Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Sample Mip

Caricato da

Chelliah SelvavishnuCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Sample Mip

Caricato da

Chelliah SelvavishnuCopyright:

Formati disponibili

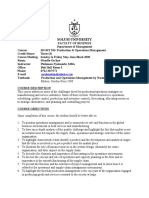

MODULE IMPLEMENTATION PLAN

Doc No:

Rev. No:

Effective Date:

DETAILS OF THE MODULE

Module

Quality Management and Assurance

Code

Pre-requisite Module None

Code

Programme

Diploma in Automotive Engineering Technology

Year/Semester

Year 2 / Semester 3

Session

Credit Value

3.0

Objective

Synopsis:

Page: 1of 1

MPU2343

TOPICS

This course develop learners knowledge and understanding of the principles and

applications of quality management.

In this course learners will investigate total quality management (TQM) and develop an

understanding of the key factors that underpin quality assurance (QA) techniques. The

unit also introduces learners to the application of quality control (QC) techniques.

The basic principles of total quality management will include management structures

and TQM techniques. Learners will also develop an understanding of the key factors,

internal and external controls and cost implications that underpin quality assurance

techniques.

Finally, the unit introduces the application of quality control techniques, process

capability and software packages to support the processes together with ISO 9001: 2008

to ensure that the standard will be maintain at all time.

Learning

Outcomes:

Upon successful completion of the module, student will be able to:

1.

Understand how total quality management (TQM) systems operate

2.

Know the key factors of quality assurance (QA) techniques

3.

Apply quality control (QC) techniques.

4.

Implement ISO 9001:2008 quallity management system (QMS)

MODULE IMPLEMENTATION PLAN

Doc No:

Weeks

1-2

3-4

5-7

8-11

12-14

Rev. No:

Details

Effective Date:

TOTAL STUDENT LEARNING TIME (SLT)

Total Guided

Face to Face

& Independent

Learning

Lectu

re

Tutorial

QUALITY CONTROL (QC)

TECHNIQUES

3.1 Quality control techniques

3.2 Process capability

3.3 Software packages

QUALITY CONTROL (QC)

TECHNIQUES

4.1 Quality control

techniques

4.2 Process capability

4.3 Software packages

ISO 9001: 2008 QUALITY

MANAGEMENT SYSTEMS

5.1 Model of a quality

management system

5.2 Documentation requirements

3.3 Performance and

customer satisfaction

1. TOTAL QUALITY

MANAGEMENT (TQM)

1.1 Principles of TQM

1.2 Management structures

1.3 TQM techniques

2. QUALITY ASSURANCE

(QA) TECHNIQUES

2.1 Key factors

2.2 Control Purposes

2.3 Costing

Subject Mapping:

Page: 1of 1

Practical

Others

MODULE IMPLEMENTATION PLAN

Doc No:

Rev. No:

Effective Date:

Page: 1of 1

Generic Skills Addressed:

LO1

1,4,5

LO2

1,2,4,5

LO3

1,2,3,4,5,6

LO4

1,4

LO5

1,2,3,4,5,6

LO6

1,4,5

LEARNING OUTCOME DOMAINS

1. Apply Knowledge of mathematics, science, engineering fundamentals & engineering

specialisation to well-defined practical & practices.

2. Troubleshoot automotive technical problems.

3. Apply appropriate techniques, resources and tools to well-defined automotive

engineering technology activities, with an awareness of their limitations.

4. Inculcate awareness of & consideration for societal health, safety, legal and cultural

issues and their consequent responsibilities.

5. Demonstrate communication and team skills; and responsibilities, ethics and norms of

automotive engineering technology practices.

6. Exhibit an awareness of management, business practices and entrepreneurship.

REFERENCES:

MAIN REFERENCES BOOKS

Amitava Mitra (2012). Fundamentals of Quality Control and Improvement(3rd

Edition). USA: John Wiley & Sons, Inc. (ISBN: 9780470226537)

Divya Singhal, L.R. Singhal. (2012). Implement ISO 9001: 2008 Quality

Management System: A Reference Guide. India: PhI Learning Private Limited.

(ISBN: 9788120345744)

Jabatan Standard Malaysia. (2010). Quality Management Systems - Particular

Requirements for the Application of ISO 9001:2008 for Automotive Production and

Relevant Service Part Organizations (first Revision) (ISO/TS 16949:2009, IDT).

MY: Jabatan Standard Malaysia.

ADDITIONAL REFERENCE BOOKS

Dimitris N. Chorafas. (2013). Quality Control Applications. UK: Springer-Verlag

London.

R. Ashley Rawlins (2008). Total Quality Management. UK: AuthorHouse.

OTHER ADDITIONAL INFORMATION

Related Magazines, Internet Sites, Newspapers, Video, Movie, CD-Rom, Other

Related web-sites

MODULE IMPLEMENTATION PLAN

Doc No:

Rev. No:

Effective Date:

No

Assessments

1

Written Assignments

Page: 1of 1

Marks

30

Test 1

15

Quiz 1

7.5

Quiz 2

5

6

7

Class Participation

Final Exam

Continuous Assessment

Percentage (%)

7.5

70%

10

Final Exam

100

30%

TOTAL

100%

GRADE AND GRADE POINT:

Marks

80-100

70-79

67-69

64-66

60-63

57-59

54-56

50-53

44-49

40-43

0-39

Grade

A-

B+

B-

C+

C-

D+

Grade

point

4.00

3.70

3.33

3.00

2.67

2.33

2.00

1.67

1.33

1.00

0.00

ACADEMIC REQUISITE AND REQUIRMENTS (Please fill if any)

1. Students who fail to comply with the 80% attendance requirement will be barred from

taking the final exams and will be given E grade for module concerned.

2. Students MUST pass BOTH COMPONENTS (coursework and final exam) in order to

pass the module.

Reminders / Notes

MODULE IMPLEMENTATION PLAN

Doc No:

Rev. No:

Effective Date:

Page: 1of 1

1. Lecture attendance must be at least 80% of the whole contact hour per semester in order to

qualify for Final Examination.

2. Tutorial session is an active learning session where students will be called to solve and

explain answers for tutorial problems to the class.

3. Group assignment:

The report should be in the following format:

I.

Title

II.

Objectives

III.

Introduction

IV. The assignment required by the question

V. Conclusion

VI.

References (if any)

4. All assignment should be submitted in accordance to the deadline given by the lecturer.

Marks will be deducted for the late submission of assignments and tutorial.

5. Students are expected not to copy other students tutorial answers or assignments.

Miscellaneous.

1. Students must wear proper attire to class

2. Students must not wear baseball caps or hat during class

3. Explicit and improper mannerism are prohibited (e.g too revealing)

4. Hand phones must be silent at all time during lecture and tutorial. If the students need to

answer calls, they should do it outside the class.

Prepared by

Checked by

Approved by

Name

Selvavishnu

Daneshwaran

Dato Edmond Chai

Post

Lecturer

Head of Lecturer

Chief Executive

Date

18/3/2015

20/3/2015

21/3/2015

Signature

Potrebbero piacerti anche

- ConsequentialismDocumento6 pagineConsequentialismAnto PuthusseryNessuna valutazione finora

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideDa EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideValutazione: 2 su 5 stelle2/5 (1)

- CAPM Success Path : MCQs and Explanations for Prep ExcellenceDa EverandCAPM Success Path : MCQs and Explanations for Prep ExcellenceNessuna valutazione finora

- Industrial Safety CurriculumDocumento67 pagineIndustrial Safety Curriculumrashid_siddiqi144100% (1)

- HND Mechatronics (NBTE)Documento281 pagineHND Mechatronics (NBTE)Favour Uche ChukwuNessuna valutazione finora

- CS127-Problem Solving and Programming 2-Syllabus 2012-ITDocumento5 pagineCS127-Problem Solving and Programming 2-Syllabus 2012-ITJohnNessuna valutazione finora

- Benefits of Practicing Good Corporate GovernanceDocumento6 pagineBenefits of Practicing Good Corporate GovernanceChelliah Selvavishnu100% (1)

- TRANSFORMATIONS Form 2Documento34 pagineTRANSFORMATIONS Form 2Rosmah Abdullah87% (15)

- Course Syllabus: Instructor InformationDocumento8 pagineCourse Syllabus: Instructor InformationGlicerio RufinoNessuna valutazione finora

- Course Outline Jf6081Documento4 pagineCourse Outline Jf6081Firdaus ZakariaNessuna valutazione finora

- MTAME HT-19 enDocumento5 pagineMTAME HT-19 enDaniyal HasanNessuna valutazione finora

- MSC (Eng) Telecommunications Engineering: School of Innovative Technologies & EngineeringDocumento10 pagineMSC (Eng) Telecommunications Engineering: School of Innovative Technologies & EngineeringXavierNessuna valutazione finora

- Maharashtra TechnicalDocumento94 pagineMaharashtra Technicalamol0037Nessuna valutazione finora

- NBA Criteria 2Documento20 pagineNBA Criteria 2SRAVANNessuna valutazione finora

- Course Outline-4Documento3 pagineCourse Outline-4Saleem ShaikhNessuna valutazione finora

- Advanced Telecom Course PlanDocumento5 pagineAdvanced Telecom Course PlanPrabhat NagpalNessuna valutazione finora

- Computing Higher 2 SyllabusDocumento12 pagineComputing Higher 2 SyllabusBilly AndikaNessuna valutazione finora

- Elet4612k IndustrialautomationandprocesscontrolDocumento6 pagineElet4612k IndustrialautomationandprocesscontrolpasinduNessuna valutazione finora

- Faculty of Engineering School of Mechanical andDocumento10 pagineFaculty of Engineering School of Mechanical andchaitankumaryadav007Nessuna valutazione finora

- MECM Study Guide 2020 (1)Documento11 pagineMECM Study Guide 2020 (1)Njabulo NgobeseNessuna valutazione finora

- Jaipuria Institute of Management PGDM Trimester Ii Academic Year 2019-20Documento9 pagineJaipuria Institute of Management PGDM Trimester Ii Academic Year 2019-20Sanjana SinghNessuna valutazione finora

- University of Petroleum & Energy Studies School of Business DehradunDocumento8 pagineUniversity of Petroleum & Energy Studies School of Business DehradunHarshil JainNessuna valutazione finora

- EML4312 - EMC5425Syllabus Fall 2020Documento4 pagineEML4312 - EMC5425Syllabus Fall 2020jorgeNessuna valutazione finora

- MEC 322 OutlineDocumento3 pagineMEC 322 OutlineBob jonesNessuna valutazione finora

- MSc Computer Science Course SpecDocumento8 pagineMSc Computer Science Course SpecViral IndiaNessuna valutazione finora

- RPP BPC 32603 Sem 2 2013-2014Documento9 pagineRPP BPC 32603 Sem 2 2013-2014Raveverma PeriyasamyNessuna valutazione finora

- Ec902 50 2022Documento4 pagineEc902 50 2022Mimansha MaheshwariNessuna valutazione finora

- BROCHURE Programme Specification EDEBMDocumento2 pagineBROCHURE Programme Specification EDEBMWatashi AmranNessuna valutazione finora

- ECE 7440 Modern Control of Power Electronics Summer 2022 HoDocumento3 pagineECE 7440 Modern Control of Power Electronics Summer 2022 HoRafael SilvaNessuna valutazione finora

- DCSN200 Operations Management Spring 2012Documento8 pagineDCSN200 Operations Management Spring 2012Maya Hariri HallabNessuna valutazione finora

- SM 313 Strategic ManagementDocumento11 pagineSM 313 Strategic Managementריאל אמנם נכוןNessuna valutazione finora

- Important Notice: Design and Technology 6043 GCE O Level 2007Documento16 pagineImportant Notice: Design and Technology 6043 GCE O Level 2007mstudy123456Nessuna valutazione finora

- Proposed Course Outline BMDocumento5 pagineProposed Course Outline BMFurqan MughalNessuna valutazione finora

- 2012.09.03 CO - PO SKMM 3242 (Instrumentation)Documento2 pagine2012.09.03 CO - PO SKMM 3242 (Instrumentation)Izzudin RozmanNessuna valutazione finora

- EBQCI4A 2023-1 CASS Learner Guide DraftDocumento25 pagineEBQCI4A 2023-1 CASS Learner Guide DrafttherealmutshidziNessuna valutazione finora

- Eastern Mediterranean University Department of Industrial Engineering IENG484/MANE484 Quality Engineering Spring 2019-2020 Course OutlineDocumento3 pagineEastern Mediterranean University Department of Industrial Engineering IENG484/MANE484 Quality Engineering Spring 2019-2020 Course OutlineIlkin JafarovNessuna valutazione finora

- Simulation Modeling Course OverviewDocumento6 pagineSimulation Modeling Course OverviewFarhad EbrahimianNessuna valutazione finora

- Attachment 1614632736Documento5 pagineAttachment 1614632736Usama AliNessuna valutazione finora

- DCME - 6th Sem SyllabusDocumento6 pagineDCME - 6th Sem Syllabusshashi preethamNessuna valutazione finora

- Assignment Handout: RICS School of Built Environment, Amity UniversityDocumento8 pagineAssignment Handout: RICS School of Built Environment, Amity UniversityParas ChauhanNessuna valutazione finora

- Rpp04 Idp Bfc43303 - Laterst02-01Documento6 pagineRpp04 Idp Bfc43303 - Laterst02-01Syamim BakriNessuna valutazione finora

- Military Technological College: MTC Academic Integrity and Misconduct PolicyDocumento7 pagineMilitary Technological College: MTC Academic Integrity and Misconduct PolicyMorsaleen ChowdhuryNessuna valutazione finora

- CDP - Design IIDocumento4 pagineCDP - Design IICholan PillaiNessuna valutazione finora

- Emerging Technologies and Business Innovation-II PDFDocumento4 pagineEmerging Technologies and Business Innovation-II PDFTanuj LalchandaniNessuna valutazione finora

- Quality Management and Six Sigma ModuleDocumento5 pagineQuality Management and Six Sigma ModulesigmasundarNessuna valutazione finora

- Tndte M Scheme Ece BookDocumento194 pagineTndte M Scheme Ece Booksmagendiran100% (2)

- Stqa Co 23-24Documento10 pagineStqa Co 23-24Ruchira suryawanshiNessuna valutazione finora

- MMAN4410 Finite Element MethodsDocumento12 pagineMMAN4410 Finite Element Methodsminhnguyenvonhat0% (1)

- Guía Del Estudiante Termodinámica y Transferencia de CalorDocumento7 pagineGuía Del Estudiante Termodinámica y Transferencia de CalorAlvaro DomenechNessuna valutazione finora

- Course Outline mtnr3200Documento12 pagineCourse Outline mtnr3200JBBARNessuna valutazione finora

- MGMT 296 Production Operations Management Syllabus-Regular 1st Semester 2020Documento5 pagineMGMT 296 Production Operations Management Syllabus-Regular 1st Semester 2020Nele GravesNessuna valutazione finora

- Tpm204 Workshop Practice and Engineering Drawing Updated DR Adejumo Taiye - 0Documento229 pagineTpm204 Workshop Practice and Engineering Drawing Updated DR Adejumo Taiye - 0Sagir Musa SaniNessuna valutazione finora

- Syllabus Course Description: Jens - Kiefer@hs-Ulm - deDocumento3 pagineSyllabus Course Description: Jens - Kiefer@hs-Ulm - deosama1928Nessuna valutazione finora

- ITDocumento129 pagineITkumudhaNessuna valutazione finora

- Course Outline MaintenanceDocumento12 pagineCourse Outline MaintenancekevinNessuna valutazione finora

- 2.2. Teaching - Learning Processes (100) 2.2.1. Describe Processes Followed To Improve Quality of Teaching & LearningDocumento8 pagine2.2. Teaching - Learning Processes (100) 2.2.1. Describe Processes Followed To Improve Quality of Teaching & LearningMalleswara RaoNessuna valutazione finora

- Kerala Tech University academic auditing manualDocumento16 pagineKerala Tech University academic auditing manualsajinirajithNessuna valutazione finora

- MecE 360 Mechanical Design II Course SyllabusDocumento3 pagineMecE 360 Mechanical Design II Course SyllabusJames MoodyNessuna valutazione finora

- 55-500314 Applied Thermodynamics and Fluid MechanicsDocumento3 pagine55-500314 Applied Thermodynamics and Fluid Mechanicszinou68Nessuna valutazione finora

- CNA Chemical Process Engineering Technology (Co-Op)Documento1 paginaCNA Chemical Process Engineering Technology (Co-Op)Audrey Patrick KallaNessuna valutazione finora

- Employee Outlook Survey (CIPD, 2017)Documento36 pagineEmployee Outlook Survey (CIPD, 2017)Chelliah SelvavishnuNessuna valutazione finora

- Employee Outlook Survey (CIPD, 2017)Documento36 pagineEmployee Outlook Survey (CIPD, 2017)Chelliah SelvavishnuNessuna valutazione finora

- Contract Law (Part 2) - 1Documento45 pagineContract Law (Part 2) - 1Chelliah SelvavishnuNessuna valutazione finora

- Consumerization of HRDocumento7 pagineConsumerization of HRChelliah SelvavishnuNessuna valutazione finora

- Assignment Individual (Answer)Documento6 pagineAssignment Individual (Answer)Chelliah SelvavishnuNessuna valutazione finora

- Exam DiscussionDocumento4 pagineExam DiscussionChelliah SelvavishnuNessuna valutazione finora

- Feedback For StudentDocumento2 pagineFeedback For StudentChelliah SelvavishnuNessuna valutazione finora

- Negligence Duty (Economic Loss)Documento8 pagineNegligence Duty (Economic Loss)Chelliah SelvavishnuNessuna valutazione finora

- CHAPTER 3considerationDocumento12 pagineCHAPTER 3considerationChelliah SelvavishnuNessuna valutazione finora

- 160416CGSSFAQs EnglishLRDocumento47 pagine160416CGSSFAQs EnglishLRChelliah SelvavishnuNessuna valutazione finora

- NegligenceDocumento43 pagineNegligenceChelliah SelvavishnuNessuna valutazione finora

- Hedley Byrne v. Heller: NegligenceDocumento2 pagineHedley Byrne v. Heller: NegligenceChelliah SelvavishnuNessuna valutazione finora

- Trade UnionDocumento19 pagineTrade UnionChelliah SelvavishnuNessuna valutazione finora

- Lussier4ePPT ch02Documento44 pagineLussier4ePPT ch02Chelliah SelvavishnuNessuna valutazione finora

- HND Spread Sheet June 10Documento9 pagineHND Spread Sheet June 10Chelliah SelvavishnuNessuna valutazione finora

- Conduct and Compliance ProcedureDocumento15 pagineConduct and Compliance ProcedureChelliah SelvavishnuNessuna valutazione finora

- Lussier4ePPT ch01Documento44 pagineLussier4ePPT ch01Chelliah SelvavishnuNessuna valutazione finora

- Torts - Vicarious LiabilityDocumento3 pagineTorts - Vicarious LiabilityChelliah SelvavishnuNessuna valutazione finora

- PT3 Kelantan Sains SkemaDocumento17 paginePT3 Kelantan Sains Skema纪泽勇100% (1)

- (LAW3202 0815) Pre Assessment Moderation Form (Selva Vishnu Chelliah)Documento5 pagine(LAW3202 0815) Pre Assessment Moderation Form (Selva Vishnu Chelliah)Chelliah SelvavishnuNessuna valutazione finora

- (LAW3202 0815) Pre Assessment Moderation Form (Selva Vishnu Chelliah)Documento5 pagine(LAW3202 0815) Pre Assessment Moderation Form (Selva Vishnu Chelliah)Chelliah SelvavishnuNessuna valutazione finora

- Johnson Wrote To KellyDocumento3 pagineJohnson Wrote To KellyChelliah SelvavishnuNessuna valutazione finora

- Who Is An Employee (A!)Documento5 pagineWho Is An Employee (A!)Chelliah SelvavishnuNessuna valutazione finora

- Who Is An Employee (A!)Documento5 pagineWho Is An Employee (A!)Chelliah SelvavishnuNessuna valutazione finora

- Weekly BL PlanningTool - SampleDocumento1 paginaWeekly BL PlanningTool - SampleChelliah SelvavishnuNessuna valutazione finora

- Sample MipDocumento5 pagineSample MipChelliah SelvavishnuNessuna valutazione finora