Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Filtro 630N

Caricato da

grunger30Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Filtro 630N

Caricato da

grunger30Copyright:

Formati disponibili

Data Sheets Manual

MAW Y-STRAINERS FOR INDUSTRIAL APPLICATION

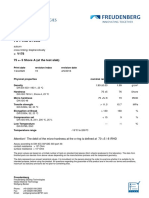

Series 630N

Attributes of Design

MAW Series 630N Y-Strainers are compact, of a cylindrical shape and strong enough to handle hot water, steam,

air and gases. Gases, being readily compressible, will flow through Y-strainers of the same size as a pipeline easily,

with little pressure loss.

They are designed with adequate safety margins. This means sufficiently heavy wall thickness and blow off connections. As an example, in improperly trapped steam lines, condensate can collect in low points and become a slug

of water traveling at very high velocity down the line. Even the slight change in direction caused by a Y-strainer can

produce a tremendous shock which can break the strainer wall.

Raised Flange ends; and machined slots

to better accommodate the assemblying

gaskets.

Precise Machine seat slot; to accommodate the

screen and avoid dirt to by pass the strainer.

Marking and Tagging; positive flow

marking by an arrow, raised symbols

of Heat Number, Desing Pressure and

Nominal Size. Riveted steel name

plate showing working limits and PED

approval.

Blue painted RAL 5002

Inner painted wall; for better

preservation during storage

periods.

Removable bolting cover;

to ease maintenance operations.

Supporting end rings; to provide

greater consistency and ease the

screen placement into the strainer

chamber.

Standard Blow Off connection; for in line emptying of

condensate or water.

High Quality stainless steel screen; made out

of high resistance wire, rugged and braided

type. Thick enough to avoid deformation.

Reinforced Graphite Gasket;

with stainless steel layers to

resist high fluid temperature.

Data subject to change without prior notice

Tappered Drainage Screw

sealing; with a metallic

gasket thus avoiding the

gasket replacement on

every emptying operation.

Leakage proof.

20

Data Sheets Manual

MAW Y-STRAINERS FOR INDUSTRIAL APPLICATION

Series 630N

Parts and Materials

Part

Description

Material

Especification

01

Body

Cast Iron

EN 1561 / EN GJL 250 - EN JL 1040 (Former GG-25)

02

Cover

Cast Iron

EN 1561 / EN GJL 250 - EN JL 1040 (Former GG-25)

03

Gasket

Graphite

CrNi Steel Reinforced

04

Screen

St. Steel

EN 10088 / X5CrNi18-10 (1.4301)

05

Studs-Nuts

Steel

25 CrMo4, 1.721-C35E, 1.181

06

Draining Plug Gasket

St. Steel

A4 (WNR-1.4571)

07

Draining Plug

Ductile Iron

EN 1563 / EN JS1030 (Former GGG-40)

Other Material Options on request

Data subject to change without prior notice

21

Data Sheets Manual

MAW Y-STRAINERS FOR INDUSTRIAL APPLICATION

Series 630N

Dimensions

DN

H1

L1

nxd

Weight (kg)

15

130

90

135

10

23

56

95

65

4 x 14

2,5

20

150

100

150

10

28

68

105

75

4 x 14

4,0

25

160

115

180

25

36

82

115

85

4 x 14

5,0

32

180

125

205

35

42

98

140

100

4 x 18

7,0

40

200

150

235

45

50

114

150

110

4 x 18

9,5

50

230

160

250

45

61,5

119

165

125

4 x 18

12,5

65

290

180

285

25

78,5

134

185

145

4 x 18

17,0

80

310

215

330

40

89,5

149

200

160

8 x 18

21,5

100

350

235

365

55

109,5

169

220

180

8 x 18

29,0

125

400

275

425

65

137,5

199

250

210

8 x 18

42,0

150

480

305

480

50

160

224

285

240

8 x 22

61,0

200

600

390

610

80

210

284

340

295

12 x 22

118,0

250

730

540

915

230

258

434

405

355

12 x 26

157,0

300

850

680

1.110

350

308

555

460

410

12 x 26

258,0

Dimensions are expressed in mm. Data can be altered without notice by our Design Department for the product benefit.

Manufacture Design Standards:

QA certified to ISO 9001:2000

According to Pressure Equipment Directive PED 97/23/CE by a recognised Notify Body

Testing Standard: EN 12266-1 (Former DIN 3230 part 3) / BS6755 Part 1

Marking Standard: EN 19

Face to Face length: EN-558-1 Series 1 (Former DIN 3202 F1)

Body End Connections: Flanges sized and drilled to EN 1092-2 (Former DIN 2533) PN 16

Operating Parameters:

Working Pressure: 0...16bar-g

Working Temperature: -10C ... +300C

See Engineering Data for Pressure / Temperature relationship

Main Applications:

Saturated Steam, Vapours, Gases, Compressed Air and Lubricants, etc.

Data subject to change without prior notice

22

Potrebbero piacerti anche

- Fouling FactorsDocumento2 pagineFouling Factorsgrunger30Nessuna valutazione finora

- FichaDocumento2 pagineFichagrunger30Nessuna valutazione finora

- Therminol - 66 Synthetic Heat Trasnfer Fluid. Aceite Termico Therminol Venezuela.Documento8 pagineTherminol - 66 Synthetic Heat Trasnfer Fluid. Aceite Termico Therminol Venezuela.Renso PiovesanNessuna valutazione finora

- Fin TubesDocumento4 pagineFin TubesBhanu K PrakashNessuna valutazione finora

- Bocas de Hombre - VentanillasDocumento87 pagineBocas de Hombre - Ventanillasgrunger30Nessuna valutazione finora

- AppendixA Case7 Turbine-Generator Set Improvement (A-5)Documento2 pagineAppendixA Case7 Turbine-Generator Set Improvement (A-5)grunger30Nessuna valutazione finora

- AppendixA Case9 Multiple ECM With Metered Baseline Data (A-7) PDFDocumento3 pagineAppendixA Case9 Multiple ECM With Metered Baseline Data (A-7) PDFgrunger30Nessuna valutazione finora

- AppendixA Case8 Boiler Efficiency Improvement (A-6) PDFDocumento2 pagineAppendixA Case8 Boiler Efficiency Improvement (A-6) PDFgrunger30Nessuna valutazione finora

- AppendixA Case7 Turbine-Generator Set Improvement (A-5)Documento2 pagineAppendixA Case7 Turbine-Generator Set Improvement (A-5)grunger30Nessuna valutazione finora

- AppendixA Case9 Multiple ECM With Metered Baseline Data (A-7) PDFDocumento3 pagineAppendixA Case9 Multiple ECM With Metered Baseline Data (A-7) PDFgrunger30Nessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Pave RuttingDocumento440 paginePave RuttingbloomdidoNessuna valutazione finora

- Hot and Dry Climate SolarPassiveHostelDocumento4 pagineHot and Dry Climate SolarPassiveHostelMohammed BakhlahNessuna valutazione finora

- National Institute of Technology Durgapur: Department of Chemical EngineeringDocumento2 pagineNational Institute of Technology Durgapur: Department of Chemical Engineeringpiyush dwivediNessuna valutazione finora

- Development of A Belt Conveyor For Small Scale Industry: September 2017Documento6 pagineDevelopment of A Belt Conveyor For Small Scale Industry: September 2017DatNessuna valutazione finora

- FST - 70 FKM 37508 enDocumento2 pagineFST - 70 FKM 37508 enXavierNessuna valutazione finora

- ThermometryDocumento29 pagineThermometryaelle00Nessuna valutazione finora

- 2012 Movie SummaryDocumento2 pagine2012 Movie SummaryRenée NinteNessuna valutazione finora

- Xavier University - Ateneo de Cagayan University College of Engineering Electronics Engineering DepartmentDocumento9 pagineXavier University - Ateneo de Cagayan University College of Engineering Electronics Engineering DepartmentMor DepRzNessuna valutazione finora

- Structural Course Descriptions - 2Documento26 pagineStructural Course Descriptions - 2AdnanRasheedNessuna valutazione finora

- CSE 2261 Structural Analysis II: Course OutlineDocumento38 pagineCSE 2261 Structural Analysis II: Course OutlinezakheusNessuna valutazione finora

- Activity 1Documento6 pagineActivity 1Aldwin AjocNessuna valutazione finora

- 2010 Aisc Steel ToolsDocumento4 pagine2010 Aisc Steel Toolsmuh2006Nessuna valutazione finora

- Sound Isolation 2017Documento81 pagineSound Isolation 2017vartika guptaNessuna valutazione finora

- Software For Enumerative and Analytic CombinatoricsDocumento47 pagineSoftware For Enumerative and Analytic CombinatoricsamacfiesNessuna valutazione finora

- SR Capital Public SchoolDocumento6 pagineSR Capital Public SchoolLakshya KumarNessuna valutazione finora

- K-Flex English-Catalog-2019 (Ic Clad)Documento4 pagineK-Flex English-Catalog-2019 (Ic Clad)ashishvaidNessuna valutazione finora

- B. Sc. IC Semester III To VIDocumento29 pagineB. Sc. IC Semester III To VIJainam JoshiNessuna valutazione finora

- Light NcertDocumento55 pagineLight NcertDani MathewNessuna valutazione finora

- Drop Impact Dynamics: Splashing, Spreading, Receding, BouncingDocumento36 pagineDrop Impact Dynamics: Splashing, Spreading, Receding, BouncingHarshini AichNessuna valutazione finora

- 0i Connection Manual 64113EN1 PDFDocumento1.224 pagine0i Connection Manual 64113EN1 PDFAnkit SabhayaNessuna valutazione finora

- Acid Base SeparationDocumento6 pagineAcid Base SeparationAlexandra CatalinaNessuna valutazione finora

- Hydrologic CycleDocumento35 pagineHydrologic CycleFachri JahriNessuna valutazione finora

- Tolerances and FitsDocumento12 pagineTolerances and FitsnikitaNessuna valutazione finora

- Chapter1 Electrostatic 2016 ReviewedDocumento98 pagineChapter1 Electrostatic 2016 ReviewedSyaza IzzatyNessuna valutazione finora

- M. Tech. Computer Aided DesignDocumento42 pagineM. Tech. Computer Aided DesignHamid MojiryNessuna valutazione finora

- Ficha Tecnica 750 GPMDocumento156 pagineFicha Tecnica 750 GPMByron Chele0% (2)

- Topographical Surveys - Direct LevellingDocumento1 paginaTopographical Surveys - Direct LevellingTsegab DereseNessuna valutazione finora

- Applied III, Worksheet 1Documento4 pagineApplied III, Worksheet 1mintuwondeNessuna valutazione finora

- Micro Servo RobotDocumento40 pagineMicro Servo Robotlokesh mahor0% (1)

- Rigaku Journal 33-2-26-28Documento3 pagineRigaku Journal 33-2-26-28Eduardo ArdilesNessuna valutazione finora