Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Impedance, Electrical Conductivity and Piezoelectric Studies On Nb5+ Doped (Bi0.5Na0.5) 0.94Ba0.06TiO3 - PVDF 0-3 Composites

Caricato da

IOSRjournalTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Impedance, Electrical Conductivity and Piezoelectric Studies On Nb5+ Doped (Bi0.5Na0.5) 0.94Ba0.06TiO3 - PVDF 0-3 Composites

Caricato da

IOSRjournalCopyright:

Formati disponibili

IOSR Journal of Applied Physics (IOSR-JAP)

e-ISSN: 2278-4861.Volume 7, Issue 2 Ver. III (Mar. - Apr. 2015), PP 17-26

www.iosrjournals.org

Impedance, Electrical Conductivity and Piezoelectric Studies on

Nb5+ doped (Bi0.5Na0.5)0.94Ba0.06TiO3 -PVDF 0-3 composites

Amrita Singh1, Kumar Amarnath2, Kamal Prasad1,2, and Ashutosh Prasad1*

1

University Department of Physics, T.M. Bhagalpur University, Bhagalpur 812007 India

Aryabhatta Centre for Nanoscience and Nanotechnology, Aryabhatta Knowledge University, Patna 800001

India

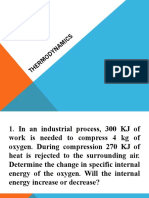

Abstract: The present work makes use of experimental ac complex impedance data to obtain the electrical

parameters like electrical conductivity and activation energy of ((Bi 0.5Na0.5)0.94Ba0.06TiO3+0.2 wt%Nb2O5)

PVDF 0-3 composites with 10, 20 and 30 vol. percentage of ((Bi 0.5Na0.5)0.94Ba0.06TiO3+0.2 wt%Nb2O5) in the

frequency range 1kHz1 MHz over a temperature range of 35oC-145C. SEM micrographs exhibited good

dispersion of almost spherical dense grains (sizes ranging between 8-14 m). Cole-Cole analysis for frequencydependent complex impedance data indicated the presence of grain-boundary effect along with the bulk

contribution, thereby showing the NTCR character for the composites, especially in the lower frequency and

higher temperature regime. Results were also analyzed via the electric modulus formalism. Experimental results

evidenced that the recorded relaxation phenomena include contributions from both the polymeric matrix and the

presence of the reinforcing phase. Temperature dependent ac conductivity data also endorsed the NTCR

character for the composites. Activation energy data allowed an insight into the mechanism of hopping of

charge carriers in the materials. Ceramic filler concentration dependent increase of d33 (ranging between 20-40

pC/N) of the composite was seen to follow the first order exponential growth type of equation.

Keywords: Ceramic-polymer 0-3 composites; Grains /grain-boundaries; piezoelectric ceramics; Complex

impedance/modulus spectroscopy; AC conductivity

e-mail id of the corresponding author: apd.phy@gmail.com

I.

Introduction

During the last few years, increased global environmental concern has prompted considerable efforts to

reduce the quantity of hazardous substances, like the highly toxic lead, in electronic consumer products.

Regulatory agencies on global level have begun putting strict restrictions on the use of lead, however with the

exception of the electronics and electromechanical devices industry, in view of the lack of a suitably harnessed

lead-free material having comparable properties with those of (Pb, Zr)TiO3 (PZT), containing toxic lead.

Piezoelectric ceramics have, in general, large dielectric constant, high piezoelectric charge coefficient

as well as acoustic impedance, whereas polymers have generally lower dielectric constant and acoustic

impedance close to that of water as well as of human body tissue. This low value of acoustic impedance

combined with higher values of piezoelectric voltage coefficients for piezoelectric polymers makes the

piezoelectric ceramic-polymer composites suitable candidates for dielectric, ferroelectric, piezoelectric,

pyroelectric, electro-optic, as well as superconducting properties in micro-devices making good strainmonitoring and hydrostatic sonar sensors [1]. Moreover, these ceramic-polymer composite materials have been

suggested to be viable alternative tools in piezoelectric and pyroelectric transducer as well as in energy

harvesting applications [2-6]. Hence, piezoelectric composites are now treated as established alternatives to

conventional ferroelectric ceramic materials as well as to the more recently discovered ferroelectric polymers.

In short, these systems form the basis of current area of active research activities and have received intensive

global attention [7-10] in view of the fact that these composites, having excellent dielectric and mechanical

properties, can be prepared under lower temperature conditions and can be designed according to specific

requirements by tailoring the relative fraction of the filler materials. Recently, there has been a great interest in a

new generation of composite materials exhibiting superior dielectric properties with lower cost, size, weight,

and easy processibility [1115]. Composite systems, which are apt for variation of some of their properties

(such as shape, natural vibration frequency, damping coefficient, polarization etc) in a controllable fashion

under the influence of an external stimulus, are considered as adaptive or smart materials [1618].

In an attempt to provide lead-free perovskite ceramic materials having optimal dielectric and

piezoelectric properties, Takenaka [19], Wang et al [20], Wu et al [21], Li et al [22] as well as the present group

of workers [23] worked with some of the lead-free materials and reported that (Na1/2Bi1/2)0.94Ba0.06TiO3, the

morphotropic phase boundary (MPB) composition, is one of the most suited lead-free materials for its use in

electronic and electromechanical devices. However, from these studies it transpired that although BNBT-x

ceramics are seen to possess good piezoelectric properties near the MPB, the gap still exists in between the

DOI: 10.9790/4861-07231726

www.iosrjournals.org

17 | Page

Impedance, Electrical Conductivity and Piezoelectric Studies on Nb5.

comparable ferroelectric and electromechanical properties of these ceramics with those of PZT. In order to

further improve the properties of BNBT-x ceramics, some additions, including Nb5+ at the B- sites of ABO3 type

of perovskite structures, have been suggested for specific applications [24-28]. Some of these studies reveal that

the doping of Nb5+ enhanced the piezoelectric coefficient, however at the cost of increased dielectric loss

tangent (tan ), of BNBT-x ceramics. On the basis of a systematic study on the samples having different Nb5+

doping levels (0.2-1.0 wt%), the present group of workers observed that the (Na1/2Bi1/2)0.94Ba0.06TiO3(BNBT6),

the morphotropic phase boundary (MPB) composition doped with 0.2 wt% Nb5+ exhibited optimal dielectric,

and piezoelectric properties.

As far as the polymer phase of the biphasic composite(s) is concerned, piezoelectric polymer PVDF,

despite many of its deficient properties, has appeared appealing to numerous industries for its inexpensive,

lightweight, biologically compatible and mechanically stable structures. It can undertake large amount of

deformation while sustaining large forces. It has expeditious response time, very low density, and notable

flexibility when compared to those of electro-active ceramics and shape memory alloys. The piezoelectric

PVDF and its copolymers are widely applied materials in both actuation and sensing mechanisms. They can be

utilized as fibers and films as energy harvesters in linear movement requirements in various engineering

applications such as active micro air vehicle wings, piezo -laminated columns, and shape correction films in

space applications, endoscopic tactile sensors and macro-fluidic control [12, 13, 27].

Literature survey on the above referred topic revealed that the complex impedance/modulus, ac

conductivity and piezoelectric studies on ((Bi 0.5Na0.5)0.94Ba0.06TiO3+0.2 wt% Nb2O5)PVDF ((BNBT6N0.2)PVDF) 0-3 composites with different contents of BNBT6N0.2 have not been undertaken in the recent past. In

view of the above, the present work relating to the study of the electrical properties of ((BNBT6N0.2)-PVDF) 03 composite samples having 10, 20 and 30 volume percent of BNBT6N0.2 powder was undertaken via complex

impedance/electric modulus spectroscopic, electrical conductivity and piezoelectric properties analyses.

II.

Materials and Methods

Polycrystalline samples of ceramic solid solutions of (BNBT6) were prepared by the conventional

high-temperature solid-state reaction technique at 1170C for about 3h. The XRD patterns were observed on

BNBT6N0.2 powder at the ambient temperature with an X-ray diffractometer (Xpert-PRO, USA), using CuK

radiation (=1.5405 ) over a broad range of Bragg angles (20280). The obtained XRD pattern did not fit

to any single space group model (including monoclinic Cm, tetragonal P4mm, or rhombohedral R3c), whereas it

could be fitted to the Cm+P4mm mixed phases. This observed co-existence of two phases confirmed a

tetragonal side of the monoclinic/tetragonal MPB composition. Hence, these patterns for the ceramic were fitted

with the tetragonal unit cell structure. The calcined powder was again ground using an agate mortar and pestle

and then 0.2 wt. % Nb2O5 was added to it and mixed thoroughly in dry as well as in wet acetone medium. A part

of the dried powder was then pressed into discs using pressure of 200MPa in a hydraulic press with 5 wt% PVA

solution added as a binder. The fabricated compact green pellets were sintered at an optimized temperature of

1175 for about 2h. The frequency and temperature dependent dielectric constant (r) and loss tangent (tan ),

complex impedance (Z*) and phase angle () of the sintered ceramic samples were measured using a computercontrolled LCR Hi-Tester (HIOKI 3532-50, Japan) on a symmetrical cell consisting of AgceramicAg, where

Ag is a conductive paint coated on each side of the pellet. The ceramic sample was poled under an applied DC

electric field of 2.5kV/mm at 80C in a silicone oil bath. Longitudinal piezoelectric charge coefficients (d33) of

the poled ceramic samples were measured at the room temperature using a PM3500 d33 / d31 meter (KCF

Technologies, USA). Now, ((BNBT6N0.2)-PVDF) 0-3 composite samples having 10, 20 and 30 volume

percentage of calcined BNBT6N0.2 powder were prepared by solution cast method (using DMF as the solvent

for PVDF) at an elevated temperature (~70oC-80oC) under constant stirring with the help of a magnetic stirrer

and ultrasonic agitator. The composite samples in the molten (viscous) state were poured into cylindrical and

rectangular stainless steel dies and were then allowed to dry for a few days in open air. The fabricated

composites were taken out of the dies and were then cut into the disk-shaped pieces of suitable thicknesses.

They were allowed to dry for a few days further before any measurements on them were made. The green

samples were then polished and painted on both sides by the use of high grade silver paste. Microstructures of

the fabricated composites were observed at the ambient temperature by using a scanning electron microscope

(JEOL-JSM840A).The complex impedance (Z*) and phase angle () of the different composite samples were

measured in the frequency range 1kHz-1MHz between the ambient temperature and 145oC by the same

computer interfaced LCR Hi-Tester (HIOKI 3532-50, Japan) in the same way as for the ceramic samples.

Longitudinal piezoelectric charge coefficients (d33) of the poled composite samples were measured at the

ambient temperature using a PM3500 d33 / d31 meter (KCF Technologies, USA). The poling of the composite

samples was done under an applied DC electric field of about 1.5kV/mm at 80 C in a silicone oil bath for

about 15 minutes because the composite samples were seen to be unable to withstand higher field strengths than

1.5kV/mm and higher dwell time on account of leakage currents,

DOI: 10.9790/4861-07231726

www.iosrjournals.org

18 | Page

Impedance, Electrical Conductivity and Piezoelectric Studies on Nb5.

III.

Results and discussion

3.1 Microstructural analysis

Fig. 1(a), (b), and (c) shows the EDAX patterns and SEM micrographs (insets) for the ((BNBT6N0.2)PVDF) 0-3 composites having (a) 10, (b) 20 and (c) 30 vol. % of BNBTN0.2 ceramic fillers. SEM micrographs

showed homogeneous distribution of dense grains for all the compositions and the EDAX patterns confirmed

the presence of different constituent elements of the composite like Bi, Na, Ba, Ti, O, C, Nb etc. SEM

micrographs (shown separately in Fig. 2(a), 2(b), and 2(c)) revealed that the grains are spherical in shape for all

the fabricated composite samples having their sizes ~8.5 m, 12.5m, and 14m, respectively, for 10, 20 and

30 volume percentage of BNBT6N0.2 powder.

3.2 Complex impedance analysis

Most of the real ceramics contain grains and grain-boundary regions, which individually have very

different physical properties and are well observed in the impedance and modulus spectra. Electrical ac data

may be presented in any of the four interrelated formalisms: Relative permittivity (*) = - j (the real part

being given by C/C0 where C ~Cparellel is directly given by the LCR Hi-Tester); Impedance (Z*) = Z+ jZ =

1/jC0*, where Z (=Z* cos) is the real part of complex impedance ; Z* and are directly given by the

computer-controlled LCR Hi-Tester; Electric modulus (M*) = M + jM = 1/*; Admittance (Y*) = Y + jY =

jC0*; and tan = / = M /M = Z/Z = Y/Y, where (=2f) is the angular frequency; C0 (= 0A/t) is

the geometrical capacitance; j = -1; 0 is the permittivity of free space (=8.8541012 Fm1); t is the thickness

and A the area of the pellet; is complementary to the phase angle (). However, the present work is confined to

the use of only the impedance/modulus data for the entire analysis.

Fig. 3 (a)-(f) shows the Z (f) and Z (f) plots for ((BNBT6N0.2)-PVDF) 0-3 composites having (i) 10,

(ii) 20 and (iii) 30 vol. % of BNBT6N0.2 ceramic fillers at several temperatures between ambient temperature

and 145C. The plots reveal that at lower temperatures, Z' values decrease monotonically with increasing

frequency up to a certain limiting value (~10 kHz) above which Z' becomes almost frequency- independent. The

higher values of Z at lower frequencies and higher temperatures indicate that the polarization in the test material

is comparatively larger at these frequencies and temperatures. The temperature where this frequency-dependent

to frequency-independent change of Z occurs, varies with frequency in different material compositions. This

also signifies that the resistive grain boundaries become conducting at these temperatures and that the grain

boundaries are not relaxing even at the highest measurement ranges of frequency and temperature. Z (f) plots

showed almost identical monotonically decreasing type of variation up to a certain frequency limit ~10kHz

beyond which they are seen to merge together at a very low value of Z to show frequency- independent nature

of variation extending up to the highest frequency limit at all the chosen temperatures. The merger of Z (as well

as of Z) at higher frequencies for all the temperatures indicate possible release of space charge

polarization/accumulation at the boundaries of homogeneous phases in the test material system under the

applied external field. At lower temperatures, monotonic decrease of Z indicated that at lower temperatures the

relaxation is almost absent in the material system. This means that relaxation species are immobile defects to

which only the orientation effects may be associated. Also, the decreasing magnitudes of Z and Z with

increasing frequencies imply that relaxation in the material system is temperature-dependent, and there is

apparently not a single relaxation time. Fig. 3 (g) - (h) shows the frequency dependent variation of real and

imaginary parts (Z and Z), respectively, for the three compositions at the room temperature. From the plots it

is seen that at the lowest range of measurement frequency (~1 kHz) the magnitude of Z decreases from ~2.89

M to 2.51 M with increase in volume content of the ceramic filler from 10% to 30%. However, the trend of

ceramic filler concentration dependent variation of Z in the lower frequency region is just opposite to that of

Z in the sense that it increases from ~10.79 M to 11.21 M with an increase in volume content of the ceramic

filler from 10% to 30%, thereby indicating an increased resistive grain boundaries contribution with increase in

volume content of the ceramic filler in the composite.

The electrical properties of the present composite material system have been first investigated using

Complex Impedance Spectroscopy (CIS) technique. The Nyquist plots between Z (f) and Z(f) (for the sake of

convenience, only the modulus of Z has been used in all of the plots drawn in the present work, whereas

actually it is - Z) for (BNBT6N0.2)-PVDF 0-3 composites having (a) 10, (b) 20 and (c) 30 vol. percentage of

NBT6N0.2 at different temperatures between 35-145oC have been shown in Fig. 4(a)-(c). The impedance

spectrum is distinguished by semicircles. A series array of lone parallel RC combination (Rg, Cg) in series with a

resistor (Rs) (though the almost frequency-independent data of Rs are not shown in any of the plots, for brevity

sake) was found to best fit the experimental data for the given composition, thereby indicating the dominance of

bulk contributions from intrinsic grains in the samples. No other relaxation mechanism, such as the grainboundaries or electrode effects in the sample could be identified through the CIS technique in the studied

frequency range. The resulting curves for the composite having 30 volume percentage of the ceramic filler, as

shown in Fig.4(c), showed a comparatively better tendency to bend towards the abscissa to form semicircles

DOI: 10.9790/4861-07231726

www.iosrjournals.org

19 | Page

Impedance, Electrical Conductivity and Piezoelectric Studies on Nb5.

with their centers below the real axis, having comparatively larger radii and the radii decreasing with the

increase of temperature, thereby representing the distribution of relaxation times in the test sample and

indicating a decrease in the resistivity of the material with a clear-cut departure from the ideal Debye type

behaviour. With increasing temperature, intercept points on the real axis are shown to shift towards the origin,

thereby showing the NTCR character of the test composite samples.

3.3 Complex modulus analysis

Complex modulus analysis is an alternative approach to explore electrical properties of the material

and magnify any other effects present in the sample (which are unidentifiable or superimposed in CIS

technique) as a result of different relaxation time constants. Electric modulus is defined as the inverse of

complex permittivity by the Equation (1) given below:

* () M * () 1

M ' ( ) M ' ( ) jM " ( ) 1 / * ( ) ' ( ) /( ' ( )2 " ( )2 ) " ( ) /( ' ( )2 " ( )2 )

jC0 Z * ( ) jC0 ( Z ' ( ) jZ " ( ))

(1)

Fig. 5(a) and 5(b) shows the complex modulus plane Nyquist plots for these compositions (having 10, 20, and

30 vol. percentages of BNBT6N0.2 corresponding to the two higher measurement temperatures i.e., at 90 oC and

100oC. Both the plots corresponding to the two temperatures are seen to be almost identical in shape and size.

These semicircles indicate that both grain and grain boundary capacitance started playing their active roles in

the conduction mechanism of the material system at higher temperatures. The intensities of the peaks are seen to

diminish with increase of the content of BNBT6N0.2 ceramic particles and at the same time they are seen to

slightly shift towards lower frequency side at the higher concentrations. From the definition and formulation of

electric modulus given in Equation (1), decreasing values of (M) correspond to enhanced values of dielectric

loss index () and thus, to a more pronounced relaxation phenomenon. Increased values of dielectric loss

signify that the relative effect consumes more energy. These results indicate that the kinetics of -relaxation

process, which is associated with glass- to- rubber transition in ceramic-polymer composites and is a

characteristic phenomenon dominant at low frequencies~0.1Hz (that is outside our experimental frequency

range/window), is modified or lessened by the amount of ceramic particles and, in particular, the whole process

becomes slower as the amount of ceramic filler increases.

3.4 Electrical conductivity analysis

The real part of ac conductivity is given by following equation:

ac o

(2)

Thus, ac is directly related to the dielectric properties of the material. Alternatively, the real part of

the dominant bulk conductivity may be evaluated from the impedance spectrum using the relation ac = t /

(ZA); where Z (=Z*cos) is the real part of complex impedance. As referred to earlier, the second formulation

has been used in the present study.

Fig. 6 shows the log-log plot of the real part of ac electrical conductivity ( ac ) versus frequency at

different temperatures for ((BNBT6N0.2)-PVDF) 0-3 composites having 30 vol. percentage of BNBT6N0.2

filler. The plots reveal that the real part of ac conductivity of the present composite material does not change

appreciably in the measurement ranges of frequency (from 1 kHz to 1MHz) and temperature (from the

temperature of ambience to 145oC). Further, all the ac(f) curves were found to be merging at high frequencies

(at ~500kHz) above which an opposite dispersion was observed, thereby suggesting the less defect mobility and

low conductivity in the material system [29]. However, each of the curves indicated at least two slopes-one in

the lower and the other in the higher frequency region, as clearly depicted in Fig. 6. The frequency and

temperature dependence of ac conductivity data for the ((BNBT6N0.2)-PVDF) 0-3 composites correspond to

the hopping type of conduction. Applying JRM to the frequency response, experimental conductivity data for

the ((BNBT6N0.2)-PVDF) 0-3 composites were found to fit the Jonschers modified double power law [30-36]

given as:

(3),

ac o A S B S

where o is the frequency independent (electronic or dc) part of ac conductivity. The exponent s1 (0

1

s1 1) corresponds to the low frequency region i.e., to the grain-boundary conductivity, pertaining to

translational ion hopping whereas the exponent s2 (0 < s2 < 2) characterizes the high frequency region i.e., to the

grain conductivity indicating the existence of well localized relaxation/re-orientational process [30], the

activation energy of which is ascribed to the reorientation ionic hopping. In the jump relaxation model (JRM)

introduced by Funke [31] and extended by Elliot [32] to account for ionic conduction in solids, there is a high

DOI: 10.9790/4861-07231726

www.iosrjournals.org

20 | Page

Impedance, Electrical Conductivity and Piezoelectric Studies on Nb5.

probability for a jumping ion to jump back (unsuccessful hop). However, if the neighborhood becomes relaxed

with respect to the ions position, the ion stays in the new site. The conductivity in the low frequency region is

associated with successful hops. Beyond the low frequency region, many hops are unsuccessful and as the

frequency increases, there is higher possibility of more hops to be unsuccessful. The change in the ratio of

successful to unsuccessful hops is seen to result in dispersive conductivity in the test material(s). In the

perovskite type oxide materials, presence of charge traps in the band gap is expected. The JRM suggests that

different activation energies are associated with unsuccessful and successful hopping processes.

Fig. 7(a)-(c) shows the ln(ac) vs. 1000/T plots for the three compositions i.e., (BNBT6N0.2)-PVDF 0-3

composites with 10, 20, and 30 vol. percentage of BNBT6N0.2 filler at different indicated frequencies (1kHz,

10kHz, 100kHz, and 1MHz). In the low temperature regime, ac conductivity of all the compositions was seen to

increase sharply with increase in frequency, thereby indicating dispersion of conductivity with frequency. With

increase in temperature, dispersion in conductivity narrowed down and all the curves for different frequencies

showed a tendency to merge at high temperatures, although they didnt merge completely in the chosen range of

temperature. The conductivity of the materials was found to increase with increase in temperature, and merger

of the conductivity curves in the higher temperature region is assumed to result with the release of space charge.

The enhancement in conductivity with temperature may be considered on the basis that within the bulk, the

oxygen vacancies due to the loss of oxygen (usually created during sintering) allow the charge compensation

process following the Krger-Vink equation [33]: Oo 12 O2 Vo 2e 1 to occur, thereby showing that

free electrons are left behind in the process, making the materials n-type. The activation energy for conduction

was obtained using the Arrhenius relationship:

ac o exp( Ea / kBT )

4(a)

whence ln(ac) = ln (o)-Ea / kBT

4(b)

The slope of the linear least- squares- fit of the ac conductivity data to Eq. 4(b) gives the value of the apparent

activation energy, Ea. Using Arrhenius relation (Eq. 4), the ac activation energies were calculated in the higher

temperature region at 1kHz and 10 kHz and the values for the composite having 30 vol. % of the ceramic filler

are given in the Table 1. It is observed that ac conductivity-based activation energies computed at higher

frequencies are lower than those at lower ones in the same temperature range. The ac conductivity-based

activation energy values are found to increase sharply with increase in temperature. The activation energies for

((BNBT6N0.2)-PVDF) 0-3 composites having 30 volume percentage of BNBT6N0.2 were found to be ~0.1350.596eV at 1 kHz and ~0.080-0.644eV at 10 kHz in the higher temperature region (115-145oC), thereby

suggesting that the conductivity may be the result of defects and associated charge carriers of metal ions such as

Na+, Bi3+, and Ba2+ at the A-site and Ti4+, Ti3+ and Nb5+ at the B-site in the ceramic phase of the composite. At

higher sintering temperatures, bismuth ions are the first to get evaporated and thereby oxygen vacancies are

created for charge neutralization. Defects such as bismuth VBi and oxygen vacancies VO are considered to be

the most mobile charges and play an important role in polarization fatigue and conduction [32]. However, the

conductivity based activation energies for the other two compositions (having. 10 and 20 volume % of the

ceramic filler) were found to be unreliable for analysis in the sense that these composites exhibited very high

order of magnitude for resistivity, as indicated in Fig. 3 as well as in Fig. 4 and at this high order of magnitude

for resistivity, the complex impedance Nyquist plots have been treated to be unreliable.

3.5 Piezoelectric characterization

Measured value of longitudinal piezoelectric charge coefficient (d33) of host polymer (PVDF) was

found to be equal to 4 pC/N [18] while that of the ceramic filler (Bi0.5Na0.5)0.94Ba0.06TiO3 doped with 0.2wt% of

Nb2O5 (BNBT6N0.2) it was found to be equal to 150pC/N. The d33 values for the composites having 10, 20, and

30 volume percent of BNBT6N0.2 were found to be ~20, 25, and 40 pC/N, respectively.

The ceramic filler concentration dependence of experimentally measured effective d33 of 0.2 wt%

Nb2O5 doped (Bi0.5Na0.5)0.94Ba0.06TiO3 -PVDF 0-3 composites are shown in Fig. 8. In an attempt to provide an

acceptable model for the ceramic (filler) concentration dependent variation of piezoelectric constant (d33) of the

test composite materials under the present study, the first order exponential growth type of mathematical model

in the form Y = Yo + A exp(x/) (where Yo, A and t or (= 1/ ) are the model parameters and x is the volume

fraction of ceramic in the composite) was found suitable. The value of r2 is ~0.99658, thereby showing good

agreement between theoretical and experimental results. In the present context, the term (Yo+ A) corresponds to

the d33 value at x = 0 i.e. for the polymer matrix, while the term [Yo+ A exp()] for x = 1 corresponds to the value

for the ceramic filler. Here (=1/) 0.6459 may be designated as the filler concentration dependent

piezoelectric coefficient growth parameter. From the study it transpired that if quite different types of ceramic

fillers as well as polymer matrices were chosen as the test materials, the filler concentration dependent growth

parameter () for piezoelectric constant would certainly assume different values, at least due to the different

nature of densification of the samples (lighter polymer particles being replaced by denser ceramic particles), as

DOI: 10.9790/4861-07231726

www.iosrjournals.org

21 | Page

Impedance, Electrical Conductivity and Piezoelectric Studies on Nb5.

the ceramic concentration is increased. The growth may also be ascribed to the different ratios of ac

conductivity values for ceramic to those for polymer phases (which are generally greater than 1) in the

composite. Thus, it is expected that the values of for different test composite materials might throw some light

on the nature of such type of variation (sharp or flat) and could thus assume a type of calibration parameter,

which may be useful for further studies. The effective piezoelectric coefficient of the composite as a function of

ceramic content can be expressed in the form:

(d33)eff = -153.38864 +159.00789 exp(0.6459x) (r2=0.99658)

(5)

where x (0 x 1) is the volume fraction of the ceramic filler (0.2% Nb2O5 doped (Bi0.5Na0.5)0.94Ba0.06TiO3) in

the composite.

IV.

Conclusions

The present work describes the impedance, electric modulus and conductivity studies on 0.2 wt %

Nb2O5 doped (Bi0.5Na0.5)0.94Ba0.06TiO3 (BNBT6N0.2) -PVDF 0-3 composites with 10, 20, and 30 vol. percentage

of BNBT6N0.2 at different frequencies between1kHz- 1MHz. Analysis of X-ray diffraction data confirmed the

formation of tetragonal unit cell structure for calcined BNBT6N0.2 ceramic. SEM micrographs for 0-3

composites showed dense homogeneous distribution of almost spherical grains in all the composite samples.

Conduction mechanism in the material system is explained on the basis of Jump Relaxation hopping model of

charge carriers. The complex impedance, electric modulus and electrical conductivity data as the functions of

temperature and frequency indicated the presence of grain-boundary effect along with the bulk contribution,

especially at higher temperatures and negative temperature coefficient of resistance (NTCR) behaviour of the

test ceramic-polymer composites. Ceramic filler concentration dependent increase of d33 of the composite is

seen to follow the first order exponential growth type of equation.

References

[1].

[2].

[3].

[4].

[5].

[6].

[7].

[8].

[9].

[10].

[11].

[12].

[13].

[14].

[15].

[16].

[17].

[18].

[19].

[20].

[21].

[22].

C. Cui, R.H. Baughman, Z. Igbal, T.R. Kazmar, D.K. Dalstrom, Improved piezoelectric ceramic/polymer composites for

hydrophone applications, Synthetic Mat. 85, 1997, 1391-1392.

C.J. Das, D.K. Das-Gupta, Inorganic ceramic/polymer ferroelectric composite electrets, IEEE Transactions on Dielectrics and

Electrical Insulation 3 , 1996, 706-734.

N.S. Shenck, J.A. Paradiso, Energy scavenging with shoe-mounted piezoelectrics, IEEE Micro. 21, 2001, 3042.

J. Granstorm, J. Feenstra, H.A. Sodano, K. Farinholt, Energy harvesting from a backpack instrumented with piezoelectric shoul der

straps, Smart Mater. Struct. 16, 2007, 18101820.

L. Wu, L. Chen, C. Liu, Acoustic energy harvesting using resonant cavity of a sonic crystal, Appl. Phys. Lett. 95, 2009, 013506.

D. Wang, H. Ko, Piezoelectric energy harvesting from flow-induced vibration, J. Micromech. Microeng. 20, 2010, 025019.

W.SUN, B.LIU, CHARACTERISATION OF PROTON-IRRADIATED 65PMN35PT/P (VDFTRFE) 03 COMPOSITES MATER. SCI. ENGG. B

127, 2006, 144-149.

Z. Kutnjak, B. Vodopivec, D. Kuer, M. Kosec, V. Bobnar, and B. Hilczer, Calorimetric and dielectric study of vinylidene

fluoride-trifluoroethylene-based composite, J. Non-Cryst. Solids, 351, 2005, 1261-1265.

S.H. Xie, B.K. Zhu, X.Z. Wei, Z.K. Xu, and Y.Y. Xu, Polyimide/BaTiO 3 composites with controllable dielectric properties,

Compos. Part A - Applied Science 36, 2005, 1152-1157.

Jeong-Hyeon Seol, Jae Shin Lee, Han-Na Ji, Yun-Po Ok, Gyoung Pyo Kong, Ki-Soo Kim, Chang Yoon Kim, Weon-Pil Tai,

Piezoelectric and dielectric properties of (K0.44Na0.52Li0.04) (Nb0.86Ta0.10Sb0.04)O3PVDF composites, Ceramics International, 38,

2012, S263-S266.

T. Furukawa, K. Fujino, and E. Fukada, Electromechanical properties in the composites of epoxy resin and PZT ceramics,

Japanese Journal of Applied Physics, 15, 1976, 21192129.

W.W. Clegg, D.F.L. Jenkins, and M.J. Cunningham, The preparation of piezoceramicpolymer thick films and their application as

micromechanical actuators. Sensors and Actuators A, 58, 1997, 173177.

W.K. Sakamoto, S. Shibatta-Kegesawa, D.H.F. Kanada, and D.K. Das-Gupta, Electrical properties of a composite of polyurethane

and ferroelectric ceramics. Journal of Materials Science, 33, 1998, 33253329.

H.C. Pant, M.K. Patra, A. Verma, S.R. Vadera, and N. Kumar, Study of the dielectric properties of Barium Titanatepolymer

composites. Acta Materialia, 54, 2006, 31633169.

L.A. Ramajo, M.M. Reboredo, and M.S. Castro, Characterisation of epoxy/BaTiO 3 composites processed by dipping for integral

capacitor films (ICF). Journal of Materials Science, 42, 2007, 36853691.

X.X. Wang, K.H. Lam, X.G. Tang, H.L.W. Chan, Dielectric characteristics and polarization response of lead-free ferroelectric

(Bi0.5Na0.5)0.94Ba0.06TiO3-P(VDF-TrFE) 0-3 composites, Solid State Communications, 130, 2004, 695-699.

K.H. Lam, X. Wang, H.L.W. Chan, Piezoelectric and pyroelectric properties of Bi 0.5Na0.5)0.94Ba0.06TiO3/P (VDF-TrFE) 0-3

composites, Composites. Part A - Appl. Physics, 36, 2005, 1595-1599.

K. Prasad, A. Prasad, K.P. Chandra, A.R. Kulkarni, Electrical Conduction in 0-3 BaTiO3/PVDF Composites, Integrated

Ferroelectrics, 117, 2010, 55-67.

T. Takenaka., A. Huzumi, T. Hata, and K. Sakata, Mechanical properties of (Bi, Na)1/2TiO3-based piezoelectric ceramics. Silicates

Industrials 7(8), 1993. 136-142.

X.X. WANG, H.L.W. CHAN, C.L. CHOY, PIEZOELECTRIC AND DIELECTRIC PROPERTIES OF CEO2-ADDED

(BI0.5NA0.5)0.94BA0.06TIO3 LEAD-FREE CERAMICS, SOLID STATE COMMUN. 125, 2003, 395399.

S.J. WU, Q. XU, X.Z. ZHAO, T. LIU, Y.M. LI, PROCESSING AND PROPERTIES OF CEO2-DOPED FERROELECTRIC

(NA0.5BI0.5)0.94BA0.06TIO3 , MATER. LETT. 60, 2006, 14531458.

H. D. Li, C. D. Feng, and P. H. Xiang, Electrical properties of La 3+ doped Na0.5Bi0.5)0.94Ba0.06TiO3 ceramics. Jpn. J. Appl. Phys., 42,

2003, 73877391.

DOI: 10.9790/4861-07231726

www.iosrjournals.org

22 | Page

Impedance, Electrical Conductivity and Piezoelectric Studies on Nb5.

[23].

[24].

[25].

[26].

[27].

[28].

[29].

[30].

[31].

[32].

[33].

[34].

[35].

[36].

A. K. Roy, A. Singh, K. Kumari, K. Amaranth, A. Prasad, K. Prasad, Electrical properties and ac conductivity of

(Bi0.5Na0.5)0.94Ba0.06TiO3

ceramic,

ISRN

Ceramics,

vol.

2012,

2012,

Article

ID

854831,

10

pages.

http://dx.doi.org/10.5402/2012/854831.

Hongqiang Wang, Ruzhong Zuo, Yi Liu, Jian Fu, Densication behavior, microstructure, and electrical properties of solgelderived niobium-doped (Bi0.5Na0.5)0.94Ba0.06TiO3 ceramics J. Mater. Sci. 45, 2010, 3677-3682.

B.J. Chu, D.R. Chen, G.R. Li, Q.R. Yin, Electrical properties of Na1/2Bi1/2TiO3-BaTiO3 ceramics, J. Eur. Ceram. Soc. 22, 2002,

21152121.

A. Herabut, A. Safari, Processing and electromechanical properties of (Bi1/2Na1/2)(11.5x)LaxTiO3, J. Am. Ceram. Soc., 80, 1997,

29542958.

J. Yoo, J. Hong, H. Lee, Y. Jeong, B. Lee, H. Song, J. Kwon, Piezoelectric and dielectric properties of La 2O3 added Bi (Na,K)TiO3

SrTiO3 ceramics for pressure sensor application Sensors Actu. A 126, 2006, 4147.

K. PENGPAT, S. HANPHIMOL, S. EITSSAYEAM, U. INTATHA, G. RUJIJANAGUL, T. TUNKASIRI, MORPHOTROPIC PHASE BOUNDARY AND

ELECTRICAL PROPERTIES OF LEAD-FREE BISMUTH SODIUM LANTHANUM TITANATE BARIUM TITANATE CERAMICS

J

ELECTROCERAM. 16, 2006, 301305.

K. Sambasiva Rao, K. Varada Rajuluua, B. Tilak, A Swathi, Effect of Ba2+ in BNT ceramics on dielectric and conductivity

properties, Natural Science 2, 2010, 357-367.

M. J. Forbess, S. Seraji, Y. Wu, C. P. Nguyen, G. Z. Cao, Dielectric properties of layered perovskite Sr 1ABi2Nb2O9 ferroelectrics

(A = La, Ca and = 0, 0.1), Applied Physics Letters, 76, 2000, 29342936.

K. Funke, Jump relaxation in solid electrolytes, Progress in Solid State Chemistry, 22(2), 1993, 111195.

S. R. Elliot, AC conduction in amorphous chalcogenide and pnictide semiconductors, Advances in Physics, 36, 1987, 135217.

F. A.Krger and H. J. Vink, Relations between the concentrations of imperfections in crystalline solids, Solid State Phys, 3, 1956,

307-435.

S. Sumi, P. Prabhakar Rao, M. Deepa, and Koshy Peter, Electrical conductivity and impedance spectroscopy studies of cerium

based aeschynite type semiconducting oxides CeTiMO 6 (M = Nb or Ta), J. Appl. Phys. 108, 2010,063718.

Pelaiz-Barranco A, Gutierrez-Amador MP, Huanosta A and Valenzuela R Appl Phys Lett 73, 1998, Article ID 2039, 3 pages.

A. A. Youssef Ahmed, The permittivity and AC conductivity of the layered perovskite [(CH3)(C6H5)3P]3HgI4, Z. Naturforsch,

vol. 57, 2002, 263269.

Table 1. AC Conductivity based activation energy for 0.2wt% Nb2O5 doped (Bi0.5Na0.5)0.94Ba0.06TiO3

(BNBT6N0.2)-PVDF 0-3 composites having 10, 20 and 30 volume percentage of BNBT6N0.2 at different

indicated frequencies in the high temperature region 115oC -145oC

Volume fraction of ceramic

at 1kHz

10

20

30

DOI: 10.9790/4861-07231726

0.596

0.135

0.223

Activation Energy (eV)

at 10kHz

0.644

0.080

0.196

www.iosrjournals.org

23 | Page

Impedance, Electrical Conductivity and Piezoelectric Studies on Nb5.

Fig.1. EDAX patterns and SEM micrographs (insets) of 0.2 wt% Nb2O5 doped (Bi0.5Na0.5)0.94Ba0.06TiO3

(BNBT6N0.2)-PVDF 0-3 composites having (a) 10, (b) 20 and (c) 30 vol.% of BNBT6N0.2

Fig. 2. SEM micrographs of 0.2wt.% Nb2O5 doped (Bi0.5Na0.5)0.94Ba0.06TiO3 (BNBT6N0.2)-PVDF 0-3

composites having (a) 10, (b) 20 and (c) 30 vol.% of BNBT6N0.2

DOI: 10.9790/4861-07231726

www.iosrjournals.org

24 | Page

Impedance, Electrical Conductivity and Piezoelectric Studies on Nb5.

2.5

10

3.0

o

35 C

50 C

35 C

(a)

2.0

50 C

(b)

50 C

80 C

60 C

2.0

80 C

70 C

90 C

90 C

80 C

100 C

1.0

90 C

1.5

Z' (M )

100 C

Z'' (M )

100 C

1.0

0.5

0.5

0.0

10

10

0.0

10

10

10

10

10

10

10

10

10

10

Frequency (Hz)

Frequency (Hz)

10

Frequency (Hz)

3.0

o

35 C

35 C

40 C

8

(d)

50 C

60 C

50 C

o

60 C

2.0

70 C

40 C

(f)

50 C

35 C

10

40 C

(e)

2.5

60 C

70 C

70 C

80 C

80 C

Z' (M )

90 C

o

100 C

4

80 C

90 C

1.5

Z'' (M )

Z' (M )

40 C

(c)

70 C

70 C

Z'' (M )

2.5

60 C

60 C

1.5

35 C

100 C

1.0

90 C

o

100 C

4

2

2

0.5

0.0

10

10

0

3

10

10

10

10

10

Frequency (Hz)

10

10

10

10

Frequency (Hz)

10

Frequency(Hz)

12

3.0

Composite with Nb2O5 10 wt.%

Composite with Nb2O5 10 wt.%

10

Composite with Nb2O5 20 wt.%

(g)

2.5

(h)

Composite with Nb2O5 20 wt.%

Composite with Nb2O5 30 wt.%

Composite with Nb2O5 30 wt.%

8

Z" (M )

Z' (M )

2.0

1.5

1.0

0.5

0.0

0

3

10

10

10

10

10

10

Frequency (Hz)

10

10

Frequency (Hz)

Fig.3(a)-(f): Frequency dependence of real and imaginary parts (Z and Z) of complex impedance of

0.2wt.% Nb2O5 doped (Bi0.5Na0.5)0.94Ba0.06TiO3 (BNBT6N0.2)-PVDF 0-3 composites having (a) 10, (b) 20

and (c) 30 vol. percentage of NBT6N0.2 at different indicated temperatures. Fig.3 (g)-(h) shows the

frequency dependence of real and imaginary parts (Z and Z), respectively, for the three compositions at

the room temperature

1200

1200

o

35 C

35 C

55 C

1000

70 C

o

1500

85 C

100 C

800

100 C

115 C

Z'' (M )

Z'' (M )

70 C

85 C

100 C

o

130 C

600

55 C

70 C

85 C

800

35 C

145 C

115 C

600

400

400

200

200

1200

130 C

Z'' (M )

1000

1800

55 C

145 C

115 C

o

130 C

o

145 C

900

600

(b)

200

400

600

800

1000

Z' (M)

(c)

300

(a)

0

1200

200

400

600

800

1000

1200

Z' (M)

0

0

300

600

900

1200

1500

1800

Z' (M)

Fig. 4(a)-(c): Nyquist plots for of 0.2wt.% Nb2O5 doped (Bi0.5Na0.5)0.94Ba0.06TiO3 (BNBT6N0.2)-PVDF 0-3

composites having (a) 10, (b) 20 and (c) 30 vol. percentage of NBT6N0.2 at different indicated

temperatures

DOI: 10.9790/4861-07231726

www.iosrjournals.org

25 | Page

Impedance, Electrical Conductivity and Piezoelectric Studies on Nb5.

45

45

40

40

(a)

35

(b)

35

100 C

90 C

30

-3

M" (x10 )

-3

M" (x10 )

30

25

10 vol.% BNBT6N0.2

20

20 vol.% BNBT6N0.2

30 vol.% BNBT6N0.2

15

25

10 vol.% BNBT6N0.2

20 vol.% BNBT6N0.2

20

30 vol.% BNBT6N0.2

15

10

10

5

0

0

0

10

15

20

25

30

35

40

45

10

15

20

-3

25

30

35

40

45

-3

M' (x10 )

M' (x10 )

o

Fig. 5(a) & (b) : Complex modulus plots corresponding to 90oC and 100 C, respectively, for 0.2 wt%

Nb2O5 doped (Bi0.5Na0.5)0.94Ba0.06TiO3 (BNBT6N0.2)-PVDF 0-3 composites with 10, 20 and 30 vol.

percentages of BNBT6N0.2

-4

10

-5

-1

ac (S m )

10

35 C

o

40 C

o

50 C

o

60 C

-6

10

70 C

o

80 C

o

90 C

o

100 C

-7

10

10

10

10

10

Frequency(Hz)

Fig. 6. Frequency dependence of real part of AC conductivity for 0.2 wt. % Nb 2O5 doped (Bi0.5Na0.5)0.94Ba0.06TiO3

(BNBT6N0.2)-PVDF 0-3 composites with 30 vol. percentage of BNBT6N0.2 at different indicated temperatures

-4

-4

10

-5

(c)

-5

-5

10

10

ac (S m-1)

ac (S m-1)

ac (S m-1)

10

(b)

10

-6

-6

10

10

1kHz

10KHz

100KHz

1 MHz

10

2.7

2.8

2.9

3.0

3.1

3.2

3.3

-6

10

1kHz

10KHz

100KHz

1 MHz

1kHz

10KHz

-7

-7

10

-4

10

(a)

100KHz

1 MHz

-7

2.7

-1

1000/T (K )

2.8

2.9

3.0

3.1

3.2

3.3

10

2.7

2.8

2.9

3.0

3.1

3.2

3.3

-1

1000/T (K )

-1

1000/T (K )

Fig. 7 (a)-(c): Variation of log of the real part of ac conductivity with inverse absolute temperature for 0.2 wt. %

Nb2O5 doped (Bi0.5Na0.5)0.94Ba0.06TiO3 (BNBT6N0.2)-PVDF 0-3 composites with 10, 20, and 30 vol. percentage of

BNBT6N0.2 at different indicated frequencies (1kHz, 10kHz, 100kHz, and 1MHz)

Effective d33 of the composite (deff)

160

140

120

100

80

60

40

20

0

0.0

0.2

0.4

0.6

0.8

1.0

Volume fraction of the ceramic filler in the composite (x)

Fig. 8. Ceramic filler concentration dependent piezoelectric coefficient (d33) of (Bi0.5Na0.5)0.94Ba0.06TiO3 (BNBT6N0.2)PVDF 0-3 composites

DOI: 10.9790/4861-07231726

www.iosrjournals.org

26 | Page

Potrebbero piacerti anche

- Socio-Ethical Impact of Turkish Dramas On Educated Females of Gujranwala-PakistanDocumento7 pagineSocio-Ethical Impact of Turkish Dramas On Educated Females of Gujranwala-PakistanInternational Organization of Scientific Research (IOSR)Nessuna valutazione finora

- "I Am Not Gay Says A Gay Christian." A Qualitative Study On Beliefs and Prejudices of Christians Towards Homosexuality in ZimbabweDocumento5 pagine"I Am Not Gay Says A Gay Christian." A Qualitative Study On Beliefs and Prejudices of Christians Towards Homosexuality in ZimbabweInternational Organization of Scientific Research (IOSR)Nessuna valutazione finora

- Attitude and Perceptions of University Students in Zimbabwe Towards HomosexualityDocumento5 pagineAttitude and Perceptions of University Students in Zimbabwe Towards HomosexualityInternational Organization of Scientific Research (IOSR)Nessuna valutazione finora

- Comparative Visual Analysis of Symbolic and Illegible Indus Valley Script With Other LanguagesDocumento7 pagineComparative Visual Analysis of Symbolic and Illegible Indus Valley Script With Other LanguagesInternational Organization of Scientific Research (IOSR)Nessuna valutazione finora

- Relationship Between Social Support and Self-Esteem of Adolescent GirlsDocumento5 pagineRelationship Between Social Support and Self-Esteem of Adolescent GirlsInternational Organization of Scientific Research (IOSR)Nessuna valutazione finora

- The Role of Extrovert and Introvert Personality in Second Language AcquisitionDocumento6 pagineThe Role of Extrovert and Introvert Personality in Second Language AcquisitionInternational Organization of Scientific Research (IOSR)Nessuna valutazione finora

- A Review of Rural Local Government System in Zimbabwe From 1980 To 2014Documento15 pagineA Review of Rural Local Government System in Zimbabwe From 1980 To 2014International Organization of Scientific Research (IOSR)Nessuna valutazione finora

- Investigation of Unbelief and Faith in The Islam According To The Statement, Mr. Ahmed MoftizadehDocumento4 pagineInvestigation of Unbelief and Faith in The Islam According To The Statement, Mr. Ahmed MoftizadehInternational Organization of Scientific Research (IOSR)Nessuna valutazione finora

- A Proposed Framework On Working With Parents of Children With Special Needs in SingaporeDocumento7 pagineA Proposed Framework On Working With Parents of Children With Special Needs in SingaporeInternational Organization of Scientific Research (IOSR)Nessuna valutazione finora

- The Impact of Technologies On Society: A ReviewDocumento5 pagineThe Impact of Technologies On Society: A ReviewInternational Organization of Scientific Research (IOSR)100% (1)

- Assessment of The Implementation of Federal Character in Nigeria.Documento5 pagineAssessment of The Implementation of Federal Character in Nigeria.International Organization of Scientific Research (IOSR)Nessuna valutazione finora

- An Evaluation of Lowell's Poem "The Quaker Graveyard in Nantucket" As A Pastoral ElegyDocumento14 pagineAn Evaluation of Lowell's Poem "The Quaker Graveyard in Nantucket" As A Pastoral ElegyInternational Organization of Scientific Research (IOSR)Nessuna valutazione finora

- Role of Madarsa Education in Empowerment of Muslims in IndiaDocumento6 pagineRole of Madarsa Education in Empowerment of Muslims in IndiaInternational Organization of Scientific Research (IOSR)Nessuna valutazione finora

- Topic: Using Wiki To Improve Students' Academic Writing in English Collaboratively: A Case Study On Undergraduate Students in BangladeshDocumento7 pagineTopic: Using Wiki To Improve Students' Academic Writing in English Collaboratively: A Case Study On Undergraduate Students in BangladeshInternational Organization of Scientific Research (IOSR)Nessuna valutazione finora

- Edward Albee and His Mother Characters: An Analysis of Selected PlaysDocumento5 pagineEdward Albee and His Mother Characters: An Analysis of Selected PlaysInternational Organization of Scientific Research (IOSR)Nessuna valutazione finora

- Designing of Indo-Western Garments Influenced From Different Indian Classical Dance CostumesDocumento5 pagineDesigning of Indo-Western Garments Influenced From Different Indian Classical Dance CostumesIOSRjournalNessuna valutazione finora

- Importance of Mass Media in Communicating Health Messages: An AnalysisDocumento6 pagineImportance of Mass Media in Communicating Health Messages: An AnalysisInternational Organization of Scientific Research (IOSR)Nessuna valutazione finora

- The Lute Against Doping in SportDocumento5 pagineThe Lute Against Doping in SportInternational Organization of Scientific Research (IOSR)Nessuna valutazione finora

- An Exploration On The Relationship Among Learners' Autonomy, Language Learning Strategies and Big-Five Personality TraitsDocumento6 pagineAn Exploration On The Relationship Among Learners' Autonomy, Language Learning Strategies and Big-Five Personality TraitsInternational Organization of Scientific Research (IOSR)Nessuna valutazione finora

- Beowulf: A Folktale and History of Anglo-Saxon Life and CivilizationDocumento3 pagineBeowulf: A Folktale and History of Anglo-Saxon Life and CivilizationInternational Organization of Scientific Research (IOSR)Nessuna valutazione finora

- Classical Malay's Anthropomorphemic Metaphors in Essay of Hikajat AbdullahDocumento9 pagineClassical Malay's Anthropomorphemic Metaphors in Essay of Hikajat AbdullahInternational Organization of Scientific Research (IOSR)Nessuna valutazione finora

- Human Rights and Dalits: Different Strands in The DiscourseDocumento5 pagineHuman Rights and Dalits: Different Strands in The DiscourseInternational Organization of Scientific Research (IOSR)Nessuna valutazione finora

- Transforming People's Livelihoods Through Land Reform in A1 Resettlement Areas in Goromonzi District in ZimbabweDocumento9 pagineTransforming People's Livelihoods Through Land Reform in A1 Resettlement Areas in Goromonzi District in ZimbabweInternational Organization of Scientific Research (IOSR)Nessuna valutazione finora

- Motivational Factors Influencing Littering in Harare's Central Business District (CBD), ZimbabweDocumento8 pagineMotivational Factors Influencing Littering in Harare's Central Business District (CBD), ZimbabweInternational Organization of Scientific Research (IOSR)Nessuna valutazione finora

- Women Empowerment Through Open and Distance Learning in ZimbabweDocumento8 pagineWomen Empowerment Through Open and Distance Learning in ZimbabweInternational Organization of Scientific Research (IOSR)Nessuna valutazione finora

- Micro Finance and Women - A Case Study of Villages Around Alibaug, District-Raigad, Maharashtra, IndiaDocumento3 pagineMicro Finance and Women - A Case Study of Villages Around Alibaug, District-Raigad, Maharashtra, IndiaInternational Organization of Scientific Research (IOSR)Nessuna valutazione finora

- Substance Use and Abuse Among Offenders Under Probation Supervision in Limuru Probation Station, KenyaDocumento11 pagineSubstance Use and Abuse Among Offenders Under Probation Supervision in Limuru Probation Station, KenyaInternational Organization of Scientific Research (IOSR)Nessuna valutazione finora

- A Study On The Television Programmes Popularity Among Chennai Urban WomenDocumento7 pagineA Study On The Television Programmes Popularity Among Chennai Urban WomenInternational Organization of Scientific Research (IOSR)Nessuna valutazione finora

- Kinesics, Haptics and Proxemics: Aspects of Non - Verbal CommunicationDocumento6 pagineKinesics, Haptics and Proxemics: Aspects of Non - Verbal CommunicationInternational Organization of Scientific Research (IOSR)Nessuna valutazione finora

- Design Management, A Business Tools' Package of Corporate Organizations: Bangladesh ContextDocumento6 pagineDesign Management, A Business Tools' Package of Corporate Organizations: Bangladesh ContextInternational Organization of Scientific Research (IOSR)Nessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Diagnostic Trouble Code ChartDocumento5 pagineDiagnostic Trouble Code ChartGregory AshleyNessuna valutazione finora

- Fluid Flow Contuity (Tutorial Part 3)Documento13 pagineFluid Flow Contuity (Tutorial Part 3)asapamoreNessuna valutazione finora

- Manual Cessna 188 PG 01-108Documento108 pagineManual Cessna 188 PG 01-108Nilton César LimaNessuna valutazione finora

- Friction in OrthodonticsDocumento9 pagineFriction in Orthodonticsaa bbNessuna valutazione finora

- Cisco IOS XR Configuration Guide Master IndexDocumento66 pagineCisco IOS XR Configuration Guide Master IndexvictorpetriniNessuna valutazione finora

- Ducha EmpotradaDocumento1 paginaDucha Empotradagilmar melendresNessuna valutazione finora

- Adobe 2017 Download LinksDocumento4 pagineAdobe 2017 Download LinksDaśhīñg ÆžīNessuna valutazione finora

- Iec61000 4 7 (Ed2.0) en - DDocumento8 pagineIec61000 4 7 (Ed2.0) en - Dtwinvbooks100% (1)

- IES 2012 Exam Civil Engineering Paper II Solved With Answer KeyDocumento21 pagineIES 2012 Exam Civil Engineering Paper II Solved With Answer KeyPratik Nayak0% (2)

- 363-5 Machine Ride Control Actuator - Current Below NormalDocumento3 pagine363-5 Machine Ride Control Actuator - Current Below NormalArtin HykoNessuna valutazione finora

- Caterpillar Cat 320d 320dl Excavator Parts ManualDocumento34 pagineCaterpillar Cat 320d 320dl Excavator Parts ManualSara Sarmiento Echeverry100% (1)

- Verdi TCL TrainingDocumento24 pagineVerdi TCL TrainingPratyush ShrotriyaNessuna valutazione finora

- Plate Girder DesignDocumento109 paginePlate Girder Designhasib100% (3)

- Marking Fixture PresentationDocumento31 pagineMarking Fixture PresentationAvinash JejurkarNessuna valutazione finora

- Distance Measurement Methods & CalculationsDocumento16 pagineDistance Measurement Methods & CalculationsAlfonso John AnthonyNessuna valutazione finora

- PROTECTIVE RELAY TYPE CPR FOR RUBBER BAG CONSERVATORDocumento5 paginePROTECTIVE RELAY TYPE CPR FOR RUBBER BAG CONSERVATORAshraf NazifNessuna valutazione finora

- Vibratory Motion and Single Degree of Freedom SystemsDocumento29 pagineVibratory Motion and Single Degree of Freedom Systemsmm0493440Nessuna valutazione finora

- PackagesDocumento2 paginePackagesSteven MirandaNessuna valutazione finora

- Preliminary: SPCA702ADocumento60 paginePreliminary: SPCA702Avetchboy0% (1)

- Intelligent Traffic Manager - White PaperDocumento12 pagineIntelligent Traffic Manager - White Paperharishv_scribdNessuna valutazione finora

- OEM Industrial Air Handling Products CatalogDocumento31 pagineOEM Industrial Air Handling Products CatalogalexNessuna valutazione finora

- 2D Vs 3D ReviewDocumento7 pagine2D Vs 3D ReviewBhasker RamagiriNessuna valutazione finora

- DRC800 Remote Control UserGuideDocumento2 pagineDRC800 Remote Control UserGuideLuis MurilloNessuna valutazione finora

- MP3 - Equations of StateDocumento8 pagineMP3 - Equations of StatePatrick ValdezNessuna valutazione finora

- NACA Report 184 The Aerodynamic Forces On Airship HullsDocumento16 pagineNACA Report 184 The Aerodynamic Forces On Airship Hullsshatal16Nessuna valutazione finora

- Chainsaw SparesDocumento2 pagineChainsaw SpareswanttobeanmacccNessuna valutazione finora

- LATERAL EARTH PRESSURE CALCULATIONSDocumento55 pagineLATERAL EARTH PRESSURE CALCULATIONSRakesh SheteNessuna valutazione finora

- Eductor AgitationDocumento2 pagineEductor AgitationNicolás Solano CondeNessuna valutazione finora

- Solid Mechanics: Amit Sir (M-Tech (STRUCTURE), BE, Diploma in Civil), 7020059691/7385990691Documento9 pagineSolid Mechanics: Amit Sir (M-Tech (STRUCTURE), BE, Diploma in Civil), 7020059691/7385990691Nikita GonnadeNessuna valutazione finora

- ID-Operator Guide r2Documento138 pagineID-Operator Guide r2Mahdi DehghankarNessuna valutazione finora