDocumento24 pagineGoedhartVCI P 2012 en Version1 IRodrigo GonçalvesNessuna valutazione finora

- Mod1 Nptel Process Exchanger DesignDocumento41 pagineMod1 Nptel Process Exchanger DesignAnirudh KaulNessuna valutazione finora

- Heat Exchanger Design - ProcessDocumento42 pagineHeat Exchanger Design - Processalokbdas100% (1)

- eBroc-Shell and Tube Heat Exchangers Model Series and Customer Oriented Solutions, FunkeDocumento18 pagineeBroc-Shell and Tube Heat Exchangers Model Series and Customer Oriented Solutions, FunkeMoly69xNessuna valutazione finora

- Heat Exchanger ChecklistDocumento9 pagineHeat Exchanger Checklistraja rani67% (3)

- Factors Affecting The Performance of Shell and Tube Heat ExchangerDocumento9 pagineFactors Affecting The Performance of Shell and Tube Heat ExchangerMuhammed NayeemNessuna valutazione finora

- Lecture 6 - Heat Transfer EquipmentDocumento72 pagineLecture 6 - Heat Transfer EquipmentLouie GresulaNessuna valutazione finora

- Heat Exchanger DesignDocumento13 pagineHeat Exchanger DesignDaksh Parashar80% (5)

- Heat Exchanger Design - Part 1Documento26 pagineHeat Exchanger Design - Part 1Siddhant SoymonNessuna valutazione finora

- What Are Double Pipe Heat Exchangers and Their Working PrinciplesDocumento8 pagineWhat Are Double Pipe Heat Exchangers and Their Working PrinciplesAngel RatuNessuna valutazione finora

- Shell and Tube Heat ExchangerDocumento23 pagineShell and Tube Heat ExchangerBernard BaluyotNessuna valutazione finora

- Chapter 4 Shell and Tube Heat ExchangersDocumento45 pagineChapter 4 Shell and Tube Heat Exchangerslockas222Nessuna valutazione finora

- Thermal Rating - Single-Phase S&T Heat ExchangerDocumento43 pagineThermal Rating - Single-Phase S&T Heat ExchangervictorvikramNessuna valutazione finora

- Synopsis Heat ExchangerDocumento9 pagineSynopsis Heat ExchangerJitesh PaulNessuna valutazione finora

- Heat Exchanger Lectures CompleteDocumento72 pagineHeat Exchanger Lectures CompletehananNessuna valutazione finora

- Funke Shell Tube He eDocumento24 pagineFunke Shell Tube He eSubrata DasNessuna valutazione finora

- Heaters Exchangers Designs & EquipmentDocumento22 pagineHeaters Exchangers Designs & Equipmentanil kumarNessuna valutazione finora

- Heat Exchanger Design: ME 310 Thermo-Fluid System DesignDocumento30 pagineHeat Exchanger Design: ME 310 Thermo-Fluid System DesignAlif RifatNessuna valutazione finora

- Double Pipe Heat ExchangerDocumento5 pagineDouble Pipe Heat ExchangerSheb LorenoNessuna valutazione finora

- Shell and Tube Exchanger YuanDocumento37 pagineShell and Tube Exchanger YuanVerdianto Indra WNessuna valutazione finora

- Process Design of Heat Exchangers PDFDocumento80 pagineProcess Design of Heat Exchangers PDFUdayan Panda100% (2)

- Design HeatexchangerDocumento15 pagineDesign HeatexchangerMayurMahajan100% (1)

- Procedure For Fired Heater DesignDocumento72 pagineProcedure For Fired Heater DesignKanagarajNKNessuna valutazione finora

- Air Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&ADa EverandAir Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&ANessuna valutazione finora

- Fundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationDa EverandFundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationNessuna valutazione finora

- Heat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersDa EverandHeat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersValutazione: 4 su 5 stelle4/5 (13)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersDa EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNessuna valutazione finora

- 2022 Instrumentation and Control Servicing NC3 OutlineDocumento2 pagine2022 Instrumentation and Control Servicing NC3 OutlineMikee FelipeNessuna valutazione finora

- 2022 Metrologyx Manila Training ScheduleDocumento4 pagine2022 Metrologyx Manila Training ScheduleMikee FelipeNessuna valutazione finora

- Actual Man-Hours Rendered: MonthDocumento1 paginaActual Man-Hours Rendered: MonthMikee FelipeNessuna valutazione finora

- Work Center 5 Work Center 3 Work Center 4/ Man - Pack./Carbgel Work Center 2 Work Center 1Documento1 paginaWork Center 5 Work Center 3 Work Center 4/ Man - Pack./Carbgel Work Center 2 Work Center 1Mikee FelipeNessuna valutazione finora

- Compliance To Man-Hour Per Thousand Units (Kosu)Documento1 paginaCompliance To Man-Hour Per Thousand Units (Kosu)Mikee FelipeNessuna valutazione finora

- (Y) Manpower (Q) BD On Cartoning (N) BD On Capping (A) Bulk Unavailability (M) BD On FillingDocumento1 pagina(Y) Manpower (Q) BD On Cartoning (N) BD On Capping (A) Bulk Unavailability (M) BD On FillingMikee FelipeNessuna valutazione finora

- November 2011 ChE Board Exam Questions PDFDocumento8 pagineNovember 2011 ChE Board Exam Questions PDFMikee Felipe100% (1)

- Sample HAZOP Study Worksheet (P&ID 100-002)Documento5 pagineSample HAZOP Study Worksheet (P&ID 100-002)Mikee Felipe88% (8)

- Brochure-MakatiMed Health Packages 2015Documento2 pagineBrochure-MakatiMed Health Packages 2015Mikee FelipeNessuna valutazione finora

- Lenyx Chemicals Limay, Bataan, PhilippinesDocumento1 paginaLenyx Chemicals Limay, Bataan, PhilippinesMikee FelipeNessuna valutazione finora

- Aprilia RS 50 AM6 2000 Service ManualDocumento50 pagineAprilia RS 50 AM6 2000 Service ManualDaan van der MeulenNessuna valutazione finora

- SPE-15103-PA - Prediction of Slug Length in Horizontal Large-Diameter PipesDocumento6 pagineSPE-15103-PA - Prediction of Slug Length in Horizontal Large-Diameter PipesMubarik AliNessuna valutazione finora

- Kata LogDocumento12 pagineKata LogOscarAriasNessuna valutazione finora

- Paper3 DR Choo PDFDocumento49 paginePaper3 DR Choo PDFzaedmohdNessuna valutazione finora

- 2 High Pressure Compressor PDFDocumento132 pagine2 High Pressure Compressor PDFHarry Wart Wart100% (3)

- Engine Especifications G3520BDocumento4 pagineEngine Especifications G3520BYaneth100% (1)

- Danfoss H1P 069-H1P 250 Axial Piston Single Pumps Service ManualDocumento68 pagineDanfoss H1P 069-H1P 250 Axial Piston Single Pumps Service ManualJustinNessuna valutazione finora

- 1 OXE InstallationManual - Rev ODM1003-180322Documento68 pagine1 OXE InstallationManual - Rev ODM1003-180322VNessuna valutazione finora

- Poster 'I Want To Be ' - Rev0Documento4 paginePoster 'I Want To Be ' - Rev0hafizahmad84Nessuna valutazione finora

- Auxilary Boiler Basuki Inc)Documento56 pagineAuxilary Boiler Basuki Inc)mail_mulyadi5151Nessuna valutazione finora

- Water DopingDocumento19 pagineWater Dopingvanderwalt.paul2286Nessuna valutazione finora

- Basin ModellingDocumento6 pagineBasin ModellingMartin OviedoNessuna valutazione finora

- UOP CCR PlatformingDocumento3 pagineUOP CCR PlatformingRodrigo PerezNessuna valutazione finora

- Feasibility Study of Citric Acid ProductionDocumento3 pagineFeasibility Study of Citric Acid ProductionIntratec Solutions0% (1)

- Engine Principles and Fundamentals (Final)Documento14 pagineEngine Principles and Fundamentals (Final)velumani2003Nessuna valutazione finora

- Guide To The Location of Gasoline (Motor Fuel) Filling Stations and Filling-Cum-Serv1Ce Stations in Urban Areas ForewordDocumento8 pagineGuide To The Location of Gasoline (Motor Fuel) Filling Stations and Filling-Cum-Serv1Ce Stations in Urban Areas ForewordRenugopalNessuna valutazione finora

- 2007 Annual Report - English 2007 PDFDocumento57 pagine2007 Annual Report - English 2007 PDFjokotsNessuna valutazione finora

- Canadian Bleve TextDocumento31 pagineCanadian Bleve Textarachman297988Nessuna valutazione finora

- Jobs Safety Plan - TemplateDocumento16 pagineJobs Safety Plan - TemplateFairus Md Yusof100% (1)

- Aet Model QN PaperDocumento5 pagineAet Model QN PaperJagadishRajNessuna valutazione finora

- Safety Moment - DeadlegsDocumento7 pagineSafety Moment - DeadlegsJaned PerwiraNessuna valutazione finora

- Table 2.1: Chemical Plant Cost Value Index (CEP Index) Year CEP Year CEP Year CEPDocumento6 pagineTable 2.1: Chemical Plant Cost Value Index (CEP Index) Year CEP Year CEP Year CEPSolehah OmarNessuna valutazione finora

- H P 2011 02 PDFDocumento97 pagineH P 2011 02 PDFErvin WatzlawekNessuna valutazione finora

- Dynaco g101 g102 Dump Pump PDFDocumento6 pagineDynaco g101 g102 Dump Pump PDFnbgearsNessuna valutazione finora

- VNX - Su Avensis Supplement Chassis Body 2000 rm781 PDFDocumento776 pagineVNX - Su Avensis Supplement Chassis Body 2000 rm781 PDFprog-toy75% (4)

- Case Study On Acid RainDocumento11 pagineCase Study On Acid RainMayraaj KhaanamNessuna valutazione finora

- Classification of Internal Combustion EnginesDocumento33 pagineClassification of Internal Combustion EnginesPraveen SharmaNessuna valutazione finora

- Ipr RegDocumento34 pagineIpr RegNicolae PopNessuna valutazione finora

- YALE (C810) GDP030 LIFT TRUCK Service Repair Manual PDFDocumento20 pagineYALE (C810) GDP030 LIFT TRUCK Service Repair Manual PDFhfjsjekmmdNessuna valutazione finora

- Wellsite GeologyDocumento6 pagineWellsite GeologyLeonardo CarrilloNessuna valutazione finora