Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Doka Bean h20 P Manual

Caricato da

nikosbbwTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Doka Bean h20 P Manual

Caricato da

nikosbbwCopyright:

Formati disponibili

User information

08/2011

Method statement

999791002 en-GB

Timber formwork beams

The Formwork Experts

Introduction

User information Timber formwork beams

by Doka Industrie GmbH, A-3300 Amstetten

Introduction

999791002 - 08/2011

The Formwork Experts

User information Timber formwork beams

Introduction

Contents

4

4

6

8

Introduction

Elementary safety warnings

Doka services

Eurocodes at Doka

9

9

10

12

15

Product description

Instructions for assembly and use

Technical condition

Transporting, stacking and storing

16

Component overview

999791002 - 08/2011

3

The Formwork Experts

Introduction

User information Timber formwork beams

Elementary safety warnings

Introduction

User target groups

Planning

This User Information booklet (Method Statement) is

aimed at everyone who will be working with the Doka

product or system it describes. It contains information on the standard design for setting up this system, and on correct, compliant utilisation of the system.

All persons working with the product described

herein must be familiar with the contents of this manual and with all the safety instructions it contains.

Persons who are incapable of reading and understanding this booklet, or who can do so only with difficulty, must be instructed and trained by the customer.

The customer is to ensure that the information materials provided by Doka (e.g. User Information booklets, Instructions for Assembly and Use, Operating

Instruction manuals, plans etc.) are available to all

users, and that they have been made aware of them

and have easy access to them at the usage location.

In the relevant technical documentation and formwork utilisation plans, Doka shows the workplace

safety precautions that are necessary in order to use

the Doka products safely in the usage situations

shown.

In all cases, users are obliged to ensure compliance

with national OH&S (occupational health and safety)

rules throughout the entire project and to take appropriate additional or alternative workplace safety precautions where necessary.

Provide safe workplaces for those using the formwork (e.g. for when it is being erected/dismantled,

modified or repositioned etc). It must be possible to

get to and from these workplaces via safe access

routes!

If you are considering any deviation from the

details and instructions given in this booklet, or

any application which goes beyond those

described in the booklet, then revised static calculations must be produced for checking, as well

as supplementary assembly instructions.

Hazard assessment

The customer is responsible for drawing up, documenting, implementing and continually updating a

hazard assessment at every job-site.

This document serves as the basis for the site-specific hazard assessment, and for the instructions

given to users on how to prepare and utilise the system. It does not substitute for these, however.

Remarks on this document

This User Information booklet can also be used as a

generic method statement or incorporated with a

site-specific method statement.

Many of the illustrations in this booklet show the

situation during formwork assembly and are

therefore not always complete from the safety

point of view.

Any safety accessories not shown in these illustrations must still be used by the customer, in accordance with the applicable rules and regulations.

Further safety instructions, especially warnings,

will be found in the individual sections of this

document!

Rules applying during all phases of

the assignment:

The customer must ensure that this product is

erected and dismantled, reset and generally used for

its intended purpose under the direction and supervision of suitably skilled persons with the authority to

issue instructions.

These persons' mental and physical capacity must

not in any way be impaired by alcohol, medicines or

drugs.

Doka products are technical working appliances

which are intended for industrial/commercial use

only, always in accordance with the respective Doka

User Information booklets or other technical documentation authored by Doka.

The stability of all components and units must be

ensured during all phases of the construction work!

The functional/technical instructions, safety warnings and loading data must all be strictly observed

and complied with. Failure to do so can cause accidents and severe (even life-threatening) damage to

health, as well as very great material damage.

Fire-sources are not permitted anywhere near the

formwork. Heating appliances are only allowed if

properly and expertly used, and set up a safe distance away from the formwork.

The work must take account of the weather conditions (e.g. risk of slippage). In extreme weather,

steps must be taken in good time to safeguard the

equipment, and the immediate vicinity of the equipment, and to protect employees.

All connections must be checked regularly to ensure

that they still fit properly and are functioning correctly.

It is very important to check all screw-type connections and wedge-clamped joins whenever the construction operations require (particularly after exceptional events such as storms), and to tighten them if

necessary.

999791002 - 08/2011

The Formwork Experts

User information Timber formwork beams

Introduction

Assembly

Regulations; industrial safety

The equipment/system must be inspected by the

customer before use, to ensure that it is in suitable

condition. Steps must be taken to rule out the use of

any components that are damaged, deformed, or

weakened due to wear, corrosion or rot.

Combining our formwork systems with those of other

manufacturers could be dangerous, risking damage

to both health and property. If you intend to combine

different systems, please contact Doka for advice

first.

The assembly work must be carried out by suitably

qualified employees of the client's.

It is not permitted to modify Doka products; any such

modifications constitute a safety risk.

Always observe all industrial safety regulations and

other safety rules applying to the application and utilisation of our products in the country and/or region

in which you are operating.

Erecting the formwork

Doka products and systems must be set up in such

a way that all loads acting upon them are safely

transferred!

Pouring

Do not exceed the permitted fresh-concrete pressures. Excessively high pouring rates lead to formwork overload, cause greater deflection and risk

causing breakage.

Striking the formwork

Do not strike the formwork until the concrete has

reached sufficient strength and the person in charge

has given the order for the formwork to be struck!

When striking the formwork, never use the crane to

break concrete cohesion. Use suitable tools such as

timber wedges, special pry-bars or system features

such as Framax stripping corners.

When striking the formwork, do not endanger the

stability of any part of the structure, or of any scaffolding, platforms or formwork that is still in place!

Transporting, stacking and storing

Observe all regulations applying to the handling of

formwork and scaffolding. In addition, the Doka

slinging means must be used - this is a mandatory

requirement.

Remove any loose parts or fix them in place so that

they cannot be dislodged or fall free!

All components must be stored safely, following all

the special Doka instructions given in the relevant

sections of this User Information booklet!

Instruction as required by EN 13374:

If a person or object falls against, or into, the edge

protection system and/or any of its accessories, the

edge protection component affected may only continue in use after it has been inspected and passed

by an expert.

Maintenance

Only original Doka components may be used as

spare parts. Repairs may only be carried out by the

manufacturer or authorised facilities.

Symbols used

The following symbols are used in this booklet:

Important note

Failure to observe this may lead to malfunction or damage.

CAUTION / WARNING / DANGER

Failure to observe this may lead to material

damage, and to injury to health which may

range up to the severe or even life-threatening.

Instruction

This symbol indicates that actions need to be

taken by the user.

Sight-check

Indicates that you need to do a sight-check

to make sure that necessary actions have

been carried out.

Tip

Points out useful practical tips.

Reference

Refers to other documents and materials.

Miscellaneous

We reserve the right to make alterations in the interests

of technical progress.

999791002 - 08/2011

5

The Formwork Experts

Introduction

User information Timber formwork beams

Doka services

Support in every phase of the

project

Doka offers a broad spectrum of services, all with a single aim: to help you succeed on the site.

Every project is unique. Nevertheless, there is one

thing that all construction projects have in common

and that is a basic structure with five phases. We at

Doka know our clients' varying requirements. With our

consulting, planning and other services, we help you

achieve effective implementation of your formwork

assignment using our formwork products in every one

of these phases.

1

Project development phase

Tendering phase

Operations scheduling phase

Taking well-founded decisions

thanks to professional advice and

consulting

Optimising the preliminary work

with Doka as an experienced partner

Controlled, regular forming operations, for greater efficiency

resulting from realistically calculated

formwork concepts

Find precisely the right formwork

solutions, with the aid of

help with the bid invitation

in-depth analysis of the initial situation

objective evaluation of the planning, execution, and time-risks

Draw up potentially winning bids, by

basing them on realistically calculated guideline prices

making the right formwork

choices

having an optimum time-calculation basis

Plan cost-effectively right from the

outset, thanks to

detailed offers

determination of the commissioning quantities

co-ordination of lead-times and

handover deadlines

999791002 - 08/2011

The Formwork Experts

User information Timber formwork beams

4

(Shell) construction phase

Introduction

5

(Shell) completion phase

The advantages for you

thanks to professional advice and

consulting

Cost savings and time gains

When we advise and support you

right from the word "go", we can

make sure that the right formwork

systems are chosen and then

used as planned. This lets you

achieve optimum utilisation of the

formwork equipment, and effective forming operations because

your workflows will be correct.

Maximised workplace safety

The advice and support we can

give you in how to use the equipment correctly, and as planned,

leads to greater safety on the job.

Optimum resource utilisation

with assistance from the Doka

Formwork Experts

Seeing things through to a positive conclusion

with professional support

Workflow optimisation, thanks to

thorough utilisation planning

internationally experienced

project technicians

appropriate transport logistics

on-site support

Doka Services are a byword for

transparency and efficiency here,

offering

jointly handled return of rented

formwork

professional dismantling

efficient cleaning and reconditioning using special equipment

Transparency

Because our services and costs

are completely transparent, there

is no need for improvisation during the project and no unpleasant surprises at the end of it.

Reduced close-out costs

Our professional advice on the

selection, quality and correct use

of the equipment helps you avoid

damage, and minimise wear-andtear.

999791002 - 08/2011

7

The Formwork Experts

Introduction

User information Timber formwork beams

Eurocodes at Doka

In Europe, a uniform series of Standards known as

Eurocodes (EC) was developed for the construction

field by the end of 2007. These are intended to provide

a uniform basis, valid throughout Europe, for product

specifications, tenders and mathematical verification.

The EC are the world's most highly developed Standards in the construction field.

In the Doka Group, the EC are to be used as standard

from the end of 2008. They will thus supersede the DIN

norms as the "Doka standard" for product design.

Ed

Ed

Fd

Fk

Design value of effect of actions

(E ... effect; d ... design)

Internal forces from action Fd

(VEd, NEd, MEd)

Design value of an action

Fd = F Fk

(F ... force)

Characteristic value of an action

"actual load", service load

(k ... characteristic)

e.g. dead weight, live load, concrete pressure,

wind

Partial factor for actions

(in terms of load; F ... force)

e.g. for dead weight, live load, concrete pressure, wind

Values from EN 12812

Comparison of the safety concepts (example)

Permissible stress design

115.5 [kN]

Fyield

EC/DIN concept

Rk

115.5 [kN]

Rd gM = 1.1

90<105 [kN]

n ~ 1.65

Factual

98013-100

60 [kN]

gF = 1.5

Fpermissible

98013-102

60<70 [kN]

Ed

90 [kN]

Factual Fpermissible

The widely used "Permissible stress design" (comparing the actual stresses with the permissible stresses)

has been superseded by a new safety concept in the

EC.

The EC contrast the actions (loads) with the resistance

(capacity). The previous safety factor in the permissible

stresses is now divided into several partial factors. The

safety level remains the same!

Rd

Rd

Design value of the resistance

(R ... resistance; d ... design)

Design capacity of cross-section

(VRd, NRd, MRd)

Rk

Rk

Timber: Rd = kmod

Steel: Rd =

M

M

Rk

Characteristic value of the resistance

e.g. moment resistance to yield stress

Partial factor for a material property

(in terms of material; M...material)

e.g. for steel or timber

Values from EN 12812

kmod

Modification factor (only for timber to take

account of the moisture and the duration of load

action)

e.g. for Doka beam H20

Values as given in EN 1995-1-1 and EN 13377

The "permissible values" communicated in

Doka documents (e.g.: Qpermissible = 70 kN)

do not correspond to the design values

(e.g.: VRd = 105 kN)!

Avoid any confusion between the two!

Our documents will continue to state the permissible values.

Allowance has been made for the following partial factors:

F = 1.5

M, timber = 1.3

M, steel = 1.1

kmod = 0.9

In this way, all the design values needed in an

EC design calculation can be ascertained from

the permissible values.

Ed Rd

A Utilisation factor

999791002 - 08/2011

The Formwork Experts

User information Timber formwork beams

Product description

Types of beam

20.0

8.0

4.0

20.0

8.0

Approval Number

Z-9.1-391

Z-9.1-21

Z-9.1-391

or EN 13377

Doka beams with no EN mark (i.e. those produced on or before 3rd

Nov. 2008) are covered by the above-mentioned DIB ( German

Institute of Building Technology) Approval.

Doka beams with an EN mark (i.e. those produced from 4th Nov.

2008 onward) are covered by EN 13377.

Z-9.1-222

Overall height tolerance 1.0 mm, assuming 12% timber moisture

content.

H36

36.0

H30

9736-252-01

H24 N

Z-9.1-317

5.4

5.4

8.0

4.0

A

C

H20 P

4.0

16.0

6.5

24.0

Code letter

P

Web made of special flat-pressed sheet

N

Web made of three-ply

Innovative polyurethane end reinforcement for highly

top

effective protection of the formwork beam

Tried-and-tested end reinforcement in the form of

eco

bevelled ends with plastic rivet in the beam flange

6.5

H20 N

30.5

Meanings of the code letters used in the article designation

H16 P

3.5

Other features include:

Beam-flange markings in a 50 cm grid for the

Dokaflex and Dokaflex 30 tec systems

Option of adding "customer name" to wording (indicated by the suffix "BS" in the article designation.).

Wood for flanges is graded by automatic grading

machines for maximised dependability

H16 N

16.0

Doka formwork beams are solid-webbed beams made

of wood or wood-based material to EN 13377 and in

accordance with the approvals issued by the German

Institute for Construction Engineering, Berlin (Z-9.1***), exclusively for use in wall and floor formwork.

3.5

Doka formwork beams

9.7

9.7

Approval Number

Z-9.1-21

Z-9.1-21

Overall height tolerance 1.0 mm, assuming 12% timber moisture

content.

A Web (yellow)

B Flange (yellow)

C Beam-flange markings for the Dokaflex system

D System holes

E End reinforcement (blue plastic cap for Doka beam H20 top, rivet

for Doka beam H20 eco)

F Notch for chalking line

The innovative end reinforcement of the Doka

beam H20 top significantly reduces damage to

the beam ends.

999791002 - 08/2011

9

The Formwork Experts

User information Timber formwork beams

Instructions for assembly and use

Deflection diagrams

Doka formwork beams H20 N and P

16

Practical example

2.5

3

9732-105

14

p [kN/m]

10

8

6

10

0.5 kN/m

2

0

9768-200-01

Permissible values from EN 13377, Schedule E

perm. Q [kN]

perm. M [kNm]

E J [kNm2]

perm. span [m]

H20

N and P

11.0

5.0

450

4.00

H16 P H16 N H24 H30* H36*

8.5

2.7

250

3.20

7.5 12.5 15.0 17.0

2.7

6.5 13.5 17.0

250 700 1250 1850

3.20 4.80 6.00 6.00

These values allow for a F = 1.5, a kmod of 0.9 and a M

= 1.3.

Based on a residual moisture content of 20 % or less.

The values must be adjusted accordingly if conditions

of use differ.

*According to approval issued by the Institute for Construction Engineering, Berlin

10

30

20

1.0

2.0

3.0

4.0

5.0

Doka formwork beams H16 N and P

16

9732-110

14

p [kN/m]

12

L/500

1

4.5

7.5

0.5 kN/m

10

2

40 30

0.5

20

1.5

4

5

3.5

2.5

10

To prevent any staining of the concrete from

direct contact with new formwork beams, we

recommend covering the formwork beams with

a non-woven fabric.

40

15

Span L [m]

M ... Permitted bending moment

Q ... Permitted transverse force

p ... Applied load (working load)

Deflection [mm]

You will also find information on correct usage in the in

user information for the individual products, for example:

Large-area formwork Top 50

Dokaflex

Doka Xtra

L/500

1

7.5

In order to maximise durability, it is important to handle

the components with due care; this applies particularly

when stripping out floor-slab formwork.

1.5

4.5

5

Deflection [mm]

12

3.5

Doka beams and Doka formwork beams can be used

only as formwork beams for floor and wall formwork

and only when subjected to the loads occurring in situations of direct support for floor or wall formwork in

structural concreting, but not for higher individual loads

(e.g. safety beams).

15

1.0

1.5

2.0

2.5

3.0

3.5

Span L [m]

M ... permissible bending moment

Q ... permissible transverse force

p ... applied load (working load)

999791002 - 08/2011

The Formwork Experts

User information Timber formwork beams

Doka formwork beams H24

16

Possible incorrect usages

2.5

3

2

9732-111

3.5

14

WARNING

Always position Doka formwork beams

"upright".

1.5

p [kN/m]

Correct "upright" positioning

Incorrect positioning "turned on

(load direction is parallel to web

side" (load direction at right

plane).

angles to web plane).

Wall formwork

1

L/500

10

4.5

5

7.

Deflection [mm]

12

10

0.5 kN/m

15

1.0

2.0

3.0

4.0

5.0

6.0

9791-205-01

40

20

30

9791-206-01

Span L [m]

M ... permissible bending moment

Q ... permissible transverse force

p ... applied load (working load)

Floor formwork

7.5 4.5 3.5 2.5

1.5

5 4 3

2

9732-112

14

p [kN/m]

L/500

12

WARNING

The uses illustrated below are prohibited, as

are other, similar uses!

10

8

15

0.5 kN/m

6

4

2

0

Do not use as scaffold flooring.

Deflection [mm]

9791-220-01

16

9791-219-01

Doka formwork beams H30

40

30

20

10

Q

1.0

2.0

3.0

4.0

5.0

6.0

7.0

Span L [m]

M ... permissible bending moment

Q ... permissible transverse force

p ... applied load (working load)

16

7.5

5

9732-113

9791-200-01

Doka formwork beams H36

4.5 3.5 2.5

4 3

2

p [kN/m]

14

1.5

Do not use as traffic-route flooring.

L/500

10

1

10

8

6

4

15

2

0

40 30

20

1.0

2.0

3.0

4.0

5.0

6.0

7.0

9791-201-01

0.5 kN/m

Deflection [mm]

12

Span L [m]

M ... permissible bending moment

Q ... permissible transverse force

p ... applied load (working load)

999791002 - 08/2011

11

The Formwork Experts

User information Timber formwork beams

Technical condition

The following quality criteria define the extent of damage permissible in terms of load-bearing strength.

Use is prohibited if damage is beyond these limits.

Flange

Splintering at side

permissible up to depth a = 10 mm and length b =

500 mm on one side.

Angled cracks (across the grain)

Not permissible.

9791-210-02

9791-208-01

Straight cracks (parallel to the flange)

parallel to flange, permissible up to width a = 2 mm.

If the flange can be parted at the crack the beam is

not in usable condition.

a

9791-211-02

Angled splintering across the edge

permissible up to a = 30 mm across the diagonal and

up length b = 500 mm.

9791-213-01

9791-214-01

9791-207-01

9791-207-02

12

999791002 - 08/2011

The Formwork Experts

User information Timber formwork beams

Saw cuts

Drilled holes

Superficial saw cuts up to depth a = 2 mm are permissible.

Not permissible, with the exception of system holes:

9791-207-09

- Waling attachment with beam screw

b

b

9791-209-02

9791-207-07

- Attachment of table head with beam screw

a

9791-207-08

a ... 15 mm

b ... 112 mm

c ... 396 mm

Drilled-hole diameter max. 10 mm

9791-209-01

Flange end

Splintering a up to length = 60 mm is permissible.

Damage to the plastic cap has no effect on loadbearing strength, but beams damaged evincing

damage of this kind do not necessarily meet the

quality criteria for Doka rental formwork

a

9791-212-02

999791002 - 08/2011

13

The Formwork Experts

User information Timber formwork beams

Drilled holes in web

Web

Damage to web

permissible only if slight and at one side of the beam.

9791-216-01

Permissible drilled holes:

Standard holes

- Each standard beam has 2 drilled holes, dia. 21.5

mm

Additional system holes for:

- Flange claw

- Fastening plate

- Connection splice plate

- Table head 30

- Lifting bracket

- Portal head

One drilled hole of maximum diameter 20 mm per running metre in addition to the system holes is permissible.

If the incidence of drilled holes is frequent the overall

condition of the beam is definitive.

9791-207-04

Damage to web end

permissible up to max. a = 20 mm

9791-215-01

9791-217-01

9791-207-06

Detachment of flange from web

Not permissible.

9791-207-03

14

999791002 - 08/2011

The Formwork Experts

User information Timber formwork beams

Transporting, stacking and storing

Protect stacked beams from extreme climatic

influences such as exposure to sunshine or

moisture by covering them (with breathable tarpaulins). This reduces cracking. Only cover

them never envelope them completely.

Always use edge protectors when strapping beams

together. Edge protectors can be padding made of

plastic, wood or cardboard.

Transport

Always use strap slings to lift stacked beams - do not

use chains.

Packs of up to 90 units

9791-218-01

9791-218-02

Packs of up to 45 units.

When moving beams not securely strapped

together, take care that loose beams cannot

slip.

9791-202-03

Stacked beams

9791-203-03

Max. 2 packs stacked one on top Max. 4 packs stacked one on top

of the other

of the other

max. 2500 kg per stack

Ground conditions for stacking

Maximum angle of inclination of ground 3%.

The ground on which the stack is to be placed must

be adequately firm and level. Best-case conditions

are concreted or paved storage areas.

Storage on asphalt:

Depending on the parts stored, place wooden battens, strips of formwork sheeting or metal sheet

between the parts and the asphalt surface to ensure

that the weight is adequately spread.

Storage on other surfaces (sand, gravel...):

Adopt suitable measures for storage (e.g. place thick

plywood sheets underneath the loads).

9791-202-01

Max. number of beams per stack

Minimum number of wooden battens (min. 8 x 8 x 100 cm)

Size a

Size b for beam H20 P

Size b for beam H20 N

Beam lengths

more than

up to 5.90 m

5.90 m

90

45

2

108 cm

95 cm

112 cm

108 cm

49 cm

57 cm

Always sort beams for stacking, in other words do

not stack beams N and P together in a mixed stack.

Reprocessing scrap material

Doka formwork beams contain no wood preservatives

and, consequently, they can be deposited for reprocessing.

Reprocessing by incineration in suitable incineration

plants is recommended. It is advisable not to attempt to

burn scrap material in open fires or domestic woodburners.

Always comply with the applicable local or national regulations.

P

N

N

N

9791-204-01

999791002 - 08/2011

15

The Formwork Experts

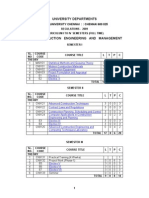

Component overview

User information Timber formwork beams

[kg]

Article n

9.5

12.8

13.8

15.0

17.0

18.5

20.0

23.0

25.0

30.0

5.2

5.2

189011000

189012000

189013000

189014000

189015000

189016000

189017000

189018000

189019000

189020000

189010000

189021000

[kg]

Article n

8.6

10.2

12.6

13.7

17.2

20.7

189802000

189803000

189809000

189805000

189813000

189814000

Component

Doka

Formwork

System

beams

overview

Components

Doka beam H20 top N 1.80m

Doka beam H20 top N 2.45m

Doka beam H20 top N 2.65m

Doka beam H20 top N 2.90m

Doka beam H20 top N 3.30m

Doka beam H20 top N 3.60m

Doka beam H20 top N 3.90m

Doka beam H20 top N 4.50m

Doka beam H20 top N 4.90m

Doka beam H20 top N 5.90m

Doka beam H20 top N .....m

Doka beam H20 top N .....m BS

Doka-Trger H20 top N

Doka formwork beam H16 N 2.45m

Doka formwork beam H16 N 2.90m

Doka formwork beam H16 N 3.60m

Doka formwork beam H16 N 3.90m

Doka formwork beam H16 N 4.90m

Doka formwork beam H16 N 5.90m

Doka-Schalungstrger H16 N

Varnished yellow

Varnished yellow

Doka formwork beam H16 P 2.45m

Doka formwork beam H16 P .....m

Doka-Schalungstrger H16 P

10.4 189961000

4.3 189960000

Varnished yellow

Doka beam H20 top P 1.80m

Doka beam H20 top P 2.45m

Doka beam H20 top P 2.65m

Doka beam H20 top P 2.90m

Doka beam H20 top P 3.30m

Doka beam H20 top P 3.60m

Doka beam H20 top P 3.90m

Doka beam H20 top P 4.50m

Doka beam H20 top P 4.90m

Doka beam H20 top P 5.90m

Doka beam H20 top P .....m

Doka beam H20 top P .....m BS

Doka-Trger H20 top P

9.9

13.2

14.3

15.6

17.7

19.2

20.8

23.9

26.0

31.2

5.4

5.4

189701000

189702000

189703000

189704000

189705000

189706000

189707000

189708000

189709000

189710000

189700000

189711000

Doka formwork beam H24 N 4.90m

Doka formwork beam H24 N 7.40m

Doka-Schalungstrger H24 N

Varnished yellow

Doka formwork beam H30 N .....m

8.0 189099000

Doka formwork beam H36 N .....m

9.0 189199000

Timber varnish yellow 5l

5.0 176005000

Doka-Schalungstrger H30 N .....m

Varnished yellow

Varnished yellow

Doka-Schalungstrger H36 N .....m

Varnished yellow

Holzlasur gelb 5l

Doka beam H20 eco N 1.25m

Doka beam H20 eco N 1.80m

Doka beam H20 eco N 2.45m

Doka beam H20 eco N 2.65m

Doka beam H20 eco N 2.90m

Doka beam H20 eco N 3.30m

Doka beam H20 eco N 3.60m

Doka beam H20 eco N 3.90m

Doka beam H20 eco N 4.50m

Doka beam H20 eco N 4.90m

Doka beam H20 eco N 5.90m

Doka beam H20 eco N 12.00m

Doka beam H20 eco N .....m

Doka beam H20 eco N .....m BS

Doka-Trger H20 eco N

6.3

9.0

12.3

13.3

14.5

16.5

18.0

19.5

22.5

24.5

29.5

60.3

5.0

5.0

189282000

189283000

189271000

189272000

189273000

189284000

189285000

189276000

189286000

189277000

189287000

189288000

189299000

189289000

6.5

9.4

12.7

13.8

15.1

17.2

18.7

20.3

23.4

25.5

30.7

46.8

62.4

5.2

5.2

189939000

189940000

189936000

189937000

189930000

189941000

189942000

189931000

189943000

189932000

189955000

189956000

189993000

189999000

189957000

27.7 189601000

41.8 189602000

Varnished yellow

Doka beam H20 eco P 1.25m

Doka beam H20 eco P 1.80m

Doka beam H20 eco P 2.45m

Doka beam H20 eco P 2.65m

Doka beam H20 eco P 2.90m

Doka beam H20 eco P 3.30m

Doka beam H20 eco P 3.60m

Doka beam H20 eco P 3.90m

Doka beam H20 eco P 4.50m

Doka beam H20 eco P 4.90m

Doka beam H20 eco P 5.90m

Doka beam H20 eco P 9.00m

Doka beam H20 eco P 12.00m

Doka beam H20 eco P .....m

Doka beam H20 eco P .....m BS

Doka-Trger H20 eco P

Varnished yellow

16

999791002 - 08/2011

The Formwork Experts

User information Timber formwork beams

Component overview

999791002 - 08/2011

17

The Formwork Experts

Component overview

18

User information Timber formwork beams

999791002 - 08/2011

The Formwork Experts

User information Timber formwork beams

Component overview

999791002 - 08/2011

19

The Formwork Experts

The Doka beam H20 top a high-end product of engineering technology

Day in, day out, thousands of Doka solid-web formwork beams do sterling service on building sites the world over.

Our superior standard of manufacturing ensures uniformly high quality and load-bearing strength

for safe and dependable usage.

You can rent, lease or buy Doka formwork beams.

At any of the Doka branches in your region.

Why not give us a call?

The Doka Group's central plant at Amstetten, Austria

Doka international

Certied to

Doka GmbH

ISO 9001

Josef Umdasch Platz 1, A 3300 Amstetten, Austria

Tel.: +43 (0)7472 605-0, Fax: +43 (0)7472 64430

E-Mail: info@doka.com

Internet: www.doka.com

Algeria

Japan

Qatar

SARL Doka Algrie

24 A Route de la Rassauta

Bordj-El-Kifane, BP 170, 16120 Alger

Telephone: +213 (0)21 21 27 26

Telefax: +213 (0)21 21 28 98

E-Mail: Algerie@doka.com

Doka Japan K.K.

Miwanoyama 744-6 Nagareyama-shi

270-175 Chiba-Ken

Telephone: +81 (0)471 78 8808

Telefax: +81 (0)471 78 8812

E-Mail: Japan@doka.com

www.dokajapan.co.jp

Doka Qatar WLL

2nd Gate, Light Industrial Area,

Mesaieed-Qatar

P.O. Box 23439, Doha-Qatar

Telephone: +974 44500628

Telefax: +974 44500608

E-Mail: Qatar@doka.com

Korea

Saudi Arabia

Doka Korea Ltd.

Rm.N.220, Doosan Venture Digm Bldg.,

126-1 Pyeongchon-Dong, Dongan-Gu,

431-755 Anyang City, Gyeonggi-Do

Telephone: +82 31 478 3700

Telefax: +82 31 478 3701

E-Mail: Korea@doka.com

Doka Formwork Technology

Mahmoud Othman & Sons LLC

P.O. Box 7620

Jeddah 21472

Telephone: +966 0)2 669 10 08

Telefax: +966 (0)2 664 86 25

E-Mail: Jeddah@doka.com

Kuwait

Singapore

Doka Kuwait

Div. of Riham Gen. Trad.& Cont. Co.

P.O. Box 2217 Salmiyah

22023 Kuwait

Telephone: + 965 2 4822 462

Telefax: +965 2 4822 472

E-Mail: Kuwait@doka.com

Doka Formwork Pte. Ltd.

9 Gul Circle

Singapore 629565

Telephone: +65 6897 7737

Telefax: +65 6897 8606

E-Mail: Singapore@doka.com

Lebanon

Doka South Africa (Pty) Ltd.

Johannesburg Branch

2 Sebasa Road

Chloorkop Ext.10

Kempton Park 1619

Telephone: +27 (0)11 310 9709

Telefax: +27 (0)11 310 9711

E-Mail: South-Africa@doka.com

Canada

Doka Canada Ltd./Lte

5404 - 36th Street S.E.

Calgary AB T2C 1P1

Telephone: +1 403 243-6629

Telefax: +1 403 243-6787

E-Mail: Canada@doka.com

China

Doka Formwork (Shanghai) Co. Ltd.

Bldg. 2, No.3883 Yuanjiang Road

Minhang District

Shanghai 201109

Telephone: +86 21 6090 0899

Telefax: +86 21 6090 1099

E-Mail: China@doka.com

India

Doka India Pvt. Ltd.

Mahavir Landmark Bldg.

6th Floor, Plot No. 26 A

Sector-7, Kharghar - 410210

Navi Mumbai

Telephone: +91 22 27746452

Telefax: +91 22 27746451

E-Mail: India@doka.com

Doka Branch Lebanon

Sodeco Square, Block C / 9th oor

Beirut

Telephone: +961 (0)1 612569

Telefax: +961 (0)1 612570

E-Mail: Lebanon@doka.com

Ireland

Norway

Doka Ireland Formwork Techn. Ltd.

Monasterboice, Drogheda

County Louth

Telephone: +353 (0)41 686 1620

Telefax: +353 (0)41 686 1525

E-Mail: Ireland@doka.com

Doka Norge AS

Heggstadmoen 4

N 7080 Heimdal

Telephone: +47 72 89 38 10

Telefax:n +47 72 89 38 11

E-Mail: Norge@doka.com

South Africa

Sweden

Doka Sverige AB

Kurdsvgen 20

S 451 55 Uddevalla

Telephone: +46 (0)10 45 16 300

Telefax: +46 (0)10 45 16 309

E-Mail: Sverige@doka.com

Tunisia

Doka Tunisia Ltd.

Bureau de Liaison

Zone Industrielle, Rue d lusine

Le Kram 2015 Tunis

Telephone: +216 (0)71 977 350

Telefax: +216 (0)71 977 856

E-Mail: Tunisia@doka.com

Turkey

Doka Kalip-Iskele

Sanayi ve Ticaret A.S.

Gzeller Org. San. Blgesi

Inn Mah. Nazarbayev Sok. No:19

41400 Gebze, Kocaeli

Telephone: +90 262 751 50 66

Telefax: +90 262 751 50 05

E-Mail: Turkiye@doka.com

United Arab Emirates

Doka Gulf FZE

P.O. Box 61407

Jebel Ali Free Zone, Dubai

Telephone: +971 (0)4 870 8700

Telefax: +971 (0)4 870 8702

E-Mail: Emirates@doka.com

United Kingdom

Doka UK Formwork Technologies Ltd

Monchelsea Farm, Heath Road

Boughton Monchelsea

Maidstone, Kent, ME17 4JD

Telephone: +44 (0)1622 74 90 50

Telefax: +44 (0)1622 74 90 33

E-Mail UK@doka.com

Other subsidiaries and

representatives:

Angola

Azerbaijan

Bahrain

Belgium

Belarus

Bosnia and

Herzegovina

Brazil

Bulgaria

Chile

Croatia

Czech Republic

Denmark

Egypt

Estonia

Finland

France

Germany

Greece

Hungary

Iceland

Iran

Italy

Jordan

Kazakhstan

Latvia

Lithuania

Luxembourg

Marocco

Mexico

Netherlands

New Zealand

Oman

Panama

Poland

Portugal

Romania

Russia

Senegal

Serbia

Slovakia

Slovenia

Spain

Switzerland

Taiwan

Thailand

Ukraine

Vietnam

USA

Doka USA, Ltd.

214 Gates Road

Little Ferry, NJ 07643

Telephone: +1 201 329-7839

Telefax: +1 201 641-6254

E-Mail: usa@doka.com

Internet: www.dokausa.com

The Formwork Experts

999791002 - 08/2011

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Circuitos Freno - KNORRDocumento352 pagineCircuitos Freno - KNORRPaulo Jorge Oliveira100% (6)

- Deutz Engine ManualsDocumento9 pagineDeutz Engine Manualsnikosbbw100% (1)

- Concrete Pavement Construction MethodDocumento21 pagineConcrete Pavement Construction Methodjoshua Manggala100% (7)

- CAST IN-SITU WORKSDocumento30 pagineCAST IN-SITU WORKSBhargav BbvsNessuna valutazione finora

- Township BOQ With CorrigendumDocumento40 pagineTownship BOQ With CorrigendumPoornima D GowdaNessuna valutazione finora

- Working Size Blinding Base SL Wall THK Slab THK SpaceDocumento5 pagineWorking Size Blinding Base SL Wall THK Slab THK SpaceKorupoluNessuna valutazione finora

- Koshin General Catalog en 2012 Small 01Documento28 pagineKoshin General Catalog en 2012 Small 01nikosbbwNessuna valutazione finora

- RCC CHIMNEY METHOD STATEMENTDocumento17 pagineRCC CHIMNEY METHOD STATEMENTpoovazhagan100% (3)

- R. D. S. O.: Rdso/b - 10408/6Documento1 paginaR. D. S. O.: Rdso/b - 10408/6MUTHU PANDINessuna valutazione finora

- Reinforced Concrete IntroductionDocumento45 pagineReinforced Concrete IntroductionAnonymous ELujOV3Nessuna valutazione finora

- Smartdek Design ManualDocumento48 pagineSmartdek Design ManualranddyNessuna valutazione finora

- Construction Method Statement GuideDocumento30 pagineConstruction Method Statement GuideEmad Rakat86% (7)

- SOR Civil Engineering Works 2012Documento28 pagineSOR Civil Engineering Works 2012Faizan Fathizan100% (1)

- F&F Application Guide PEWJ0074-02Documento850 pagineF&F Application Guide PEWJ0074-02Jony Hilasaca100% (2)

- F&F Application Guide PEWJ0074-02Documento850 pagineF&F Application Guide PEWJ0074-02Jony Hilasaca100% (2)

- Kato 22 Load Chart 30058Documento17 pagineKato 22 Load Chart 30058nikosbbw100% (4)

- Pumpa Za Upravljenje Cat 725 PDFDocumento3 paginePumpa Za Upravljenje Cat 725 PDFnikosbbwNessuna valutazione finora

- Flat Slab (Efficient Construction)Documento4 pagineFlat Slab (Efficient Construction)tanhh5678Nessuna valutazione finora

- Bond Ek Design and Construction Manual June 2012Documento56 pagineBond Ek Design and Construction Manual June 2012rocketNessuna valutazione finora

- BurnsDocumento11 pagineBurnsnikosbbwNessuna valutazione finora

- NN43140-101 NewDocumento151 pagineNN43140-101 NewnikosbbwNessuna valutazione finora

- NN43142-101 06.04 IP 1230 UG UNIStim5.x PDFDocumento210 pagineNN43142-101 06.04 IP 1230 UG UNIStim5.x PDFnikosbbwNessuna valutazione finora

- 12g Instalacija 004Documento2 pagine12g Instalacija 004nikosbbwNessuna valutazione finora

- 8c - 9788 Air Conditioner GPDocumento2 pagine8c - 9788 Air Conditioner GPnikosbbwNessuna valutazione finora

- 345 9gs ControllerDocumento2 pagine345 9gs ControllernikosbbwNessuna valutazione finora

- 345 9gs ControllerDocumento2 pagine345 9gs ControllernikosbbwNessuna valutazione finora

- 12g Instalacija 001Documento3 pagine12g Instalacija 001nikosbbwNessuna valutazione finora

- 345 9gs ControllerDocumento2 pagine345 9gs ControllernikosbbwNessuna valutazione finora

- 1006TAG2 ElectropaK PN1793Documento2 pagine1006TAG2 ElectropaK PN1793kazamxNessuna valutazione finora

- PRODUCTGUIDESatJan3010:40:45GMT 05:302021Documento90 paginePRODUCTGUIDESatJan3010:40:45GMT 05:302021Anonymous PkvM83sNessuna valutazione finora

- Cast-in Place Concrete StructuresDocumento26 pagineCast-in Place Concrete StructuresKathleen Denise Doria MacaraegNessuna valutazione finora

- Requisition Form: Date: Required Delivery DateDocumento1 paginaRequisition Form: Date: Required Delivery Datejoel torcuatorNessuna valutazione finora

- Concept To Completion For WebsiteDocumento14 pagineConcept To Completion For WebsiteAntonNessuna valutazione finora

- Parking ShedDocumento257 pagineParking ShedD V BHASKARNessuna valutazione finora

- Project ReportDocumento19 pagineProject ReportSomeshwar BàndNessuna valutazione finora

- TR - Type - 2 - Box Shape - Hot - DryDocumento17 pagineTR - Type - 2 - Box Shape - Hot - DryFreedom Love NabalNessuna valutazione finora

- Construction Engineering ManagementDocumento34 pagineConstruction Engineering ManagementLeilani JohnsonNessuna valutazione finora

- Formwork System: CatalogueDocumento83 pagineFormwork System: CatalogueNguyễn Anh TuấnNessuna valutazione finora

- Industrial Training ReportDocumento20 pagineIndustrial Training Reportch umairNessuna valutazione finora

- TERADOWEL APAC - Load Transfer System - Technical ManualDocumento12 pagineTERADOWEL APAC - Load Transfer System - Technical ManualGilbert Escolano AnchetaNessuna valutazione finora

- Installation Guideline For AGRUSAFE Sure Grip Concrete Protective Double Sealing SystemDocumento22 pagineInstallation Guideline For AGRUSAFE Sure Grip Concrete Protective Double Sealing SystemManriquez Andres100% (1)

- Model BillDocumento211 pagineModel BillGerhard C L Coetzer100% (1)

- Krishak Bazar at Tehatta-I Block Seed Farm2 (Unhide)Documento18 pagineKrishak Bazar at Tehatta-I Block Seed Farm2 (Unhide)Hironmoy DashNessuna valutazione finora

- Ifnit: 4 Principles of Design and Detailing of Formwork and ScaffoldingDocumento46 pagineIfnit: 4 Principles of Design and Detailing of Formwork and ScaffoldingMohamed ElfawalNessuna valutazione finora

- HALFEN Cast-In Channels Concrete B2000.1-EDocumento56 pagineHALFEN Cast-In Channels Concrete B2000.1-EPaul ConstantinescuNessuna valutazione finora

- Estimate For PKG-03Documento191 pagineEstimate For PKG-03SwanandNessuna valutazione finora

- PERI ACS Core 400Documento36 paginePERI ACS Core 400Moch Firman AlfianaNessuna valutazione finora