Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Ampacity White Paper FINAL Compress

Caricato da

DenisTarasCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Ampacity White Paper FINAL Compress

Caricato da

DenisTarasCopyright:

Formati disponibili

SensorTran DTS Information Series:

Transmission & Distribution Applications

Cable Ampacity Analysis

Software (CAAS)

Paul Nicholls, Executive VP, SensorTran

Introduction

Fiber optic-based Distributed Temperature Sensing

(DTS) systems provide real-time temperature

measurements along the complete length of optical

fibers. They provide a proven temperature

monitoring solution for power cables. The data

allows operators to maximize circuit load while

avoiding over-temperature conditions, therefore

increasing cable life and avoiding potential

catastrophic loss of circuits.

January 2009

The cable insulation can withstand different

temperatures dependent upon duration and

intensity of the current circulating in the conductors.

The consequence of operating cables at excessive

temperatures is life-reducing damage to the cable or

surrounding environment as typically shown below:

While DTS systems alone provide excellent power

cable monitoring solutions, adding ampacity

analysis software increases the value of the data and

offers enhanced functionality with clearly definable

benefits to utility operators.

SensorTrans CAAS software suite is comprised of

several modules that provide flexible, appropriate,

cost-effective tools which expand the benefits of

DTS systems for power cable monitoring. Labor

intensive pre-modeling is kept to minimum by the

use of artificial intelligence algorithms which finetune ampacity predictions to give greater accuracy.

Normal lifetime

of the cable

decreased by

50%

Maximum

allowed

temperature

increased by

8%

Normal lifetime

of the cable

decreased by

75%

Maximum

allowed

temperature

increased by

15%

Max. Operating Temperature vs. Cable Life

Ampacity and Ratings: a brief overview

Cable Temperature Ratings

Ampacity is the current-carrying capacity of a cable.

For an underground cable, ampacity is determined

by the capacity of the installation to extract cable

heat and dissipate that heat into the surrounding soil

and/or atmosphere.

Cable operating temperatures depend on the load

shape applied (i.e. the intensity of the current and

variation in current over time). Subsequently, cables

have different temperature ratings for different

loadings - i.e. steady state, cyclic, transient

(emergency), and short-circuit.

The maximum operating temperature of a cable is

typically limited by its insulation material but can

also be limited by the maximum temperature

which the surrounding environment can

withstand without degradation.

Transient analyses are typically used to calculate

cable thermal ratings under emergency situations.

Cable installations also have thermal inertia,

as it takes time for the cable and its

surroundings to heat up.

Distributed Monitoring

Solutions

Cable Ampacity Analysis Software (CAAS)

Power Cable Monitoring Issues

Cable Component Temperatures

DTS systems monitor the fiber temperature. It is the

temperature of the conductor core (for the

maximum insulation temperature) and sometimes

that of the outer jacket (in cases where the

surrounding environment is temperature sensitive)

which should ideally be monitored.

The variation between the fiber temperature and

that of the conductor core (or outer jacket) will vary

depending upon the location of the fiber relative to

the core (or outer jacket) and the thermal

coefficients of the cable construction, as shown in

the example below:

09 - January

In effect, the cables temperature responds over

time to a change in load. The shape of the cables

responding temperature curve varies depending

upon the load shape and the thermal

characteristics of both the cable and the surrounding

environment.

Benefits of Ampacity Analysis

The additional implementation of ampacity analysis

software, in conjunction with DTS systems, provides

the following valuable enhancements and benefits:

Cable Component Temperatures

Ampacity analysis produces real-time temperature

data for multiple elements of the cable, such as the

conductor core (insulation) and the outer sheath.

This provides more exacting data to allow operators

to maximize circuit loading while avoiding overtemperature conditions, therefore increasing cable

life and avoiding potential catastrophic loss of

circuits.

Cable Temperature Predictions

Typical Temperature Variations from the

Core to the Outer Jacket

Load Temperature Latency

DTS systems provide real-time temperature data.

However, there is latency between a change in the

circuit load and the responding cable temperature,

as shown below.

Ampacity analysis provides predicted cable

temperatures in response to variations of the cable

load. There are two elements to this, namely Static

and Transient methods.

Static method calculates the

final stable temp. of the conduct

when a load is specified.

Latency

Latency

Sensortran

Transient method

calculates the conduct

temp. at any time, any

load.

The Static method predicts the final stable cable

temperature based on load condition whereas the

Transient method predicts the responding cable

temperature at any time to a load variation.

Page 2 of 6

Cable Ampacity Analysis Software (CAAS)

09 - January

SensorTrans Cable Ampacity Analysis Software (CAAS)

Introduction

Features and Principles Overview

SensorTrans CAAS software suite consists of three

modules as shown. Each module provides a specific

function to provide configuration flexibility to ensure

a cost-effective solution customized to meet

exacting customer requirements.

Provides Cable Element, Static and Transient

Condition Calculators in separate modules

Complies with IEC guidelines for static

calculations with optimized transient

calculations

On-board self-learning artificial intelligence

algorithms provide fine-tuning of calculations

with relatively small amounts of historical data

Open architecture for inter-system

communication

Principles based on: Optimized IEC Standard,

Neher-McGrath methods, IEC Standards 287-11, 287-1-2, 287-2-1, 287-2-2, 287-3-1

CAAS Modules

The table below describes the CAAS modules, required data inputs, and implementation form:

Module

Cable Element

Temperature

Calculator

Static Condition

Calculator

Transient

Condition

Calculator

Sensortran

Description

Data Inputs

Form

Provides real-time conductor

core and/or outer sheath

component temperatures based

on fiber temperature and load

1. Fiber temperature

2. Real-time load

Provides off-line estimate of

steady-state cable temperature

given the existing load

1. Real-time load

2. Load frequency and voltage

(optional but provides better

accuracy)

3. Fiber temperature (not

required if accurate environment

conditions are supplied)

Hardware

Module

Provides off-line query tools for

estimating time-based

temperature conditions based on

load and durations

Same as Static Condition

Calculator

Hardware

Module

Software

(loaded onto

DTS unit)

Page 3 of 6

Cable Ampacity Analysis Software (CAAS)

09 - January

Cable Element Temperature Calculator

The Cable Element Temperature

Calculator provides real-time conductor

core and other cable element

temperatures based on fiber temperature

and load.

In addition to the fiber temperature and

load, basic characteristics of the installed

cable are required for initial modeling.

This data can be superimposed on the

DTS temperature trace screen typically as

shown at right:

Static Condition Calculator

This module provides an off-line estimate

of the predicted steady-state cable

temperature with the existing load using

the Static method. A simple user interface

provides for the use of this tool.

Transient Condition Calculator

The Transient Condition Calculator

provides off-line query tools for

estimating time-based temperature

conditions based on load and durations.

These provide the operator with tools to

determine appropriate load scenarios.

Examples of these queries are shown at

left.

Query inputs are entered using a simple

interface. Queries can be saved and

reused.

Sensortran

Page 4 of 6

Cable Ampacity Analysis Software (CAAS)

09 - January

Implementation

The Cable Element Calculator module can

readily reside on the integral PC within a

SensorTran Gemini DTS system. The

Static and Transient Condition Calculator

modules are supplied as separate hardware

units complete with their own CPU and

hard-disk cache as shown at right:

External CAAS Module

(includes CPU, hard disk

cache & pre-loaded software)

TCP/IP Comms Link

Gemini DTS System

TM

DTS\CAAS systems can be integrated within the operators control systems in a variety of schemes, two of

which are shown below:

Sensortran

Page 5 of 6

Cable Ampacity Analysis Software (CAAS)

09 - January

Power Cable Monitoring

SensorTrans advanced DTS systems capture and record dense temperature measurements over time providing operators with vital information that leads to reduced costs by increasing the usable capacity of the

circuits, avoiding cable damage, and extending cable life by maintaining optimal loading.

Distributed

Temperature Sensing data is used for:

Small hotspot identification

Load optimization through real-time

thermal monitoring

Substation

Monitoring

Access to all usable capacity without

exceeding thermal limits

Lifetime asset protection and monitoring of

aging circuits

Verification of mathematical models

Early identification of joint deterioration

Fire detection capability in cable tunnels,

ducts, and chases

Underground

Transmission &

Distribution Line

Monitoring

The SensorTran Advantage

SensorTran, a NASA technology spin-off, is committed to supplying its customers with smart distributed

monitoring solutions. SensorTrans systems are conceived to have a low lifetime cost of ownership (LCO) by

way of efficient design, superior engineering and reliable construction. SensorTrans team is dedicated to

providing best-in-industry customer care from project conception to the development of specifications,

through installation, training and beyond.

Distributed Monitoring

Solutions

Sensortran

Corporate HQ & Manufacturing

Regional Offices

4401 Freidrich Lane, Bldg. 307

Austin, TX 78744

USA

Southampton, England UK

+44 1489 576648

+1-512-583-3520

+1-866-333-2861 (toll free domestic)

Richmond, VA USA

+1 804-364-2645

e-mail inquiries to sales@sensortran.com

www.sensortran.com

Page 6 of 6

Potrebbero piacerti anche

- TR - 101245 - V2 - Effect of DC Testing On Extruded Crosslinked Polyethylene Insulated Cables - Phase IIDocumento44 pagineTR - 101245 - V2 - Effect of DC Testing On Extruded Crosslinked Polyethylene Insulated Cables - Phase IIDenisTarasNessuna valutazione finora

- TDS 01ofg V08 enDocumento2 pagineTDS 01ofg V08 enDenisTarasNessuna valutazione finora

- CIGRE TECHNICAL BROCHURE 506 Gas Insulated System For HVDC DC Stress at DC and AC SystemsDocumento79 pagineCIGRE TECHNICAL BROCHURE 506 Gas Insulated System For HVDC DC Stress at DC and AC SystemsDenisTarasNessuna valutazione finora

- TB345 Alternating Current (Ac) Resistance of Helically Stranded ConductorsDocumento59 pagineTB345 Alternating Current (Ac) Resistance of Helically Stranded ConductorsDenisTarasNessuna valutazione finora

- CIGRE TECHNICAL BROCHURE 520 Material Properties of Solid HVDC Insulation SystemsDocumento16 pagineCIGRE TECHNICAL BROCHURE 520 Material Properties of Solid HVDC Insulation SystemsDenisTarasNessuna valutazione finora

- Analysis of The Free Surface Instabilities in Extrusion and Coextrusion Flows For Metallocene Based PolyolefinsDocumento12 pagineAnalysis of The Free Surface Instabilities in Extrusion and Coextrusion Flows For Metallocene Based PolyolefinsDenisTarasNessuna valutazione finora

- Session 75 Corning 164 PaperDocumento6 pagineSession 75 Corning 164 PaperDenisTarasNessuna valutazione finora

- Exploring The Limits of Buffering Process For Both Standard and Micro TubesDocumento5 pagineExploring The Limits of Buffering Process For Both Standard and Micro TubesDenisTarasNessuna valutazione finora

- ASTM-D991 Usa Standard 2004Documento5 pagineASTM-D991 Usa Standard 2004DenisTarasNessuna valutazione finora

- Heat Meter Accuracy Testing ReportDocumento155 pagineHeat Meter Accuracy Testing ReportDenisTarasNessuna valutazione finora

- TransientDocumento60 pagineTransientDenisTarasNessuna valutazione finora

- Non-Monitored or Simple: VLF Withstand TestDocumento14 pagineNon-Monitored or Simple: VLF Withstand TestDenisTarasNessuna valutazione finora

- B-11F0070 (Fusion Splicing Loss Between G652 and G657)Documento5 pagineB-11F0070 (Fusion Splicing Loss Between G652 and G657)DenisTarasNessuna valutazione finora

- Case Study of VLF Tan Delta Partial DischargeDocumento38 pagineCase Study of VLF Tan Delta Partial DischargeDenisTarasNessuna valutazione finora

- 200 Micron Fiber Enables New Cable DesignsDocumento6 pagine200 Micron Fiber Enables New Cable DesignsDenisTarasNessuna valutazione finora

- VLF Sinus 45kVDocumento2 pagineVLF Sinus 45kVDenisTarasNessuna valutazione finora

- Maxwell OnlinehelpDocumento1.484 pagineMaxwell OnlinehelpDenisTaras0% (1)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- PDF Android Application Development Black BookDocumento2 paginePDF Android Application Development Black Bookpushparaj SNessuna valutazione finora

- Hf23e 0Documento2 pagineHf23e 0BokiNessuna valutazione finora

- Raychem DS Eu1422 E150 enDocumento2 pagineRaychem DS Eu1422 E150 enTrung Trinh BaoNessuna valutazione finora

- CDS VAM TOP ® 3.5in. 9.2lb-ft L80 Type 1 API Drift 2.867in. 87.5%Documento1 paginaCDS VAM TOP ® 3.5in. 9.2lb-ft L80 Type 1 API Drift 2.867in. 87.5%anon_798581734100% (1)

- Lesson 2 Underlying Philosophies of The Varying Definitions of GlobalizationDocumento22 pagineLesson 2 Underlying Philosophies of The Varying Definitions of GlobalizationReven Villarta60% (5)

- JIS B 1301-1996 - Chavetero PDFDocumento1 paginaJIS B 1301-1996 - Chavetero PDFPablo PasqualiniNessuna valutazione finora

- Directory of Electric CooperativesDocumento11 pagineDirectory of Electric CooperativesRyan JayNessuna valutazione finora

- D00167 PDFDocumento96 pagineD00167 PDFthanhvinh710Nessuna valutazione finora

- Manual (As of 31/10/2020)Documento5 pagineManual (As of 31/10/2020)Turtle GamesNessuna valutazione finora

- Sigma Supplies Luster Ribbon SsDocumento2 pagineSigma Supplies Luster Ribbon SsDeng FlynnNessuna valutazione finora

- Historical Development of Computers FSC 113Documento15 pagineHistorical Development of Computers FSC 113amodusofiat77Nessuna valutazione finora

- Employee Experience at The Intersection of People AND TechnologyDocumento14 pagineEmployee Experience at The Intersection of People AND Technologyashwin.royNessuna valutazione finora

- Oic Presentation en VfinalDocumento27 pagineOic Presentation en Vfinalricky patealNessuna valutazione finora

- GFK2749 - RX3i PSM PDFDocumento100 pagineGFK2749 - RX3i PSM PDFgabsNessuna valutazione finora

- SAURE LEICA IWAA2018 Laser Tracker StandardsDocumento10 pagineSAURE LEICA IWAA2018 Laser Tracker Standardscmm5477Nessuna valutazione finora

- Network Automation Technical EbookDocumento20 pagineNetwork Automation Technical EbookAamir MalikNessuna valutazione finora

- Function CatalogueDocumento591 pagineFunction CatalogueAshish PatwardhanNessuna valutazione finora

- Part 1 - Design: Water Supply Code of Australia Agency RequirementsDocumento12 paginePart 1 - Design: Water Supply Code of Australia Agency RequirementsTailieukythuat DataNessuna valutazione finora

- Chapter 12 Problems Group 1Documento5 pagineChapter 12 Problems Group 1Peña Tahiris100% (2)

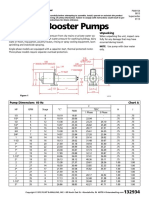

- FWPB Booster Pumps InstructionsDocumento15 pagineFWPB Booster Pumps InstructionsRamadanNessuna valutazione finora

- Barang Inventaris Kantor PT - Kahade Mitra Sejati: Registrasi Keterangan QTY Nilai Perolehan Tanggal Perolehan KondisiDocumento2 pagineBarang Inventaris Kantor PT - Kahade Mitra Sejati: Registrasi Keterangan QTY Nilai Perolehan Tanggal Perolehan KondisiAdam Saidina FikriNessuna valutazione finora

- Principles of Programming: Flow Charts, Illustrations Through ExamplesDocumento9 paginePrinciples of Programming: Flow Charts, Illustrations Through Examplesعبدالعزيز عابدNessuna valutazione finora

- Am - Is - Are - Was - Were WorksheetDocumento1 paginaAm - Is - Are - Was - Were WorksheetВалентин КечкоNessuna valutazione finora

- Java Examination: Multiple Choice QuestionsDocumento7 pagineJava Examination: Multiple Choice QuestionsAnand ls nairNessuna valutazione finora

- Oracle Certkiller 1z0-822 140qDocumento106 pagineOracle Certkiller 1z0-822 140qDenazareth JesusNessuna valutazione finora

- Image ProcessingDocumento12 pagineImage Processingsiddharth.20bcun006Nessuna valutazione finora

- Process Design and Control: Course Code Monday & FridayDocumento37 pagineProcess Design and Control: Course Code Monday & FridayElia SaadNessuna valutazione finora

- CNG Kits 468 CylinderDocumento13 pagineCNG Kits 468 CylinderRoberto HernandezNessuna valutazione finora

- Women's Safety Measures Through Sensor Device Using Iot: T.Sathyapriya, R.Auxilia Anitha MaryDocumento3 pagineWomen's Safety Measures Through Sensor Device Using Iot: T.Sathyapriya, R.Auxilia Anitha MaryCSE ROHININessuna valutazione finora

- TLD1124Documento29 pagineTLD1124nguyen bacNessuna valutazione finora