Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Anchor Bolt - BiAxial

Caricato da

Arivoli JayaramanDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Anchor Bolt - BiAxial

Caricato da

Arivoli JayaramanCopyright:

Formati disponibili

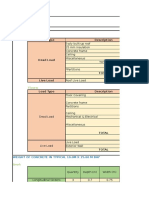

Node

L/C

Tension

Shear

NOTE: This spreadsheet is valid for

UNIAXIAL BENDING only.

However, an approximate,

simplified and conservative

approach is taken to design

for BIAXIAL BENDING.

Moments are combined to

design the bolts about the

major axis, while only the

moment about the minor

axis is used to design the

minor axis bolts.

SUBJECT: CONNECTION DESIGN FOR SULPHUR PELLETIZER SHED

PROJECT : SINGAPORE SULPHUR DISPOSITION PROJECT

SHEET NO.

OF

REV

DATE

ORIGINATOR

CHECKER

O1

May-12

MMJ

GC

CONTRACT No. : 1-PD-0376A

SAFETY CALC. Y/N : Y

CALC. No. : 0376A-8320-CA-0001

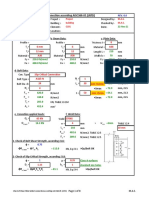

DESIGN OF ANCHOR BOLTS (TYPE A422)

Concrete strength, fcu =

Nominal bolt diameter, D =

40

N/mm2

42

mm

Corrosion allowance, c =

Effective tensile area, At =

mm

1120

mm2

Effective tensile stress diameter, Dt =

37.76

mm

Tensile stress diameter after corrosion, Dtc =

34.76

mm

Tensile stress area after corrosion, Atc =

Shear stress area after corrosion, Asc =

Tension strength, pt =

Shear strength, ps =

(C35)

BS3692: 2001, Table 10

Dt = sqrt(At 4/)

Dtc = Dt - c

949.12

mm

Atc = Dtc2/4

949.12

mm2

Asc = Atc

240

N/mm2

Grade 4.6

160

N/mm

Grade4.6

Nominal tension capacity, Pnom = 0.8pt Atc

= 182.23

Shear capacity, Ps = ps Asc

=

151.86

BS 5950-1:2000, Cl. 6.6

KN

KN

A. COMPUTATION OF TENSILE AND SHEAR FORCES ON BOLT

Factored moment, M =

Factored shear, V =

250.465

KN-m

80.2

KN

Factored load on pedestal, N =

279.688

KN

Total number of bolts, n =

Number of bolts per side, ns =

Bolt spacing, s =

hp =

h=

bp =

4

0.5

0.62

0.56

0.62

M = 0.6fcubpx(h-x/2) -

N(h-hp/2)

Solving for x,

x=

0.065

C = 0.6fcubpx

=

T=

=

607.56

KN

C-N

327.87

KN

B. BOLT CAPACITY CHECK

Tensile force per bolt, Ft =

T / nT

=

Shear force per bolt, Fs =

82

where nT = 4 bolts

KN

<

182.23

PASS

KN

<

151.86

PASS

V/n

11

SUBJECT: CONNECTION DESIGN FOR SULPHUR PELLETIZER SHED

PROJECT : SINGAPORE SULPHUR DISPOSITION PROJECT

SHEET NO.

OF

REV

DATE

ORIGINATOR

CHECKER

O1

May-12

MMJ

GC

<

1.40

PASS

<

250

PASS

CONTRACT No. : 1-PD-0376A

SAFETY CALC. Y/N : Y

CALC. No. : 0376A-8320-CA-0001

Interaction,

Fs/Ps + Ft/Pnom =

0.52

C. COMPUTATION OF PROJECTION LENGTH

Grout thickness, t =

25

mm

Plate thickness, b =

35

mm

Number of nuts, n =

Projection, Preq =

2

215

mm

D. CHECKING FOR PULLOUT FAILURE

As per sec 3.7.2.1 of the ASCE Publication "Wind Loads and Anchor Bolt Design for Petrochemical

Facilities", provided that the distance of the reinforcement from the anchor bolt head does not exceed

the smaller of 1/3 the embedment length or 150 mm, the area of reinforcing steel required A st is,

Ast = Tu / Fy

where,

Tu = Factored tensile load per bolt

Fy = Mimimum specified yield strength of reinforcing steel

= Strength reduction factor

However, for ductile design, the required reinforcement would just be the ratio of the anchor bolt

strength pt to the reinforcement strength Fy, multiplied by the total anchor bolt area in tension A anchor.

Aanchor = ns At

=

Rebar diameter, dr =

Number of rebars on tension side, nt =

Rebar yield strength, Fy =

4480

mm2

28

mm2

4

460

N/mm2

Ast = (pt / Fy) Aanchor

Aprov

=

2337

= nt dr2/4

mm2

mm2

2463

>

2337

PASS

Furthermore, the embedment length of the anchor bolts was checked against the pier reinforcement to

ensure that the reinforcement is fully developed, both above and below the failure plane of the anchor.

E. CHECKING FOR LATERAL BURSTING (BLOWOUT) FAILURE

As per sec 3.7.2.2 of the ASCE Publication, the minimum edge distance required to prevent lateral

bursting of concrete is 4 times the bolt diameter. The minimum plinth edge distances recommended in

sec 12.1 of FW Standard: 40A3(Reading) are more than 4 times the bolt diameter.

As such, adherence to the FW standard ensures that lateral bursting will not occur.

F. CHECKING FOR LOCALIZED BEARING FAILURE

As per sec 3.6.4 of the ASCE Publication, bearing could be ignored provided that the bearing area

of the anchor bolt head is at least 1.5 times the tensile stress area. Type "A" anchor bolts in the FW

Anchor Bolt standard drawing satisfy this requirement. As such, bearing can be ignored.

G. CHECKING FOR CONCRETE SPLITTING FAILURE

As per Appendix D of ACI 318-02, sec D.8.1 states that the minimum center-to-center spacing of

SUBJECT: CONNECTION DESIGN FOR SULPHUR PELLETIZER SHED

PROJECT : SINGAPORE SULPHUR DISPOSITION PROJECT

CONTRACT No. : 1-PD-0376A

SHEET NO.

OF

REV

DATE

ORIGINATOR

CHECKER

O1

May-12

MMJ

GC

SAFETY CALC. Y/N : Y

CALC. No. : 0376A-8320-CA-0001

anchors shall be 4 times the outside diameter of the anchor, while sec D.8.2 states that the minimum

edge distance shall be based on minimum cover requirements for reinforcement. Sec 14.2 of the FW

standard: 40A3(Reading) states that structural steelwork shall have bolt spacings not less than 4 times

the bolt diameter. Compliance with the FW standard will preclude splitting failure.

Node

L/C

Tension

Shear

NOTE: This spreadsheet is valid for

UNIAXIAL BENDING only.

However, an approximate,

simplified and conservative

approach is taken to design

for BIAXIAL BENDING.

Moments are combined to

design the bolts about the

major axis, while only the

moment about the minor

axis is used to design the

minor axis bolts.

SUBJECT: FOUNDATION DESIGN CALCULATION FOR PIPERACK PR A2-4

SHEET NO.

OF

PROJECT: BTR SINGAPORE

REV

DATE

ORIGINATOR

CHECKER

CONTRACT No.: 1-PD-0353

O1

15/06/11

GEPC

DP

SAFETY CALC. Y/N: Y

CALC. No.: 0353-8310-CA-9000-0121

DESIGN OF ANCHOR BOLTS (TYPE A422)

Concrete strength, fcu =

Nominal bolt diameter, D =

40

N/mm2

42

mm

Corrosion allowance, c =

Effective tensile area, At =

mm

1120

mm2

Effective tensile stress diameter, Dt =

37.76

mm

Tensile stress diameter after corrosion, Dtc =

34.76

mm

Tensile stress area after corrosion, Atc =

Shear stress area after corrosion, Asc =

Tension strength, pt =

Shear strength, ps =

(C35)

BS3692: 2001, Table 10

Dt = sqrt(At 4/)

Dtc = Dt - c

949.12

mm

Atc = Dtc2/4

949.12

mm2

Asc = Atc

240

N/mm2

Grade 4.6

160

N/mm

Grade4.6

Nominal tension capacity, Pnom = 0.8pt Atc

= 182.23

Shear capacity, Ps = ps Asc

=

151.86

BS 5950-1:2000, Cl. 6.6

KN

KN

A. COMPUTATION OF TENSILE AND SHEAR FORCES ON BOLT

Factored moment, M =

Factored shear, V =

6.582

KN-m

80.2

KN

Factored load on pedestal, N =

279.688

KN

Total number of bolts, n =

Number of bolts per side, ns =

Bolt spacing, s =

hp =

h=

bp =

2

0.5

0.62

0.56

0.62

M = 0.6fcubpx(h-x/2) -

N(h-hp/2)

Solving for x,

x=

0.015

C = 0.6fcubpx

=

T=

=

138.45

KN

C-N

-141.23

KN

B. BOLT CAPACITY CHECK

Tensile force per bolt, Ft =

T / nT

=

Shear force per bolt, Fs =

where nT = 2 bolts

KN

<

182.23

PASS

KN

<

151.86

PASS

V/n

21

SUBJECT: FOUNDATION DESIGN CALCULATION FOR PIPERACK PR A2-4

SHEET NO.

OF

PROJECT: BTR SINGAPORE

REV

DATE

ORIGINATOR

CHECKER

CONTRACT No.: 1-PD-0353

O1

15/06/11

GEPC

DP

<

1.40

PASS

<

250

PASS

SAFETY CALC. Y/N: Y

CALC. No.: 0353-8310-CA-9000-0121

Interaction,

Fs/Ps + Ft/Pnom =

0.14

C. COMPUTATION OF PROJECTION LENGTH

Grout thickness, t =

25

mm

Plate thickness, b =

35

mm

Number of nuts, n =

Projection, Preq =

2

215

mm

D. CHECKING FOR PULLOUT FAILURE

As per sec 3.7.2.1 of the ASCE Publication "Wind Loads and Anchor Bolt Design for Petrochemical

Facilities", provided that the distance of the reinforcement from the anchor bolt head does not exceed

the smaller of 1/3 the embedment length or 150 mm, the area of reinforcing steel required A st is,

Ast = Tu / Fy

where,

Tu = Factored tensile load per bolt

Fy = Mimimum specified yield strength of reinforcing steel

= Strength reduction factor

However, for ductile design, the required reinforcement would just be the ratio of the anchor bolt

strength pt to the reinforcement strength Fy, multiplied by the total anchor bolt area in tension A anchor.

Aanchor = ns At

=

Rebar diameter, dr =

Number of rebars on tension side, nt =

Rebar yield strength, Fy =

2240

mm2

28

mm2

4

460

N/mm2

Ast = (pt / Fy) Aanchor

Aprov

=

1169

= nt dr2/4

mm2

mm2

2463

>

1169

PASS

Furthermore, the embedment length of the anchor bolts was checked against the pier reinforcement to

ensure that the reinforcement is fully developed, both above and below the failure plane of the anchor.

E. CHECKING FOR LATERAL BURSTING (BLOWOUT) FAILURE

As per sec 3.7.2.2 of the ASCE Publication, the minimum edge distance required to prevent lateral

bursting of concrete is 4 times the bolt diameter. The minimum plinth edge distances recommended in

sec 12.1 of FW Standard: 40A3(Reading) are more than 4 times the bolt diameter.

As such, adherence to the FW standard ensures that lateral bursting will not occur.

F. CHECKING FOR LOCALIZED BEARING FAILURE

As per sec 3.6.4 of the ASCE Publication, bearing could be ignored provided that the bearing area

of the anchor bolt head is at least 1.5 times the tensile stress area. Type "A" anchor bolts in the FW

Anchor Bolt standard drawing satisfy this requirement. As such, bearing can be ignored.

G. CHECKING FOR CONCRETE SPLITTING FAILURE

As per Appendix D of ACI 318-02, sec D.8.1 states that the minimum center-to-center spacing of

SUBJECT: FOUNDATION DESIGN CALCULATION FOR PIPERACK PR A2-4

SHEET NO.

OF

PROJECT: BTR SINGAPORE

REV

DATE

ORIGINATOR

CHECKER

CONTRACT No.: 1-PD-0353

O1

15/06/11

GEPC

DP

SAFETY CALC. Y/N: Y

CALC. No.: 0353-8310-CA-9000-0121

anchors shall be 4 times the outside diameter of the anchor, while sec D.8.2 states that the minimum

edge distance shall be based on minimum cover requirements for reinforcement. Sec 14.2 of the FW

standard: 40A3(Reading) states that structural steelwork shall have bolt spacings not less than 4 times

the bolt diameter. Compliance with the FW standard will preclude splitting failure.

Potrebbero piacerti anche

- TCC81 Foundation PadsDocumento1 paginaTCC81 Foundation PadsReetesh0% (1)

- Chequer Plate DesignDocumento1 paginaChequer Plate Designmanish_chhuganiNessuna valutazione finora

- Anchor Chair Design CheckDocumento5 pagineAnchor Chair Design CheckHomer SilvaNessuna valutazione finora

- Vertical Equation Foundation-Spread Sheet PDFDocumento6 pagineVertical Equation Foundation-Spread Sheet PDFmassive85Nessuna valutazione finora

- Staad Pro Stainless Steel ReportDocumento29 pagineStaad Pro Stainless Steel ReportRaviteja Girijala100% (1)

- Vertical Vessel Foundation Design Input Parameters: Geometrical DescriptionDocumento8 pagineVertical Vessel Foundation Design Input Parameters: Geometrical DescriptionAnonymous xcFcOgMiNessuna valutazione finora

- Seismic DesignDocumento27 pagineSeismic Designamachmouchi100% (1)

- Brace Frame Connection ECBFDocumento48 pagineBrace Frame Connection ECBFleonid48Nessuna valutazione finora

- Flust-Extended End Plate ConnectionDocumento8 pagineFlust-Extended End Plate ConnectionamachmouchiNessuna valutazione finora

- Pile StirrupDocumento1 paginaPile Stirrupbuffyto5377Nessuna valutazione finora

- Design of Non Composite Beams With Large OpeningsDocumento73 pagineDesign of Non Composite Beams With Large OpeningsbalaNessuna valutazione finora

- Anchor Bolt Design As Per American CodeDocumento1 paginaAnchor Bolt Design As Per American CodeS A K ClostreNessuna valutazione finora

- Bolt Design (Blodget)Documento4 pagineBolt Design (Blodget)Mayuresh KudveNessuna valutazione finora

- AISC Connection Design With StiffnerDocumento8 pagineAISC Connection Design With StiffnerVinayak PatilNessuna valutazione finora

- Steel BeamCal - Pointed Load + Beam's WeightDocumento6 pagineSteel BeamCal - Pointed Load + Beam's WeightMana MungkornkritNessuna valutazione finora

- Fe Report of Base SkidDocumento16 pagineFe Report of Base SkidpawanNessuna valutazione finora

- Seismic Load EurocodeDocumento1 paginaSeismic Load EurocodedantevariasNessuna valutazione finora

- Base Plate & BoltsDocumento3 pagineBase Plate & BoltsarvnndNessuna valutazione finora

- Structural Calcs SHEDDocumento24 pagineStructural Calcs SHEDvtalexNessuna valutazione finora

- Crack WidthDocumento6 pagineCrack Widthnitin400Nessuna valutazione finora

- Wind Load Calculation For Multiple Framed Open Structures Design Wind PressureDocumento2 pagineWind Load Calculation For Multiple Framed Open Structures Design Wind Pressurechirag01020% (1)

- Anchor Bolt Calc.Documento1 paginaAnchor Bolt Calc.nishant131100% (1)

- Moment Connection Design-BS CODEDocumento5 pagineMoment Connection Design-BS CODEMuthukumaran SivalingamNessuna valutazione finora

- Anchor Bolt DesignDocumento3 pagineAnchor Bolt DesignKrishna Veni100% (1)

- Aisc 34Documento4 pagineAisc 34AlaaBadwyNessuna valutazione finora

- Pinned Base Plate - 03SF01Documento15 paginePinned Base Plate - 03SF01vivekNessuna valutazione finora

- "EMBEDPL2" - Embedment Strength of Stud Plate: Program DescriptionDocumento23 pagine"EMBEDPL2" - Embedment Strength of Stud Plate: Program DescriptionBolarinwaNessuna valutazione finora

- Concrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part7-Pryout Strength in ShearDocumento4 pagineConcrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part7-Pryout Strength in ShearVenu GopalNessuna valutazione finora

- Grating DesignDocumento1 paginaGrating DesigngaratetaNessuna valutazione finora

- IBC 2006 and ASCE 7-05Documento1 paginaIBC 2006 and ASCE 7-05Omar RubioNessuna valutazione finora

- M3D - SampleProblemSet ACI PDFDocumento6 pagineM3D - SampleProblemSet ACI PDFasaisenthilNessuna valutazione finora

- Seismic Analysis of Structures - Concrete Ductile Moment Resisting Space FrameDocumento34 pagineSeismic Analysis of Structures - Concrete Ductile Moment Resisting Space FrameEmmanuel LazoNessuna valutazione finora

- Client Comment Response - DG FoundationDocumento7 pagineClient Comment Response - DG FoundationAnnelzNessuna valutazione finora

- ACI BendDocumento3 pagineACI Bendمصطفى عبدالرحيمNessuna valutazione finora

- Bolted Moment Connection 2x2Documento22 pagineBolted Moment Connection 2x2Немања Караклајић100% (1)

- HSS Flange Plate Moment Connection - Temporary SteelDocumento9 pagineHSS Flange Plate Moment Connection - Temporary SteelrajedmaglinteNessuna valutazione finora

- Footing Upon Pile DesignDocumento5 pagineFooting Upon Pile DesignCivilax.comNessuna valutazione finora

- AISC360 05 LRFD Shear Plate Bolted Connection Check 17-09-2013Documento8 pagineAISC360 05 LRFD Shear Plate Bolted Connection Check 17-09-2013RUBEN BARTOLOME GARCIANessuna valutazione finora

- BeamDocumento7 pagineBeamsomumallidiNessuna valutazione finora

- RAM Connection Input With CommentsDocumento6 pagineRAM Connection Input With CommentsAhmed Saeed OokaNessuna valutazione finora

- 6.3 Wind Load Calculation: Description Variable Formula Value UnitDocumento4 pagine6.3 Wind Load Calculation: Description Variable Formula Value UnitNitesh SinghNessuna valutazione finora

- Fin Plate-Beam To Beam Inside (AISC-LRFD)Documento184 pagineFin Plate-Beam To Beam Inside (AISC-LRFD)AshishNessuna valutazione finora

- Anchor Bolt Design Example As Per Indian Code - Google SearchDocumento2 pagineAnchor Bolt Design Example As Per Indian Code - Google Searchjebin_87Nessuna valutazione finora

- End Plate Connection Design Per AISCDocumento5 pagineEnd Plate Connection Design Per AISCAdam Michael GreenNessuna valutazione finora

- Space 2001Documento43 pagineSpace 2001Nguyen Duc CuongNessuna valutazione finora

- Column W10x49 Brace 2L6x4x1/2Documento10 pagineColumn W10x49 Brace 2L6x4x1/2narasimmans100% (1)

- Dike Wall DesignDocumento4 pagineDike Wall Designdantevarias100% (1)

- Design of Headed Concrete AnchorDocumento121 pagineDesign of Headed Concrete AnchorkalpanaadhiNessuna valutazione finora

- Beam Shear TabDocumento13 pagineBeam Shear TabGautam SharmaNessuna valutazione finora

- Uplift With Moment CalculationDocumento4 pagineUplift With Moment CalculationdennykvgNessuna valutazione finora

- Foundation Design For 66kV Steel Poles Bo-Kenema-SOIL CLASS 2A-08-11-21Documento22 pagineFoundation Design For 66kV Steel Poles Bo-Kenema-SOIL CLASS 2A-08-11-21BAWA ALEXNessuna valutazione finora

- 10.0 Connection Moment ConnectionDocumento232 pagine10.0 Connection Moment Connectionklynchelle100% (1)

- Cantilever BeamDocumento3 pagineCantilever BeamFeliciano Esteban DominguezNessuna valutazione finora

- Anchor Bolt (CSA) Rev1.1Documento10 pagineAnchor Bolt (CSA) Rev1.1coolkaisyNessuna valutazione finora

- Anchor Bolt BiAxialDocumento10 pagineAnchor Bolt BiAxialALPHYL BALASABASNessuna valutazione finora

- 35M GRD Tower Design Report STCDocumento10 pagine35M GRD Tower Design Report STCEhtesham AliNessuna valutazione finora

- Analysis and Design of Members For TensionDocumento91 pagineAnalysis and Design of Members For TensionAL DANIEL VIN FULVADORANessuna valutazione finora

- Analysis and Design of Members For TensionDocumento84 pagineAnalysis and Design of Members For TensionicpertacortaNessuna valutazione finora

- Design of Base PlateDocumento14 pagineDesign of Base Plateruel galutanNessuna valutazione finora

- Riveted Joints ASME IDocumento7 pagineRiveted Joints ASME ICastoriadisNessuna valutazione finora

- Connections and Tension Member DesignDocumento9 pagineConnections and Tension Member DesignVigneshwari MahamuniNessuna valutazione finora

- UB 610 X 179 - BP - PinnedDocumento3 pagineUB 610 X 179 - BP - PinnedArivoli JayaramanNessuna valutazione finora

- CV Arivoli J 2019 PM CsaDocumento4 pagineCV Arivoli J 2019 PM CsaArivoli JayaramanNessuna valutazione finora

- IZZ OMAN Engineering LLC: Pipe Bridge Steel Structure Connection DesignDocumento1 paginaIZZ OMAN Engineering LLC: Pipe Bridge Steel Structure Connection DesignArivoli JayaramanNessuna valutazione finora

- Indman Application FormDocumento12 pagineIndman Application FormArivoli JayaramanNessuna valutazione finora

- Macro For Concrete Plate Element DesignDocumento8 pagineMacro For Concrete Plate Element DesignArivoli JayaramanNessuna valutazione finora

- Column Effective Length CalculationDocumento45 pagineColumn Effective Length CalculationArivoli JayaramanNessuna valutazione finora

- TORSION OF BARS Lab Sheet 2Documento6 pagineTORSION OF BARS Lab Sheet 2mrsmartguysNessuna valutazione finora

- Strength of Materials 1Documento31 pagineStrength of Materials 1Marcelo Abrera100% (1)

- Failure Theories in Brittle MaterialDocumento21 pagineFailure Theories in Brittle MaterialKing EverestNessuna valutazione finora

- Coke StrengthDocumento6 pagineCoke StrengthGaurav SrivastavaNessuna valutazione finora

- 11 Heat TreatmentDocumento5 pagine11 Heat TreatmentamokhtaNessuna valutazione finora

- Stress Strain CurveDocumento16 pagineStress Strain CurveMedakayala Nagasravanthi 20PHD7125Nessuna valutazione finora

- LAB 3 - Testing Concrete: ObjectivesDocumento2 pagineLAB 3 - Testing Concrete: ObjectiveslolenlennNessuna valutazione finora

- IRC 112 2011 (Reprinted With Amds & Errata Upto June 2014)Documento296 pagineIRC 112 2011 (Reprinted With Amds & Errata Upto June 2014)Vaibhav Sonje100% (2)

- 2 Basic Principles of Metal FormingDocumento28 pagine2 Basic Principles of Metal Formingshreeshail_mp6009Nessuna valutazione finora

- Lecture On Polymer BlendsDocumento11 pagineLecture On Polymer BlendsManny de JesusNessuna valutazione finora

- Casting Surface DefectsDocumento5 pagineCasting Surface DefectsKarthiKeyan SNessuna valutazione finora

- Design Methods: Types of BeamsDocumento9 pagineDesign Methods: Types of BeamsSyazaa SalimNessuna valutazione finora

- Analysis of Individual Deep Foundations Under Axial Loading Using The T-Z ModelDocumento28 pagineAnalysis of Individual Deep Foundations Under Axial Loading Using The T-Z ModelAndré OliveiraNessuna valutazione finora

- Exam Sheet MetalDocumento19 pagineExam Sheet MetalIbraheem SabryNessuna valutazione finora

- A Study On Characteristics of Sisal Fiber and Its Performance in Fiber Reinforced ConcreteDocumento5 pagineA Study On Characteristics of Sisal Fiber and Its Performance in Fiber Reinforced ConcreteErnandes Macêdo PaivaNessuna valutazione finora

- DNV RP-F201Documento26 pagineDNV RP-F201Mr. EngineerNessuna valutazione finora

- Aisi 4140Documento3 pagineAisi 4140Patrícia CanazartNessuna valutazione finora

- Mechanical Properties of 5083 Aluminium Welds After Manual and GMAW-P PDFDocumento4 pagineMechanical Properties of 5083 Aluminium Welds After Manual and GMAW-P PDFabraham silva hernandezNessuna valutazione finora

- Tabussum PDFDocumento330 pagineTabussum PDFMisael AlejandroNessuna valutazione finora

- Technical Data Sheet - Original Hoop MaterialDocumento2 pagineTechnical Data Sheet - Original Hoop MaterialMichelle Kozmik JirakNessuna valutazione finora

- Farahmand Et Al (2017) - Investigating The Scale-Dependency of The Geometrical and MechanicalDocumento19 pagineFarahmand Et Al (2017) - Investigating The Scale-Dependency of The Geometrical and MechanicalRaul PozoNessuna valutazione finora

- Book 1Documento80 pagineBook 1Ranjan Kumar SinghNessuna valutazione finora

- Worksheet & AssignmentDocumento2 pagineWorksheet & AssignmentAdnan Shafi100% (3)

- Roaches Catalogue - enDocumento56 pagineRoaches Catalogue - enlthyaguNessuna valutazione finora

- Celsius Oval 355 Technical Data - Corus (2007)Documento12 pagineCelsius Oval 355 Technical Data - Corus (2007)PNessuna valutazione finora

- TIE33 Design Strength of Optical Glass and ZerodurDocumento10 pagineTIE33 Design Strength of Optical Glass and Zerodur侯涛Nessuna valutazione finora

- Structural Design of Reinforced Concrete U Shaped Channels Basins and Drop Structures PDFDocumento39 pagineStructural Design of Reinforced Concrete U Shaped Channels Basins and Drop Structures PDFuntel untelNessuna valutazione finora

- Altecrete - MineCrete S3 Shotcrete Hybrid Technical Paper EnglishDocumento10 pagineAltecrete - MineCrete S3 Shotcrete Hybrid Technical Paper EnglishJason BorejszoNessuna valutazione finora

- The Effect of Zirconia Sintering Temperature On Flexural Strength, Grain Size, and Contrast RatioDocumento6 pagineThe Effect of Zirconia Sintering Temperature On Flexural Strength, Grain Size, and Contrast RatioFrontiersNessuna valutazione finora

- Sloboda (2007) - Generalized Elasticity Method For Curved Beam Stress Analysis-Analytical and Numerical Comparisons For A Lifting HookDocumento16 pagineSloboda (2007) - Generalized Elasticity Method For Curved Beam Stress Analysis-Analytical and Numerical Comparisons For A Lifting HookGogyNessuna valutazione finora