Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

M1301 4in High Thrust Brochure 03.11 WEB-6

Caricato da

Prodipto SumonCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

M1301 4in High Thrust Brochure 03.11 WEB-6

Caricato da

Prodipto SumonCopyright:

Formati disponibili

4 HIGH THRUST

SUBMERSIBLE MOTORS

Single-Phase 3 & 5 hp & Three-Phase 3-10 hp

Application Data:

These motors are built for superior dependability in 4 diameter or larger water wells.

Temperature and time rating continuous in 86 F (30 C) water at 1/4 ft/sec flow past

motor. Rotation: single-phase, CCW facing shaft end; three-phase, electrically reversible.

For further information, refer to Franklin Electrics Submersible Motors:

Application, Installation, Maintenance Manual.

Basic Features:

n Single-phase Voltage 230 V 60 Hz,

220 V 50 Hz

n Pressure Equalizing Diaphragm

n Built-in Lightning Arrestors (single-phase)

n Three-phase Voltages 200 V, 230 V,

n Removable Water-Bloc Lead installed in

380 V, 575 V 60 Hz, 460/380 V 60/50 Hz

60 Hz and dual frequency rated water

well motors. Consult factory for

n Corrosion-Resistant Construction

additional leads.

n Stainless Steel Splined Shaft

n NEMA Pump Mounting Dimensions

n Hermetically-Sealed Windings

n UL 778 Recognized (North American Voltages)

n Anti-Track Self-Healing Resin System

n CSA C22.2 #108 Certified

n Water Lubrication

n Sand Fighter Slinger

n Filter Check Valve (Water Well)

n Kingsbury-type Thrust Bearing

Special Features:

n 316 Stainless Steel: Special construction option for acid, low pH, and saline applications.

n Oil Stripper: Special construction option for secondary oil recovery wells, geothermal, or

other applications with high ambient temperatures. Consult factory for details.

n World Wide Adaptability: All standard voltage and Hertz ratings are offered. Contact

Franklin Electric for availability.

Control Boxes:

n Franklin's single-phase submersible Control Boxes are suitable for outdoor mounting

with operation over temperature ranges of +14 F (-10 C) to +122 F (50 C).

n Start and run winding overloads protect the motor from failure due to abnormal

operating conditions.

n Available in 3 and 5 hp ratings, the DELUXE Control Box incorporates a magnetic line

contactor to eliminate the need for auxiliary contactors and heavy duty pressure switches.

n A heavy duty terminal strip with box type lugs makes it easy to install up to #2 AWG wire.

n Ground lugs provide a means of grounding the motor and Control Box to the power

supply ground in compliance with NEC and other national and local codes.

WARNING: Serious or fatal electrical shock or fire hazard may result from failure

to follow the instructions for proper installation and use which accompany this

equipment. Do not use motor in swimming areas.

Motors

Drives

Controls

Protection

Availability

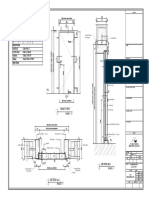

1.48"

MAX

0.030" R

MAX

Single-Phase Capacitor start, capacitor run (Control Box required)

HP

KW

"L" DIM INS

2.2

3.7

KW

KGS

23.2

56

25.4

29.2

71

32.2

"L" DIM INS

1.508"

1.498"

SHIPPING WEIGHT

LBS

0.91"

1.09"

0.161" MAX LEAD

BOSS HEIGHT

Three-Phase (Special control required)

HP

0.50 MIN.

FULL SPLINE

3.75" DIA.

" L"

SEE

TABLE

SHIPPING WEIGHT

LBS

KGS

2.2

20.2

44

20.0

3.7

23.2

56

25.4

7.5

5.5

29.2

71

32.2

10

7.5

32.9

77

34.9

60 Hz - 3.450 rpm

50 Hz - 2,875 rpm

Construction Materials

Component

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

Top Casting

Bottom Casting

Stator Shell

Stator Ends

Shaft Extension

Fasteners

Seal Cover

Seal

Diaphragm

Diaphragm Cup

Diaphragm Spring

Diaphragm Cover

Slinger

Lead Wire (or Cable)

Lead Potting

Lead Clamp

Filter

Standard Water Well

Environment Type

Chemical (316 STNLS)

Oil Stripper

303 SS

303 SS Over Painted Cast Iron

301 SS

Low Carbon Steel

17-4 SS

300 Series SS

Acetal

Nitrile Rupper Lip Seal

Nitrile Rubber

304 SS

316 SS

316 SS

Nitrile Rubber

XLPE

Epoxy

316 SS

Delrin & Polyester

316 SS

316 SS

316 SS

316 SS

17-4 SS

316 SS

316 SS

Sand Fighter SiC Mech Seal

Nitrile Rubber

316 SS

316 SS

316 SS

Nitrile Rubber

XLPE

Epoxy

316 SS

316 SS Plug

316 SS

316 SS

316 SS

316 SS

17-4 SS

316 SS

316 SS

Sand Fighter Viton

Viton

316 SS

316 SS

316 SS

Viton

XLPE

Epoxy

316 SS

316 SS Plug

Removable type leads installed. Consult Submersible Service Hotline at 800.348.2420 for

information regarding replacement leads.

Specifications subject to change without notice. Contact Franklin Electric if current material

types are required for bid specifications.

400 East Spring Street, Bluffton, Indiana 46714 Tel: 260.824.2900 Fax: 260.824.2909 www.franklin-electric.com

M1301 3.11

Potrebbero piacerti anche

- Brosur Motor 4 High Thrust 4-10 HPDocumento2 pagineBrosur Motor 4 High Thrust 4-10 HPDevi AndriNessuna valutazione finora

- Anexo 1Documento110 pagineAnexo 1rhusseinpos4765Nessuna valutazione finora

- PPN Spot Projection Welders Technical SpecsDocumento4 paginePPN Spot Projection Welders Technical SpecsAnonymous SkU7PyNessuna valutazione finora

- HCM634HDocumento8 pagineHCM634H3efooNessuna valutazione finora

- Gei 85803fDocumento4 pagineGei 85803fMuhammad SalmanNessuna valutazione finora

- Motors Submersible: 8" - Encapsulated - Water Well - Six-Lead Wye-DeltaDocumento2 pagineMotors Submersible: 8" - Encapsulated - Water Well - Six-Lead Wye-DeltaDaniel CicognaNessuna valutazione finora

- Det 375Documento10 pagineDet 375nicesreekanthNessuna valutazione finora

- De11 PDFDocumento12 pagineDe11 PDFYosi DarmawansyahNessuna valutazione finora

- Tipe NGRDocumento4 pagineTipe NGRAde Y SaputraNessuna valutazione finora

- Ngcat00 PDFDocumento4 pagineNgcat00 PDFK.RamachandranNessuna valutazione finora

- NGRDocumento4 pagineNGRrakeshshinganeNessuna valutazione finora

- Arc Suppression Coils PDFDocumento11 pagineArc Suppression Coils PDFmc315895Nessuna valutazione finora

- Circuit Breaker GTSDocumento31 pagineCircuit Breaker GTScpandey01_688066930Nessuna valutazione finora

- HCM634JDocumento8 pagineHCM634J3efooNessuna valutazione finora

- UCM274EDocumento8 pagineUCM274E3efooNessuna valutazione finora

- Troubleshooting Guide For Capacitor Excited GeneratorsDocumento16 pagineTroubleshooting Guide For Capacitor Excited GeneratorstracypearlNessuna valutazione finora

- Stamford UCI274D Data SheetDocumento9 pagineStamford UCI274D Data SheetFelipe LimaNessuna valutazione finora

- E21451 1Documento8 pagineE21451 1Hillary McgowanNessuna valutazione finora

- 72.5 420kV CVT Crompton GreavesDocumento4 pagine72.5 420kV CVT Crompton Greavesbcqbao100% (1)

- HCM434DDocumento8 pagineHCM434D3efooNessuna valutazione finora

- UCM274FDocumento8 pagineUCM274F3efooNessuna valutazione finora

- Uljanik TESU - Main Catalogue PDFDocumento15 pagineUljanik TESU - Main Catalogue PDFAlex19751205Nessuna valutazione finora

- Hyundai Generator 01Documento17 pagineHyundai Generator 01Can BektaşNessuna valutazione finora

- GIS Switchgear SpecificationDocumento11 pagineGIS Switchgear SpecificationbonekbenjeNessuna valutazione finora

- Specifications of HV SwitchgearDocumento61 pagineSpecifications of HV Switchgeardeepthik27Nessuna valutazione finora

- NOLTA US Catalog CompleteDocumento16 pagineNOLTA US Catalog CompleteFelix BonnNessuna valutazione finora

- Overall View of 220kv Switch YardDocumento34 pagineOverall View of 220kv Switch YardnitishsparxNessuna valutazione finora

- Data Sheet Uc I 224 DDocumento9 pagineData Sheet Uc I 224 DFederico Pérez de LeónNessuna valutazione finora

- BCI164BDocumento8 pagineBCI164B3efooNessuna valutazione finora

- NEA Power SolutionsDocumento8 pagineNEA Power Solutionsdip461Nessuna valutazione finora

- TD Hci634y 312Documento9 pagineTD Hci634y 312foroNessuna valutazione finora

- Chapter 5 Generator TransformerDocumento27 pagineChapter 5 Generator TransformerAnonymous nwByj9LNessuna valutazione finora

- Low voltage air-breaker 600V below Molded Case Circuit BreakerDocumento19 pagineLow voltage air-breaker 600V below Molded Case Circuit BreakeronyekaNessuna valutazione finora

- HCM534FDocumento8 pagineHCM534F3efooNessuna valutazione finora

- HCM534EDocumento8 pagineHCM534E3efooNessuna valutazione finora

- Easeweld Pdfs Saw Thyristorised Saw Welding MachineDocumento2 pagineEaseweld Pdfs Saw Thyristorised Saw Welding MachinesimsonNessuna valutazione finora

- PI734BDocumento8 paginePI734BsusantojNessuna valutazione finora

- Electrical System Data SheetDocumento9 pagineElectrical System Data SheetpmlikrishnaNessuna valutazione finora

- Calpeda MXV BDocumento6 pagineCalpeda MXV B2009tamerNessuna valutazione finora

- UCM224EDocumento8 pagineUCM224E3efooNessuna valutazione finora

- HV Sytem in ShipsDocumento40 pagineHV Sytem in ShipsvenugopalNessuna valutazione finora

- The Power of Blue .: Quick SpecsDocumento4 pagineThe Power of Blue .: Quick SpecszulaikhaabdrahmanNessuna valutazione finora

- BCI164CDocumento8 pagineBCI164C3efooNessuna valutazione finora

- Info Condensadores VarplusCanDocumento28 pagineInfo Condensadores VarplusCanjhoansilvaNessuna valutazione finora

- Starting Dengan ReostadDocumento5 pagineStarting Dengan ReostadTonoTonyNessuna valutazione finora

- S-20 Railroad Highway Crossing Gate: Instruction & MaintenanceDocumento28 pagineS-20 Railroad Highway Crossing Gate: Instruction & MaintenanceThanh Bình VũNessuna valutazione finora

- UCM224CDocumento8 pagineUCM224C3efooNessuna valutazione finora

- BJWSA Pump Station Electrical SpecificationsDocumento6 pagineBJWSA Pump Station Electrical SpecificationsÇiik ÓurNessuna valutazione finora

- E 51 06 - 092017Documento4 pagineE 51 06 - 092017Imtiyaz KhanNessuna valutazione finora

- UCM224D - Technical Data SheetDocumento8 pagineUCM224D - Technical Data Sheet3efooNessuna valutazione finora

- DC-Motor Description & MaintenanceDocumento51 pagineDC-Motor Description & MaintenanceSotila Ionut100% (4)

- 17 - Datos Tecnicos PDFDocumento4 pagine17 - Datos Tecnicos PDFAnonymous iu95trpxNNessuna valutazione finora

- Marine Electrical Practice: Marine Engineering SeriesDa EverandMarine Electrical Practice: Marine Engineering SeriesValutazione: 4 su 5 stelle4/5 (8)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Da EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Nessuna valutazione finora

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Da EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Valutazione: 2.5 su 5 stelle2.5/5 (3)

- Fault Detection in Transmission LinesDocumento90 pagineFault Detection in Transmission LinesMohd SameerNessuna valutazione finora

- Ultra Precise RTD SensorsDocumento4 pagineUltra Precise RTD SensorsmarcusNessuna valutazione finora

- ZS080 BB-6000 - 4000-FSA Crankset (English-20090109) v0Documento2 pagineZS080 BB-6000 - 4000-FSA Crankset (English-20090109) v0manuelNessuna valutazione finora

- Manual Euro-Pro Shark V1950 Shark VX3 Cordless Rechargeable Floor-And-Carpet CleanerDocumento13 pagineManual Euro-Pro Shark V1950 Shark VX3 Cordless Rechargeable Floor-And-Carpet CleanerJer EmyNessuna valutazione finora

- Hand Held Torque GaugeDocumento1 paginaHand Held Torque GaugeMuhammadTaufikAliRahmanNessuna valutazione finora

- Phase Antiphase Boost Control PDFDocumento2 paginePhase Antiphase Boost Control PDFNugrahaNessuna valutazione finora

- Hysteresis MotorsDocumento13 pagineHysteresis MotorsDivyansh GoyalNessuna valutazione finora

- GGSS1074 Rev 14.1 Gen TRFR SpecificationDocumento147 pagineGGSS1074 Rev 14.1 Gen TRFR SpecificationKhashane Willy MohaleNessuna valutazione finora

- Indra Drive Tech Support Manual PDFDocumento18 pagineIndra Drive Tech Support Manual PDFCristopher Entena100% (1)

- Advisor111 K Disconnect Switches Web PDFDocumento76 pagineAdvisor111 K Disconnect Switches Web PDFFariz NugrahaNessuna valutazione finora

- Manual de Operação PDFDocumento50 pagineManual de Operação PDFRogerio Nunes Marinho100% (2)

- Product Overview Customer Service M 9500: Date OriginatedDocumento3 pagineProduct Overview Customer Service M 9500: Date OriginatedciccioNessuna valutazione finora

- All Test Procedures (31121016-000-Gap-00023-000)Documento155 pagineAll Test Procedures (31121016-000-Gap-00023-000)Zeeshan Hashmi100% (1)

- Kioti RX6630PSC-JP, RX7330PSC-JP Tractor Parts ManualDocumento10 pagineKioti RX6630PSC-JP, RX7330PSC-JP Tractor Parts ManualLisakolyNessuna valutazione finora

- How To Bypass LCD TV Inverter BoardDocumento5 pagineHow To Bypass LCD TV Inverter BoardMecael DesuyoNessuna valutazione finora

- Door Design and Hardware DetailsDocumento1 paginaDoor Design and Hardware Detailsedo artisaeNessuna valutazione finora

- Content For Auto Electrical WebsiteDocumento3 pagineContent For Auto Electrical WebsiteshermanNessuna valutazione finora

- Technical Service Information: Automatic Transmission Service GroupDocumento4 pagineTechnical Service Information: Automatic Transmission Service Groupdamian berduscoNessuna valutazione finora

- RENAULT CAPTUR Brochure ENG2 PDFDocumento15 pagineRENAULT CAPTUR Brochure ENG2 PDFGOKUL PRASADNessuna valutazione finora

- Dual Latero Log TheoryDocumento121 pagineDual Latero Log TheoryHariomNessuna valutazione finora

- 950G Series II, 962G Series II, and Electrical System IT62G Series II Wheel LoaderDocumento4 pagine950G Series II, 962G Series II, and Electrical System IT62G Series II Wheel LoaderElie Abisaad100% (1)

- Agitator Trucks: Unit - 3Documento9 pagineAgitator Trucks: Unit - 3PavithravasuNessuna valutazione finora

- Engine D001 PDFDocumento53 pagineEngine D001 PDFLakiNessuna valutazione finora

- LP28013 DatasheetDocumento7 pagineLP28013 DatasheetGeorge KamberogiannisNessuna valutazione finora

- HY TB3DV K Series Three Axis ManualDocumento20 pagineHY TB3DV K Series Three Axis ManualP BNessuna valutazione finora

- Upgrade FADECs Citation Service BulletinDocumento1 paginaUpgrade FADECs Citation Service BulletinturboshaftNessuna valutazione finora

- TSV Less Semicon TaiwanDocumento21 pagineTSV Less Semicon TaiwankbrinaldiNessuna valutazione finora

- BT1340G/1 Bench Lathe Operation ManualDocumento55 pagineBT1340G/1 Bench Lathe Operation ManualJhon SantosNessuna valutazione finora

- Inspection and Acceptance Report Pandayan Bookshop, IncDocumento3 pagineInspection and Acceptance Report Pandayan Bookshop, IncErwin BucasasNessuna valutazione finora

- Mercer 9100Documento16 pagineMercer 9100dtmgoNessuna valutazione finora