Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Ti 2 313 Us SPIRAX

Caricato da

GUZMANTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Ti 2 313 Us SPIRAX

Caricato da

GUZMANCopyright:

Formati disponibili

Float &

Thermostatic

Steam Traps

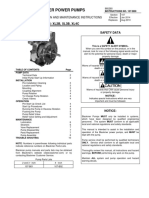

Cast Iron Float & Thermostatic Steam Traps

FT-15, FT-30, FT-75, FT-125

The trap contains a

float valve mechanism

which modulates to

discharge condensate

continuously at steam

temperature, while

non-condensible gases

are released by a separate internal balanced

pressure thermostatic

air vent.

Model

PMO

FT-15

FT-30 FT-75 FT-125

15 psig

30 psig

Sizes

75 psig

Typical Applications

125 psig

All process equipment, particularly when

controlled by modulating temperature control valves; unit heaters, air heating coils,

heat exchangers and steam main drip stations.

3/4", 1", 1-1/4", 1-1/2", 2"

Connections

NPT

Construction

Cast Iron Body &Cover

Stainless Steel Internals

Options

For Capacities,

See TIS 2.317

Gauge Glass, Vacuum Breaker

All 1-1/2", 2"

1-1/4" FT-75,

FT-125

All 3/4", 1"

1-1/4" FT-15, FT-30

1

7

8,18

5

15

6

16

2 3

Max. Operating Pressure (PMO) FT-15: 15 psig

FT-30: 30 psig

FT-75: 75 psig

FT-125: 125 psig

(1.0 barg)

(2.1 barg)

(5.2 barg)

(8.6 barg)

Max. Operating Temperature 450F (25C) at all

operating pressures

Pressure Shell Design Conditions

Max. allowable pressure

TMA

125 psig/up to 450F

450F/0-125 psig

Max. allowable temperature

Construction Materials

Limiting Operating Conditions

PMA

17

6 5 18 16

9 barg/up to 232C

232C/0-9 barg

No.

1

2

3

4

5

6

7

8

9

15

16

17

18

Part

Material

Body

Cast Iron

ASTMA126 CL B

Cover Screws

Carbon Steel

ASTM A449

Cover Gasket

Graphite

Cover

Cast Iron

ASTMA126 CL B

Valve Seat

Stainless Steel

Valve Seat Gasket

Stainless Steel

Ball Float

Stainless Steel

Float Arm

Stainless Steel

Air Vent Assembly

Stainless Steel

Air Vent Head

Stainless Steel

Air Vent Seat

Stainless Steel

Seat Bracket

Stainless Steel

Pivot Pins

Stainless Steel

Head Bracket, Stop, Link

Stainless Steel

Valve Head

Stainless Steel

Local regulation may restrict the use of this product below the conditions quoted. Limiting conditions refer to standard connections only.

In the interests of development and improvement of the product, we reserve the right to change the specification.

TI-2-313-US 2.14

2:158

Cast Iron Float & Thermostatic Steam Traps

FT-15, FT-30, FT-75, FT-125

All 3/4", 1"

1-1/4" FT-15, FT-30

Dimensions

(nominal) in inches and millimeters

B

D

2"

E E1 F G Weight

4.6

117

3.3

84

3

77

5.75

146

1"* 1" 8.5 4.25 3

216

108

76

A

6.2

157

E1

3/8" NPT Drain

4.7

119

3

76

0.3 9 lb

7.9 4.1 kg

0.7 8.4 3.5 18 lb

17

213 89

8.2 kg

9.8

4.9

4.9

0.12

249 124 124 3

*1-1/4" 6.2

FT-15, FT-30 157

1.3

33

Steam Traps

3/8" NPT Drain

Size

3/4", 1"

9.1

1.9

26 lb

230

49 11.8 kg

2.8

72

5.75

146

1.5

38

0.3 9.3 lb

7.9 4.2 kg

Float &

Thermostatic

C E

All 1-1/2", 2"

1-1/4" FT-75, FT-125

Sample Specification

Spare Parts

Steam traps shall be of the mechanical ball float type

having cast iron bodies, NPT connections, and all stainless

steel internals. Incorporated into the trap body shall be

a stainless steel balanced pressure thermostatic air vent

capable of withstanding up to 450F(25C) and resisting

waterhammer without sustaining damage. Internals of the

trap shall be completely servicable without disturbing the

piping.

Air V

All 3/4", 1"

1-1/4" FT-15, FT-30

ent A

ssem

bly

Installation

C D

Maintenance

D

Valv

eM

inclu Ass echan

ding emb ism

Pin ly

s&

Link

s

This product can be maintained without disturbing the piping connections. Complete isolation from both supply and

return line is required before any servicing is performed.

The trap should be disassembled periodically for inspection and cleaning of the valve head and seat, operating

mechanism and air vent.

Worn or damaged parts should be replaced using a complete valve mechanism assembly and/or air vent assembly.

Complete installation and maintenance instructions

are given in IM-2-300, which accompanies the product.

E F

Valve M

ech

Assem anism

bly

All 1-1/2", 2"

1-1/4" FT-75, FT-125

Gasket Kit (3 of each)

B, E

Air Vent Kit

H, J, L, M, N, O

Valve Mechanism

C, D, E, F, (G)

Kit (less float)

Float Kit P

Consists of: Air Vent Assembly and

Replacement Module

Valve Mechanism (w/Float) attached

3/4", 1", 1-1/4" FT-15

to a Cover and supplied with a Cover

3/4", 1", 1-1/4" FT-30

Gasket, Nameplat and a set of Cover

3/4", 1", FT-15, FT-125

Bolts. (Assembled)

Spirax Sarco, Inc., 1150 Northpoint Blvd, Blythewood, SC 29016

Spirax Sarco, Inc. 2014

A pipeline strainer should be installed ahead of any steam

trap. Full port isolating valves should be placed to permit

servicing. The trap should be installed below the drainage

point of the equipment with a collecting leg before the

trap, in a position so that the float arm is in a horizontal

plane so that the float rises and falls vertically, and with

the direction of flow as indicated on the body. Refer to

IM-2-300 for complete instructions.

TI-2-313-US 2.14

Telephone: (803) 714-2000 FAX (803) 714-2222

2:159

Potrebbero piacerti anche

- XR15 Performance DataDocumento16 pagineXR15 Performance Databarber bobNessuna valutazione finora

- The Weir Direct-Acting Feed Pump - Working InstructionsDa EverandThe Weir Direct-Acting Feed Pump - Working InstructionsNessuna valutazione finora

- FW SuperLite Standard Range Catalogue 2012-13Documento212 pagineFW SuperLite Standard Range Catalogue 2012-13majortayNessuna valutazione finora

- Chilled Water Pump Head CalculationDocumento18 pagineChilled Water Pump Head CalculationMohammed Ahmed Khan88% (8)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGDa EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNessuna valutazione finora

- CO2 AnsulDocumento17 pagineCO2 AnsulJorge RVNessuna valutazione finora

- Mosque BOQDocumento17 pagineMosque BOQHossam Al-Dein Mostafa HelmyNessuna valutazione finora

- AST F2033 Hip JointDocumento5 pagineAST F2033 Hip Jointdeepdreamx6400Nessuna valutazione finora

- Fixed Platforms, Walkways, Stairways and Ladders-Design, Construction and InstallationDocumento7 pagineFixed Platforms, Walkways, Stairways and Ladders-Design, Construction and InstallationgeofounNessuna valutazione finora

- Solar Mars 100 Technical and Commercial-Rev0Documento20 pagineSolar Mars 100 Technical and Commercial-Rev0Jojo Aboyme Corcilles100% (1)

- Danfoss Expansion ValveDocumento42 pagineDanfoss Expansion ValveLokesh GandhiNessuna valutazione finora

- Peco Gas Scrubber Fs 85 SL 01Documento4 paginePeco Gas Scrubber Fs 85 SL 01Rigoberto LozanoNessuna valutazione finora

- Solenoid Valve Data SheetDocumento14 pagineSolenoid Valve Data SheetGuido Moreno PeredoNessuna valutazione finora

- Trampadevapor Flotador y TermostaticaDocumento9 pagineTrampadevapor Flotador y TermostaticaLuis Gutiérrez AlvarezNessuna valutazione finora

- Valvulas HenryDocumento3 pagineValvulas Henrygeoteg2011Nessuna valutazione finora

- Ti 2 315 Us Spirax SarcoDocumento2 pagineTi 2 315 Us Spirax SarcoGUZMANNessuna valutazione finora

- Series TY-B - 2.8, 5.6, and 8.0 K-Factor Upright, Pendent, and Recessed Pendent Sprinklers Standard Response, Standard CoverageDocumento8 pagineSeries TY-B - 2.8, 5.6, and 8.0 K-Factor Upright, Pendent, and Recessed Pendent Sprinklers Standard Response, Standard CoverageFlorin IordacheNessuna valutazione finora

- CL38 Commercial and Industrial RegulatorDocumento27 pagineCL38 Commercial and Industrial RegulatorJesus Castro OrozcoNessuna valutazione finora

- PND1000 3 AccessoriesDocumento40 paginePND1000 3 AccessoriesPartsGopher.comNessuna valutazione finora

- Valvula Reductora de Presion Bermad Area 675 720-ULDocumento4 pagineValvula Reductora de Presion Bermad Area 675 720-ULChristian FherNessuna valutazione finora

- Caleffi: Safety Relief Valves For Thermal, Hydraulic and Domestic Water SystemsDocumento6 pagineCaleffi: Safety Relief Valves For Thermal, Hydraulic and Domestic Water SystemsjeffjozoNessuna valutazione finora

- SPRK Ssu + SSPDocumento8 pagineSPRK Ssu + SSPdanateoNessuna valutazione finora

- Carrier Air Con 38QRR ManualDocumento30 pagineCarrier Air Con 38QRR ManualYorkistNessuna valutazione finora

- Dimensions - Inches Product Data: Split-System Evaporator Blowers 15 & 20 TONDocumento4 pagineDimensions - Inches Product Data: Split-System Evaporator Blowers 15 & 20 TONRafyss RodriguezNessuna valutazione finora

- Mustang Series M115-74 (Globe), M1115-74 (Angle) Specification SheetDocumento7 pagineMustang Series M115-74 (Globe), M1115-74 (Angle) Specification SheetWattsNessuna valutazione finora

- Air System ComponentsDocumento6 pagineAir System ComponentsEliasNessuna valutazione finora

- Mustang Series M115-3 (Globe), M1115-3 (Angle) Specification SheetDocumento7 pagineMustang Series M115-3 (Globe), M1115-3 (Angle) Specification SheetWattsNessuna valutazione finora

- HPCO2Documento23 pagineHPCO2Abdul RahmanNessuna valutazione finora

- Rociador Standard TYCODocumento8 pagineRociador Standard TYCOysaiasdannyNessuna valutazione finora

- BallValues PDFDocumento12 pagineBallValues PDFDevdatt WaghuleNessuna valutazione finora

- CGAT Catalog0303Documento2 pagineCGAT Catalog0303Chinith HengNessuna valutazione finora

- PVC & CPVC True Union 2000 Valves: One of The Most Versatile, Compact Valve Designs AvailableDocumento4 paginePVC & CPVC True Union 2000 Valves: One of The Most Versatile, Compact Valve Designs AvailableKarthick VenkateshNessuna valutazione finora

- ASCO SolenoidDocumento10 pagineASCO Solenoidsharib26Nessuna valutazione finora

- MyersDocumento3 pagineMyersJuan Camilo Tejada OrjuelaNessuna valutazione finora

- 1800 PFM Regulator Brochure EAM-BR8552 PDFDocumento6 pagine1800 PFM Regulator Brochure EAM-BR8552 PDFhataefendiNessuna valutazione finora

- TWO STAGE GAS BURNERS FOR HEATING OUTPUTS RANGING FROM 80 TO 3200 KWDocumento24 pagineTWO STAGE GAS BURNERS FOR HEATING OUTPUTS RANGING FROM 80 TO 3200 KWLenier Andrés VillalbaNessuna valutazione finora

- 100G - 2100G ClavalDocumento2 pagine100G - 2100G Clavale1901bNessuna valutazione finora

- BVG4P 1 LOCK Parker Brass Ball ValveDocumento2 pagineBVG4P 1 LOCK Parker Brass Ball ValveMROstop.comNessuna valutazione finora

- Flowserve Valvulas de Bolas y Valvulas YDocumento148 pagineFlowserve Valvulas de Bolas y Valvulas YJuan Gutierrez CastilloNessuna valutazione finora

- 4TTA3060Documento2 pagine4TTA3060Giovanny Buitrago ArenasNessuna valutazione finora

- 399ADocumento24 pagine399ADana Mera100% (2)

- Mustang Series M115 (Globe), M1115 (Angle) Specification SheetDocumento7 pagineMustang Series M115 (Globe), M1115 (Angle) Specification SheetWattsNessuna valutazione finora

- Ec 0301Documento25 pagineEc 0301Silvio RomanNessuna valutazione finora

- Pressure Reducing: Model 129FcDocumento6 paginePressure Reducing: Model 129Fcjames alfarasNessuna valutazione finora

- Air Conditioning Design Basis for Shop Floor and First Floor 38Documento8 pagineAir Conditioning Design Basis for Shop Floor and First Floor 38jnmanivannanNessuna valutazione finora

- Mustang Series M115-7 (Globe), M1115-7 (Angle) Specification SheetDocumento8 pagineMustang Series M115-7 (Globe), M1115-7 (Angle) Specification SheetWattsNessuna valutazione finora

- Valves BarendsenDocumento63 pagineValves BarendsenidontlikeebooksNessuna valutazione finora

- Tyco Ty-B PDFDocumento8 pagineTyco Ty-B PDFJorge ValenciaNessuna valutazione finora

- Diapham Valve PDFDocumento8 pagineDiapham Valve PDFthouche007Nessuna valutazione finora

- Valves and Solenoid Valves Series EDocumento12 pagineValves and Solenoid Valves Series EMijin28Nessuna valutazione finora

- 38CKC Product DataDocumento26 pagine38CKC Product DataCarlos Enrique Godoy Sifontes0% (1)

- Actuated ValvesDocumento4 pagineActuated ValvestjendraNessuna valutazione finora

- Pfeiffer Br26d EngDocumento4 paginePfeiffer Br26d EngAleksandr KrigerNessuna valutazione finora

- Fisher 1190 Low-Pressure Gas Blanketing RegulatorDocumento20 pagineFisher 1190 Low-Pressure Gas Blanketing Regulatorneurolepsia3790Nessuna valutazione finora

- BaileyDocumento14 pagineBaileyhecdomNessuna valutazione finora

- BVGT4 1 4C ParkerBall ValveDocumento2 pagineBVGT4 1 4C ParkerBall ValveMROstop.comNessuna valutazione finora

- 7785 A5Documento13 pagine7785 A5hmltdt9221100% (1)

- 2012 Stanley Heating CatalogueDocumento20 pagine2012 Stanley Heating Cataloguelulu3232Nessuna valutazione finora

- Seriesgp1000 PDFDocumento3 pagineSeriesgp1000 PDFanbumani123Nessuna valutazione finora

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDa EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNessuna valutazione finora

- Marvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SDa EverandMarvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SNessuna valutazione finora

- Operating Manual VAMcDocumento24 pagineOperating Manual VAMcGUZMANNessuna valutazione finora

- 9003 Sigma S1Ba Diaphragm Metering Pumps Performance DiagramDocumento2 pagine9003 Sigma S1Ba Diaphragm Metering Pumps Performance DiagramGUZMANNessuna valutazione finora

- Salsnes Filter SF EnglishDocumento2 pagineSalsnes Filter SF EnglishGUZMANNessuna valutazione finora

- Cross Reference: Thermodynamic Traps Steel Float & Thermostatic TrapsDocumento1 paginaCross Reference: Thermodynamic Traps Steel Float & Thermostatic TrapsGUZMANNessuna valutazione finora

- SITRANS AS 100 Acoustic Sensor: Lista de Precios y Configuración de ModelosDocumento1 paginaSITRANS AS 100 Acoustic Sensor: Lista de Precios y Configuración de ModelosGUZMANNessuna valutazione finora

- Tabla Americana de Avances de Accesorios...Documento9 pagineTabla Americana de Avances de Accesorios...GUZMANNessuna valutazione finora

- SITRANS F US SONOFLO - Ultrasonic Flow Meters SONOKIT, 1-TrackDocumento4 pagineSITRANS F US SONOFLO - Ultrasonic Flow Meters SONOKIT, 1-TrackGUZMANNessuna valutazione finora

- SITRANS CU 02 Control Unit: Lista de Precios y Configuración de ModelosDocumento1 paginaSITRANS CU 02 Control Unit: Lista de Precios y Configuración de ModelosGUZMANNessuna valutazione finora

- Description: NGA Network Graphic AnnunciatorDocumento1 paginaDescription: NGA Network Graphic AnnunciatorGUZMANNessuna valutazione finora

- Uni CellDocumento2 pagineUni CellGUZMANNessuna valutazione finora

- Tabla Americana de Avances de Accesorios...Documento9 pagineTabla Americana de Avances de Accesorios...GUZMANNessuna valutazione finora

- 7100 Manual 9021-60554Documento44 pagine7100 Manual 9021-60554GUZMANNessuna valutazione finora

- Mass Notification Solutions - E3 Series: SurvivabilityDocumento2 pagineMass Notification Solutions - E3 Series: SurvivabilityGUZMANNessuna valutazione finora

- GW Voice BrochureDocumento8 pagineGW Voice BrochureGUZMANNessuna valutazione finora

- SITRANS TF Transmitter For Temperature / Field Indicators: Lista de Precios y Configuración de ModelosDocumento3 pagineSITRANS TF Transmitter For Temperature / Field Indicators: Lista de Precios y Configuración de ModelosGUZMANNessuna valutazione finora

- Flex Series Brochure 9021 60287Documento2 pagineFlex Series Brochure 9021 60287GUZMANNessuna valutazione finora

- Ter More Siste Nci AsDocumento16 pagineTer More Siste Nci AsGUZMANNessuna valutazione finora

- CS-2023 600 Series Power SupliesDocumento2 pagineCS-2023 600 Series Power SupliesGUZMANNessuna valutazione finora

- 9020-0622 ADPF Duct SensorDocumento2 pagine9020-0622 ADPF Duct SensorGUZMANNessuna valutazione finora

- Mass Notification Solutions - E3 Series: SurvivabilityDocumento2 pagineMass Notification Solutions - E3 Series: SurvivabilityGUZMANNessuna valutazione finora

- CS-2401 600 Series IdentiFlex 602 Analog Addr PanelDocumento3 pagineCS-2401 600 Series IdentiFlex 602 Analog Addr PanelGUZMANNessuna valutazione finora

- Cs 2501 GW UdactDocumento3 pagineCs 2501 GW UdactGUZMANNessuna valutazione finora

- 9020-0623 ABD-2F Photo BeamDocumento2 pagine9020-0623 ABD-2F Photo BeamGUZMANNessuna valutazione finora

- CS-2025 600 Series Remote AnnunciatorsDocumento2 pagineCS-2025 600 Series Remote AnnunciatorsGUZMANNessuna valutazione finora

- CS-2073 600 Series Smart LinkDocumento2 pagineCS-2073 600 Series Smart LinkGUZMANNessuna valutazione finora

- CS-2027 600 Series Serial Annunciator DriversDocumento2 pagineCS-2027 600 Series Serial Annunciator DriversGUZMANNessuna valutazione finora

- 9020-0622 ADPF Duct SensorDocumento2 pagine9020-0622 ADPF Duct SensorGUZMANNessuna valutazione finora

- 9020-0620 ATD-L2F Thermal SensorDocumento2 pagine9020-0620 ATD-L2F Thermal SensorGUZMANNessuna valutazione finora

- Negotiation - Course Outline APR17Documento8 pagineNegotiation - Course Outline APR17ravindrarao_mNessuna valutazione finora

- Bernstein ToolsDocumento138 pagineBernstein Toolsjoeblow56100% (1)

- Project ScopeDocumento2 pagineProject ScopeRahul SinhaNessuna valutazione finora

- Mechanical Fitting - ICE Level 3 - 06 10 14Documento6 pagineMechanical Fitting - ICE Level 3 - 06 10 14KingsleyOwunariDokuboNessuna valutazione finora

- About The Business 1.1 Business Profile Positif CorporationDocumento7 pagineAbout The Business 1.1 Business Profile Positif CorporationLinh DalanginNessuna valutazione finora

- Timeouts PT8.5xDocumento21 pagineTimeouts PT8.5xJack WangNessuna valutazione finora

- 107-b00 - Manual OperacionDocumento12 pagine107-b00 - Manual OperacionJuan David Triana SalazarNessuna valutazione finora

- Army C-sUAS Systems AssessmentDocumento4 pagineArmy C-sUAS Systems AssessmentArthur WongNessuna valutazione finora

- Cisco Mobility Express Command Reference, Release 8.3Documento1.158 pagineCisco Mobility Express Command Reference, Release 8.3Ion Vasilescu100% (1)

- TYPE 183 1.8m Extended RXTX Class I 14-11-14Documento2 pagineTYPE 183 1.8m Extended RXTX Class I 14-11-14Amy KennedyNessuna valutazione finora

- Malaysia Grid CodeDocumento2 pagineMalaysia Grid Codebee398Nessuna valutazione finora

- The Changing Face of The NewsDocumento2 pagineThe Changing Face of The NewsYanaNessuna valutazione finora

- Caracterización Y Zonificación Edáfica Y Climática de La Región de Coquimbo, ChileDocumento23 pagineCaracterización Y Zonificación Edáfica Y Climática de La Región de Coquimbo, ChileSantos DamasNessuna valutazione finora

- HelicommandDocumento11 pagineHelicommandNandin OnNessuna valutazione finora

- CIECO PPC1000R Installation Manual V3.3Documento61 pagineCIECO PPC1000R Installation Manual V3.3TomNessuna valutazione finora

- BPO Management System SoftwareDocumento22 pagineBPO Management System SoftwareSathyaaishuNessuna valutazione finora

- BingDocumento5 pagineBingdheaNessuna valutazione finora

- TNEB vacancy cut-off datesDocumento7 pagineTNEB vacancy cut-off dateswinvenuNessuna valutazione finora

- 1 Guntha Horizontal Green Poly House ProjectDocumento1 pagina1 Guntha Horizontal Green Poly House ProjectRajneeshNessuna valutazione finora

- Radio Amateur's Software GuideDocumento251 pagineRadio Amateur's Software GuideZdenko NagyNessuna valutazione finora

- Business Functional Areas Functions ProcessesDocumento4 pagineBusiness Functional Areas Functions ProcessesDan MaliwatNessuna valutazione finora

- Project Title: Hospital Management System Description: Hospital Management System Is A Web Based Project. It Consists of Client RegistrationDocumento68 pagineProject Title: Hospital Management System Description: Hospital Management System Is A Web Based Project. It Consists of Client Registrationshahid198950% (2)

- Mechanics of Flight by A.C KermodeDocumento2 pagineMechanics of Flight by A.C KermodeJhony BhatNessuna valutazione finora

- Twingo 3 & Clio 4Documento10 pagineTwingo 3 & Clio 4Alexandre Le GrandNessuna valutazione finora

- Biodegradabilty Prediction Using Deep LearningDocumento9 pagineBiodegradabilty Prediction Using Deep LearningMadhuri DNessuna valutazione finora

- 120FF51A Installation Guide For SAP Solutions PDFDocumento234 pagine120FF51A Installation Guide For SAP Solutions PDFNaqib Hassan100% (1)

- 4 V2 2250 PR Pid 000001 - 1 - PDFDocumento1 pagina4 V2 2250 PR Pid 000001 - 1 - PDFdavidNessuna valutazione finora