Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

25 TM Installation Manual

Caricato da

Reynold SuarezCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

25 TM Installation Manual

Caricato da

Reynold SuarezCopyright:

Formati disponibili

Rev.

Oct. 2005

ELEVATOR

INSTALLATION GUIDE BOOK

(For Electrical Parts)

NOTICE

1) This guidebook is for the use of STVF5 system Elevator

ONLY.

2) This guidebook does NOT cover safety related subjects.

3) Contact us for your detail queries which this guidebook

does not cover.

CONTENTS

GM-204-0A001

CONTENTS

1. MACHINE ROOM WIRING

1 - 1

2. TRAVELING CABLE INSTALLATION

2 - 1

3. CAR DEVICES CONNECTION

3 - 1

3.1 OPB

3 - 1

3.2 Car Devices

3 - 2

4. HOISTWAY WIRING PREPARATION

4 - 1

4.1 Indicator

4 - 2

4.2 Interlock

4 - 3

4.3 Final Limit Switch

4 - 3

4.4 Pit Area

4 - 3

5. MACHINE ROOM CONNECTORS

5 - 1

6. LOW SPEED OPERATION

6 - 1

7. LCD AND VANE INSTALLATION

7 - 1

7.1 LCD

7 - 1

7.2 Vane

7 - 1

8. HIGH SPEED OPERATION

8 - 1

8.1 Conditions of High Speed Operation

8 - 1

8.2 Operation for Initialization

8 - 1

8.3 High Speed Operation

8 - 1

Oct. 2005

MACHINE ROOM WIRING

GM-204-0A001

1. MACHINE ROOM WIRING

Wire STARTING point and DESTINATION (See Table 1.1)

Table 1.1 Machine room wiring

STARTING

DESTINATION

Motor : A A'(TB BLOCK)

Motor Junction Box

Wiring : U, V, W, GROUND

Thermal : B B'(Inverter)

Wiring : TH1, THC , Shield

Brake Coil : C C'(TD BLOCK)

Wiring : B3, B4

Brake confirm switch : D D'(TD BLOCK)

Wiring : P24, BKOP

Rotary Encoder : E E'(Inverter)

Rotary Encoder

Wiring : PGP, PGM, PA, PB, Shield

If the wiring of PGP/PGM is changed,

the Rotary Encoder shall be DAMAGED.

Governor

Governor switch : F F'(TD BLOCK)

Wiring : P110 ,GOV, GROUND

Install Duct/Conduit for each Motor J. Box, Encoder and Governor separately

1 - 1

Oct. 2005

TRAVELING CABLE INSTALLATION

GM-204-0A001

2. TRAVELING CABLE INSTALLATION

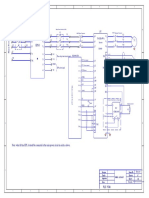

Wire Traveling Cable as shown in Figure 2.1

Connect Car Junction Box to Ground point in Control Panel

3 pieces connector to Control Panel (T1, T1B, T2)

2 pieces connector to Car Junction Box (T1, T2)

Figure 2.1

Traveling Cable installation

2 - 1

Oct. 2005

CAR DEVICES CONNECTION

GM-204-0A001

3. CAR DEVICES CONNECTION

3.1 OPB

Connect STARTING point and DESTINATION point (See Table 3.1, Figure 3.1)

(Refer to OPB Abbreviation description in Table 3.2)

Table 3.1 OPB Connection

PARTS

STARTING

FROM

NAME

CABLE FUNCTION

DESTINATION

TO

NAME

A1

OPB Switch

OPB Switch

CO1

CCB-3

CO1

B1

OPB Signal

M.OPB-3

CC51, CC52

CCB-3

CC51, CC52

C1

CAN

M.OPB-3

CC54A

CCB-3

CC54A

D1

CP

M.OPB-3

CU46B

CPI

CH1

E1

Interphone

CCB-3

CO2

F1

Call

BN

CU47, CU48,

CU49

M.OPB-3

CU47, CU48,

CU49

M.OPBI

CH2

G1

OPBI

D.OPBI or (BN)

CH1

M.OPB-3

CU46

CCB-3

CO1S

CCB-3

CC54B

M.OPB-3

CC26

M.OPB-3

CC54B

Main OPB

D.Interphone

Disable OPB

A2

Interphone

C2

CAN

S.Interphone

Sub OPB

S.OPB-3

Load Switch

OPB-3 Board

CAN

CC54A

Load Switch

Load

Compensator

CN5

Table 3.2 OPB Abbreviation descriptions

NO.

NAME

DESCRIPTION

NO.

NAME

OPBI

DESCRIPTION

BN

Button Network board

with indicator

CCB-3

Car Connection Board

10

M.OPBI

Main OPB Indicator

CJB

Car Junction Box

11

S.OPBI

Sub OPB Indicator

CPI

Car Positioned Indicator

12

D.OPBI

Disable OPB Indicator

OPB

Operating Panel Box

13

OPB-3

OPB control board-3

M.OPB

Main OPB

14

M.OPB-3

Main OPB control board-3

S.OPB

Sub OPB

15

S.OPB-3

Sub OPB control board-3

D.OPB

Disable OPB

16

CAN

3 - 1

OPB Indicator

Controller Area Network

Oct. 2005

CAR DEVICES CONNECTION

GM-204-0A001

CAR J. BOX

CC51, CC52

CCB-3 Bd

EMERGENCY

POWER SUPPLY

CO1

CC54A, B, C

VOICE SYNTH.

CN2

CO2

"A1" Cable

"C2" Cable

"B1" Cable

CAR TOP

INNER CAR

"C1" Cable

SUB OPB

MAIN OPB

CPI

"E2" Cable

CH1

"D1" Cable

"E1" Cable

MAIN DISABLE OPB

5

4

BN Bd.

Interphone

3

2

Interphone

3

2

CH1

"G1" Cable

BN Bd.

CSB Bd.

CU46

"F1"

Cable

CSB Bd.

SUB DISABLE OPB

BN Bd.

CU47

CU48

CU49

OPB-3 Bd

CC54A

CO1

CU46

CH1

CU47

CU48

CU49

"F2" Cable

CO1

"G2" Cable

"A2" Cable

CC51

CC52

CC54A

CU46B

CC54B

LOAD

SWITCH

Figure 3.1

Wiring preparation diagram of OPB and Car Junction Box

3 - 2

Oct. 2005

CAR DEVICES CONNECTION

GM-204-0A001

3.2 CAR DEVICES CONNECTION

Connect the car devices to CCB-3 board. (See Table 3.3, Figure 3.2)

Table 3.3 Connection of car surrounding devices

DEVICE

CONNECTOR

Safety Device Switch

Exit Switch

Compensation Switch

Gate Switch

Gate Switch (Rear)

Door Inverter

Safety Edge X 1

Safety Edge X 2

Safety Ray Power

Safety Ray X 1

Safety Ray X 2

CC5

CC8

CC7

CC4

CC4B

CC50

CC25

CC25B

CC23, CC23B

CC24,

CC24B

CC24B

Multi-Beam

CC24

CC16

CC3

CC55

CC56

CC17

CC18

CC28

CC11

CC54C

Leveling Sensor

Dummy Sensor

Rear Door Zone Sensor

Ventilation Fan

Fluorescent Lamp

Emergency Lighting

BGM Speaker

Voice Synthesizer

Emergency Power

Supply

CC27

REMARK

If not applied, use jumper connector

If not applied, use jumper connector

If not applied, use jumper connector

If not applied, use jumper connector

If not applied, use jumper connector

If the multi-beam is applied, use jumper

connector.

Multi-beam adapter

In case of non-stop floor

CAN Communication (Inside Car Junction Box)

Inside Car Junction Box

LCD

EXIT SWITCH

FAN

DOOR OPERATOR

GATE SWITCH

SAFETY DEVICE

SWITCH

OPB

LOAD SWITCH

SAFETY EDGE

OPB

Figure 3.2

Location of car devices

3 - 3

Oct. 2005

HOISTWAY WIRING PREPARATION

GM-204-0A001

4. HOISTWAY WIRING PREPARATION

Connect all cables of the Hoistway (See Figure 4.1, Figure 4.2)

HPI

INTERLOCK

INTERLOCK

BTN BOX

HIP

INTERLOCK

HPI

INTERLOCK

INTERLOCK

BTN BOX

HIP

Hanger Case

HPI

INTERLOCK

INTERLOCK

BTN BOX

HIP

SERIAL

HARNESS

1m

HPI

INTERLOCK

EVV 0.5SQ X 7C

FROM BUTTON

INTERLOCK

H-1.2m=

1.8m

BTN BOX

HIP

PIT HARNESS

SERIAL

HARNESS

PIT HARNESS

INTERLOCK

HARNESS

INTERLOCK

HARNESS

Figure 4.1 HPI Type

Figure 4.2 HIP Type

With no power input, connect the Hoistway cables.

4 - 1

Oct. 2005

HOISTWAY WIRING PREPARATION

GM-204-0A001

4.1 INDICATOR

TOP FLOOR

CH1

CH4

(T-1)FLOOR

CH1

BOTTOM FLOOR

CH4

CH1

CH4

CT35

CT34

From C/P

(TCB -1 Board)

COMMUNICATION CABLE

Figure 4.3 Communication cable

1) Indicator

HIP(Hall Indicator Position) type

- Connect CH4 connector of upper floor into CH1 connector of lower floor and the

connection of other floors is same procedure. (See Figure 4.4)

HPI(Hall Position Indicator) type

- Connect CH4 connector of upper floor into CH1 connector of lower floor and the

connection of other floors is same procedure.

- Connect UP/DOWN button into CH2 connector. (See Figure 4.5)

Figure 4.5 HPI Connection

Figure 4.4 HIP Connection

Connect CT35 connector of Control Panel into CH4 connector of HIP or HPI board of the

bottom floor. (See Figure 4.3)

4 - 2

Oct. 2005

HOISTWAY WIRING PREPARATION

GM-204-0A001

4.2 INTERLOCK CABLE

Connect Hoistway Interlock Cable connector and Interlock Cable connector of each floor.

(See Figure 4.6)

Connect Interlock Cable connector of the bottom floor and Pit Harness connector.

(See Figure 4.1, Figure 4.2)

CT4

From C/P

To PIT HARNESS

GROUND

0.75SQ x 3CORE

TOP FLOOR

(T-1) FLOOR

1st FLOOR

Figure 4.6

Hoistway Interlock Cable detail

4.3 FINAL LIMIT SWITCH CABLE (See Electrical wiring diagram COL 10)

Connect Final Limit Switch cable of top floor into Control Panel.

(See Table 5.1)

Connect Final Limit Switch cable of the bottom floor into Pit Harness.

4.4 PIT AREA

Connect Pit Switch Box(E-STOP switch, Pit lamp, Outlet) cable into Pit Harness.

Connect optional functions (Parking switch, Fire Man Return switch) into Pit Harness.

4 - 3

Oct. 2005

MACHINE ROOM CONNECTORS

GM-204-0A001

5. MACHINE ROOM CONNECTORS

Turn off main power before wiring and connection of Machine Room.

Connect cables to Control Panel after hoistway and car wiring preparation is done.

(See Table 5.1)

Table 5.1 Connection of Machine Room

CONTROL PANEL

CONNECTOR

CT1

Top Final Limit Switch

CT2

Bottom Final Limit Switch

CT3B

TCB-3 Board

DESCRIPTION

FMR or Parking Switch

CT4

Top Floor Interlock Switch

CT5

Bottom Floor Interlock Switch

CT6

Pit E-STOP Switch

CT34

Hall Communication Cable (Top Floor)

CT35

Hall Communication Cable (Bottom Floor)

T1

Traveling Cable

Control Panel Inside

T1B, T2

TC11, TC12

Pit Light

Terminal Block "TC"

"N24"

Interlock Switch Ground

5 - 1

Oct. 2005

LOW SPEED OPERATION

GM-204-0A001

6. LOW SPEED OPERATION

1) Each voltage(P110, P24) of Control Panel and ground shall be open.

Check it before power input.

2) Check power of distribution box in Machine Room and turn it on.

3) Turn NFB1 on and then turn NFB2 on (See Electrical wiring diagram COL1)

4) Input 24VDC by turning CPR1 on. (See Electrical wiring diagram COL2)

5) Verify that output voltage is each 110VDC, 24VDC and 220VAC.

6) Check relay 29(Safety line), 40(Gate switch), 41(Interlock switch) is operated.

(See Electrical wiring diagram COL3B)

7) Turn Auto / Inspection switches as follows :

"SW1" of TCB-3 board : to the lower direction(MCS)

"SW3" of TCB-3 board : to the upper direction(E-STOP)

("cd" shall be displayed on LED display of M33 board)

Car top/internal AUTO/INS switch : to AUTO

8) See Inverter manual and verify data by using HHT.

See Inverter description of STVF5 manual.

9) Running direction of car shall be in accordance with the UP/DOWN switch location of

"SW2" on TCB-3 board.

(If not, swap any one pair of U, V, W wiring.)

10) Verify brake working and adjust brake.

11) Check E-STOP, UP/DOWN switch of Car Junction Box working.

6 - 1

Oct. 2005

LCD AND VANE INSTALLATION

GM-204-0A001

7. LCD AND VANE INSTALLATION

7.1 LCD

Install LCD on Top Beam of car top by using bracket.

LCD shall not be installed at the near position of Governor rope, Final Limit Switch,

Traveling Cable, etc. To avoid interference.

ULA sensor shall be located at top in LCD. (See Figure 7.1)

7.2 VANE

Level car sill and hatch sill.

Install Vane on rail to be on the center of LCD sensor. (See Figure 7.1)

Install Vane at all floors in same way and there are no interference.

Maintain regular interval between LCD and Vane at all floors.

Vane shall be on the center of LCD sensor at all floors.

Figure 7.1

LCD and Vane installation

7 - 1

Oct. 2005

HIGH SPEED OPERATION

GM-204-0A001

8. HIGH SPEED OPERATION

8.1 CONDITIONS OF HIGH SPEED OPERATION

Verify conditions of high speed operation after completing wiring and connection

work.

1) LCD

In the order of "ULADZDLA" LED on TCB-3 board shall be "ON" while car in upward.

In the order of "DLADZULA" LED on TCB-3 board shall be "ON" while car in downward.

2) Final Limit Switches

Verify the location of final limit switches and they are working accurately.

(See Electrical wiring diagram COL3B, COL10)

8.2 OPERATION FOR INITIALIZATION

Turn AUTO/INS switch to "AUTO" (Car top/Internal) and turn AUTO/INS switch to

"INS" (TCB-3 board).

Move car where only DLA is off at bottom floor level.

(DLA : OFF, DZ/ULA : ON, See Figure 8.1)

Turn dip switch No. 1, 2 to "ON" (M33 board), input "01" to data section of address "0c80"

and then press ENTER key.

Car starts operation for initialization automatically.

Car is stopped automatically at top floor, operation for initialization is completed.

8.3 HIGH SPEED OPERATION

Turn dip switch No. 1, 2 to "ON" (M33 board), input "01"

to data section of address "0888" and then press ENTER key.

(Stop open/close door function (AUTO DOOR))

Turn AUTO/INS switch to "AUTO" (in Control Panel).

Now car can be run at rated speed.

Car shall be leveled at all stops by inputting car call from

Control Panel.

Turn dip switch No. 1, 2 to "ON" (M33 board), input "00" to

data section of address "0888" and then press ENTER key

to start AUTO DOOR function.

Check door open/close, call register/service and Indicator display, etc.

Figure 8.1

LCD condition to initialize operation

8 - 1

Oct. 2005

Elevator Installation Guide Book

Rev. 0, Oct. 2005

This guide book is the PROPERTY of HYUNDAI ELEVATOR Co., Ltd.

and is loaned subject to return upon demand. Contents of this

publication

shall

NOT

be

REPRODUCED

in

any

written PERMISSION of HYUNDAI ELEVATOR Co., Ltd

form

without

Potrebbero piacerti anche

- Elevator Troubleshooting & Repair: A Technician's Certification Study GuideDa EverandElevator Troubleshooting & Repair: A Technician's Certification Study GuideValutazione: 4 su 5 stelle4/5 (9)

- 02 IRIS2 - NV - Controller-ENDocumento36 pagine02 IRIS2 - NV - Controller-ENAhmedNessuna valutazione finora

- KONE Motor Modernization - FinalDocumento17 pagineKONE Motor Modernization - FinalEdhimj UnmeNessuna valutazione finora

- ME-LIFT-P Microprocessor Control User Manual 20071226 PDFDocumento38 pagineME-LIFT-P Microprocessor Control User Manual 20071226 PDFKen LeeNessuna valutazione finora

- 211Documento14 pagine211AdjieNessuna valutazione finora

- MMR Elevator - SI: FOD Test & Commissioning For SI210 ControllerDocumento20 pagineMMR Elevator - SI: FOD Test & Commissioning For SI210 ControllerBrahim Chergui100% (1)

- STVF5 Trouble REV0 PDFDocumento42 pagineSTVF5 Trouble REV0 PDFUpien Ayah MahardikaNessuna valutazione finora

- Hamcb SwordDocumento101 pagineHamcb SwordNaseh Ya NasehNessuna valutazione finora

- Schemi Hyundai STVF GRBT Scheda BluDocumento237 pagineSchemi Hyundai STVF GRBT Scheda Blulorenzo50% (2)

- Si210 ANNDocumento34 pagineSi210 ANNFERNSNessuna valutazione finora

- Elevador SWORD HAMCB Tipo OtisDocumento41 pagineElevador SWORD HAMCB Tipo OtisRaul GutierrezNessuna valutazione finora

- Mitsubishi Elevator GPS-III Fault Code - A Water Logging - Netease BlogDocumento7 pagineMitsubishi Elevator GPS-III Fault Code - A Water Logging - Netease BlogTroubleshootingNessuna valutazione finora

- Di S1Documento9 pagineDi S1FERNS100% (2)

- Aljotronic Control 2 PDFDocumento30 pagineAljotronic Control 2 PDFjhfbtyNessuna valutazione finora

- Nice 1000Documento204 pagineNice 1000Elius AhmedNessuna valutazione finora

- Si210 WiringDocumento4 pagineSi210 WiringFERNS0% (2)

- Group Control System Troubleshooting Manual - Ring-Type - ENGDocumento25 pagineGroup Control System Troubleshooting Manual - Ring-Type - ENGReynold Suarez100% (1)

- Electric Drawing-FR2000Documento19 pagineElectric Drawing-FR2000MuMoMa100% (1)

- Di1 (Si210) Elevator: Start-Up RoutineDocumento34 pagineDi1 (Si210) Elevator: Start-Up RoutineQuyết50% (2)

- Start Up Sigma Solon LDDocumento7 pagineStart Up Sigma Solon LDJesus Checa100% (1)

- DiSi (210) TroubleshootingDocumento4 pagineDiSi (210) TroubleshootingFERNSNessuna valutazione finora

- OTIS 506, 506SL, 510 UNITS: Precision Escalator Products, IncDocumento10 pagineOTIS 506, 506SL, 510 UNITS: Precision Escalator Products, IncmohammedalathwaryNessuna valutazione finora

- Control Bl2000Documento9 pagineControl Bl2000AliRouyou100% (1)

- FUJI2000 蓝光主板说明书-英文Documento199 pagineFUJI2000 蓝光主板说明书-英文Ahmed Al-RabayahNessuna valutazione finora

- مخطط كهرباء فوجي اليابانDocumento24 pagineمخطط كهرباء فوجي اليابانbassemalelwyNessuna valutazione finora

- User Manual For Ds Product (Ver1.3)Documento56 pagineUser Manual For Ds Product (Ver1.3)thanhhung_hyNessuna valutazione finora

- 11 - Solon TCD171-188Documento8 pagine11 - Solon TCD171-188Fabian VirgiliNessuna valutazione finora

- ARES Maintenance Manual: IndexDocumento7 pagineARES Maintenance Manual: IndexGutmonarchNessuna valutazione finora

- Iris NV Iris NV - Parameter Parameter: Speed Curve Configuration: F00 F05Documento32 pagineIris NV Iris NV - Parameter Parameter: Speed Curve Configuration: F00 F05Moises PerelloNessuna valutazione finora

- AS380 Machine On-Site DebuggingDocumento5 pagineAS380 Machine On-Site DebuggingTroubleshooting100% (1)

- System Diagram Ec3000a 5r5 011 4 (Ups Epm S)Documento24 pagineSystem Diagram Ec3000a 5r5 011 4 (Ups Epm S)Tuân HoàngNessuna valutazione finora

- How To Change The Eld Frequency (Held-2009S) : "MODE" " " "PD - 0"Documento1 paginaHow To Change The Eld Frequency (Held-2009S) : "MODE" " " "PD - 0"Rachmad Maulana RamadhanNessuna valutazione finora

- WBFV PDFDocumento14 pagineWBFV PDFDidik Sukoco100% (2)

- Adjustment ManualDocumento23 pagineAdjustment ManualViệt Thảo Trần100% (2)

- GeN2 Regen UpgradeDocumento22 pagineGeN2 Regen UpgradeLliego Jara50% (2)

- 78 Fuji SanyoDocumento4 pagine78 Fuji SanyoBAAAK100% (2)

- Stvf7 Troubleshooting Manuel EnglishDocumento32 pagineStvf7 Troubleshooting Manuel EnglishResul ŞenayNessuna valutazione finora

- Sigma MRL E1000 PDFDocumento15 pagineSigma MRL E1000 PDFGiandra AlfaNessuna valutazione finora

- Toshiba Spacel IIIDocumento11 pagineToshiba Spacel IIITran Huy50% (2)

- BOMO EnglishDocumento16 pagineBOMO EnglishSunil Kumar100% (1)

- AscensoresDocumento12 pagineAscensoresOvidio ReyesNessuna valutazione finora

- Main Control Board User ManualDocumento15 pagineMain Control Board User Manualmohammedalathwary100% (1)

- Electrical Wiring DiagramDocumento46 pagineElectrical Wiring DiagramTùng Phạm xuânNessuna valutazione finora

- Gaa 24350 Aw11 Ii PDFDocumento22 pagineGaa 24350 Aw11 Ii PDFEvgeniy100% (1)

- Afpelevator Doorcontroller Ec10 DDocumento40 pagineAfpelevator Doorcontroller Ec10 DTroubleshootingNessuna valutazione finora

- Lift Monitoring & Diagnostics: SystemDocumento53 pagineLift Monitoring & Diagnostics: SystemMohd Abu AjajNessuna valutazione finora

- GSD SM Instruction Book PDFDocumento15 pagineGSD SM Instruction Book PDFMitro100% (1)

- SI210 SystemDocumento17 pagineSI210 SystemAgus YohanesNessuna valutazione finora

- s50 Monarch Commissioning ManuelDocumento36 pagines50 Monarch Commissioning ManuelReynold Suarez100% (3)

- Gba 26800 H Viii SoftwareDocumento4 pagineGba 26800 H Viii SoftwarePeter100% (1)

- Elcom Pa 08 3Documento23 pagineElcom Pa 08 3Cristal CristalNessuna valutazione finora

- Diagrama SL1 Incompleto PDFDocumento14 pagineDiagrama SL1 Incompleto PDFmarcos_herrera_58Nessuna valutazione finora

- Elevator Mechanic: Passbooks Study GuideDa EverandElevator Mechanic: Passbooks Study GuideNessuna valutazione finora

- Elevator Apprentice: Passbooks Study GuideDa EverandElevator Apprentice: Passbooks Study GuideNessuna valutazione finora

- Elevator Mechanic's Helper: Passbooks Study GuideDa EverandElevator Mechanic's Helper: Passbooks Study GuideNessuna valutazione finora

- Elevator Inspector: Passbooks Study GuideDa EverandElevator Inspector: Passbooks Study GuideNessuna valutazione finora

- Start Up Routine: Field Component ManualDocumento12 pagineStart Up Routine: Field Component Manualihwisso100% (5)

- Operation Manual For Transmission Monitor RSUK0919: ORSUK0919Documento31 pagineOperation Manual For Transmission Monitor RSUK0919: ORSUK0919Baena75Nessuna valutazione finora

- I Ma 3010.71 1320 622 Huy 067 - A - ComDocumento140 pagineI Ma 3010.71 1320 622 Huy 067 - A - ComValério de Oliveira Santos100% (1)

- Passo 2010-2015 PDFDocumento32 paginePasso 2010-2015 PDFWaqar KhattakNessuna valutazione finora

- Lift Kobang RSDocumento8 pagineLift Kobang RSAndhy Azhari RihasbyNessuna valutazione finora

- 04.observation ElevatorsDocumento18 pagine04.observation ElevatorsReynold SuarezNessuna valutazione finora

- 11.marine ElevatorsDocumento2 pagine11.marine ElevatorsReynold SuarezNessuna valutazione finora

- The El Door Controller Operating Manual PDFDocumento13 pagineThe El Door Controller Operating Manual PDFReynold Suarez83% (6)

- HSVF Trouble Manual (Ver-0) 20111223Documento32 pagineHSVF Trouble Manual (Ver-0) 20111223Reynold Suarez82% (11)

- Hwhitney PDFDocumento2 pagineHwhitney PDFReynold SuarezNessuna valutazione finora

- 78-Bea - vt460-Tg - en Variotec 460 TracergasDocumento72 pagine78-Bea - vt460-Tg - en Variotec 460 TracergasMNessuna valutazione finora

- V Ug Type ListDocumento3 pagineV Ug Type ListDanang BiantaraNessuna valutazione finora

- Renold Transmission Chain Catalogue ENG 0112Documento94 pagineRenold Transmission Chain Catalogue ENG 0112nataliaNessuna valutazione finora

- Tank 44M3Documento15 pagineTank 44M3Tech DesignNessuna valutazione finora

- AVN Speaker RepairDocumento5 pagineAVN Speaker RepairMoises Martins RochaNessuna valutazione finora

- Cat 2 STSDocumento424 pagineCat 2 STSVardhanNessuna valutazione finora

- Metaza MPX-80 AND MPX-70: Photo Impact PrintersDocumento4 pagineMetaza MPX-80 AND MPX-70: Photo Impact PrinterstinnlogicNessuna valutazione finora

- 12 TriesDocumento10 pagine12 TriesNikhil 20528Nessuna valutazione finora

- Analysis of Vibration Detection Using Active Controller in The Smart Cantilever Composite Beam With LQR and Fuzzy TechniquesDocumento10 pagineAnalysis of Vibration Detection Using Active Controller in The Smart Cantilever Composite Beam With LQR and Fuzzy TechniquesTJPRC PublicationsNessuna valutazione finora

- Endress-Hauser Cerabar PMP11 ENDocumento4 pagineEndress-Hauser Cerabar PMP11 ENSensortecsa SensortecsaNessuna valutazione finora

- WT R13 Lab Manual PDFDocumento119 pagineWT R13 Lab Manual PDFsiddarth rpNessuna valutazione finora

- Datasheet ArcMate 120ic 12LDocumento1 paginaDatasheet ArcMate 120ic 12LmuertesalvajeNessuna valutazione finora

- EVB Series: End-Of-Line Deflagration Flame ArrestersDocumento2 pagineEVB Series: End-Of-Line Deflagration Flame Arresterstienhm_pve1553Nessuna valutazione finora

- Le Veritable Dragon RougeDocumento142 pagineLe Veritable Dragon RougeDavid GourmetNessuna valutazione finora

- Special Topic Presentation: Subject: Wireless Communication Topic: Global System For Mobile CommunicationDocumento18 pagineSpecial Topic Presentation: Subject: Wireless Communication Topic: Global System For Mobile Communicationtabish khatriNessuna valutazione finora

- GRT8 M Instruction ManualDocumento2 pagineGRT8 M Instruction ManualJosé Antonio Vega SimónNessuna valutazione finora

- Catalog AP Merit Installer V4Documento264 pagineCatalog AP Merit Installer V4BillNessuna valutazione finora

- Whats NewDocumento17 pagineWhats NewcosminconstantinNessuna valutazione finora

- ABC Functional Requirements Doc SampleDocumento57 pagineABC Functional Requirements Doc SampleSharang Bhasin100% (1)

- WAMP Server and PHP ZeroMQ Extension InstallationDocumento2 pagineWAMP Server and PHP ZeroMQ Extension InstallationGautambuddha AirportNessuna valutazione finora

- Id Motors: Operation and Maintenance ManualDocumento64 pagineId Motors: Operation and Maintenance ManualJose Maria Redondo CarsiNessuna valutazione finora

- Magnum MS2812 64-0007-12-04-MS-ManualDocumento44 pagineMagnum MS2812 64-0007-12-04-MS-ManualTom KakanowskiNessuna valutazione finora

- IgniteDocumento2 pagineIgniteMartinito MacraméNessuna valutazione finora

- The Market For Airborne ASW Sensors: Product Code #F672Documento18 pagineThe Market For Airborne ASW Sensors: Product Code #F672Gautam NatrajanNessuna valutazione finora

- Em 1110 1 1000Documento371 pagineEm 1110 1 1000ingaboNessuna valutazione finora

- Amperis Manual XDP IIDocumento28 pagineAmperis Manual XDP IIme_vahabi100% (1)

- Aeg DC 2000 enDocumento2 pagineAeg DC 2000 enmauriceauNessuna valutazione finora

- BONFYRE InterviewBook InternalComms FINALDocumento56 pagineBONFYRE InterviewBook InternalComms FINALsdas123100% (1)

- Phy 104 Lab ReportDocumento6 paginePhy 104 Lab ReportMd. Abdullah ZishanNessuna valutazione finora

- Society of International Gas Tanker & Terminal Operators (Sigtto)Documento8 pagineSociety of International Gas Tanker & Terminal Operators (Sigtto)Mohamed MekkyNessuna valutazione finora