Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Quantitative Analysis by X - R A Y Diffraction

Caricato da

Jun Rey LincunaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Quantitative Analysis by X - R A Y Diffraction

Caricato da

Jun Rey LincunaCopyright:

Formati disponibili

QUANTITATIVE ANALYSIS BY

X-RAY DIFFRACTION

By K. NORRISH and R. M. TAYLOR

Division of Soils, C.S.I.R.O., Adelaide, South Australia.

[Received 18th April, 1962]

ABSTRACT

Certain minerals in soil clays may be directly estimated from diffraction

line intensity and the mass absorption coefficient of the sample to the

radiation used. The main advantages of the method described are that

no internal standards or calibration charts are required, and any diffraction line of the component to be estimated may be chosen. The

results obtained compare favourably with chemical determinations.

Orientation of particles during sample preparation makes the estimation

of some minerals very difficult. The uncertainty involved in choosing

the background level under a diffraction line is the chief source of error

in estimating small amounts of very fine-grained minerals.

INTRODUCTION

Because the intensity of an X-ray diffraction pattern is directly

proportional to the concentration of the component producing it,

when due allowance is made for absorption effects (Klug and Alexander, 1954), it has been possible to develop methods of quantitative

analysis based on diffracted intensities. The diffracted intensity of

any hkl reflection from any crystalline compound can be related to

the composition of the compound and its matrix, and to the instrumental geometry (Klug and Alexander, 1954; yon Engelhardt, 1961).

However, for any particular reflection, many of the parameters can

be reduced to a constant.

The following derivation of the relationship between diffracted

intensity and absorption is reproduced in part from Klug and Alexander (1954). Therein, it is demonstrated that if the incident and

diffracted X-ray beam enter and emerge symmetrically on the same

side of a 'thick' flat powder specimen,

I~ =KV

(l)

where Ix is the measured intensity of a diffraction line of a crystMline

component of the sample, V is the volume fraction of the component,

/~ is the linear absorpt on coefficient of the specimen, and K is a constant for any particular line of a particular mineral. This constant

depends on the incident X-ray intensity, the diffracting power of the

spacing being measured, the geometry of the instrument, etc. The

sample has to be sufficiently 'thick' to completely attenuate the incident beam.

98

99

QUANTITATIVE DIFFRACTION ANALYSIS

If Ois the apparent density of the specimen and p~ the true density

of the component being estimated, then

KX

/~--pxAx

(2)

where X=pxV/p-the weight fraction of the component being estimated, and A x =tx/p the mass absorption coefficient of the specimen.

If now the same diffraction line is measured on a standard sample

for which X is known and equal to S, then

KS

/~-(3)

psAs

Since ps=px, combination of equations (2) and (3) gives

x

AxI~S

A,ls

(4)

Generally a pure material can be selected as the standard, in which

case S = 1.

These equations were derived assuming that the crystallites of the

specimen were small enough not to give micro-absorption effects

(Brindley, 1945), an assumption that will be justified for clay separates of < 5 tL equivalent spherical diameter. With larger particles,

the incident and diffracted beams may be attenuated to different

degrees in the mineral to be estimated and the matrix, and the use of

the average measured mass absorption coefficient in equation (4)

would not necessarily give the correct estimation. The maximum

permissible crystallite size at which micro-absorption effects are

still negligible will depend on the difference between the absorptions

of the component and the matrix to the radiation being used. Von

Engelhardt (1961) has classified the particles of a sample by the product of their particle size (in cm.) and their linear absorption coefficient to a particular radiation. When this product is Jess than

0-01, no correction for micro-absorption is necessary.

Most commercial diffractometers have a geometry such that the

above equations are satisfied and the measurement of Ix and Is with

them presents no problem in principle. Leroux, Lennox and Kay

(1953) used equation (4) to determine quartz in various mixtures,

using a diffractometer to measure Ix and Is. Ax and As were calculated from the measured absorption coefficient of the samples to

shorter 'white' radiation. In principle this method cannot be used

to obtain absorption coefficients with any high or constant degree of

accuracy for two reasons: (a) because the beam is not monochromatic, the absorption coefficient will change with the sample thickness; (b) if the absorption coefficient is measured for any wavelength

other than that used in measuring diffracted intensities, the presence

of any element with an absorption edge between the two wavelengths

would give rise to serious errors.

Leroux (1957) in later work used monochromatic Mo Ka radiation

(reflected from the 101 plane of quartz) instead of the white radiation

I00

K . N O R R I S H A N D R . M. T A Y L O R

direct from a Cu target, to measure A ~ and As. Using this technique,

he estimated quartz with a standard deviation of 2 per cent. from the

nominal values. Short wavelengths, such as Mo Ka, are more

satisfactory for absorption measurements because much thicker

samples can be used, but these wavelengths do not give sufficient

dispersion for diffraction studies of clay minerals.

Despite the simplicity of equation (4) and the fact that its application does not involve the tedium of making calibration curves with

internal standards '(Ballard, Oshry and Schrenk, 1940; Klug, 1953),

or with artificial samples, it has been used very little. The various

other methods of analysis (internal standards, etc.) are essentially

indirect methods of allowing for A~/A~. Leroux, Lennox and Kay

(1953) used Ax and As but did not measure these quantities directly,

possibly because of difficulties associated with making specimens

thin enough for direct measurement.

Since not all the advantages of applying equation (4) as a method

of analysis are immediately obvious, they are worth brief mention.

For most estimations, a method in which As and As are measured

eliminates the need of any sample pretreatment other than that

necessary to obtain a suitable diffraction trace. Moreover, because

Ax and As do not occur as angular functions, as they do in photographic techniques, any diffraction peak in a routine trace may be

selected for the measurement of Ix. This is particularly important in

the analysis of rocks and soils where, because of the numbers of

minerals which may occur and the complexity of their patterns, there

is a high probability that any preselected line may suffer interference

from adjacent or coincident lines. The technique therefore has the

big advantage that the selection of a suitable line for measurement

can be made after the diffractometer trace has been obtained.

In the present study it is shown that satisfactory analyses can be

made using Cu or Co radiations for both absorption and diffraction

measurements.

EXPERIMENTAL

Methods. In preliminary experiments a Norelco high-angle

diffractometer using a Geiger-counter detector in conjunction with a

ratemeter and recorder was used to estimate I~ and Is. This equipment has since been modified by the addition of a pulse-height

analyser and the Geiger counter has been replaced by a scintillation

detector. Using the scintillation detector, counting losses are less

and non-monochromatic radiation can be partially eliminated, thus

increasing the line to background ratio.

A monochromatic beam of high intensity for absorption measurements, was obtained by putting single-crystal slabs (e.g., quartz,

lithium fluoride, or sodium chloride) or oriented powder specimens

(e.g., graphite) in the sample position of the diffractometer, the detector being set to the 20 position corresponding to the reflecting

plane. The absorption of the sample was measured by placing it ia

QUANTITATIVE DIFFRACTION ANALYSIS

10I

front of the receiving slits of the detector and measuring the reduction in intensity.

It is very desirable to use a reflecting plane which has very weak

second and third order reflections, otherwise it is necessary to run the

X-ray tube at a low kilo-voltage to avoid contaminating the monochromatic beam with harmonics.

Sample Preparation. In general, the samples analyzed were < 5Vfractions. For the various artificial mixtures the individual components of the required particle sizes were mixed together by grinding.

Specimens for diffractometry were prepared by lightly pressing the

powder into rectangular metal holders, 2 cm 1 cm (Klug and

Alexander, 1954). Sometimes minerals with a pronounced fibrous

or platy habit became preferentially oriented during this treatment,

in which case the diffracted intensity of a peak was no longer linearly

related to the mineral concentration. It was found that orientation

effects could be reduced a little if, during the preparation, the front

surface of the specimen was pressed against a surface of ground glass

or coarse paper rather than a polished surface, as this preserved some

degree of randomness in the surface packing.

Specimens for the measurement of the mass absorption coefficients

were prepared by pressing the powdered sample into a 89in. (1.27 cm)

diameter hole in an ~ in. Perspex holder. Pressures varying between

200 and 2000 kg/cm 2 were necessary to ensure self supporting samples,

(Preferred orientation does not affect this determination.) Samples

of uniform thickness were obtained with the aid of jigs. The sample

holders were weighed before and after loading. Samples weighing

less than 0.03 g are difficult to make, and 0.07-0.10 g is generally

required.

When a sample cannot be made sufficiently thin, it may be diluted

with a material with low absorption, such as boric acid. The

measured absorption coefficient must then be corrected for the

amount of diluent added. This type of mixture is particularly prone

to errors from micro-absorption effects, so great care must be taken

to ensure complete mixing of sufficiently fine particles. The measurement of the absorption coefficient is generally made on duplicate

samples.

Measurement of Mass Absorption Coefficient. If a sample of

thickness I is inserted in a monochromatic X-ray beam of intensity

Io, the attenuated beam, intensity I, is related to the incident beam

intensity by the relationship

I-- Ioexp( -tzl)

so that measurement of I and Io determine txl. The weight of the

sample and its area (1.27 cm z) gives its mass/cm 2, pl, and the mass

absorption coefficient, A=tz/p--izl/pl.

Ratios of I/Io as low as 3 10 -5 (/xl= 10)* could be measured to

*These measurements were made using fluorescent radiation. It is doubtful

if radiation taken direct from an X-ray generator could give such results as it h a s

associated with it m u c h m o r e 'white' radiation.

102

K. NORRISH AND R. M. TAYLOR

give accurate measurements of A. Table 1 shows some mass absorption measurements compared with those calculated from

standard tables.

TABLE 1--Comparison of measured and calculated mass absorption coefficients.

Cu K a

Sample

Aluminium

Quartz, SiOz*

He natite, FezO3*

Goethitet

Kaolins

Dolomite, CaMg(CO3)2*

Calcite, CaCO3*

Co Kct

Meas- Calc~ 9 Meas- Calcuured

latec

ured

lated

48.7

36.1

-! 87

32.0

48.9

35-0

230

200

31.6

75"0

55"1

44 "7

43 '4

48 "0

69

108

73.4

54.8

47.7

43.7

47.0

71

106

Fe K a

Meas- Calcuured

lated

94-5

69 '2

56.4

53.0

93.8

67.6

56.3

51.4

*Chemical composition assumed to correspond to formula.

tAnalysis: Fe203 86"7, H20, 13.2 Si02 0.15.

SAssumed: Si02 45, A1203 40.5, H20 14"5.

The deviations between calculated and experimental absorption

coefficients are generally less than the uncertainty in published mass

absorption coefficients of the elements. The data available on

experimentally determined absorption coefficients (Compton and

Allison, 1935; Hodgman, Weast and Selby, 1956) are very incomplete so that calculated coefficients (Henry, Lipson and Wooster,

1953), had to be used and for low atomic number elements the latter

often disagree seriously with the former. Mass absorption coefficients could generally be measured with a reproducibility of about

1 per cent. and counting errors were reduced to 1 per cent. The main

source of error in the determination is the deviation of the sample

from a uniform parallel sided slab (error in l). Sample preparation

and the measurement of mass absorption requires only a few minutes.

Measurement of Line Intensities. The most accurate method of

measuring diffraction intensities is to take a large number of counts

at the required angle. Then, if sufficient counts are taken, the accuracy is limited by output stability of the X-ray set--and this can

be reduced to a small fraction of 1 per cent. If no other lines lie

near that being measured and if the background in this region is flat,

there is no problem in obtaining an accurate measure of the peak

height of the line above background.

For complex natural mixtures, however, the integrated area (or a

modification of this) was chosen as the most convenient measure o f / ,

for several reasons. In the analyses of soils and rocks, the background is rarely flat so that averaging the background on either side

o f the line does not necessarily give an accurate estimate of the line

QUANTITATIVE DIFFRACTION ANALYSIS

103

background, particularly if other lines lie near that being measured.

In these instances it is desirable to see the intensity distribution over

an angular region on either side of the line, because the background

estimation requires some judgement. If diffraction lines suffer

broadening because of small particle size or other causes, the measurement of peak height will not give a good estimate of line intensity

(line broadening is common in soil minerals). If the crystallite size

of specimens is not sufficiently small (< 5t~), relatively large errors can

occur in the measurement of the peak height of lines due to the small

number of particles contributing to diffraction at a particular angle

(Klug and Alexander, 1954). Many more crystallites are considered

when the line intensity is integrated over a small angular range and

the errors will therefore be reduced.

The integrated intensity can itself be measured by two methods,

either by measuring the area enclosed by the peak and the estimated

background, or by taking the product of the maximum peak height

and the peak width at half maximum height.

There are, however, further problems associated with the accurate

measurement of peak areas. A diffraction line has the profile of a

tailed triangle (Fig. 1) for which the level of the base (background) is

40

39

2e

38

37

DEGREES

FIG. 1--Profile of a typical X-ray diffractionline, the 130 line of goethite.

the most uncertain feature, whilst the area changes markedly with

small changes of background because of line width in this region.

To overcome the large errors which might thus occur, and to take

cognisance of line width, the product of the peak height and the width

at half peak height was chosen as the most satisfactory compromise

104

K. NORRISH AND R. M. TAYLOR

:for the measurement of L Table 2 shows the errors introduced into

the various measures of line intensity by purposeful errors in background.

TABLE2--Variations in line intensity due to background uncertainty

(assumed 5% of peak height).

Method of Measuring line intensity

Mineral and line width

Peak

height

Goethite 130 line

Width at ~-peak height 0-3 ~

Quartz 101 line

Width at 89peak height 0.175 ~

+5%

--5%

+5%

-5%

Area

Peak height width

at 89peak height

+22.4~

+12"2~

--16-1%

+ 3"7%

--13 '2%

-15.8%

--

8"8%

I n o b t a i n i n g diffractometer traces for m e a s u r e m e n t the scanning

speed o f the d e t e c t o r a n d the time c o n s t a n t o f the r a t e m e t e r were

a d j u s t e d so that line profiles were n o t altered appreciably.

RESULTS AND DISCUSSION

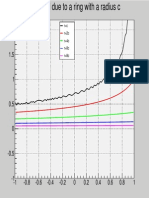

Fig. 2 shows experimental values o f Ix~Is for C o K a a n d C u K ~

radiations, for artificial mixtures o f goethite a n d kaolinite, and it is

1.0

O8

~C

06

~9

.=.

~/

04

02

//84

",/

0.2

>~

04

06

0.8

tx/i s

Fzo. 2---Variatiort of Ix~Is with goethite content for Co and Cu radiations.

Continuous lines show the predicted relationship; experimental points.

QUANTITATIVEDIFFRACTIONANALYSIS

105

seen that these values lie close to the curves predicted by equation (4).

The two curves are quite different because the mass absorption

coefficients of kaolinite and goethite for Cu Ka differ widely (32 and

187 respectively) whereas for Co Ka radiation they are almost the

same. Hence there is an almost linear relation between I~/I~ and

goethite concentration for Co Kct.*

In obtaining the theoretical curves for Fig. 2, A x was calculated

from the relationship,

Ax=xAg + (1--x)A.,

Ag and AK being the mass absorption coefficients of goethite and

kaolinite, and x the proportion of goethite present.

TABLE3--Calculated and nominal compositions for various synthetic mixtures.

Mixtures

in Kaolin

Nominal

composition

(%)

Sample 1

50 Goethite

Sample 2

Sample 3

Calculated comp. (~)

Using

areas

49.2

5 Haematite

50 Quartz

47

50.5

<{%

Sample 4

20 Quartz

$20-2

s249.4

o.,

Sample 5

50 Goethite

Sample 6

25 Haematite

25 Goethite

37.5 Haematite

25 Quartz

%22

48.2

23.2

f24.6"

\22"2

37"5

21

Line

Using

products

130

111

102

101

112

10l

112

130

111

102

130

lll

102

101

4'25

$21.5

~20.4

.5

(~'5

20"7

*Calculatedfromthe intensityof the compound peak at 2"69~ by subtracting

duo to the 102 line of the hematite component

the

intensity

Table 3 shows the results obtained by the application of equation

(4) to some artificial mixtures, the quantities As, Is, Ax and Ix being

determined experimentally. The agreement between the actual and

determined amounts is satisfactory, in that the errors are of the same

order as errors in A and L Analyses made using different lines o f

a diffraction pattern gave good agreement, even when the lines have

a large angular separation (Table 3).

Table 4a presents the analyses of some soils and clays for goethite

and haematite, these particular results being given for comparison

*This is a very good reason, apart from the high background associated with Ctt

radiation, for using Co radiation on soil samples high in iron.

106

K. NORRISH AND R. M. TAYLOR

with i n d e p e n d e n t chemical estimates of the total Fe203. Table 4b

compares the percentages o f gorceixite a n d crandallite measured by

diffraction methods with those calculated from the P content. These

calculations were made assuming that the minerals had a n invariant

composition. The two methods of estimation agree well b u t several

factors prevent a n absolute comparison. The chemical variability

o f gorceixite prevents accurate estimations from the p h o s p h o r u s

TABLE4a--X-ray diffraction estimations of iron oxide minerals in soils.

Sample

Cookls. whole soil

...

West. Aust.

< 2/* Lateritic . . . . . .

West. Aust.

< 2 1. Lateritic . . . . . .

West. Aust.

< 2 1. Lateritic . . . . . .

Victoria

<5t*

.........

Tasmania

< 0.51. . . . . . . . . .

Barbados W. I.

< 2 1. Terra Rossa

...

Diffraction

estimation

(%)

Free FezO3

(%)

Fe203

accounted for

(%)

Goethite 42

49 "5*

76

29"6t

91

Goethite 39

37 "8"["

93

Haematite 1.2

Goethite 2

4'6

65

Haematite 6

Goethite 3

9.5

92

Goethite 3.5

79

Goethite 6.2

7.5

74

Goethite 30

*A small amount o f ilmenite or haematite was identified from diffraction photographs.

i ' A very small amount of the iron of these clays is probably present as ilmenite.

TABLE4b---Estimation of gorceixite in three fractions of a soil.

Gorceixite (%)

Sample

9 '

By diffraction

Calcuiated

from total

P content

Ratio of

estimations

Whole Soil

......

0.5--5 ~ .. . . . . . . .

0.5--5 1. after HF treatment

3.2

12.5

70

2.6

11.5

56

1-23

1.10

1.25

content, whilst this same variability means that the standard mineral

is n o t identical with that of the soil, so that absolute estimations

c a n n o t be m a d e accurately by diffraction methods. Most complex

m i n e r a l s - - p a r t i c u l a r l y those forming m u l t i - c o m p o n e n t solid solutions

- - s h o w such chemical variability and are therefore difficult to analyze

absolutely. Most clay minerals fall into this category. The failure

to account for m u c h o f the measured free Fe203 in some samples,

(Table 4a), can also be attributed to a similar cause. Norrish a n d

107

QUANTITATIVE DIFFRACTION ANALYSIS

Taylor (1961) have shown that aluminium isomorphously replaces

iron in soil goethites. Replacements up to 25 mole per cent. have

been measured and there are corresponding changes in the diffracted

intensities. The diffraction line used to measure Ix for goethite in

these soils was the 111 reflection whose intensity varies linearly with

the degree of substitution. When correction is made for this factor

the diffraction estimates agree better with the chemical determination.

Preferred orientation of particles during the preparation of the flat

sFecimen used with focusing diffractometers may also give rise to

serious errors. Materials which have a good cleavage or a platy or

fibrous habit are very prone to orientation effects. In analyses for

150

12o

9o

o

60

(11,)

(13o)

(,',1

NON- ORIENTED

(,ooo ,,~,)

L

43

a"

'

..a

42

~O

' " L.~-.-J

3q

DEGREES

30

3~

39

<.3

20

38

DEGREES

3b

FIG. 3 - - T h e effect o f orientation on the relative intensities o f geothite 130 and

111 diffraction peaks.

goethite orientation effects were observed, the 111 line decreasing

and the 130 line increasing in intensity with increased orientation.

Fig. 3a demonstrates the increase in intensity of the 130 and an

associated decrease in the 111 peaks after pressing the sample on a

fiat surface to a pressure of 4000 p.s.i. Fig. 3b shows the height of

two goethite peaks when the sample was prepared under a slight

pressure on a filter paper surface, which tends to eliminate orientation. Satisfactory results were obtained only from those specimens

for which the intensity ratio of the 111 and 130 lines was the same as

that of the standard. Here, the ratio used was 1.43 and probably

corresponds to random or almost random packing. This value agrees

108

K. NORRISH AND R. M. TAYLOR

well with the ratio of 1.38 calculated from the structure of goethite.

With minerals of more pronounced habit it has not been possible to

make specimens in which the particles are even approximately

randomly orientated. The degree of orientation of a mineral in

samples prepared by identical methods will vary with its particle

shape and size. Table 5 gives results for various kaolin minerals,

TABLE 5--Orientation in kaolins as measured by the intensity ratios of the

002 and 060 lines.

Sample

Kaolinite

Kaolinite < 2 t*

Kaolinite < 2 t~

Kaolinite

Kaolinite

Dickite

Hallyosite*

Halloysite*

Halloysite*

Origin

Mt. Crawford

Sth. Aust.

West Aust.

West. Aust.

McNamee, Sth.

Carolina

Germapy

N.S. Wales

Black Spur,

N.S. Wales

Tasmania

Bedford,

Indiana

Area o f

002 line

Area o f

060 line

55

18'5

2.99

174

103 "5

56.1

10.6

1l

24 "9

16"4

9"4

2"25

202

138

69 "9

6 '5

15.2

28.3

31 .I

9'1

2 "46

78

62.1

32.5

24-7

2-4

2.56

Ratio

*All haUoysites were measured after being oven dried for 4 hours at 105~

orientation being measured by the intensity ratio of the 002 to the

060 line. The halloysites, which are tubular in habit, give the lowest

values for this ratio and are probably nearly randomly oriented.

Even within the one specimen it is rash to assume that various clay

minerals will have the same degree of orientation, an assumption

which is implicit in many recent clay and soil analyses made using

diffractometers. A powder diffraction photograph of an oriented

flake of a soil clay clearly shows how the various clay components

may be very differently oriented.

Though there does not yet appear to be any reliable method of

overcoming orientation problems, the authors are experimenting

with various techniques for either overcoming orientation or allowing

for it. A satisfactory technique, however, will probably require more

elaborate methods of sample preparation and subsequent analysis

than those described here.

CONCLUSIONS

From the results presented it is clear that this method gives very

good results on artificial samples or when estimating large amounts

of a mineral under ideal conditions. The accuracy will normally be

less when analyzing an unknown sample, the limit being set by nature

QUANTITATIVE DIFFRACTION ANALYSIS

109

of the mineral, its orientation, micro-absorption variability, concentration, and the measurement of the diffracted intensity above

the background. However, these problems are present in any

method of quantitative diffraction analysis.

Even considering these limitations this method gives results as

good as those obtained by other methods and avoids the necessity

of calibration curves (which imply a knowledge of the sample) or

additions of an internal standard which itself may introduce into

an otherwise satisfactory sample micro-absorption or orientation

effects.

Acknowledgements.--Dr E. W. Radoslovich of this Division is thanked for his

critical reading of the manuscript.

REFERENCES

BALLARD, J. W., OSHRY, H. i., and SCHRENK,H. H., 1940. Rep. Invest. U.S.

Bur. of Min., No. 3520.

B~NOLEY, G. W., 1945. Phil. MAR., 36, 347.

COMPTON, A. H., and ALLISON,S. K., 1935. X-ray in Theory and Experiment.

Van Nostrand, New York.

HE~Y, N. F. M., LXPSON,H., and WOOSTER,W. A., 1953. The Interpretation

of X-ray Diffraction Photographs. Macmillan, London.

HODGMAr~,C. D., WEAST,R. C., and SELBY,S. M., 1956. Handbook of Chemistry

and Physics. Chemical Rubber Publishing Co., Ohio.

KLUG, H. P., 1953. Analyt. Chem. 25, 704.

KLUG, H. P., and ALEXANDER, L. E., 1954. X-ray Diffraction Procedures.

Wiley, New York.

LEROLrX,J., LENNOX,D. H., and KAY, K., 1953. Analyt. Chem., 25, 740.

LEROtrX, J., 1957. Norelco Reporter, 4, 107.

"CON ENG~LHARDT,W., 1961. Science and Industry (Philips Electrical Industries

Ltd.), 8, 2.

NORRISHK., and TAYLOR,R. M., 1961. J. Soil Sci., 12, 294.

Potrebbero piacerti anche

- WASA Design Manual Final Mar 09 PDFDocumento234 pagineWASA Design Manual Final Mar 09 PDFrealchicNessuna valutazione finora

- Cellulose - Fascinating Biopolymer and Sustainable Raw MaterialDocumento36 pagineCellulose - Fascinating Biopolymer and Sustainable Raw MaterialJun Rey LincunaNessuna valutazione finora

- Chrischiansen Effect in IRDocumento6 pagineChrischiansen Effect in IRmushtaq521Nessuna valutazione finora

- Johnson1972 PDFDocumento10 pagineJohnson1972 PDFShyamal MondalNessuna valutazione finora

- Johnson 1972Documento10 pagineJohnson 1972Andrés DuqueNessuna valutazione finora

- The Crystal and Molecular Structure of Naphthalene. I. X-Ray MeasurementsDocumento6 pagineThe Crystal and Molecular Structure of Naphthalene. I. X-Ray MeasurementsRudolf KiraljNessuna valutazione finora

- Surface Plasmon Resonance: K. Scott Phillips and Quan Jason ChengDocumento12 pagineSurface Plasmon Resonance: K. Scott Phillips and Quan Jason ChengTin Tức Mỗi NgàyNessuna valutazione finora

- Approximation of Crystallite Size and Microstrain Via XRD Line Broadening Analysisin TiSiN ThinfilmsDocumento6 pagineApproximation of Crystallite Size and Microstrain Via XRD Line Broadening Analysisin TiSiN ThinfilmsmustafaNessuna valutazione finora

- 3D Micro X-Ray Fluorescence Analysis: Wolfgang MalzerDocumento8 pagine3D Micro X-Ray Fluorescence Analysis: Wolfgang MalzeredsonmkNessuna valutazione finora

- Davidson 1987Documento4 pagineDavidson 1987shahin774Nessuna valutazione finora

- Refractive Index and Thickness Determination of Thin-Films Using Lloydõs InterferometerDocumento8 pagineRefractive Index and Thickness Determination of Thin-Films Using Lloydõs InterferometerLuis MestaNessuna valutazione finora

- Joint Inversion of Seismic Refraction and Resistivity Data Using Layered Models - Applications To Groundwater InvestigationDocumento13 pagineJoint Inversion of Seismic Refraction and Resistivity Data Using Layered Models - Applications To Groundwater InvestigationDian Pratiwi MalikNessuna valutazione finora

- Analysis of Semiconductors by Double-Crystal X-Ray DiffractometryDocumento8 pagineAnalysis of Semiconductors by Double-Crystal X-Ray DiffractometryChun Yu YangNessuna valutazione finora

- Nature 04912Documento3 pagineNature 04912Sudip ChakrabortyNessuna valutazione finora

- New TechniquesDocumento60 pagineNew Techniquesm a zargarNessuna valutazione finora

- Experiment-4: Aim: Synthesis and Characterization of Carbon Nanotube/Polypyrrole Requirements: Formula Used: TheoryDocumento4 pagineExperiment-4: Aim: Synthesis and Characterization of Carbon Nanotube/Polypyrrole Requirements: Formula Used: TheoryTush RohNessuna valutazione finora

- EXPERIMENT 8. Monolayer Characterization: Contact Angles, Reflection Infrared Spectroscopy, and EllipsometryDocumento9 pagineEXPERIMENT 8. Monolayer Characterization: Contact Angles, Reflection Infrared Spectroscopy, and EllipsometryavniNessuna valutazione finora

- Ultra-Small-Angle Neutron Scattering With Azimuthal AsymmetryDocumento10 pagineUltra-Small-Angle Neutron Scattering With Azimuthal AsymmetryKarthikPrakashNessuna valutazione finora

- DSSC 978-94-007-1019-1 - 25Documento2 pagineDSSC 978-94-007-1019-1 - 25Azhar ZaidiNessuna valutazione finora

- Angle Resolved X-Ray Photoelectron SpectrosDocumento7 pagineAngle Resolved X-Ray Photoelectron Spectrosharibhakta oliNessuna valutazione finora

- Quantitative X-Ray Powder Diffraction Analysis Applied To Transmission DiffractionDocumento6 pagineQuantitative X-Ray Powder Diffraction Analysis Applied To Transmission Diffractioncristhian alvarezNessuna valutazione finora

- Fuller & Griffiths (1978) KMDocumento5 pagineFuller & Griffiths (1978) KMpchin13Nessuna valutazione finora

- BF 01052813Documento25 pagineBF 01052813Kevin KNessuna valutazione finora

- An ADV For The Characteristisation of Turubulence in Concentrated Fluid Mud (Gratiot - Etal)Documento17 pagineAn ADV For The Characteristisation of Turubulence in Concentrated Fluid Mud (Gratiot - Etal)Sutanto HadiNessuna valutazione finora

- First Laboratory X-Ray Diffraction Contrast Tomography For Grain Mapping of PolycrystalsDocumento7 pagineFirst Laboratory X-Ray Diffraction Contrast Tomography For Grain Mapping of PolycrystalsXiaobing HuangNessuna valutazione finora

- Journal of Quantitative Spectroscopy & Radiative Transfer: A.V. GusarovDocumento15 pagineJournal of Quantitative Spectroscopy & Radiative Transfer: A.V. GusarovСергей БадюкNessuna valutazione finora

- Oradea LS MV AS CP PRB HK Measurements SCRDocumento4 pagineOradea LS MV AS CP PRB HK Measurements SCRayjezNessuna valutazione finora

- Nuclear Instruments and Methods in Physics Research ADocumento7 pagineNuclear Instruments and Methods in Physics Research Acordella_francescoNessuna valutazione finora

- Cris W. Barnes Et Al - Observation of Mix in A Compressible Plasma in A Convergent Cylindrical GeometryDocumento5 pagineCris W. Barnes Et Al - Observation of Mix in A Compressible Plasma in A Convergent Cylindrical GeometryMfdrrNessuna valutazione finora

- Artzner 1998Documento15 pagineArtzner 1998Mitadru BiswasNessuna valutazione finora

- Photon Detection - UV-Vis-IR EDocumento10 paginePhoton Detection - UV-Vis-IR EdoggydogNessuna valutazione finora

- Optik: Mohammad Naser-Moghadasi, Amir Zara Nia, Mohammad Toolabi, Samaneh HeydariDocumento8 pagineOptik: Mohammad Naser-Moghadasi, Amir Zara Nia, Mohammad Toolabi, Samaneh HeydariJuhi GargNessuna valutazione finora

- J Optcom 2003 11 062Documento12 pagineJ Optcom 2003 11 062Ana Candelaria Dávila PérezNessuna valutazione finora

- Artigo 7Documento11 pagineArtigo 7Letícia SerrouNessuna valutazione finora

- Powder DiffractionDocumento9 paginePowder DiffractionGary TrumpNessuna valutazione finora

- Photoacoustic Studies of Annealed Cdsxse1-X (X 0.26) Nanocrystals in A Glass MatrixDocumento6 paginePhotoacoustic Studies of Annealed Cdsxse1-X (X 0.26) Nanocrystals in A Glass MatrixVigneshwaran MuruganNessuna valutazione finora

- Batch Measurements of Wood Density On Intact or Prepared Drill Cores Using X-Ray MicrodensitometryDocumento18 pagineBatch Measurements of Wood Density On Intact or Prepared Drill Cores Using X-Ray MicrodensitometrySeble GetachewNessuna valutazione finora

- 5 Pages XRD AssignmentDocumento5 pagine5 Pages XRD AssignmentZia ud din KhanNessuna valutazione finora

- Randle 2001Documento11 pagineRandle 2001Vallimanalan AsokanNessuna valutazione finora

- PROJECTDocumento2 paginePROJECTRajat TomarNessuna valutazione finora

- Method For Determining Crystal Grain Size by X-RayDocumento6 pagineMethod For Determining Crystal Grain Size by X-RayJulio César Huillca HuillcaNessuna valutazione finora

- Applied Sciences: From Far-Field To Near-Field Micro-And Nanoparticle Optical TrappingDocumento18 pagineApplied Sciences: From Far-Field To Near-Field Micro-And Nanoparticle Optical TrappingjuzinhaaNessuna valutazione finora

- Cathodoluminescence and DepthDocumento6 pagineCathodoluminescence and DepthCAMELIA Neagu-COGALNICEANUNessuna valutazione finora

- Dynamics of #Uidized-Bed Reactors. Development and Application of A New Multi-"Ber Optical ProbeDocumento10 pagineDynamics of #Uidized-Bed Reactors. Development and Application of A New Multi-"Ber Optical Probeaugustus1189Nessuna valutazione finora

- RBD ConceptDocumento14 pagineRBD ConceptAmar Bishram EkkaNessuna valutazione finora

- Sound Absorption Coefficient Measurement: Re-Examining The Relationship Between Impedance Tube and Reverberant Room methodsMcGrory Castro Gaussen Cabrera AAS 2012fDocumento8 pagineSound Absorption Coefficient Measurement: Re-Examining The Relationship Between Impedance Tube and Reverberant Room methodsMcGrory Castro Gaussen Cabrera AAS 2012fDaniel CastroNessuna valutazione finora

- III Growth of L-Proline Sodium Sulphate Single Crystals:) Group in Them (27) .Especially Some Amino Acid LikeDocumento16 pagineIII Growth of L-Proline Sodium Sulphate Single Crystals:) Group in Them (27) .Especially Some Amino Acid LikeramNessuna valutazione finora

- Simultaneous Control of Nanocrystal Size and Nanocrystal-Nanocrystal Separation in Cds Nanocrystal AssemblyDocumento6 pagineSimultaneous Control of Nanocrystal Size and Nanocrystal-Nanocrystal Separation in Cds Nanocrystal Assemblyprakush01975225403Nessuna valutazione finora

- Metasurface Broadband Solar AbsorberDocumento6 pagineMetasurface Broadband Solar AbsorberSumanjus MontesNessuna valutazione finora

- By Recording Spectrometer: Degree X-RayDocumento7 pagineBy Recording Spectrometer: Degree X-RaySamuel GideyNessuna valutazione finora

- X-Ray Diffraction Studies of Catalysts: It Is Now PossibleDocumento6 pagineX-Ray Diffraction Studies of Catalysts: It Is Now PossibleIsadora PereiraNessuna valutazione finora

- 1 s2.0 S0969804319301381 MainDocumento8 pagine1 s2.0 S0969804319301381 MainMara IacobNessuna valutazione finora

- Synthesis of Zns / Sodium Hexameta Phosphate Nanoparticles: R. Mohan, B. Rajamannan and S. SankarrajanDocumento6 pagineSynthesis of Zns / Sodium Hexameta Phosphate Nanoparticles: R. Mohan, B. Rajamannan and S. SankarrajanphysicsjournalNessuna valutazione finora

- DOAS-Differential Optical Absorption SpectrosDocumento9 pagineDOAS-Differential Optical Absorption SpectrosĐặng Hoàng DươngNessuna valutazione finora

- Lec 7 - X-RayDocumento32 pagineLec 7 - X-RayNur Izzati KzmnNessuna valutazione finora

- Diffraction Regimes of Single Holes: Week Ending 13 JULY 2012Documento5 pagineDiffraction Regimes of Single Holes: Week Ending 13 JULY 2012Fernando de León-PérezNessuna valutazione finora

- Peeyush Paper 2Documento7 paginePeeyush Paper 2ShreyaNessuna valutazione finora

- Basic Principles and Application of Electron Channeling in A Scanning Electron Microscope For Dislocation AnalysisDocumento8 pagineBasic Principles and Application of Electron Channeling in A Scanning Electron Microscope For Dislocation AnalysisMichael AbereNessuna valutazione finora

- Negative and Anomalous Refraction inDocumento166 pagineNegative and Anomalous Refraction inDaniel MoránNessuna valutazione finora

- 2018 - Nguyen - Evaluation of Multiplier Coefficients For A Pile Group Under Seismic Loading in Dry Loose SandDocumento8 pagine2018 - Nguyen - Evaluation of Multiplier Coefficients For A Pile Group Under Seismic Loading in Dry Loose SandBảo Ngọc NguyễnNessuna valutazione finora

- Ultra-Thin Wideband Polarization-Insensitive Metasurface Absorber For Aviation TechnologyDocumento7 pagineUltra-Thin Wideband Polarization-Insensitive Metasurface Absorber For Aviation TechnologyGHADANessuna valutazione finora

- ARR 190514 Book1Documento187 pagineARR 190514 Book1Jun Rey LincunaNessuna valutazione finora

- ARR 190514 Book2Documento199 pagineARR 190514 Book2Jun Rey LincunaNessuna valutazione finora

- Mod05 s06 Lfa Indicators Ho1 Toc Evidences Exampleethiopia 0Documento6 pagineMod05 s06 Lfa Indicators Ho1 Toc Evidences Exampleethiopia 0Jun Rey LincunaNessuna valutazione finora

- PET Final Evaluation ReportDocumento82 paginePET Final Evaluation ReportJun Rey LincunaNessuna valutazione finora

- Rptreceipt PDFDocumento2 pagineRptreceipt PDFJun Rey LincunaNessuna valutazione finora

- MECHANICS - Regional Robotics CompetitionDocumento3 pagineMECHANICS - Regional Robotics CompetitionJun Rey LincunaNessuna valutazione finora

- School Form 10 SF10 Learner's Permanent Academic Record For Junior High School - 0Documento8 pagineSchool Form 10 SF10 Learner's Permanent Academic Record For Junior High School - 0Jun Rey LincunaNessuna valutazione finora

- E H 1500-1700: A O C: Nglish Andwriting N Nline OurseDocumento3 pagineE H 1500-1700: A O C: Nglish Andwriting N Nline OurseJun Rey LincunaNessuna valutazione finora

- School Form 10 SF10 Learner Permanent Academic Record JHS Data Elements DescriptionDocumento3 pagineSchool Form 10 SF10 Learner Permanent Academic Record JHS Data Elements DescriptionJun Rey LincunaNessuna valutazione finora

- CM AllDocumento47 pagineCM AllJun Rey LincunaNessuna valutazione finora

- Lect 14. Enthalpy Calculations PDFDocumento18 pagineLect 14. Enthalpy Calculations PDFJun Rey LincunaNessuna valutazione finora

- Feynman PaperDocumento4 pagineFeynman PaperJun Rey LincunaNessuna valutazione finora

- Jackson SolutionsDocumento8 pagineJackson SolutionsJun Rey LincunaNessuna valutazione finora

- Fund - Elect DE52.Documento355 pagineFund - Elect DE52.atashi baran mohantyNessuna valutazione finora

- Job Safety Analysis Form: Law M. Mechanical Supervisor Alex A./ Egbejimi Adebayo PSCDocumento4 pagineJob Safety Analysis Form: Law M. Mechanical Supervisor Alex A./ Egbejimi Adebayo PSCChukwuma Emmanuel Onwufuju0% (1)

- Superpave Laboratory WorkshopDocumento62 pagineSuperpave Laboratory WorkshopAugusto M. ReyesNessuna valutazione finora

- 37 - Weldability and Performance of AHSSDocumento27 pagine37 - Weldability and Performance of AHSSsivaNessuna valutazione finora

- Plastic Waste Into FuelDocumento13 paginePlastic Waste Into FuelArul RajNessuna valutazione finora

- Behavior of Steel Under TensionDocumento6 pagineBehavior of Steel Under TensionAshNessuna valutazione finora

- (1967) History of The Lenz-Ising ModelDocumento13 pagine(1967) History of The Lenz-Ising ModelJakler NicheleNessuna valutazione finora

- Mod 7 23-09-09 Extras PDFDocumento23 pagineMod 7 23-09-09 Extras PDFU TubeNessuna valutazione finora

- 03 Lewabrane Manual System Design 03Documento13 pagine03 Lewabrane Manual System Design 03zamijakaNessuna valutazione finora

- Design of Syphon AqueductDocumento118 pagineDesign of Syphon AqueductGuru MurthyNessuna valutazione finora

- Standardization of Sodium Hydroxide: Experiment No. 1.2Documento8 pagineStandardization of Sodium Hydroxide: Experiment No. 1.2theressaNessuna valutazione finora

- 170 Gtaw&Smaw Zug Asme (Afri S 5g) WPQDocumento4 pagine170 Gtaw&Smaw Zug Asme (Afri S 5g) WPQMuhammad Fitransyah Syamsuar PutraNessuna valutazione finora

- Alchemy at The Crowning of NatureDocumento30 pagineAlchemy at The Crowning of NatureMano DasruthiNessuna valutazione finora

- Columbia Lighting Product Selection Guide Edition 3 1996Documento116 pagineColumbia Lighting Product Selection Guide Edition 3 1996Alan MastersNessuna valutazione finora

- Fosroc Dekguard E2000: (Also Known As Nitocote FBC)Documento4 pagineFosroc Dekguard E2000: (Also Known As Nitocote FBC)Tejinder KumarNessuna valutazione finora

- Aakash Rank Booster Test Series For NEET Aakash Rank Booster Test Series For NEET-2020 2020Documento12 pagineAakash Rank Booster Test Series For NEET Aakash Rank Booster Test Series For NEET-2020 2020VedNessuna valutazione finora

- Chem Record AnalysisDocumento7 pagineChem Record AnalysisKasi Bala Guru VNessuna valutazione finora

- Problem Set 1 Data Regression and Numerical Integration - 2013Documento3 pagineProblem Set 1 Data Regression and Numerical Integration - 2013April TanjayNessuna valutazione finora

- Ohe Fitting GuidelineDocumento56 pagineOhe Fitting Guidelinepretha56Nessuna valutazione finora

- Binary LiquidsDocumento8 pagineBinary LiquidsSuzanne Clariz M. BaltazarNessuna valutazione finora

- Solar Water HeaterDocumento14 pagineSolar Water Heaterapi-262592867Nessuna valutazione finora

- Lutrol L and Lutrol F-GradesDocumento8 pagineLutrol L and Lutrol F-GradeslovehopeNessuna valutazione finora

- Chem 40.1 Msds Exer 6Documento7 pagineChem 40.1 Msds Exer 6Angela Sietereales RamosNessuna valutazione finora

- ME Vol 2 FMDocumento364 pagineME Vol 2 FMDeepak Gupta100% (4)

- Steel Pipes and Tubes For Pressure Purposes: Carbon and Carbon Manganese Steel With Specified Elevated Temperature PropertiesDocumento24 pagineSteel Pipes and Tubes For Pressure Purposes: Carbon and Carbon Manganese Steel With Specified Elevated Temperature PropertiessyakirohNessuna valutazione finora

- Alcohols, Phenols and Ethers - MCQs Test - 3Documento3 pagineAlcohols, Phenols and Ethers - MCQs Test - 3Prasant KumarNessuna valutazione finora

- Uni of Frankfurt - Thermodynamic PotentialsDocumento15 pagineUni of Frankfurt - Thermodynamic PotentialstaboogaNessuna valutazione finora

- Design of Cold Storage Structure For Thousand PDFDocumento8 pagineDesign of Cold Storage Structure For Thousand PDFzhyhhNessuna valutazione finora

- AD-761 644 Structural and Force Diagrams of The Landing Gear V. L. Belskii, Et AlDocumento42 pagineAD-761 644 Structural and Force Diagrams of The Landing Gear V. L. Belskii, Et Alebooks list1Nessuna valutazione finora