Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Company Profile

Caricato da

Anonymous MB5YbaLrBECopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Company Profile

Caricato da

Anonymous MB5YbaLrBECopyright:

Formati disponibili

Company Profile

Established in 1972, as a Division of Systech International, and then on July 1, 1980, as an independent and

separate identity, Systech Consultancy Services (SCS) is a consulting engineering Organisation providing

computer aided engineering (CAE) software, and services. Based in Mumbai, Systech Consultancy Services has

been meeting the needs of industries for more than three-decades.

The Engineering Analysis Section within Systech Consultancy Services is able to provide a comprehensive stress

analysis service, in accordance with strict quality assurance procedures. A summary of previous projects is available

upon request.

Finite Element Analysis and CFD is carried out by Systech Consultancy Services using Internationally Validated

and Approved Finite Element & CFD Analysis Software, ANSYS Multiphysics and meets the requirements of ISO

9001:2008, the internationally accepted quality standard for software, and United States Nuclear Regulatory

Commission (NRC) rules and regulations, which set forth some of the most stringent software quality standards

around the globe.

Systech Consultancy Services provides Computer Aided Engineering (CAE / CAD) Services for:

Design of Static Equipment (Pressure Vessels / Columns as per ASME / PD / Pressure Equipment Directive

97/23/EC, Heat Exchangers as per ASME / TEMA)

Finite Element Analysis for Pressure Vessels as per ASME Sec. VIII Div. 2 / PD: 5500, Annex A, B, & C / PED

(Pressure Equipment Directive 97/23/EC) / EN-13445 / A.D. Merkblatt.

Finite Element Analysis for Storage Tanks including Horton Spheres as per API 620 and API 650.

Mechanical Design and Finite Element Method (FEM) Analysis of Mounded Storage Bullets as per ASME Sec.

VIII Div. 2 / PD: 5500, Annex A, B, & C / PED (Pressure Equipment Directive 97/23/EC) / EN-13445 / A.D.

Merkblatt.

Fatigue Analysis of Pressure Vessels as per ASME Sec. VIII Div. 2 / PD: 5500, Annex A, B, & C / PED (Pressure

Equipment Directive 97/23/EC) / EN-13445 / A.D. Merkblatt.

Computer Aided Fitness-for-Service (FFS), Level 1, 2 & 3 Assessment using Numerical Method [Finite Element

Analysis and Fracture Mechanics (Part-9) using ANSYS] as per Fitness-For-Service, API 579-1/ASME FFS-1,

June 5, 2007 (API 579 Second, Second Edition) for Fertilizer, Refinery / Petrochemical Plant Static Equipments

(Pressure Vessels, Storage Tanks, Heat Exchangers) and Piping.

Plant Piping / Onshore Piping / Offshore Piping / Nuclear Piping (Flexibility / Vibrations Analysis / Failure Analysis

/ Seismic Analysis) as per ANSI B31.1, B31.3, B31.4 or B31.8, ASME III including code compliance reports.

Rotating Equipment, Vibration & Noise Control for Centrifugal Pumps (Water Hammer) / Compressors

(Surge)/Turbines, Engines, Rotor Dynamics (Lateral / Torsional Analysis as per API-610, 611, 617), Acoustic

Pulsation Studies (Digital) for Reciprocating Compressor (API 618 DA3) / Pumps (API 674 DA2).

Acoustic Induced Vibration (AIV) and the Flow Induced Vibration (FIV) with Transient Dynamic Analysis Services for

Pressure Reducing Devices such as Valves [Anti-surge Valve / FOV (Fast Opening Valve) / BPRV (Buckling Pin Relief

Valve) in Piping including small bore tapingsas for Flare / compressors / per Procedure given in DEP 31.38.01.11

(2014), Piping General Requirements, Appendix 17 and 19 read along with the guidelines given in Energy Institute,

U.K., Guidelines for the avoidance of vibration induced fatigue failure in process pipework (2008)

Seismic Qualification of equipment (Pressure Vessel, Heat Exchangers, Reactors, Piping, Engines, Turbines,

Pumps, Compressors, Blowers, Fans, Chillers, Filters, Screens, Dryers, PA Systems, Coolers, Motors,

Transformers, Control / Instrument Panels, and other machinery), components (Valves, Dampers, Expansion

Joints / Bellows, Instruments / Gauges), structures (Steel and RCC), and installed systems for seismic loading

using Finite Element Analysis (FEA) as per ASME Sec. III Class NB, NC, ND & NF.

Seismic Qualification of electrical equipment including Panels, Control Panels, Transformers, Motors, LCP, PA

Systems, Glass Lined Panels, Instruments, Transducers, Gauges, Fire Protection Systems, and installed

systems for seismic loading using Finite Element Analysis (FEA) as per IEEE 344 read along with ASME Sec. III

Class NB, NC, ND & NF.

Shock & Vibration Analysis of equipment using Finite Element Analysis (FEA) based Transient Dynamic Analysis.

Fatigue / Durability / Reliability Analysis of Rotating and Reciprocating Parts of Centrifugal and Reciprocating

Pumps / Compressors, Blowers, Steam and Gas Turbines, Diesel, Gas (CNG) and Petrol Engines, Aero-space,

Automotive Parts.

Structural Analysis / Design of R.C.C. / Steel Structures

Design and Analysis of Self Supported and/or Guy Wire Supported Stacks [Support Structures for Flares,

Chimneys and Vents] as per ASME-STS-1, BS 4076, CICIND, Indian Standards (IS 6533), and TIA/EIA-222F for

Steel Antenna Towers and Antenna Supporting Structures covering Antenna Structures and Monopoles, as well

as Guyed Towers using STACKDES and ANSYS Finite Element Program.

Foundations for Vibrating Machinery (Block / Framed) using Finite Element Analysis.

Computational Fluid Dynamics (CFD) Analysis of Chemical and Process Plants including Valves, Heat

Exchangers, Surface Condensors,Furnaces, Centrifugal and Reciprocating Pumps / Compressors, Steam and

Gas Turbines, Diesel, Gas (CNG) and Petrol Engines.

Thermal Analysis including Steady-State and Transient Thermal Analysis using CFD / FEA.

Thermal and Mechanical Design of Heat Exchangers as per TEMA, ASME Section VIII including UHX.

SYSTECH CONSULTANCY SERVICES, 21 & 22 AASRA APT., ST. ANTHONY STREET, VAKOLA, SANTACRUZ (E), MUMBAI -400 055

PHONE: 91-22-2667-4506 or 2667-4787, FAX: 91-22-2667-2737, E-Mail: systech_consultancy@vsnl.com

Potrebbero piacerti anche

- Asme Nuclear CodesDocumento2 pagineAsme Nuclear CodesAnonymous MB5YbaLrBENessuna valutazione finora

- Technical Note Two Phase FlowDocumento3 pagineTechnical Note Two Phase FlowAnonymous MB5YbaLrBENessuna valutazione finora

- FEA - PresVesls - SCRBDDocumento18 pagineFEA - PresVesls - SCRBDAnonymous MB5YbaLrBENessuna valutazione finora

- FEA Tangetial Nozzle Brochure1Documento1 paginaFEA Tangetial Nozzle Brochure1Anonymous MB5YbaLrBE0% (1)

- Software Validation Test For Bearing StiffnessDocumento2 pagineSoftware Validation Test For Bearing StiffnessAnonymous MB5YbaLrBENessuna valutazione finora

- Agitator Nozzle Load Data SheetDocumento1 paginaAgitator Nozzle Load Data SheetAnonymous MB5YbaLrBENessuna valutazione finora

- Heater Outlet Vibration Analysis PDFDocumento1 paginaHeater Outlet Vibration Analysis PDFAnonymous MB5YbaLrBENessuna valutazione finora

- MineralWoolInsulation Data SheetDocumento18 pagineMineralWoolInsulation Data SheetAnonymous MB5YbaLrBENessuna valutazione finora

- Data Required For Fatigue AnalysisDocumento1 paginaData Required For Fatigue AnalysisAnonymous MB5YbaLrBENessuna valutazione finora

- Technical Basis For Reinforcing Pads Requirements On Nozzles Rev1Documento1 paginaTechnical Basis For Reinforcing Pads Requirements On Nozzles Rev1Anonymous MB5YbaLrBENessuna valutazione finora

- Pipe Roughness ValueDocumento1 paginaPipe Roughness ValueAnonymous MB5YbaLrBENessuna valutazione finora

- AKCC 400E DimensionsDocumento1 paginaAKCC 400E DimensionsAnonymous MB5YbaLrBENessuna valutazione finora

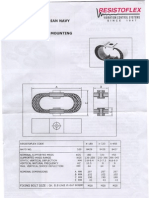

- Resistoflex x450Documento2 pagineResistoflex x450Anonymous MB5YbaLrBENessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Eaton Series 70122 70422Documento28 pagineEaton Series 70122 70422Aijaz Akbar100% (1)

- Marine Engineering Practice PDFDocumento195 pagineMarine Engineering Practice PDFThin Phichanchun100% (2)

- S34xen Schwing Pump PDFDocumento2 pagineS34xen Schwing Pump PDFAmin KmiNessuna valutazione finora

- 2011 McQuay Chilled Water CatalogueDocumento26 pagine2011 McQuay Chilled Water CatalogueRCYABONessuna valutazione finora

- Rotating Equipment SafetyDocumento34 pagineRotating Equipment SafetySuchismita Bhattacharya Bhaumik0% (1)

- Grundfos Pump Installation BookDocumento84 pagineGrundfos Pump Installation BookSujalsathwaraNessuna valutazione finora

- Monorail Beams Installation WorkDocumento1 paginaMonorail Beams Installation WorkBaisel RahumanNessuna valutazione finora

- Prostar 210 User ManualDocumento112 pagineProstar 210 User ManualMartinNessuna valutazione finora

- Quick Reference Guide: IC260L/D DUO IC261L/D DUO (Firmware Rel. 1.9)Documento64 pagineQuick Reference Guide: IC260L/D DUO IC261L/D DUO (Firmware Rel. 1.9)Ivaylo TodorovNessuna valutazione finora

- Rc250 ManualDocumento153 pagineRc250 ManualRandolfCabeza71% (7)

- LPG Vertical Compressor Sales BrochureDocumento12 pagineLPG Vertical Compressor Sales Brochurekeyonltd100% (2)

- CV Mini InstallDocumento12 pagineCV Mini InstallYu MatsuNessuna valutazione finora

- Coiled Tubing - Emergency ProceduresDocumento50 pagineCoiled Tubing - Emergency ProceduresSarasevina Anggraeni100% (2)

- Group 2-Mixed and Axial Flow PumpsDocumento39 pagineGroup 2-Mixed and Axial Flow PumpsYhuloopz AlvarezNessuna valutazione finora

- PERKINS 1506 System Testing & Adjusting OkDocumento76 paginePERKINS 1506 System Testing & Adjusting Okbagus100% (4)

- Golden Dragon ChaoYang Diesel Engine Model 100-102-105 Operation ManualDocumento210 pagineGolden Dragon ChaoYang Diesel Engine Model 100-102-105 Operation Manualorphee mandji100% (1)

- Hydraulic Training Release 14082002Documento62 pagineHydraulic Training Release 14082002rdragomiNessuna valutazione finora

- Principle of Power SteeringDocumento62 paginePrinciple of Power SteeringAtul Khanna80% (5)

- 4A TOTS ChemicalDocumento22 pagine4A TOTS ChemicalHiddenD100% (2)

- 06-Proces Flow Diagram (PFD)Documento13 pagine06-Proces Flow Diagram (PFD)Hazel Raditya MizumareruNessuna valutazione finora

- Typical Turbine System and DescriptionDocumento85 pagineTypical Turbine System and DescriptionManjunath AithalNessuna valutazione finora

- WallMountedS24S5 Chassis Inverter ServiceManualDocumento72 pagineWallMountedS24S5 Chassis Inverter ServiceManualcaovadio88100% (1)

- OMV PWS (Basis of Design)Documento13 pagineOMV PWS (Basis of Design)rizwan khanNessuna valutazione finora

- Fiche Technique Grundfos RSIDocumento2 pagineFiche Technique Grundfos RSISINES France100% (8)

- Blagdon: Air Operated Double Diaphragm PumpDocumento2 pagineBlagdon: Air Operated Double Diaphragm PumpMurthy NarayananNessuna valutazione finora

- Catalog CDPHDocumento4 pagineCatalog CDPHAhmad KoriemNessuna valutazione finora

- q456 Tankship Dangerous LiquidsDocumento12 pagineq456 Tankship Dangerous LiquidsJohn MondalaNessuna valutazione finora

- Edwards EXT255 Instruction ManualDocumento48 pagineEdwards EXT255 Instruction ManualBranislav LoncarevicNessuna valutazione finora

- C4ce22 Hydro Power Engineering Set1Documento9 pagineC4ce22 Hydro Power Engineering Set1bhkedarNessuna valutazione finora