Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Steam Flow Compensation

Caricato da

crazyprajCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Steam Flow Compensation

Caricato da

crazyprajCopyright:

Formati disponibili

526 Function Blocks

53

stfl - STEAM FLOW COMPENSATION

FUNCTION BLOCK

53.1

USE

Mass flow of steam is measured indirectly by measuring the differential pressure acting

across an orifice plate. The measurement requires compensation because it is affected

by the temperature and pressure existing at the measurement time, and the result is not

linear relative to the differential pressure.

In case of a measuring transmitter with square root extraction, it is necessary to define

the squared scale of the measured value for the measurement channel (compare with

cwsqrt's square root feature).

53.2

FUNCTIONAL DESCRIPTION

53.2.1

Operation

Compensation occurs in accordance with the following formula:

f + fscale *

f

fscale

dp

dpscale

r

rq

dp

* r , where

dpscale rq

= compensated measured flow

= scaling factor for f

= differential pressure across orifice plate

= differential pressure scaling

= steam density at operating point

= steam density at design point

The rq constant is determined by stfl on the basis of the design point pressure and tem

perature by accessing the corresponding density value from steam table.

Compensated flow at the design point has the value fscale when the value of differential

pressure is dpscale.

Density r at each operating point is derived from steam table when the existing tempera

ture and pressure are known.

Rev. 1

stfl 527

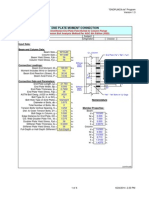

53.2.2

Symbolic representation

Rev. 1

528 Function Blocks

53.2.3

Example configuration

Rev. 1

stfl 529

ADMINISTRATION_PART

NAME:

TYPE:

STATUS:

CREATOR:

CREATED:

MODIFIER:

MODIFIED:

DESTINATION:

EXECUTION:

ORDINAL:

DESCRIPTION:

pr:40F419.F

function

incomplete

dna

20011212 15:23:00

dna

20011212 15:30:14

AP01

1000

20

stfl

REPRESENTATION_PART

EXTERNALS

pr:40F406:av

SURE ;

pr:40T405:av

RETURE ;

pr:40F419.I:m

TYPE ana TRANSFER 192,10,0,0 PK4 STEAM PRESTYPE ana TRANSFER 192,10,0,0 PK4 STEAM TEMPETYPE ana TRANSFER 192,10,0,0 ;

DIRECT_ACCESS

BLOCK pr:40F419 ;

INTERFACE

MODSTAT TYPE ktstat < ( 1,1,0 ) ;

FUNCTIONAL_PART

1stfl

p0= ( 392.0 )

t0= ( 170.0 )

dpscale= ( 15.0 )

fscale= ( 8.30 )

dp< pr:40F419.I:m

p< pr:40F406:av

t< pr:40T405:av

f>

wd>

;

2am IS pr:40F419

hyst= ( 1 )

un=

av< 1stfl:f

hh< ( 400.0 )

h< ( 400.0 )

l< ( 0.0 )

ll< ( 0.0 )

out>

hha>

ha>

la>

lla>

fa>

;

END

Rev. 1

530 Function Blocks

53.3

DATA STRUCTURE

53.3.1

Configuration parameters

p0

Type:

Default:

Description:

float

1.0

Absolute pressure at design point [kPa]

Type:

Default:

Description:

float

1.0

Temperature at design point [C]

t0

dpscale

Type:

Default:

Description:

float

1.0

Differential pressure scale at design point, i.e., 0 <= dp <=

dpscale

Type:

Default:

Description:

float

1.0

Output scale at design point, i.e., 0 <= f <= fscale

fscale

53.3.2

Connection parameters

Inputs

dp

Type:

Default:

Description:

ana

16 0.0

Differential pressure across orifice plate

Unit is not significant, since the value of dp is scaled by means of dpscale.

p

Type:

Default:

Description:

ana

16 0.0

Steam pressure, [kPa], excess pressure

Type:

Default:

Description:

ana

16 0.0

Steam temperature [C]

Rev. 1

stfl 531

Outputs

f

Type:

Default:

Description:

ana

48 0.0

Compensated steam flow

Unit is not significant, since f is scaled with fscale. Fault bit der is set when one

of the inputs is faulty. Fault bits inv and old are set when one of the outputs is

outside permissible limits.

wd

Type:

Default:

Description:

bin

48

Watchdog (operating point outside table)

When wd = ON, the values of stfl cannot be considered reliable.

If wd = ON and f gives the value 0.0, the design point was outside the stfl oper

ating range.

Rev. 1

Potrebbero piacerti anche

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Da EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Nessuna valutazione finora

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Da EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Valutazione: 2.5 su 5 stelle2.5/5 (3)

- Turbojet Engine DesignDocumento27 pagineTurbojet Engine DesignYasser BahaaNessuna valutazione finora

- Conversion TableDocumento6 pagineConversion TableDoctorObermanNessuna valutazione finora

- Planning Plant ProductionDocumento10 paginePlanning Plant ProductionjokoNessuna valutazione finora

- Pipe StackingDocumento2 paginePipe StackingUghojor ElohoNessuna valutazione finora

- Suckerrodpumpingflowrate&Power - XLS: TF To TiDocumento4 pagineSuckerrodpumpingflowrate&Power - XLS: TF To TiyoleidacrNessuna valutazione finora

- Compressor Sizing and CalculationDocumento6 pagineCompressor Sizing and CalculationOghale B. E. Omuabor100% (6)

- AM RET670 SettingExample2 RBDocumento21 pagineAM RET670 SettingExample2 RBKUNALJAY100% (1)

- Bit HydraulicsDocumento11 pagineBit HydraulicstibismtxNessuna valutazione finora

- 13 - Compressor and ExpandersDocumento40 pagine13 - Compressor and ExpandersEstuardo Javier Gan RodríguezNessuna valutazione finora

- Esp SizingDocumento17 pagineEsp SizingAmin ElfatihNessuna valutazione finora

- Calculo CortoCircuito IEC 865Documento32 pagineCalculo CortoCircuito IEC 865Víctor RojasNessuna valutazione finora

- 123Documento29 pagine123Pravin Narkhede100% (1)

- There Are No Particles, Just FieldsDocumento14 pagineThere Are No Particles, Just Fieldsriletm86Nessuna valutazione finora

- Sag-Tension Calculation IEEE STD 605 2008Documento10 pagineSag-Tension Calculation IEEE STD 605 2008vishnuvyasNessuna valutazione finora

- Tech Drilling SurgeSwabPressDocumento40 pagineTech Drilling SurgeSwabPressdaongocha108Nessuna valutazione finora

- Orifice Flow CalculationDocumento41 pagineOrifice Flow Calculationkumarram7650% (2)

- Machine Training PM Synchronous Ansoft MaxwellDocumento111 pagineMachine Training PM Synchronous Ansoft Maxwellmashinbaz1100% (3)

- End Plate Moment ConnectionDocumento4 pagineEnd Plate Moment Connectionmahhor82_635643838Nessuna valutazione finora

- Distillation DesignDocumento30 pagineDistillation Designfdc20062340100% (2)

- NM Dan NE (Yang Bener)Documento61 pagineNM Dan NE (Yang Bener)Andri RulandiNessuna valutazione finora

- Fixed Bed Reactor, Modelling&Optimal DesignDocumento74 pagineFixed Bed Reactor, Modelling&Optimal DesignRana Uzair100% (1)

- An 4134Documento14 pagineAn 4134shri.bhairavkar6977Nessuna valutazione finora

- Pfc3d40manual ModsDocumento20 paginePfc3d40manual Modsfujit999Nessuna valutazione finora

- Solution Tut#5Documento4 pagineSolution Tut#5xehranNessuna valutazione finora

- Determination of Certified Relieving Capacities: 1.0 GeneralDocumento0 pagineDetermination of Certified Relieving Capacities: 1.0 GeneralSIVANessuna valutazione finora

- Transient Chamber Pressure and Thrust in Solid Rocket MotorsDocumento37 pagineTransient Chamber Pressure and Thrust in Solid Rocket MotorsmegustalazorraNessuna valutazione finora

- Brief Spice SummaryDocumento5 pagineBrief Spice SummarygeorgesmaccarioNessuna valutazione finora

- Funcionamiento Del 5Q1265RF en La FuenteDocumento19 pagineFuncionamiento Del 5Q1265RF en La FuenteJorge Corrales100% (1)

- ADS PA WorkshopDocumento51 pagineADS PA Workshopadam_tomasNessuna valutazione finora

- Nota PemampatDocumento49 pagineNota PemampatweafareezNessuna valutazione finora

- Cullender SmithDocumento2 pagineCullender Smithmath62210Nessuna valutazione finora

- Irplpfc 1Documento29 pagineIrplpfc 1M. T.Nessuna valutazione finora

- Annex A To Appendix 9: Atpc Example CalculationsDocumento9 pagineAnnex A To Appendix 9: Atpc Example Calculationsعبد الغفور الشرقاويNessuna valutazione finora

- ZTE UMTS Power Control NewDocumento70 pagineZTE UMTS Power Control NewKhawar Waheed100% (3)

- Motivation For Impedance Control of A Pneumatic Actuator: ProblemDocumento12 pagineMotivation For Impedance Control of A Pneumatic Actuator: ProblemEASACOLLEGENessuna valutazione finora

- Average TZDocumento4 pagineAverage TZlutfi awnNessuna valutazione finora

- 02 AverageTZDocumento4 pagine02 AverageTZcris1515Nessuna valutazione finora

- Average TZDocumento4 pagineAverage TZmath62210Nessuna valutazione finora

- Duct Designing: Laminar and Turbulent Flow in TubesDocumento18 pagineDuct Designing: Laminar and Turbulent Flow in TubesMuhammad Hassan MaqsoodNessuna valutazione finora

- Determination of Certified Relieving CapacitiesDocumento6 pagineDetermination of Certified Relieving CapacitiesGustavo GarciaNessuna valutazione finora

- Pet 531 Module 2Documento18 paginePet 531 Module 2Igbereyivwe TejiriNessuna valutazione finora

- 17polytropic EffDocumento4 pagine17polytropic EffRamesh BadamNessuna valutazione finora

- 17polytropic EffDocumento4 pagine17polytropic Effjack smithNessuna valutazione finora

- Piohr, We Compute The Derivative Piobr Piobe. Thus Pinbe Piobc PP-'iodqDocumento34 paginePiohr, We Compute The Derivative Piobr Piobe. Thus Pinbe Piobc PP-'iodqpragatinareshNessuna valutazione finora

- Design of Bias Tees For A Pulsed-Bias Pulsed RF Test SystemDocumento8 pagineDesign of Bias Tees For A Pulsed-Bias Pulsed RF Test SystemElanchezhian VeeramaniNessuna valutazione finora

- Presentation ORCDocumento21 paginePresentation ORCstanlnleybudukaNessuna valutazione finora

- Product Application Guide: Inlet Pressure CorrectionDocumento2 pagineProduct Application Guide: Inlet Pressure CorrectionTino JuNessuna valutazione finora

- System Optimization of Motor ResolverDocumento27 pagineSystem Optimization of Motor ResolverBlaize PascalNessuna valutazione finora

- Example 4-3 Analyzing Two-Rate Drawdown Test When Initial Pressure IsDocumento10 pagineExample 4-3 Analyzing Two-Rate Drawdown Test When Initial Pressure Isسحر سلامتیانNessuna valutazione finora

- Bottom Hole NodalDocumento7 pagineBottom Hole NodalKharisma AkbarNessuna valutazione finora

- Overall Shape and Dimensions: GeneralDocumento40 pagineOverall Shape and Dimensions: GeneralvrgohilNessuna valutazione finora

- Boost Follower PFCDocumento3 pagineBoost Follower PFCฉัตรชัย เพ็ชรจั่นNessuna valutazione finora

- FA531X Series: FA5310BP (S), FA5314P (S), FA5316P (S) FA5311BP (S), FA5315P (S), FA5317P (S)Documento17 pagineFA531X Series: FA5310BP (S), FA5314P (S), FA5316P (S) FA5311BP (S), FA5315P (S), FA5317P (S)Denis PrivatNessuna valutazione finora

- Ch3 FilterDocumento79 pagineCh3 FiltersadyehclenNessuna valutazione finora

- Session14 Paper4Documento8 pagineSession14 Paper4Edgar Chavez MoranNessuna valutazione finora

- Aisc Lrfd-99 Example 002Documento7 pagineAisc Lrfd-99 Example 002Bùi Văn HợpNessuna valutazione finora

- C = C' = = = = = = = d = D = DL = = = ρ = e = E = = F = = = = = = Key = L = LTB = MF = N = = P = = = = = = Q = = = = S = C C C C C CDocumento44 pagineC = C' = = = = = = = d = D = DL = = = ρ = e = E = = F = = = = = = Key = L = LTB = MF = N = = P = = = = = = Q = = = = S = C C C C C Crkm_rkmNessuna valutazione finora

- Derivation of The Diffusivity EquationDocumento18 pagineDerivation of The Diffusivity EquationImranul Haque NoorNessuna valutazione finora

- Fundamentals of Electronics 3: Discrete-time Signals and Systems, and Quantized Level SystemsDa EverandFundamentals of Electronics 3: Discrete-time Signals and Systems, and Quantized Level SystemsNessuna valutazione finora

- Determination of Ascorbic Acid (Vitamin C) and Its Compounds Bi-Voltammetric Determination With IodineDocumento9 pagineDetermination of Ascorbic Acid (Vitamin C) and Its Compounds Bi-Voltammetric Determination With IodinecrazyprajNessuna valutazione finora

- Chukwu Kingsley - Homework4Documento1 paginaChukwu Kingsley - Homework4crazyprajNessuna valutazione finora

- Gift Receipt: Order # 404-4277281-9891552Documento1 paginaGift Receipt: Order # 404-4277281-9891552crazyprajNessuna valutazione finora

- Putting TechniqueDocumento4 paginePutting TechniquecrazyprajNessuna valutazione finora

- 03 Script Examples Extraction PDFDocumento31 pagine03 Script Examples Extraction PDFJeffersonPalaciosNessuna valutazione finora

- Discussion Board #1Documento3 pagineDiscussion Board #1crazyprajNessuna valutazione finora

- 05-Stance and Ball PositionDocumento2 pagine05-Stance and Ball PositioncrazyprajNessuna valutazione finora

- Final Project OutlineDocumento1 paginaFinal Project OutlinecrazyprajNessuna valutazione finora

- Introductory Mathematica 8 Tutorial ExpandDocumento37 pagineIntroductory Mathematica 8 Tutorial ExpandcrazyprajNessuna valutazione finora

- Weight Training QuizDocumento3 pagineWeight Training QuizcrazyprajNessuna valutazione finora

- DOS Test PDFDocumento138 pagineDOS Test PDFcrazyprajNessuna valutazione finora

- Dog BileDocumento1 paginaDog BilecrazyprajNessuna valutazione finora

- Lab 4 PolymersDocumento7 pagineLab 4 PolymerscrazyprajNessuna valutazione finora

- Tubing Applications: For The Connection Lab EquipmentDocumento4 pagineTubing Applications: For The Connection Lab EquipmentcrazyprajNessuna valutazione finora

- Dog BileDocumento1 paginaDog BilecrazyprajNessuna valutazione finora

- Gas Absorption:: Test by Wednes Day Will Not Be Installed Until The Table Is Set UpDocumento1 paginaGas Absorption:: Test by Wednes Day Will Not Be Installed Until The Table Is Set UpcrazyprajNessuna valutazione finora

- MIT18 357F10 Lec AllDocumento82 pagineMIT18 357F10 Lec AllSucharitha RajendranNessuna valutazione finora

- Teach Yourself CrystallographyDocumento42 pagineTeach Yourself Crystallographycrazypraj100% (1)

- MaterialDocumento11 pagineMaterialSaifuddin AzizNessuna valutazione finora

- Driving Geeks College Scholarship - Driving GeeksDocumento2 pagineDriving Geeks College Scholarship - Driving GeekscrazyprajNessuna valutazione finora

- Steam Table ChartDocumento30 pagineSteam Table ChartcrazyprajNessuna valutazione finora

- PCS 7 Cascad ControlDocumento27 paginePCS 7 Cascad ControlIgor RokvicNessuna valutazione finora

- EjectorsDocumento7 pagineEjectorsashirwad shetty50% (2)

- Steam Flow CompensationDocumento6 pagineSteam Flow CompensationcrazyprajNessuna valutazione finora

- Is 5286Documento6 pagineIs 5286crazyprajNessuna valutazione finora

- IndexDocumento5 pagineIndexcrazyprajNessuna valutazione finora

- Find PDFDocumento1 paginaFind PDFanand chowdaryNessuna valutazione finora

- NasaDocumento108 pagineNasaVelibor MinićNessuna valutazione finora

- Modul 2.3 Physics Form 4 - AnswerDocumento6 pagineModul 2.3 Physics Form 4 - AnswerNURSHAFAZLEEN BINTI AK DAMIT KPM-GuruNessuna valutazione finora

- Derivatives #3Documento49 pagineDerivatives #3tolgonai2705Nessuna valutazione finora

- Worksheet 4 Memorandum Exponents Grrade 10 MathematicsDocumento4 pagineWorksheet 4 Memorandum Exponents Grrade 10 MathematicsAat JuhatiNessuna valutazione finora

- 5950 2019 Assignment 7 Spearman RhoDocumento1 pagina5950 2019 Assignment 7 Spearman RhoNafis SolehNessuna valutazione finora

- Vocabulary: Writing To ExplainDocumento25 pagineVocabulary: Writing To Explain1 2 3Nessuna valutazione finora

- Tema 8. Quantum Mechanics 1D - 2P - 2019Documento29 pagineTema 8. Quantum Mechanics 1D - 2P - 2019Eduardo Junior Hernandez RodriguezNessuna valutazione finora

- 100 Word ProblemsDocumento29 pagine100 Word ProblemsCristy Lyn Bialen TianchonNessuna valutazione finora

- Surveying Lab ManualDocumento83 pagineSurveying Lab Manualsree204raoNessuna valutazione finora

- Introduction To Measure Theoretic Probability 2nd Edition Roussas Solutions ManualDocumento18 pagineIntroduction To Measure Theoretic Probability 2nd Edition Roussas Solutions Manualyvonnewelchdoafexwzcs100% (17)

- Puzzle Related To MathDocumento2 paginePuzzle Related To MathBeverlyBandojoNessuna valutazione finora

- Analysis Methods ReflectometryDocumento8 pagineAnalysis Methods ReflectometrymilitiamonNessuna valutazione finora

- 10 - Pulse Amplitude Modulation (PAM) PDFDocumento56 pagine10 - Pulse Amplitude Modulation (PAM) PDFPankaj KumarNessuna valutazione finora

- CHE-221: Fluid Mechanics-I: Dr. Zaib JahanDocumento10 pagineCHE-221: Fluid Mechanics-I: Dr. Zaib JahanBilal JuttNessuna valutazione finora

- Full VB DocumentationDocumento34 pagineFull VB DocumentationAnil Batra100% (1)

- Demo Lesson PlanDocumento30 pagineDemo Lesson PlanRandy-IanRexLorenzoNessuna valutazione finora

- Detailed Syllabus:: Department of Textile EngineeringDocumento3 pagineDetailed Syllabus:: Department of Textile EngineeringProf Dr Md Saifur RahmanNessuna valutazione finora

- HW 1 SolutionsDocumento33 pagineHW 1 SolutionsSilvio SoaresNessuna valutazione finora

- Part-A 1) Write A Program To Find Factorial of List of Number Reading Input As Command Line Argument.Documento22 paginePart-A 1) Write A Program To Find Factorial of List of Number Reading Input As Command Line Argument.Sanjay SanNessuna valutazione finora

- Inverse Functions Code PuzzleDocumento3 pagineInverse Functions Code PuzzleDarrenPurtillWrightNessuna valutazione finora

- Full Download Essentials of Statistics 4th Edition Triola Solutions ManualDocumento35 pagineFull Download Essentials of Statistics 4th Edition Triola Solutions Manualaphidcaterezpcw5100% (40)

- Assessment 01 - Introduction To Descrete Probability: Probability of Cyan - GeneralizedDocumento2 pagineAssessment 01 - Introduction To Descrete Probability: Probability of Cyan - Generalizedashishamitav123Nessuna valutazione finora

- Math 2701 - Week 1 - Simple and Compound InterestDocumento28 pagineMath 2701 - Week 1 - Simple and Compound InterestjasonNessuna valutazione finora

- Sachdev P.L., Vaganan B.M., Sivagami G. - Symmetries and Large Time Asymptotics of Compressible Euler Flows With Damping (2008)Documento24 pagineSachdev P.L., Vaganan B.M., Sivagami G. - Symmetries and Large Time Asymptotics of Compressible Euler Flows With Damping (2008)Anonymous idBsC1Nessuna valutazione finora

- Linear Functional. Matrix Representation. Dual Space, Conjugate Space, Adjoint Space. Basis For Dual Space. Annihilator. Transpose of A Linear Mapping - PDFDocumento3 pagineLinear Functional. Matrix Representation. Dual Space, Conjugate Space, Adjoint Space. Basis For Dual Space. Annihilator. Transpose of A Linear Mapping - PDFJEZEQUEL LoïcNessuna valutazione finora

- 2013-5.2 Riser SleeveDocumento18 pagine2013-5.2 Riser SleeveDavindRa Soni100% (1)