Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

IDP Ion Exchange

Caricato da

Arunima GhoseDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

IDP Ion Exchange

Caricato da

Arunima GhoseCopyright:

Formati disponibili

IDP Ion Exchange

Recent Advances In Membrane Technology for

Waste-Water Treatment

Traditional

water

treatment

methods

include

physical

separation

techniques for particle removal; biological and chemical treatments to

remove suspended solids, organic matter and dissolved pollutants or

toxins;

and

other

mechanical

methods.

Recent

developments

in

technology have resulted in breakthroughs in wastewater treatment and

reclamation

for

water

reuse.

This

progress

includes

membrane

technology, which has emerged as a significant innovation for treatment

and reclamation.

Already used for niche applications, usually involving high-value liquid

streams, membrane filtration was introduced in drinking water treatment

in the 1950s, mainly for desalination of seawater, brackish water and

groundwater. Since that time, advances in materials, system designs and

process combinations have opened the door to affordable implementation

in more aspects of the overall water cycle, including production of drinking

and

process

water;

industrial

process

and

wastewater

treatment;

municipal sewage treatment; product recovery from aqueous streams;

and treatment of groundwater, agricultural waste streams.

However any technology has its fair share of limitations and scope for

innovation. Currently membrane separations is a hot topic for research in

order to improve its performance, find a solution to the existing problems

and also make it economically feasible for large scale applications. This

problem aims to bring into picture the current advances in the field of

membrane technology for wastewater treatment. Participants should look

out for the following issues which crop up in the use of membranes and

find out relevant new solutions to eradicate the same.

Membrane Fouling: The biggest technical challenge with the use

of membranes for wastewater treatment is the high potential for

fouling.

Fouling results from complex phenomena linked to the

deposition of components at the surface and inside the pores of the

membrane. Membrane fouling forces to increase the feed pressure

and frequent membrane cleaning. This leads to reduced efficiency

and a shorter membrane life.

Enabling

higher

flux:

An

important

parameter

to

gauge

membrane performance is the flux through the membrane - the

amount of water passing through the membrane per unit of time

and surface area. This has a strong impact on the capital cost of the

process.

Membrane

chemistry:

In

order

to

improve

the

usage

of

membrane technology to systems or chemicals unexplored yet,

work needs to be done on improving the membrane chemistry and

find out new materials or substitutes.

The contents of the gray colored wastewater from the oil refineries are as

follows:

Oil content: 500 mg/l

COD content: 500 mg/l

Phenol: 50 mg/l

Benzene: 10 mg/l

Heavy metals (Zn, Cr, Cu): 20 mg/l

The discharge standards are:

Oil content < 5 mg/l

COD content < 120 mg/l

Phenol < 0.35 mg/l

Benzene < 0.1 mg/l

Heavy metals (Zn, Cr, Cu) < 0.5 mg/l

Suggest

qualitative

treatment

scheme

which

will

enable

the

wastewater to meet the discharge standards using membrane technology.

You can make use of any pre treatment techniques before using

membrane system only if it enhances the performance of the membrane

on the points mentioned above.

Participants will be judged on the basis of how all or any of these above

different aspects have been covered, whether their suggestions have

been implemented in the industry and cost-to-benefit analysis of the

remedies presented. Advances in the membrane technology apart from

the points mentioned will be appreciated.

Potrebbero piacerti anche

- Karl FischerDocumento9 pagineKarl FischerArunima GhoseNessuna valutazione finora

- Report 3-4-14Documento121 pagineReport 3-4-14Palash Kumar FarsoiyaNessuna valutazione finora

- Membrane Separation1Documento6 pagineMembrane Separation1Arunima GhoseNessuna valutazione finora

- IDP Ion ExchangeDocumento3 pagineIDP Ion ExchangeArunima GhoseNessuna valutazione finora

- Self Study 2Documento18 pagineSelf Study 2Arunima GhoseNessuna valutazione finora

- Practice Problems On Multiple Reactions and Non-Isothermal ReactionsDocumento1 paginaPractice Problems On Multiple Reactions and Non-Isothermal ReactionsArunima GhoseNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Swami VivekanandaDocumento20 pagineSwami VivekanandaRitusharma75Nessuna valutazione finora

- (Oxford Readers) Michael Rosen - Catriona McKinnon - Jonathan Wolff - Political Thought-Oxford University Press (1999) - 15-18Documento4 pagine(Oxford Readers) Michael Rosen - Catriona McKinnon - Jonathan Wolff - Political Thought-Oxford University Press (1999) - 15-18jyahmedNessuna valutazione finora

- A Collection of Poems by AKDocumento16 pagineA Collection of Poems by AKAnanda KrishnanNessuna valutazione finora

- Project On Hospitality Industry: Customer Relationship ManagementDocumento36 pagineProject On Hospitality Industry: Customer Relationship ManagementShraddha TiwariNessuna valutazione finora

- Rate Con PO#267800 From Parsippany - NJ To Raeford - NCDocumento2 pagineRate Con PO#267800 From Parsippany - NJ To Raeford - NCbiggbioNessuna valutazione finora

- Creative Writing PieceDocumento3 pagineCreative Writing Pieceapi-608098440Nessuna valutazione finora

- Super Typhoon HaiyanDocumento25 pagineSuper Typhoon Haiyanapi-239410749Nessuna valutazione finora

- Tucker Travis-Reel Site 2013-1Documento2 pagineTucker Travis-Reel Site 2013-1api-243050578Nessuna valutazione finora

- My Portfolio: Marie Antonette S. NicdaoDocumento10 pagineMy Portfolio: Marie Antonette S. NicdaoLexelyn Pagara RivaNessuna valutazione finora

- Listening Practice9 GGBFDocumento10 pagineListening Practice9 GGBFDtn NgaNessuna valutazione finora

- CH03 - Case1 - GE Becomes A Digital Firm The Emerging Industrial InternetDocumento4 pagineCH03 - Case1 - GE Becomes A Digital Firm The Emerging Industrial Internetjas02h10% (1)

- Slave Rebellions & The Black Radical Tradition: SOC3703 Social Movements, Conflict & Change Week 14Documento16 pagineSlave Rebellions & The Black Radical Tradition: SOC3703 Social Movements, Conflict & Change Week 14rozamodeauNessuna valutazione finora

- SOW OutlineDocumento3 pagineSOW Outlineapi-3697776100% (1)

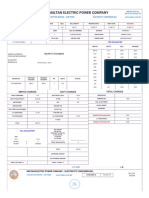

- Multan Electric Power Company: Say No To CorruptionDocumento2 pagineMultan Electric Power Company: Say No To CorruptionLearnig TechniquesNessuna valutazione finora

- The Irish Chocolate CompanyDocumento7 pagineThe Irish Chocolate CompanyMaeveOSullivanNessuna valutazione finora

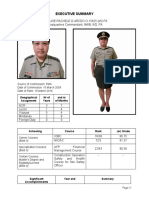

- Executive Summary: Source of Commission: PMA Date of Commission: 16 March 2009 Date of Rank: 16 March 2016Documento3 pagineExecutive Summary: Source of Commission: PMA Date of Commission: 16 March 2009 Date of Rank: 16 March 2016Yanna PerezNessuna valutazione finora

- Marketing Plan11Documento15 pagineMarketing Plan11Jae Lani Macaya Resultan91% (11)

- Ppg-Gdch-Nur-45 Crash Cart Maintenance and ChecksDocumento5 paginePpg-Gdch-Nur-45 Crash Cart Maintenance and ChecksKenny JosefNessuna valutazione finora

- Webinar2021 Curriculum Alena Frid OECDDocumento30 pagineWebinar2021 Curriculum Alena Frid OECDreaderjalvarezNessuna valutazione finora

- 1ST Term J3 Business StudiesDocumento19 pagine1ST Term J3 Business Studiesoluwaseun francisNessuna valutazione finora

- Zero Hedge - On A Long Enough Timeline The Survival Rate For Everyone Drops To Zero PDFDocumento5 pagineZero Hedge - On A Long Enough Timeline The Survival Rate For Everyone Drops To Zero PDFcaldaseletronica280Nessuna valutazione finora

- AI Intelligence (Sam Charrington and Abeba Birhane)Documento2 pagineAI Intelligence (Sam Charrington and Abeba Birhane)Ethel Shammah Waoulda Acleta90% (10)

- Unit 1 PDFDocumento5 pagineUnit 1 PDFaadhithiyan nsNessuna valutazione finora

- Rainiere Antonio de La Cruz Brito, A060 135 193 (BIA Nov. 26, 2013)Documento6 pagineRainiere Antonio de La Cruz Brito, A060 135 193 (BIA Nov. 26, 2013)Immigrant & Refugee Appellate Center, LLCNessuna valutazione finora

- The Realistic NovelDocumento25 pagineThe Realistic NovelNinna NannaNessuna valutazione finora

- SWOT Analysis and Competion of Mangola Soft DrinkDocumento2 pagineSWOT Analysis and Competion of Mangola Soft DrinkMd. Saiful HoqueNessuna valutazione finora

- 2023 10 3 19 47 48 231003 195751Documento7 pagine2023 10 3 19 47 48 231003 195751riyamoni54447Nessuna valutazione finora

- The Message of Malachi 4Documento7 pagineThe Message of Malachi 4Ayeah GodloveNessuna valutazione finora

- The Reformation MovementDocumento5 pagineThe Reformation MovementJulie Anne TasicNessuna valutazione finora

- ACCT1501 MC Bank QuestionsDocumento33 pagineACCT1501 MC Bank QuestionsHad0% (2)