Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Catalogue

Caricato da

Erica BeasleyTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Catalogue

Caricato da

Erica BeasleyCopyright:

Formati disponibili

5, Moldavskaya str., Moscow, 121 467, Russia, +7 (495) 411-7757, office@ogscomp.ru, www.oilgassystems.

com

CONTENTS

COMPANIES

Tyazhpromarmatura JSC

Privod-AZTPA Trading House

4

5

SLIDE GATE VALVES

Slide gate valves with electric actuator

DN 250, 300, 350, 400, 500, 600, 700, 800, 1000, 1050, 1200 mm

PN 1.6, 2.5, 4.0, 6.3, 8.0, 10.0, 12.5, 15.0 MPa

Slide gate valves with electric actuator or manual operation

DN 300, 350, 400, 500, 600, 700, 800, 1000, 1050, 1200 mm

PN 6.3, 8.0, 10.0, 12.5, 15.0 MPa

Slide gate valves with electric actuator or manual operation

DN 250, 300, 350, 400, 500, 600, 700, 800, 1000, 1200 mm

PN 1.6, 2.5, 4.0 MPa

13

CHECK VALVES

Check Valves

DN 300, 350, 400, 500, 600, 700, 800, 1000, 1050, 1200 mm

PN 8.0, 10.0, 12.5 MPa

18

BALL VALVES FOR NATURAL GAS

Ball valves with manual operation, pneumatic actuator or electric actuator

DN 50, 80/50, 80, 100 mm

PN 8.0, 16.0 MPa

for welding

flanged

22

23

26

Ball valves with manual operation, pneudraulic, electric or electro-hydraulic actuator

DN 150, 200, 300, 400, 500, 600, 700, 800, 1000, 1050, 1200, 1400 mm

PN 8.0, 10.0, 12.5, 16.0 MPa

29

DN 150 mm

PN 8.0, 12.5, 16.0 MPa (for welding)

31

DN 150 mm

PN 8.0, 12.5, 16.0 MPa (flanged)

33

DN 200, 300 mm

PN 8.0, 10.0, 12.5, 16.0 MPa

35

DN 400, 500 mm

PN 8.0, 10.0, 12.5, 16.0 MPa

39

DN 600, 700, 800, 1000, 1050 mm

PN 8.0, 10.0, 12.5 MPa

43

DN 1200, 1400 mm

PN 8.0, 10.0, 12.5 MPa

48

Ball valves of buried installation

DN 50, 80, 100, 150, 200, 250, 300, 400, 500, 700 mm

PN 1.6 MPa

50

5, Moldavskaya str., Moscow, 121 467, Russia, +7 (495) 411-7757, office@ogscomp.ru, www.oilgassystems.com

Ball valves of aboveground installation

DN 50, 80, 100, 150, 200, 250, 300 mm

PN 1.6 MPa

with manual operation

with electric actuator

52

53

54

BALL VALVES WITH MANUAL CONTROL OR WITH AN ELECTRIC ACTUATOR FOR TRANSPORTATION

OF CORROSIVE NATURAL GAS WITH HIGH METHANOL AND HYDROGEN SULFIDE CONTENT

DN 50, 80, 100, 150, 200, 300, 400, 500, 700

PN 16.0 MPa

with high methanol content

with high hydrogen sulfide content

56

59

BALL VALVES FOR OIL AND OIL PRODUCTS

Ball valves for manual operation or electric actuator

DN 50, 80, 100, 150, 200, 250, 300, 400, 500, 600, 700, 800, 1000, 1200 mm

PN 1.6, 6.3, 10.0, 16.0 MPa

with manual operation

with electric actuator

62

63

72

BALL VALVES FOR HEAT-AND-WATER SUPPLY SYSTEMS

Ball valves with manual operation

DN 50, 80, 100, 150, 200, 250, 300 mm

PN 1.6 MPa

81

Ball valves with manual operation or electric actuator

DN 25, 32, 40, 50, 80, 100, 150, 200, 250, 300, 400, 500 mm

PN 2.5 MPa

83

Ball valves of chambered/aboveground installation, with manual operation

PN 2.5 MPa

84

Ball valves for buried installation without the column, with manual operation (for T-shaped wrench)

PN 2.5 MPa

86

Ball valves for buried installation with the column, with manual operation (for -shaped wrench)

PN 2.5 MPa

87

Ball valves of chambered/aboveground installation, with manual operation (gearbox with handwheel)

PN 2.5 MPa

88

Ball valves of chambered/aboveground installation, with electric actuator

PN 2.5 MPa

89

WEDGE GATE VALVES

Wedge gate valves with manual operation or electric actuator

DN 100, 150, 200, 250, 300, 350, 400, 500, 600, 700, 800, 1000, 1200 mm

PN 1.6, 2.5, 4.0, 6.3, 8.0, 10.0 MPa

90

with manual operation (handwheel), flanged

DN 100, 150, 200, 250, 300, 350, 400 mm

PN 1.6, 2.5, 4.0, 6.3, 10.0 MPa

91

with manual operation (gearbox), flanged

DN 150, 200, 250, 300, 350, 400, 500, 600, 700, 800, 1000 mm

PN 1.6, 2.5, 4.0, 6.3, 10.0 MPa

93

with manual operation (handwheel), for welding

DN 250, 300, 350, 400 mm

PN 1.6, 2.5 MPa

95

5, Moldavskaya str., Moscow, 121 467, Russia, +7 (495) 411-7757, office@ogscomp.ru, www.oilgassystems.com

with manual operation (gearbox), for welding

DN 150, 250, 300, 350, 400, 500, 600, 700, 800, 1000 mm

PN 1.6, 2.5, 4.0, 6.3, 10.0 MPa

96

with electric actuator, flanged

DN 100, 150, 250, 300, 350, 400, 500, 600, 700, 800, 1000, 1200 mm

PN 1.6, 2.5, 4.0, 6.3, 10.0 MPa

98

with electric actuator, for welding

DN 150, 250, 300, 350, 400, 500, 600, 700, 800, 1000, 1200 mm

PN 1.6, 2.5, 4.0, 6.3, 8.0, 10.0 MPa

101

Wedge gate valves with manual operation (air escape connection)

DN 100, 150 mm

PN 6.3 MPa

104

SAFETY VALVES

Safety Valves

DN 200 mm

PN 1.6, 2.5 MPa

105

SPECIAL VALVES

Special valves designed for nuclear power stations

106

Wedge gate valves for welding

DN 80, 100, 125, 150, 200, 250, 300, 350, 400, 450, 500, 600, 800 mm

Pp 1.1, 1.4, 1.6, 1.96, 2.5, 4.0, 5.5, 6.0, 8.6, 9.2, 11.0, 12.0, 12.5, 14.0, 17.6, 18.0, 20.0, 24.5 MPa

107

Check valves for welding

DN 100, 125, 300, 400, 600 mm

Pp 5.5, 8.6, 11.0, 12.0, 18.0, 20.0 MPa

113

Special valves designed for heat power stations

114

HOMING DEVICES

Electro-hydraulic actuators

Pneudraulic actuators

Gearboxes

120

122

124

5, Moldavskaya str., Moscow, 121 467, Russia, +7 (495) 411-7757, office@ogscomp.ru, www.oilgassystems.com

Tyazhpromarmatura JSC (Aleksin Plant of Heavy Industrial Valves) is one of the largest and oldest plants

in the Russian machinery building industry.

The plant was founded in 1728. More than 70 years it has been specializing in design and manufacture of pipeline valves for oil and gas,

chemical and power engineering industries. This period has evidenced a lot of design solutions and manufacture of a full line of ball valves,

check valves, wedge gate valves and slide gate valves.

High-quality of the products and up-to-date design solutions allow the plant to hold the leading positions among suppliers of equipment for gas

and oil production and transport companies for many years.

Tyazhpromarmatura JSC has its own steel-making and blank production. State-of-the-art high-efficient mechanical processing equipment

makes it possible to machine workpieces of up to 4 m in diameter and of up to 30 t in weight, and welding of units of up to 25 t in weight

and welding diameter of up to 3 m.

QUALITY

The quality management system of Tyazhpromarmatura JSC is certified in accordance with ISO 9001:2008 and GOST R ISO 9001-2008

standards for design and manufacture of pipeline valves.

Since 1997 the plant has had a license of the American Petroleum Institute to use the Official Monogram API, and Specification 6D.

Product quality control is carried out with the use of various methods including non-destructive examination (radiography, ultrasound,

dye penetrant and magnetic particles) which involve up-to-date equipment.

Work with ustomers is under a strict control of the Russian regulatory agencies (including NP SC Nasthall certification center and Neftsertico

certification agency) and internationally recognized auditors such as Moody International, ILF, and Bureau Veritas General Conditions.

PRODUCTS

Tyazhpromarmatura JSC manufactures a wide range of ball valves:

Ball valves for gas, oil, petroleum product and non-aggressive fluids (gas, water, steam) of DN 101.400 mm, PN 1.616.0 MPa;

Slide gate valves of DN 2501.200 mm, PN 1.615.0 MPa;

Wedge gate valves of DN 1001.200 mm, PN 1.610.0 MPa;

Actuators and reduction gears for pipeline valves control;

Special-purpose valves for nuclear and thermal power stations.

New products:

Electrohydraulic drives (EHD) for ball valves of DN 3001.400 mm;

Check valves for oil and petroleum product lines of DN 3001.200 mm PN 8.012.5 MPa;

Ball valves of DN 50700 mm PN 16.0 MPa for fluids with high methanol and hydrogen sulphide content.

Annually the plant manufactures over 25.000 valves including valves of diameter DN 50 1.400 mm.

PRODUCT SUPPLY

Products of Tyazhpromarmatura JSC are much in demand in Russia and abroad.

The company supplies equipment for major facilities in the fuel and energy complex. Permanent customers include major oil and gas companies

in Russia and CIS.

Tyazhpromarmatura JSC

60, Nekrasova str., Aleksin, Tula Region, 301368, Russia

Tel. +7 (48753) 46-675, 46-307

Fax +7 (48753) 27-120

office@aztpa.ru

www.aztpa.ru

Exclusive supplier of the products manufactured by the plant

PrivodAZTPA Trading House.

5, Moldavskaya str., Moscow, 121 467, Russia, +7 (495) 411-7757, office@ogscomp.ru, www.oilgassystems.com

Privod-AZTPA Trading House

is dealing in the market of specialized equipment since 2003

(prior to 2010 known as Oil and Gas Systems).

Central office is located in Moscow; affiliate offices in Aleksin, Lysva, St. Petersburg and Ekaterinburg.

Privod-AZTPA Trading House is supplying the equipment to largest power plants and transport machinery facilities.

Participation in the Transport and Energy Complex projects:

Gas Pipelines: Bovanenkovo Ukhta Gas Trunkline System, North-European (Nord Stream) Gas Pipeline, Sakhalin Khabarovsk Vladivostok

Gas Transmission System, Yamal Europe Transnational Gas Pipeline, Blue Stream (Russia Turkey) Gas Pipeline, Zapolyarnoye Urengoy Gas

Pipeline, SRTO Torzhok Gas Trunkline, Ukhta Torzhok Gas Pipeline, Central Asia Center Gas Pipeline System, Trans-Asia Gas Pipeline;

Oil Pipelines: East Siberia Pacific Ocean, Baltic pipeline systems, Kazakhstan-China;

Projects: Sakhalin-1, Sakhalin-2.

The following electrical generators are supplied:

In Power Generation sector:

INTER RAO UES, RusHydro JSC, Quadra Power Generation JSC, IES CJSC, Mosenergo, Irkutskenergo JSC, OGK-6 JSC, OGK-2 JSC, SGC

TGK-8, TGC-2 JSC, TGC-11 OJSC, TGC-14 OJSC, and others.

In Oil and Gas sector:

Gazprom, Gazprom Neft, LUKOIL, Surgutneftegaz OJSC, Rosneft, TNK-BP, RussNeft, TATNEFT and others.

In Metallurgic Industry:

NLMK, UC Rusal, Mechel, EVRAZ Group S.A., Tulachermet, MMK, Severstal, and others.

In Chemical Industry:

EuroChem, PhosAgro, Soda JSC, SIBUR, Kuchuksulphate JSC and others.

In Transportation sectors:

Transmashholding CJSC, SinaraTransport Machines and others.

For Nuclear Power Plant:

Leningrad NPP, Novovoronezh NPP-2, Rostov NPP, Beloyarsk NPP, Kursk NPP, Smolensk NPP, Kalinin NPP and others.

Privod-AZTPA Trading House an exclusive supplier of products of Russian leading machine-building companies:

Tyazhpromarmatura JSC (Tula Region, Aleksin) manufacturer of pipeline valves designed for gas, petroleum, chemical, power, nuclear

and other industries;

Electrotyazhmash-Privod LLC (Perm Territory, Lysva) developer and manufacturer of turbo-generators, hydro-generators, dieselgenerators,

synchronous and asynchronous electric motors, haulage equipment for main and shunting locomotives, electric locomotives.

5, Moldavskaya str., Moscow, 121 467, Russia

+7 (495) 411-7757

office@ogscomp.ru

www.oilgassystems.com

www.privod-aztpa.com

5, Moldavskaya str., Moscow, 121 467, Russia, +7 (495) 411-7757, office@ogscomp.ru, www.oilgassystems.com

SLIDE GATE VALVES

Slide gate valves with electric actuator

DN 250, 300, 350, 400, 500, 600, 700, 800, 1000, 1050, 1200 mm

PN 1.6, 2.5, 4.0, 6.3, 8.0, 10.0, 12.5, 15.0 MPa

Slide gate valves are used as a shut-off device for blocking working medium flow in main oil and oil products pipelines, in processing lines of pumping stations

and tank batteries with working medium temperature from -15 up to +80.

The obturator leakproofness meets class A (GOST 9544-2005).

Connection to pipeline welding, flanged. The gate valves may be manufactured for the pipe size specified by the customer.

Climatic version:

mild (ambient temperature from -40 up to +40C);

cold (ambient temperature from -60 up to +40C).

Slide gate valves are manufactured with electric or manual operation. The gate valves may be completed with electric actuators made by various manufacturers.

The slide gate valves are produced for buried and aboveground installation. The gate valves of buried installation may be coated by anticorrosion polymer layer

of reinforced type.

Materials

body,

bonnet

stem

slide

steel 20, 20L for N1;

steel 09G2S, 20GML for F1

steel 13H11N2V2MF

steel 40, 45, + r 30 mkm

sealings

elastomer, polyurethane

The full service life of gate valves at least 50 years.

The warranty life is 24 months from the date of commissioning provided that the storage life does not exceed 36 months

from the date of gate valve shipment to the customer.

Manufacturing and supply (including supplies to areas with seismicity up to 10 points according to the scale MSK-64)

is carried out with factory corrosion-resistant coating.

Production and supply meet requirements of TU 374137-002-05785572-97.

Design features and advantages:

low hydraulic resistance;

capability to be pigged and tested by diagnostic devices;

relatively low electric actuator power required;

absence of dead spaces;

availability of device limiting the downmotion of stem (position open).

5, Moldavskaya str., Moscow, 121 467, Russia, +7 (495) 411-7757, office@ogscomp.ru, www.oilgassystems.com

Slide gate valves with electric actuator or manual operation

DN 300, 350, 400, 500, 600, 700, 800, 1000, 1050, 1200 mm

PN 6.3, 8.0, 10.0, 12.5, 15.0 MPa

The sizes D3 and D4 shall be

defined more precisely when

ordering for specific pipe

size

Fig. 1

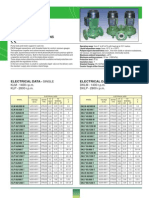

OVERALL AND MOUNTING DIMENSIONS

Designation

The mass and the sizes are specified for reference

DN,

mm

PN,

MPa

'P,

MPa

B1

300

6.3

6.3

735

735

1550

300

8.0

8.0

735

735

735

H4

H2

H1

m*, kg,

max

3175

915

725

1620

1850

1550

3175

915

725

1620

1900

735

1550

3175

915

725

1620

1900

735

735

1550

3175

915

725

1620

1900

1760

2240

770

770

1650

960

757

1765

2240

mm

ZSH-300-6.3-'P6.3-Sv-EP--N1

ZSH-300-6.3-'P6.3-Sv-EP--F1

ZSH-300-6.3-'P6.3-Sv-RU--N1

ZSH-300-6.3-'P6.3-Sv-RU--F1

ZSH-300-8.0-'P8.0-Sv-EP--N1

ZSH-300-8.0-'P8.0-Sv-EP--F1

ZSH-300-8.0-'P8.0-Sv-RU--N1

ZSH-300-8.0-'P8.0-Sv-RU--F1

ZSH-300-10.0-'P5.0-Sv-EP--N1

5.0

ZSH-300-10.0-'P5.0-Sv-EP--F1

ZSH-300-10.0-'P10.0-Sv-EP--N1

ZSH-300-10.0-'P10.0-Sv-EP--F1

300

10.0

10.0

ZSH-300-10.0-'P10.0-Sv-RU--N1

ZSH-300-10.0-'P10.0-Sv-RU--F1

ZSH-300-12.5-'P5.0-Sv-EP--N1

5.0

ZSH-300-12.5-'P5.0-Sv-EP--F1

ZSH-300-12.5-'P8.0-Sv-EP--N1

ZSH-300-12.5-'P8.0-Sv-EP--F1

ZSH-300-12.5-'P10.0-Sv-EP--N1

8.0

300

12.5

ZSH-300-12.5-'P10.0-Sv-EP--F1

10.0

ZSH-300-12.5-'P10.0-Sv-RU--N1

ZSH-300-12.5-'P10.0-Sv-RU--F1

ZSH-350-6.3-'P6.3-Sv-EP--N1

ZSH-350-6.3-'P6.3-Sv-EP--F1

ZSH-350-6.3-'P6.3-Sv-RU--N1

ZSH-350-6.3-'P6.3-Sv-RU--F1

3740

350

6.3

6.3

2980

5, Moldavskaya str., Moscow, 121 467, Russia, +7 (495) 411-7757, office@ogscomp.ru, www.oilgassystems.com

Designation

DN,

mm

PN,

MPa

'P,

MPa

350

8.0

8.0

770

B1

ZSH-350-8.0-'P8.0-Sv-RU--N1

1650

960

757

2980

ZSH-350-10.0-'P10.0-Sv-EP--N1

ZSH-350-10.0-'P10.0-Sv-RU--N1

H2

3740

770

ZSH-350-8.0-'P8.0-Sv-RU--F1

ZSH-350-10.0-'P10.0-Sv-EP--F1

H4

3740

350

10.0

10.0

H1

m*, kg,

max

1760

2240

1765

2240

1760

2240

1765

2240

mm

ZSH-350-8.0-'P8.0-Sv-EP--N1

ZSH-350-8.0-'P8.0-Sv-EP--F1

770

770

1650

960

757

2980

ZSH-350-10.0-'P10.0-Sv-RU--F1

ZSH-400-6.3-'P6.3-Sv-EP--N1

ZSH-400-6.3-'P6.3-Sv-EP--F1

ZSH-400-6.3-'P6.3-Sv-RU--N1

400

6.3

6.3

860

860

1700

3485

1090

860

1945

2850

400

8.0

8.0

860

860

1700

3485

1090

860

1945

2850

860

860

1700

3485

1090

860

1945

2850

860

860

1700

3485

1090

860

1945

2850

985

900

1900

4427

1245

980

2225

4500

985

900

1900

4427

1245

980

2225

4500

985

900

1900

4427

1245

980

2225

ZSH-400-6.3-'P6.3-Sv-RU--F1

ZSH-400-8.0-'P8.0-Sv-EP--N1

ZSH-400-8.0-'P8.0-Sv-EP--F1

ZSH-400-8.0-'P8.0-Sv-RU--N1

ZSH-400-8.0-'P8.0-Sv-RU--F1

ZSH-400-10.0-'P5.0-Sv-EP--N1

5.0

ZSH-400-10.0-'P5.0-Sv-EP--F1

ZSH-400-10.0-'P10.0-Sv-EP--N1

ZSH-400-10.0-'P10.0-Sv-EP--F1

400

10.0

10.0

ZSH-400-10.0-'P10.0-Sv-RU--N1

ZSH-400-10.0-'P10.0-Sv-RU--F1

ZSH-400-12.5-'P5.0-Sv-EP--N1

5.0

ZSH-400-12.5-'P5.0-Sv-EP--F1

ZSH-400-12.5-'P8.0-Sv-EP--N1

ZSH-400-12.5-'P8.0-Sv-EP--F1

ZSH-400-12.5-'P10.0-Sv-EP--N1

8.0

400

12.5

ZSH-400-12.5-'P10.0-Sv-EP--F1

10.0

ZSH-400-12.5-'P10.0-Sv-RU--N1

ZSH-400-12.5-'P10.0-Sv-RU--F1

ZSH-500-6.3-'P3.0-Sv-EP--N1

3.0

ZSH-500-6.3-'P3.0-Sv-EP--F1

ZSH-500-6.3-'P5.0-Sv-EP--N1

ZSH-500-6.3-'P5.0-Sv-EP--F1

500

6.3

ZSH-500-6.3-'P6.3-Sv-EP--N1

6.3

ZSH-500-6.3-'P6.3-Sv-EP--F1

ZSH-500-8.0-'P5.0-Sv-EP--N1

ZSH-500-8.0-'P5.0-Sv-EP--F1

ZSH-500-8.0-'P8.0-Sv-EP--N1

5.0

500

8.0

8.0

ZSH-500-8.0-'P8.0-Sv-EP--F1

ZSH-500-10.0-'P5.0-Sv-EP--N1

ZSH-500-10.0-'P5.0-Sv-EP--F1

ZSH-500-10.0-'P10.0-Sv-EP--N1

5.0

500

10.0

ZSH-500-12.5-'P5.0-Sv-EP--N1

4500

500

12.5

ZSH-500-12.5-'P10.0-Sv-EP--N1

ZSH-600-6.3-'P3.0-Sv-EP--N1

ZSH-600-6.3-'P6.3-Sv- EP--N1

ZSH-600-6.3-'P6.3-Sv- EP--F1

985

900

1900

4427

1245

980

2225

4600

3.0

ZSH-600-6.3-'P3.0-Sv-EP--F1

ZSH-600-6.3-'P5.0-Sv -EP--F1

8.0

10.0

ZSH-500-12.5-'P10.0-Sv-EP--F1

ZSH-600-6.3-'P5.0-Sv -EP--N1

4600

5.0

ZSH-500-12.5-'P5.0-Sv-EP--F1

ZSH-500-12.5-'P8.0-Sv-EP--F1

4500

10.0

ZSH-500-10.0-'P10.0-Sv-EP--F1

ZSH-500-12.5-'P8.0-Sv-EP--N1

5.0

6100

600

6.3

5.0

6.3

1160

1160

2400

5100

1387

1230

2445

6505

5, Moldavskaya str., Moscow, 121 467, Russia, +7 (495) 411-7757, office@ogscomp.ru, www.oilgassystems.com

Designation

DN,

mm

PN,

MPa

ZSH-600-8.0-'P3.0-Sv-EP--N1

ZSH-600-8.0-'P5.0-Sv -EP--F1

8.0

ZSH-600-10.0-'P3.0-Sv-EP--N1

10.0

ZSH-600-10.0-'P10.0-Sv- EP--F1

ZSH-700-6.3-'P3.0-Sv-EP--N1

ZSH-700-6.3-'P3.0-Sv-EP--F1

700

6.3

ZSH-700-6.3-'P6.3-Sv-EP--N1

ZSH-700-8.0-'P3.0-Sv-EP--N1

700

8.0

ZSH-700-8.0-'P8.0-Sv-EP--N1

ZSH-700-8.0-'P8.0-Sv-EP--F1

ZSH-700-10.0-'P3.0-Sv-EP--N1

ZSH-700-10.0-'P3.0-Sv-EP--F1

ZSH-700-10.0-'P5.0-Sv-EP--N1

ZSH-700-10.0-'P5.0-Sv-EP--F1

700

10.0

ZSH-700-10.0-'P10.0-Sv-EP--N1

ZSH-700-10.0-'P10.0-Sv-EP--F1

ZSH-700-12.5-'P3.0-Sv-EP--N1

ZSH-700-12.5-'P3.0-Sv-EP--F1

ZSH-700-12.5-'P5.0-Sv-EP--N1

ZSH-700-12.5-'P5.0-Sv-EP--F1

ZSH-700-12.5-'P8.0-Sv-EP--N1

800

6.3

ZSH-800-8.0-'P3.0-Sv-EP--N1

1230

2445

6495

1160

1160

2400

4410

1387

1230

2445

10.0

6495

3.0

10000

5.0

1265

1250

2550

5726

1505

1405

2690

10140

10200

1265

1250

2550

5726

1505

1405

2690

1265

1250

2550

5726

1505

1405

2690

10000

10140

5.0

8.0

10200

3.0

10000

5.0

1265

1250

2550

5726

1505

1405

2690

10140

10.0

10200

3.0

10000

10150

1265

1250

2550

5726

1505

1405

2690

5.0

1440

1250

2700

6565

1697

1625

3045

13650

1440

1250

2700

6565

1697

1625

3045

13650

1440

1250

2700

6565

1697

1625

3045

3.0

ZSH-800-8.0-'P3.0-Sv-EP--F1

800

8.0

ZSH-800-8.0-'P8.0-Sv-EP--N1

5.0

8.0

ZSH-800-8.0-'P8.0-Sv-EP--F1

ZSH-800-10.0-'P3.0-Sv-EP--N1

3.0

ZSH-800-10.0-'P3.0-Sv-EP--F1

ZSH-800-10.0-'P10.0-Sv-EP--F1

4410

6.3

ZSH-800-6.3-'P6.3-Sv-EP--F1

ZSH-800-10.0-'P5.0-Sv-EP--F1

2400

3.0

ZSH-800-6.3-'P6.3-Sv-EP--N1

ZSH-800-10.0-'P10.0-Sv-EP--N1

1160

10200

ZSH-800-6.3-'P3.0-Sv-EP--F1

ZSH-800-10.0-'P5.0-Sv-EP--N1

1160

10.0

ZSH-700-12.5-'P10.0-Sv-EP--F1

ZSH-800-8.0-'P5.0-Sv-EP--F1

1387

mm

m*, kg,

max

8.0

ZSH-800-6.3-'P3.0-Sv-EP--N1

ZSH-800-8.0-'P5.0-Sv-EP--N1

5.0

12.5

ZSH-700-12.5-'P10.0-Sv-EP--N1

ZSH-800-6.3-'P5.0-Sv-EP--F1

H1

5.0

700

ZSH-700-12.5-'P8.0-Sv-EP--F1

ZSH-800-6.3-'P5.0-Sv-EP--N1

5.0

3.0

ZSH-700-8.0-'P3.0-Sv-EP--F1

ZSH-700-8.0-'P5.0-Sv-EP--F1

H2

6.3

ZSH-700-6.3-'P6.3-Sv-EP--F1

ZSH-700-8.0-'P5.0-Sv-EP--N1

H4

6090

600

ZSH-600-10.0-'P10.0-Sv- EP--N1

ZSH-700-6.3-'P5.0-Sv-EP--F1

3.0

ZSH-600-10.0-'P3.0-Sv-EP--F1

ZSH-700-6.3-'P5.0-Sv-EP--N1

8.0

ZSH-600-8.0-'P8.0-Sv- EP--F1

ZSH-600-10.0-'P5.0-Sv -EP--F1

B1

6090

600

ZSH-600-8.0-'P8.0-Sv- EP--N1

ZSH-600-10.0-'P5.0-Sv -EP--N1

3.0

ZSH-600-8.0-'P3.0-Sv-EP--F1

ZSH-600-8.0-'P5.0-Sv -EP--N1

'P,

MPa

13650

800

10.0

5.0

10.0

13750

5, Moldavskaya str., Moscow, 121 467, Russia, +7 (495) 411-7757, office@ogscomp.ru, www.oilgassystems.com

Designation

DN,

mm

PN,

MPa

ZSH-800-12.5-'P3.0-Sv-EP--N1

800

12.5

ZSH-800-12.5-'P10.0-Sv-EP--N1

ZSH-800-12.5-'P10.0-Sv-EP--F1

ZSH-1000-6.3-'P3.0-Sv-EP--N1

ZSH-1000-6.3-'P3.0-Sv-EP--F1

ZSH-1000-6.3-'P5.0-Sv-EP--N1

1000

6.3

ZSH-1000-6.3-'P6.3-Sv-EP--N1

ZSH-1000-6.3-'P6.3-Sv-EP--F1

ZSH-1000-8.0-'P3.0-Sv-EP--N1

ZSH-1000-8.0-'P3.0-Sv-EP--F1

ZSH-1000-8.0-'P5.0-Sv-EP--N1

ZSH-1000-8.0-'P5.0-Sv-EP--F1

ZSH-1000-8.0-'P7.0-Sv-EP--N1

ZSH-1000-8.0-'P8.0-Sv-EP--F1

ZSH-1000-10.0-'P3.0-Sv-EP--N1

ZSH-1000-10.0-'P5.0-Sv-EP--N1

ZSH-1000-10.0-'P7.0-Sv-EP--N1

ZSH-1000-10.0-'P10.0-Sv-EP--N1

6565

1697

1625

3045

15950

10.0

16050

3.0

20460

5.0

1770

1600

3000

7920

2087

2020

3640

20620

6.3

20680

3.0

20460

20620

1770

1600

3000

7920

2087

2020

3640

7.0

20680

8.0

20850

1790

1600

3000

7920

2087

2020

3640

25000

10.0

ZSH-1000-12.5-'P3.0-Sv-EP--N1

ZSH-1000-12.5-'P3.0-Sv-EP--F1

ZSH-1000-12.5-'P5.0-Sv-EP--N1

ZSH-1000-12.5-'P5.0-Sv-EP--F1

ZSH-1000-12.5-'P7.0-Sv-EP--N1

3.0

24580

5.0

24750

7.0

1000

12.5

24850

1790

1600

3000

7920

2087

2020

3640

8.0

ZSH-1000-12.5-'P8.0-Sv-EP--F1

ZSH-1000-12.5-'P9.0-Sv-EP--N1

9.0

ZSH-1000-12.5-'P9.0-Sv-EP--F1

ZSH-1000-12.5-'P10.0-Sv-EP--N1

25000

10.0

ZSH-1000-12.5-'P10.0-Sv-EP--F1

ZSH-1050-6.3-'P3.0-Sv-EP--N1

3.0

ZSH-1050-6.3-'P3.0-Sv-EP--F1

10

2700

9.0

ZSH-1000-10.0-'P10.0-Sv-EP--F1

ZSH-1050-6.3-'P6.3-Sv-EP--F1

1250

8.0

ZSH-1000-10.0-'P9.0-Sv-EP--F1

ZSH-1050-6.3-'P6.3-Sv-EP--N1

1440

10.0

ZSH-1000-10.0-'P8.0-Sv-EP--F1

ZSH-1050-6.3-'P5.0-Sv-EP--F1

mm

m*, kg,

max

7.0

1000

ZSH-1000-10.0-'P9.0-Sv-EP--N1

ZSH-1050-6.3-'P5.0-Sv-EP--N1

H1

5.0

ZSH-1000-10.0-'P5.0-Sv-EP--F1

ZSH-1000-12.5-'P8.0-Sv-EP--N1

H2

3.0

ZSH-1000-10.0-'P3.0-Sv-EP--F1

ZSH-1000-12.5-'P7.0-Sv-EP--F1

H4

8.0

8.0

ZSH-1000-8.0-'P8.0-Sv-EP--N1

ZSH-1000-10.0-'P8.0-Sv-EP--N1

5.0

1000

ZSH-1000-8.0-'P7.0-Sv-EP--F1

ZSH-1000-10.0-'P7.0-Sv-EP--F1

5.0

ZSH-800-12.5-'P8.0-Sv-EP--F1

ZSH-1000-6.3-'P5.0-Sv-EP--F1

B1

13650

ZSH-800-12.5-'P5.0-Sv-EP--N1

ZSH-800-12.5-'P8.0-Sv-EP--N1

3.0

ZSH-800-12.5-'P3.0-Sv-EP--F1

ZSH-800-12.5-'P5.0-Sv-EP--F1

'P,

MPa

22650

1050

6.3

5.0

6.3

1790

1600

3050

8050

2087

2020

3666

23200

5, Moldavskaya str., Moscow, 121 467, Russia, +7 (495) 411-7757, office@ogscomp.ru, www.oilgassystems.com

Designation

DN,

mm

PN,

MPa

ZSH-1050-8.0-'P3.0-Sv-EP--N1

1050

8.0

ZSH-1050-8.0-'P8.0-Sv-EP--N1

ZSH-1050-8.0-'P8.0-Sv-EP--F1

ZSH-1050-10.0-'P3.0-Sv-EP--N1

1050

ZSH-1050-10.0-'P10.0-Sv-EP--N1

ZSH-1050-12.5-'P3.0-Sv-EP--N1

1050

ZSH-1050-12.5-'P10.0-Sv-EP--N1

ZSH-1050-15.0-'P5.0-Sv-EP--N1

ZSH-1200-6.3-'P3.0-Sv-EP--F1

1200

6.3

ZSH-1200-6.3-'P6.3-Sv-EP--N1

ZSH-1200-8.0-'P2.0-Sv-EP--N1

1200

8.0

ZSH-1200-8.0-'P7.0-Sv-EP--N1

3050

8050

2087

2020

4080

23200

10.0

24300

2020

1600

3050

8100

2087

2020

3795

7.0

24200

10.0

24650

25700

1845

1600

3050

8160

2120

2040

3827

10.0

25850

3.0

26630

5.0

1970

1600

3150

8985

2327

2260

4080

26850

27100

5.0

1970

1600

3150

8985

2327

2260

4080

26850

27100

ZSH-1200-8.0-'P8.0-Sv-EP--N1

8.0

ZSH-1200-8.0-'P8.0-Sv-EP--F1

ZSH-1200-10.0-'P3.0-Sv-EP--N1

ZSH-1200-10.0-'P3.0-Sv-EP--F1

ZSH-1200-10.0-'P5.0-Sv-EP--N1

ZSH-1200-10.0-'P5.0-Sv-EP--F1

ZSH-1200-10.0-'P7.0-Sv-EP--N1

ZSH-1200-10.0-'P10.0-Sv-EP--F1

1600

7.0

ZSH-1200-8.0-'P7.0-Sv-EP--F1

ZSH-1200-10.0-'P9.0-Sv-EP--F1

1970

7.0

3.0

ZSH-1200-8.0-'P3.0-Sv-EP--F1

ZSH-1200-10.0-'P10.0-Sv-EP--N1

24300

26630

ZSH-1200-8.0-'P3.0-Sv-EP--N1

ZSH-1200-10.0-'P8.0-Sv-EP--F1

3666

2.0

ZSH-1200-8.0-'P2.0-Sv-EP--F1

ZSH-1200-10.0-'P9.0-Sv-EP--N1

2020

6.3

ZSH-1200-6.3-'P6.3-Sv-EP--F1

ZSH-1200-10.0-'P8.0-Sv-EP--N1

2087

8.0

15.0

ZSH-1200-6.3-'P3.0-Sv-EP--N1

ZSH-1200-10.0-'P7.0-Sv-EP--F1

8050

5.0

1050

ZSH-1050-15.0-'P10.0-Sv-EP--F1

ZSH-1200-8.0-'P5.0-Sv-EP--F1

3050

23200

12.5

ZSH-1050-12.5-'P10.0-Sv-EP--F1

ZSH-1200-8.0-'P5.0-Sv-EP--N1

1600

5.0

ZSH-1050-12.5-'P7.0-Sv-EP--F1

ZSH-1200-6.3-'P5.0-Sv-EP--F1

1790

23650

ZSH-1050-12.5-'P5.0-Sv-EP--N1

ZSH-1200-6.3-'P5.0-Sv-EP--N1

mm

m*, kg,

max

3.0

ZSH-1050-12.5-'P3.0-Sv-EP--F1

ZSH-1050-15.0-'P10.0-Sv-EP--N1

H1

7.0

10.0

ZSH-1050-10.0-'P10.0-Sv-EP--F1

ZSH-1050-15.0-'P5.0-Sv-EP--F1

H2

5.0

ZSH-1050-10.0-'P7.0-Sv-EP--F1

ZSH-1050-12.5-'P5.0-Sv-EP--F1

H4

23650

ZSH-1050-10.0-'P5.0-Sv-EP--N1

ZSH-1050-12.5-'P7.0-Sv-EP--N1

3.0

ZSH-1050-10.0-'P3.0-Sv-EP--F1

ZSH-1050-10.0-'P5.0-Sv-EP--F1

5.0

ZSH-1050-8.0-'P7.0-Sv-EP--F1

ZSH-1050-10.0-'P7.0-Sv-EP--N1

B1

22650

ZSH-1050-8.0-'P5.0-Sv-EP--N1

ZSH-1050-8.0-'P7.0-Sv-EP--N1

3.0

ZSH-1050-8.0-'P3.0-Sv-EP--F1

ZSH-1050-8.0-'P5.0-Sv-EP--F1

'P,

MPa

3.0

32690

5.0

32980

7.0

1200

10.0

2020

1600

3150

9200

2420

2280

4300

8.0

33640

9.0

10.0

11

5, Moldavskaya str., Moscow, 121 467, Russia, +7 (495) 411-7757, office@ogscomp.ru, www.oilgassystems.com

Designation

DN,

mm

PN,

MPa

ZSH-1200-12.5-'P3.0-Sv-EP--N1

ZSH-1200-12.5-'P3.0-Sv-EP--F1

ZSH-1200-12.5-'P5.0-Sv-EP--N1

ZSH-1200-12.5-'P5.0-Sv-EP--F1

ZSH-1200-12.5-'P7.0-Sv-EP--N1

ZSH-1200-12.5-'P7.0-Sv-EP--F1

ZSH-1200-12.5-'P8.0-Sv-EP--N1

H4

H2

H1

mm

m*, kg,

max

32690

5.0

32980

2020

1600

3150

9200

2420

2280

4300

33640

9.0

ZSH-1200-12.5-'P9.0-Sv-EP--F1

10.0

ZSH-1200-12.5-'P10.0-Sv-EP--F1

ZSH-1200-15.0-'P8.0-Sv-EP--N1

8.0

1200

15.0

2050

10.0

* The mass is specified without the mass of electric actuator.

Legend:

N1 mild climatic version;

F1 cold climatic version;

RU with manual operation;

EP with electric actuator;

designation of seismic resistance:

SO seismic nonresistant version for areas up to 6 points as per MSK 64;

S seismic resistant version for areas over 6 up to 9 points inclusive as per MSK 64;

PS seismic highly resistant version for areas over 9 points up to 10 points as per MSK 64.

12

8.0

ZSH-1200-12.5-'P10.0-Sv-EP--N1

ZSH-1200-15.0-'P10.0-Sv-EP--F1

B1

3.0

12.5

ZSH-1200-12.5-'P8.0-Sv-EP--F1

ZSH-1200-15.0-'P10.0-Sv-EP--N1

7.0

1200

ZSH-1200-12.5-'P9.0-Sv-EP--N1

ZSH-1200-15.0-'P8.0-Sv-EP--F1

'P,

MPa

1600

3150

9250

2425

2290

4305

35930

5, Moldavskaya str., Moscow, 121 467, Russia, +7 (495) 411-7757, office@ogscomp.ru, www.oilgassystems.com

Slide gate valves with electric actuator or manual operation

DN 250, 300, 350, 400, 500, 600, 700, 800, 1000, 1200 mm

PN 1.6, 2.5, 4.0 MPa

connection to pipeline welding

The sizes D3 and D4 shall be

defined more precisely when

ordering for specific pipe size

flanged version

Fig. 2

OVERALL AND MOUNTING DIMENSIONS

Designation

DN,

mm

The mass and the sizes are specified for reference

PN,

MPa

'P,

MPa

ZSH-250-1.6-'P1.6-Sv-EP--N1

ZSH-250-1.6-'P1.6-Sv-EP--F1

ZSH-250-1.6-'P1.6-F-EP--N1

ZSH-250-1.6-'P1.6-F-EP--F1

ZSH-250-1.6-'P1.6-Sv-RU--N1

250

1.6

ZSH-250-1.6-'P1.6-F-RU--N1

ZSH-250-1.6-'P1.6-F-RU--F1

ZSH-250-2.5-'P2.5-Sv-EP--N1

ZSH-250-2.5-'P2.5-Sv-EP--F1

ZSH-250-2.5-'P2.5-F-EP--N1

ZSH-250-2.5-'P2.5-Sv-RU--N1

250

2.5

D2

D1

405

355

320

12

26

ZSH-250-2.5-'P2.5-F-RU--N1

ZSH-250-2.5-'P2.5-F-RU--F1

B1

H4

H2

H1

m*,

kg

835

875

625

550

455

2935

790

635

1430

860

405

355

320

12

26

900

835

425

370

335

12

30

2.5

ZSH-250-2.5-'P2.5-Sv-RU--F1

mm

1.6

ZSH-250-1.6-'P1.6-Sv-RU--F1

ZSH-250-2.5-'P2.5-F-EP--F1

875

625

550

455

2935

790

635

1430

860

425

370

335

12

30

900

460

410

370

12

26

ZSH-300-1.6-'P1.6-Sv-EP--N1

ZSH-300-1.6-'P1.6-Sv-EP--F1

1550

1750

ZSH-300-1.6-'P1.6-F-EP--N1

ZSH-300-1.6-'P1.6-F-EP--F1

ZSH-300-1.6-'P1.6-Sv-RU--N1

ZSH-300-1.6-'P1.6-Sv-RU--F1

300

1.6

1.6

700

460

410

370

12

26

500

x

800

500

1800

2900

860

650

1500

1550

1750

500

1800

ZSH-300-1.6-'P1.6-F-RU--N1

ZSH-300-1.6-'P1.6-F-RU--F1

13

5, Moldavskaya str., Moscow, 121 467, Russia, +7 (495) 411-7757, office@ogscomp.ru, www.oilgassystems.com

Designation

DN,

mm

PN,

MPa

'P,

MPa

D2

D1

B1

H4

H2

H1

mm

m*,

kg

ZSH-300-2.5-'P2.5-Sv-EP--N1

ZSH-300-2.5-'P2.5-Sv-EP--F1

460

410

370

12

26

1550

1750

ZSH-300-2.5-'P2.5-F-EP--N1

ZSH-300-2.5-'P2.5-F-EP--F1

ZSH-300-2.5-'P2.5-Sv-RU--N1

300

2.5

2.5

ZSH-300-2.5-'P2.5-Sv-RU--F1

700

485

430

390

16

485

430

390

500

x

800

500

1800

2900

860

650

1500

1550

1750

30

500

1800

1550

1800

16

30

ZSH-300-2.5-'P2.5-F-RU--N1

ZSH-300-2.5-'P2.5-F-RU--F1

ZSH-300-4.0-'P4.0-Sv-EP--N1

ZSH-300-4.0-'P4.0-Sv-EP--F1

ZSH-300-4.0-'P4.0-F-EP--N1

ZSH-300-4.0-'P4.0-F-EP--F1

300

4.0

4.0

ZSH-300-4.0-'P4.0-Sv-RU--N1

ZSH-300-4.0-'P4.0-Sv-RU--F1

ZSH-300-4.0-'P4.0-F-RU--N1

ZSH-300-4.0-'P4.0-F-RU--F1

ZSH-350-1.6-'P1.6-Sv-EP--N1

ZSH-350-1.6-'P1.6-Sv-EP--F1

ZSH-350-1.6-'P1.6-F-EP--N1

ZSH-350-1.6-'P1.6-F-EP--F1

ZSH-350-1.6-'P1.6-Sv-RU--N1

ZSH-350-1.6-'P1.6-Sv-RU--F1

ZSH-350-1.6-'P1.6-F-RU--N1

ZSH-350-1.6-'P1.6-F-RU--F1

ZSH-350-2.5-'P2.5-Sv-EP--N1

ZSH-350-2.5-'P2.5-Sv-EP--F1

ZSH-350-2.5-'P2.5-Sv-RU--N1

ZSH-350-2.5-'P2.5-Sv-RU--F1

ZSH-350-4.0-'P4.0-Sv-EP--N1

700

510

450

410

16

500

x

800

750

1850

2900

860

650

1500

1550

1800

33

750

1850

1650

1550

1640

350

1.6

1.6

760

500

x

800

550

1600

3110

905

770

1650

1550

1670

550

350

2.5

2.5

ZSH-350-4.0-'P4.0-Sv-EP--F1

760

500

x

800

1650

1600

3110

905

1640

1550

1690

1550

770

1650

1550

ZSH-350-4.0-'P4.0-F-EP--N1

ZSH-350-4.0-'P4.0-F-EP--F1

ZSH-350-4.0-'P4.0-Sv-RU--N1

350

4.0

4.0

770

ZSH-350-4.0-'P4.0-Sv-RU--F1

600

x

900

762

1600

3110

905

770

1750

1650

1550

762

1600

1700

3000

ZSH-350-4.0-'P4.0-F-RU--N1

ZSH-350-4.0-'P4.0-F-RU--F1

ZSH-400-1.6-'P1.6-Sv-EP--N1

ZSH-400-1.6-'P1.6-Sv-EP--F1

ZSH-400-1.6-'P1.6-F-EP--N1

ZSH-400-1.6-'P1.6-F-EP--F1

ZSH-400-1.6-'P1.6-Sv-RU--N1

ZSH-400-1.6-'P1.6-Sv-RU--F1

ZSH-400-1.6-'P1.6-F-RU--N1

ZSH-400-1.6-'P1.6-F-RU--F1

400

1.6

ZSH-400-2.5-'P2.5-Sv-RU--N1

ZSH-400-2.5-'P2.5-Sv-RU--F1

ZSH-400-2.5-'P2.5-F-RU--N1

ZSH-400-2.5-'P2.5-F-RU--F1

ZSH-400-4.0-'P4.0-Sv-EP--N1

ZSH-400-4.0-'P4.0-Sv-EP--F1

ZSH-400-4.0-'P4.0-F-EP--N1

ZSH-400-4.0-'P4.0-F-EP--F1

ZSH-400-4.0-'P4.0-Sv-RU--N1

ZSH-400-4.0-'P4.0-Sv-RU--F1

ZSH-400-4.0-'P4.0-F-RU--N1

ZSH-400-4.0-'P4.0-F-RU--F1

14

400

400

2.5

4.0

580

525

482

16

30

1.6

ZSH-400-2.5-'P2.5-Sv-EP--N1

ZSH-400-2.5-'P2.5-Sv-EP--F1

ZSH-400-2.5-'P2.5-F-EP--N1

ZSH-400-2.5-'P2.5-F-EP--F1

850

580

525

482

16

610

550

505

700

x

1000

600

3100

3900

1050

920

1950

1700

3000

30

600

3100

1700

3000

16

33

2.5

850

610

550

505

16

655

585

535

700

x

1000

600

3100

3900

1050

920

1950

1700

3000

33

600

3100

1700

3000

16

39

4.0

850

655

585

535

16

39

700

x

1000

838

3200

3900

1050

920

1950

1700

3000

838

3200

5, Moldavskaya str., Moscow, 121 467, Russia, +7 (495) 411-7757, office@ogscomp.ru, www.oilgassystems.com

Designation

DN,

mm

PN,

MPa

'P,

MPa

ZSH-500-1.6-'P1.6-Sv-EP--N1

ZSH-500-1.6-'P1.6-Sv-EP--F1

ZSH-500-1.6-'P1.6-F-EP--N1

ZSH-500-1.6-'P1.6-F-EP--F1

ZSH-500-1.6-'P1.6-Sv-RU--N1

ZSH-500-1.6-'P1.6-Sv-RU--F1

ZSH-500-1.6-'P1.6-F-RU--N1

ZSH-500-1.6-'P1.6-F-RU--F1

ZSH-500-2.5-'P2.5-Sv-EP--N1

ZSH-500-2.5-'P2.5-Sv-EP--F1

ZSH-500-2.5-'P2.5-F-EP--N1

ZSH-500-2.5-'P2.5-F-EP--F1

ZSH-500-2.5-'P2.5-Sv-RU--N1

ZSH-500-2.5-'P2.5-Sv-RU--F1

ZSH-500-2.5-'P2.5-F-RU--N1

ZSH-500-2.5-'P2.5-F-RU--F1

ZSH-500-4.0-'P4.0-Sv-EP--N1

ZSH-500-4.0-'P4.0-Sv-EP--F1

ZSH-500-4.0-'P4.0-F-EP--N1

ZSH-500-4.0-'P4.0-F-EP--F1

ZSH-500-4.0-'P4.0-Sv-RU--N1

ZSH-500-4.0-'P4.0-Sv-RU--F1

500

500

500

1.6

2.5

4.0

ZSH-600-2.5-'P2.5-F-EP--N1

ZSH-600-2.5-'P2.5-F-EP--F1

ZSH-600-2.5-'P2.5-Sv-RU--N1

ZSH-600-2.5-'P2.5-Sv-RU--F1

ZSH-600-2.5-'P2.5-F-RU--N1

ZSH-600-2.5-'P2.5-F-RU--F1

ZSH-600-4.0-'P4.0-Sv-EP--N1

ZSH-600-4.0-'P4.0-Sv-EP--F1

ZSH-600-4.0-'P4.0-F-EP--N1

ZSH-600-4.0-'P4.0-F-EP--F1

ZSH-600-4.0-'P4.0-Sv-RU--N1

ZSH-600-4.0-'P4.0-Sv-RU--F1

ZSH-600-4.0-'P4.0-F-RU--N1

ZSH-600-4.0-'P4.0-F-RU--F1

ZSH-700-1.6-'P1.6-Sv-EP--N1

ZSH-700-1.6-'P1.6-Sv-EP--F1

ZSH-700-1.6-'P1.6-F-EP--N1

ZSH-700-1.6-'P1.6-F-EP--F1

ZSH-700-1.6-'P1.6-Sv-RU--N1

ZSH-700-1.6-'P1.6-Sv-RU--F1

ZSH-700-1.6-'P1.6-F-RU--N1

ZSH-700-1.6-'P1.6-F-RU--F1

ZSH-700-2.5-'P2.5-Sv-EP--N1

ZSH-700-2.5-'P2.5-Sv-EP--F1

ZSH-700-2.5-'P2.5-F-EP--N1

ZSH-700-2.5-'P2.5-F-EP--F1

ZSH-700-2.5-'P2.5-Sv-RU--N1

ZSH-700-2.5-'P2.5-Sv-RU--F1

ZSH-700-2.5-'P2.5-F-RU--N1

ZSH-700-2.5-'P2.5-F-RU--F1

D2

D1

B1

H4

H2

H1

mm

710

650

585

33

20

1.6

1900

900

m*,

kg

3930

700

890

3840

4475

1165

985

2065

1900

3930

710

650

585

33

20

700

3840

1900

3930

730

660

615

39

20

2.5

700

890

900

3860

4475

1165

985

2065

1900

3930

730

660

615

39

20

700

3860

1900

4060

755

670

615

45

20

4.0

ZSH-500-4.0-'P4.0-F-RU--N1

ZSH-500-4.0-'P4.0-F-RU--F1

ZSH-600-1.6-'P1.6-Sv-EP--N1

ZSH-600-1.6-'P1.6-Sv-EP--F1

ZSH-600-1.6-'P1.6-F-EP--N1

ZSH-600-1.6-'P1.6-F-EP--F1

ZSH-600-1.6-'P1.6-Sv-RU--N1

ZSH-600-1.6-'P1.6-Sv-RU--F1

ZSH-600-1.6-'P1.6-F-RU--N1

ZSH-600-1.6-'P1.6-F-RU--F1

ZSH-600-2.5-'P2.5-Sv-EP--N1

ZSH-600-2.5-'P2.5-Sv-EP--F1

991

890

900

4000

4475

1165

985

2065

1900

4060

755

670

615

45

20

991

4000

2400

3715

4370

840

600

1.6

770

685

20

39

1.6

1060

770

1040

800

3510

1370

1220

2380

2400

3840

4325

840

770

685

20

39

800

2400

3635

3530

4380

840

600

2.5

770

720

20

39

2.5

1060

770

1040

800

3330

1370

1220

2427

2400

3530

4510

840

770

720

20

39

800

2400

3330

3530

4380

890

600

4.0

795

735

52

20

4.0

1060

770

1040

800

3330

1370

1220

2427

2400

3530

4510

700

700

1.6

2.5

890

795

735

52

20

800

3330

2550

6100

910

840

800

39

24

1.6

1200

910

840

800

39

960

875

820

800

1100

900

6060

5800

1492

1350

2642

2550

6100

24

900

6060

2550

6100

45

24

2.5

1200

960

875

820

45

24

800

1100

900

6250

5800

1492

1350

2642

2550

6100

900

6250

15

5, Moldavskaya str., Moscow, 121 467, Russia, +7 (495) 411-7757, office@ogscomp.ru, www.oilgassystems.com

Designation

DN,

mm

PN,

MPa

'P,

MPa

ZSH-700-4.0-'P4.0-Sv-EP--N1

ZSH-700-4.0-'P4.0-Sv-EP--F1

ZSH-700-4.0-'P4.0-F-EP--N1

ZSH-700-4.0-'P4.0-F-EP--F1

ZSH-700-4.0-'P4.0-Sv-RU--N1

ZSH-700-4.0-'P4.0-Sv-RU--F1

ZSH-700-4.0-'P4.0-F-RU--N1

ZSH-700-4.0-'P4.0-F-RU--F1

ZSH-800-1.6-'P1.6-Sv-EP--N1

ZSH-800-1.6-'P1.6-Sv-EP--F1

ZSH-800-1.6-'P1.6-F-EP--N1

ZSH-800-1.6-'P1.6-F-EP--F1

ZSH-800-1.6-'P1.6-Sv-RU--N1

ZSH-800-1.6-'P1.6-Sv-RU--F1

ZSH-800-1.6-'P1.6-F-RU--N1

ZSH-800-1.6-'P1.6-F-RU--F1

ZSH-800-2.5-'P2.5-Sv-EP--N1

ZSH-800-2.5-'P2.5-Sv-EP--F1

ZSH-800-2.5-'P2.5-F-EP--N1

ZSH-800-2.5-'P2.5-F-EP--F1

ZSH-800-2.5-'P2.5-Sv-RU--N1

ZSH-800-2.5-'P2.5-Sv-RU--F1

ZSH-800-2.5-'P2.5-F-RU--N1

ZSH-800-2.5-'P2.5-F-RU--F1

ZSH-800-4.0-'P4.0-Sv-EP--N1

ZSH-800-4.0-'P4.0-Sv-EP--F1

ZSH-800-4.0-'P4.0-F-EP--N1

ZSH-800-4.0-'P4.0-F-EP--F1

ZSH-800-4.0-'P4.0-Sv-RU--N1

ZSH-800-4.0-'P4.0-Sv-RU--F1

ZSH-800-4.0-'P4.0-F-RU--N1

ZSH-800-4.0-'P4.0-F-RU--F1

ZSH-1000-1.6-'P1.6-Sv-EP--N1

ZSH-1000-1.6-'P1.6-Sv-EP--F1

ZSH-1000-1.6-'P1.6-F-EP--N1

ZSH-1000-1.6-'P1.6-F-EP--F1

ZSH-1000-1.6-'P1.6-Sv-RU--N1

ZSH-1000-1.6-'P1.6-Sv-RU--F1

ZSH-1000-1.6-'P1.6-F-RU--N1

ZSH-1000-1.6-'P1.6-F-RU--F1

ZSH-1000-2.5-'P2.5-Sv-EP--N1

ZSH-1000-2.5-'P2.5-Sv-EP--F1

ZSH-1000-2.5-'P2.5-F-EP--N1

ZSH-1000-2.5-'P2.5-F-EP--F1

ZSH-1000-2.5-'P2.5-Sv-RU--N1

ZSH-1000-2.5-'P2.5-Sv-RU--F1

ZSH-1000-2.5-'P2.5-F-RU--N1

ZSH-1000-2.5-'P2.5-F-RU--F1

ZSH-1000-4.0-'P4.0-Sv-EP--N1

ZSH-1000-4.0-'P4.0-Sv-EP--F1

ZSH-1000-4.0-'P4.0-F-EP--N1

ZSH-1000-4.0-'P4.0-F-EP--F1

ZSH-1000-4.0-'P4.0-Sv-RU--N1

ZSH-1000-4.0-'P4.0-Sv-RU--F1

ZSH-1000-4.0-'P4.0-F-RU--N1

ZSH-1000-4.0-'P4.0-F-RU--F1

16

700

800

800

800

1000

1000

1000

4.0

1.6

2.5

4.0

1.6

2.5

4.0

D2

D1

B1

H4

H2

H1

mm

995

900

840

52

24

4.0

2550

1200

995

900

840

52

1020

950

905

800

1100

m*,

kg

7270

1550

7350

5800

1492

1350

2642

2550

7270

24

1550

7350

2700

7980

39

24

1.6

1315

1020

950

905

39

1075

990

930

900

x

1100

1000

8000

6282

1615

1520

2900

2700

7980

24

1000

8000

2700

7980

45

24

2.5

1315

1075

990

930

45

1135

1030

960

900

x

1100

1000

8100

6282

1615

1520

2900

2700

7980

24

1000

8100

2700

9520

56

24

4.0

1315

1135

1030

960

56

1255

1170

1110

900

x

1100

1750

9740

6282

1615

1520

2900

2700

9520

24

1750

9740

3000

12920

45

28

1.6

1610

1255

1170

1110

45

1315

1210

1140

1100

x

1360

1200

13000

7400

1930

1858

3377

3000

12920

28

1200

13000

3000

12920

56

28

2.5

1610

1315

1210

1140

56

1360

1250

1180

1100

x

1360

1200

13100

7400

1930

1858

3377

3000

12920

28

1200

13100

3000

15560

56

28

4.0

1610

1360

1250

1180

56

28

1100

x

1360

2150

16000

7400

1930

1858

3377

3000

15560

2150

16000

5, Moldavskaya str., Moscow, 121 467, Russia, +7 (495) 411-7757, office@ogscomp.ru, www.oilgassystems.com

Designation

ZSH-1200-1.6-'P1.6-Sv-EP--N1

ZSH-1200-1.6-'P1.6-Sv-EP--F1

ZSH-1200-1.6-'P1.6-F-EP--N1

ZSH-1200-1.6-'P1.6-F-EP--F1

ZSH-1200-1.6-'P1.6-Sv-RU--N1

ZSH-1200-1.6-'P1.6-Sv-RU--F1

ZSH-1200-1.6-'P1.6-F-RU--N1

ZSH-1200-1.6-'P1.6-F-RU--F1

ZSH-1200-2.5-'P2.5-Sv-EP--N1

ZSH-1200-2.5-'P2.5-Sv-EP--F1

ZSH-1200-2.5-'P2.5-F-EP--N1

ZSH-1200-2.5-'P2.5-F-EP--F1

ZSH-1200-2.5-'P2.5-Sv-RU--N1

ZSH-1200-2.5-'P2.5-Sv-RU--F1

ZSH-1200-2.5-'P2.5-F-RU--N1

ZSH-1200-2.5-'P2.5-F-RU--F1

ZSH-1200-4.0-'P4.0-Sv-EP--N1

ZSH-1200-4.0-'P4.0-Sv-EP--F1

ZSH-1200-4.0-'P4.0-F-EP--N1

ZSH-1200-4.0-'P4.0-F-EP--F1

ZSH-1200-4.0-'P4.0-Sv-RU--N1

ZSH-1200-4.0-'P4.0-Sv-RU--F1

ZSH-1200-4.0-'P4.0-F-RU--N1

ZSH-1200-4.0-'P4.0-F-RU--F1

DN,

mm

1200

1200

1200

PN,

MPa

1.6

2.5

4.0

'P,

MPa

D2

D1

B1

H4

H2

H1

mm

1485

1390

1330

52

32

1.6

3150

23400

2300

1805

1600

m*,

kg

24050

8860

2242

2200

3815

3150

23400

1485

1390

1330

52

32

2300

24050

3150

23400

1525

1420

1350

56

32

2300

1805

2.5

1600

24150

8860

2242

2200

3815

3150

23400

1525

1420

1350

56

32

2300

24150

3150

25770

1575

1460

1380

62

32

4.0

2300

1805

1600

26510

8860

2242

2200

3815

3150

25770

1575

1460

1380

62

32

2300

26130

* The mass is specified without the mass of electric actuator.

Legend:

N1 mild climatic version;

F1 cold climatic version;

RU with manual operation;

EP with electric actuator;

designation of seismic resistance:

S0 seismic nonresistant version for areas up to 6 points as per MSK 64;

S seismic resistant version for areas over 6 up to 9 points inclusive as per MSK 64;

PS seismic highly resistant version for areas over 9 points up to 10 points as per MSK 64.

17

5, Moldavskaya str., Moscow, 121 467, Russia, +7 (495) 411-7757, office@ogscomp.ru, www.oilgassystems.com

CHECK VALVES

Check Valves

DN 300, 350, 400, 500, 600, 700, 800, 1000, 1050, 1200 mm

PN 8.0, 10.0, 12.5 MPa

Check valves are designed for automatic blocking the pipeline to prevent the return flow of working medium in pipelines carrying oil and oil products, processing lines

of pumping stations and tank batteries.

Working medium tank petroleum, oils, oil products and other non-aggressive liquids with temperature from 15 up to +80.

Connection to pipeline for welding (the check valves may be supplied with welding pups). Installation may be buried or aboveground. The valves for buried

installation are coated with special anticorrosion coating.

Climatic version:

mild (ambient temperature from 40 up to + 40);

cold (ambient temperature from 60 up to + 40).

Seismic resistance up to 10 points as per scale MSK-64.

Time of tripping:

quick-acting valves max 1 second;

nonquick-acting valves from 1 up to 3 seconds.

Nonquick-acting valves are fitted out with damping device preventing the impact stresses and stabilizing the valve in its limit positions.

The valves are full-bored. The coefficient of hydraulic resistance at fully opened valve does not exceed 2.5.

The loss of working pressure at fully opened valve is not exceeding 0.02 MPa.

Materials

body

bonnet

disc

lever

rod

center shaft

steel 20L, 20GML

steel 20L, 20GML

steel 09G2S

steel 20L, 20GML

steel 20H13

steel 20HN3

The service life assigned at least 30 years.

Warranty period 24 months from putting into operation, however not longer than 36 months from the date of shipment.

Design features and advantages:

high reliability;

minimal weight and overall dimensions;

availability of damping device providing for smooth work without impacts;

high repair capability;

no need in technical maintenance and adjustment within the whole period of service life.

18

5, Moldavskaya str., Moscow, 121 467, Russia, +7 (495) 411-7757, office@ogscomp.ru, www.oilgassystems.com

Fig. 3

OVERALL AND MOUNTING DIMENSIONS

Designation

DN,

mm

PN,

MPa

ZO-300-8.0-NB-Sv--N1

8.0

ZO-300-10.0-NB-Sv--N1

ZO-300-10.0-NB-Sv--N1

ZO-300-10.0-B-Sv--N1

n

300

10.0

d1

ZO-300-10.0-B-Sv--N1

ZO-300-10.0-B-Sv--F1

ZO-300-12.5-NB-Sv--N1

ZO-300-12.5-NB-Sv--N1

ZO-300-12.5-NB-Sv--F1

ZO-300-12.5-B-Sv--N1

n

300

12.5

ZO-300-12.5-B-Sv--F1

ZO-400-8.0-NB-Sv--N1

ZO-400-8.0-NB-Sv--F1

ZO-400-8.0-B-Sv--N1

n

400

8.0

d1

ZO-400-8.0-B-Sv--N1

ZO-400-8.0-B-Sv--F1

ZO-400-10.0-NB-Sv--N1

ZO-400-10.0-NB-Sv--F1

ZO-400-10.0-B-Sv--N1

ZO-400-10.0-B-Sv--F1

ZO-400-10.0-B-Sv--N1

ZO-400-10.0-B-Sv--F1

n

400

10.0

from 1

up to 3

ZO-350-12.5-NB-Sv--N1

n

350

12.5

d1

ZO-350-12.5-B-Sv--N1

n

pd

ZO-500-8.0-NB-Sv--F1

from 1

up to 3

ZO-500-8.0-NB-Sv--N1

n

500

8.0

d1

d1

ZO-500-8.0-B-Sv--N1

n

pd

ZO-500-10.0-NB-Sv--F1

from 1

up to 3

ZO-500-10.0-NB-Sv--N1

ZO-500-10.0-B-Sv--F1

ZO-500-10.0-B-Sv--N1

ZO-500-10.0-B-Sv--F1

8.0

pd

ZO-500-8.0-B-Sv--F1

ZO-500-10.0-B-Sv--N1

pd

12.5

pd

ZO-350-12.5-B-Sv--F1

ZO-500-10.0-NB-Sv--F1

10.0

pd

ZO-350-12.5-NB-Sv--F1

ZO-500-10.0-NB-Sv--N1

from 1

up to 3

ZO-400-10.0-NB-Sv--N1

ZO-500-8.0-B-Sv--F1

pd

ZO-400-10.0-NB-Sv--F1

d1

ZO-350-10.0-B-Sv--N1

ZO-500-8.0-B-Sv--N1

10.0

pd

ZO-350-10.0-B-Sv--F1

ZO-500-8.0-NB-Sv--F1

8.0

pd

ZO-400-8.0-B-Sv--F1

10.0

ZO-500-8.0-NB-Sv--N1

from 1

up to 3

ZO-400-8.0-NB-Sv--N1

n

350

ZO-350-12.5-B-Sv--F1

pd

ZO-400-8.0-NB-Sv--F1

from 1

up to 3

ZO-350-10.0-NB-Sv--N1

ZO-350-12.5-B-Sv--N1

d1

ZO-300-12.5-B-Sv--N1

pd

ZO-350-10.0-NB-Sv--F1

ZO-350-12.5-NB-Sv--F1

12.5

pd

ZO-300-12.5-B-Sv--F1

d1

n

ZO-350-10.0-B-Sv--F1

from 1

up to 3

8.0

pd

ZO-350-12.5-NB-Sv--N1

pd

ZO-300-12.5-NB-Sv--F1

8.0

ZO-350-8.0-B-Sv--N1

ZO-350-10.0-B-Sv--N1

pd

ZO-300-10.0-B-Sv--F1

n

350

ZO-350-8.0-B-Sv--F1

ZO-350-10.0-NB-Sv--F1

10.0

Pressure difTime of

ferential on

tripping,

closed valve,

sec

'P (MPa)

from 1

up to 3

ZO-350-8.0-B-Sv--F1

from 1

up to 3

Inst.

pd

ZO-350-10.0-NB-Sv--N1

pd

ZO-300-10.0-NB-Sv--F1

PN,

MPa

ZO-350-8.0-NB-Sv--N1

ZO-350-8.0-B-Sv--N1

d1

ZO-300-8.0-B-Sv--F1

DN,

mm

ZO-350-8.0-NB-Sv--F1

ZO-350-8.0-NB-Sv--F1

8.0

pd

ZO-300-8.0-B-Sv--N1

Designation

ZO-350-8.0-NB-Sv--N1

n

300

ZO-300-8.0-B-Sv--F1

ZO-300-10.0-NB-Sv--F1

Time of

tripping,

sec

from 1

up to 3

ZO-300-8.0-NB-Sv--N1

ZO-300-8.0-B-Sv--N1

Pressure

differential

on closed

valve,

'P (MPa)

pd

ZO-300-8.0-NB-Sv--F1

ZO-300-8.0-NB-Sv--F1

Inst.

The mass and the sizes are specified for reference

n

500

10.0

10.0

pd

d1

n

19

5, Moldavskaya str., Moscow, 121 467, Russia, +7 (495) 411-7757, office@ogscomp.ru, www.oilgassystems.com

Designation

DN,

mm

PN,

MPa

ZO-400-12.5-NB-Sv--N1

n

400

12.5

ZO-400-12.5-B-Sv--F1

ZO-600-8.0-NB-Sv--N1

ZO-600-8.0-NB-Sv--F1

ZO-600-8.0-B-Sv--N1

n

600

8.0

ZO-600-8.0-B-Sv--F1

ZO-600-10.0-NB-Sv--N1

ZO-600-10.0-NB-Sv--F1

ZO-600-10.0-B-Sv--N1

n

600

10.0

ZO-600-10.0-B-Sv--F1

ZO-600-12.5-NB-Sv--N1

ZO-600-12.5-NB-Sv--F1

ZO-600-12.5-B-Sv--N1

n

600

12.5

d1

ZO-600-12.5-B-Sv--N1

ZO-600-12.5-B-Sv--F1

ZO-800-8.0-NB-Sv--N1

ZO-800-8.0-NB-Sv--F1

ZO-800-8.0-B-Sv--N1

n

800

8.0

ZO-800-8.0-B-Sv--F1

ZO-800-10.0-NB-Sv--N1

ZO-800-10.0-NB-Sv--N1

ZO-800-10.0-NB-Sv--F1

ZO-800-10.0-B-Sv--N1

n

800

10.0

ZO-800-10.0-B-Sv--F1

ZO-800-12.5-NB-Sv--N1

ZO-800-12.5-NB-Sv--F1

ZO-800-12.5-B-Sv--N1

ZO-800-12.5-B-Sv--F1

ZO-800-12.5-B-Sv--N1

ZO-800-12.5-B-Sv--F1

20

n

800

12.5

ZO-700-12.5-B-Sv--F1

d1

n

pd

ZO-1000-8.0-NB-Sv--F1

from 1

up to 3

ZO-1000-8.0-NB-Sv--N1

n

1000

8.0

d1

d1

ZO-1000-8.0-B-Sv--N1

n

pd

ZO-1000-10.0-NB-Sv--F1

from 1

up to 3

ZO-1000-10.0-NB-Sv--N1

n

1000 10.0

d1

ZO-1000-10.0-B-Sv--N1

n

pd

ZO-1000-12.5-NB-Sv--F1

from 1

up to 3

ZO-1000-12.5-NB-Sv--N1

ZO-1000-12.5-B-Sv--N1

ZO-1000-12.5-B-Sv--F1

10.0

pd

ZO-1000-10.0-B-Sv--F1

ZO-1000-12.5-B-Sv--F1

8.0

pd

ZO-1000-8.0-B-Sv--F1

ZO-1000-12.5-B-Sv--N1

pd

12.5

pd

ZO-700-12.5-B-Sv--N1

ZO-1000-12.5-NB-Sv--F1

12.5

12.5

ZO-1000-12.5-NB-Sv--N1

from 1

up to 3

ZO-800-12.5-NB-Sv--N1

n

700

ZO-1000-10.0-B-Sv--F1

pd

ZO-800-12.5-NB-Sv--F1

from 1

up to 3

ZO-700-12.5-NB-Sv--N1

ZO-1000-10.0-B-Sv--N1

d1

ZO-800-10.0-B-Sv--N1

pd

ZO-700-12.5-NB-Sv--F1

ZO-1000-10.0-NB-Sv--F1

10.0

pd

ZO-800-10.0-B-Sv--F1

d1

n

ZO-1000-8.0-B-Sv--F1

from 1

up to 3

10.0

pd

ZO-1000-10.0-NB-Sv--N1

pd

ZO-800-10.0-NB-Sv--F1

10.0

ZO-700-10.0-B-Sv--F1

ZO-1000-8.0-B-Sv--N1

d1

ZO-800-8.0-B-Sv--F1

n

700

ZO-700-10.0-B-Sv--N1

ZO-1000-8.0-NB-Sv--F1

8.0

pd

ZO-800-8.0-B-Sv--N1

from 1

up to 3

ZO-700-10.0-NB-Sv--N1

ZO-1000-8.0-NB-Sv--N1

from 1

up to 3

ZO-800-8.0-NB-Sv--N1

pd

ZO-700-12.5-B-Sv--F1

pd

ZO-800-8.0-NB-Sv--F1

d1

n

ZO-700-10.0-NB-Sv--F1

ZO-700-12.5-B-Sv--N1

pd

ZO-600-12.5-B-Sv--F1

ZO-700-8.0-B-Sv--F1

ZO-700-12.5-NB-Sv--F1

12.5

8.0

pd

ZO-700-12.5-NB-Sv--N1

from 1

up to 3

ZO-600-12.5-NB-Sv--N1

8.0

ZO-700-10.0-B-Sv--F1

pd

ZO-600-12.5-NB-Sv--F1

n

700

ZO-700-8.0-B-Sv--N1

ZO-700-10.0-B-Sv--N1

d1

ZO-600-10.0-B-Sv--N1

from 1

up to 3

ZO-700-8.0-NB-Sv--N1

ZO-700-10.0-NB-Sv--F1

10.0

pd

ZO-600-10.0-B-Sv--F1

pd

ZO-700-8.0-NB-Sv--F1

ZO-700-8.0-B-Sv--F1

from 1

up to 3

ZO-600-10.0-NB-Sv--N1

d1

n

ZO-700-10.0-NB-Sv--N1

pd

ZO-600-10.0-NB-Sv--F1

12.5

pd

ZO-500-12.5-B-Sv--F1

ZO-700-8.0-B-Sv--N1

d1

ZO-600-8.0-B-Sv--N1

12.5

ZO-500-12.5-B-Sv--N1

ZO-700-8.0-NB-Sv--F1

8.0

pd

ZO-600-8.0-B-Sv--F1

n

500

ZO-500-12.5-B-Sv--F1

from 1

up to 3

ZO-600-8.0-NB-Sv--N1

from 1

up to 3

ZO-700-8.0-NB-Sv--N1

pd

ZO-600-8.0-NB-Sv--F1

Pressure difTime of

ferential on

tripping,

Inst.

closed valve,

sec

'P (MPa)

pd

ZO-500-12.5-NB-Sv--N1

ZO-500-12.5-B-Sv--N1

d1

ZO-400-12.5-B-Sv--N1

PN,

MPa

ZO-500-12.5-NB-Sv--F1

ZO-500-12.5-NB-Sv--F1

12.5

pd

ZO-400-12.5-B-Sv--F1

Designation

DN,

mm

ZO-500-12.5-NB-Sv--N1

from 1

up to 3

ZO-400-12.5-NB-Sv--N1

ZO-400-12.5-B-Sv--N1

Time of

tripping,

sec

pd

ZO-400-12.5-NB-Sv--F1

ZO-400-12.5-NB-Sv--F1

Inst.

Pressure

differential

on closed

valve,

'P (MPa)

n

1000 12.5

12.5

pd

d1

n

5, Moldavskaya str., Moscow, 121 467, Russia, +7 (495) 411-7757, office@ogscomp.ru, www.oilgassystems.com

Designation

DN,

mm

PN,

MPa

ZO-1050-8.0-NB-Sv--N1

n

1050

8.0

ZO-1050-8.0-B-Sv--F1

ZO-1050-10.0-NB-Sv--N1

ZO-1050-10.0-NB-Sv--N1

ZO-1050-10.0-NB-Sv--F1

ZO-1050-10.0-B-Sv--N1

n

1050 10.0

d1

ZO-1050-10.0-B-Sv--N1

ZO-1050-10.0-B-Sv--F1

ZO-1050-12.5-NB-Sv--N1

ZO-1050-12.5-NB-Sv--N1

ZO-1050-12.5-NB-Sv--F1

ZO-1050-12.5-B-Sv--N1

ZO-1050-12.5-B-Sv--F1

ZO-1050-12.5-B-Sv--N1

ZO-1050-12.5-B-Sv--F1

n

1050 12.5

pd

ZO-1200-10.0-NB-Sv--F1

from 1

up to 3

ZO-1200-10.0-NB-Sv--N1

n

1200 10.0

ZO-1200-10.0-B-Sv--F1

d1

n

d1

pd

ZO-1200-12.5-NB-Sv--F1

from 1

up to 3

ZO-1200-12.5-NB-Sv--N1

ZO-1200-12.5-B-Sv--N1

pd

ZO-1200-12.5-B-Sv--F1

ZO-1200-12.5-B-Sv--N1

ZO-1200-12.5-B-Sv--F1

10.0

pd

ZO-1200-10.0-B-Sv--N1

ZO-1200-12.5-NB-Sv--F1

12.5

d1

n

ZO-1200-10.0-B-Sv--F1

from 1

up to 3

8.0

pd

ZO-1200-12.5-NB-Sv--N1

pd

ZO-1050-12.5-NB-Sv--F1

8.0

ZO-1200-8.0-B-Sv--F1

ZO-1200-10.0-B-Sv--N1

pd

ZO-1050-10.0-B-Sv--F1

n

1200

ZO-1200-8.0-B-Sv--N1

ZO-1200-10.0-NB-Sv--F1

10.0

Pressure difTime of

ferential on

tripping,

closed valve,

sec

'P (MPa)

from 1

up to 3

ZO-1200-10.0-NB-Sv--N1

from 1

up to 3

Inst.

pd

ZO-1200-8.0-B-Sv--F1

pd

ZO-1050-10.0-NB-Sv--F1

PN,

MPa

ZO-1200-8.0-NB-Sv--N1

ZO-1200-8.0-B-Sv--N1

d1

ZO-1050-8.0-B-Sv--N1

DN,

mm

ZO-1200-8.0-NB-Sv--F1

ZO-1200-8.0-NB-Sv--F1

8.0

pd

ZO-1050-8.0-B-Sv--F1

Designation

ZO-1200-8.0-NB-Sv--N1

from 1

up to 3

ZO-1050-8.0-NB-Sv--N1

ZO-1050-8.0-B-Sv--N1

Time of

tripping,

sec

pd

ZO-1050-8.0-NB-Sv--F1

ZO-1050-8.0-NB-Sv--F1

Inst.

Pressure

differential

on closed

valve,

'P (MPa)

n

1200 12.5

12.5

pd

d1

n

Legend:

n aboveground installation;

pd buried installation;

N1 mild climatic version;

F1 cold climatic version;

NB nonquick-acting;

B quick-acting;

designation of seismic resistance:

S0 seismic nonresistant version for areas with seismicity to 6 points inclusive as per MSK-64;

S seismic resistant version for areas with seismicity over 6 up to 9 points inclusive as per MSK 64;

PS seismic highly resistant version for areas with seismicity over 9 points up to 10 points as per MSK 64.

21

5, Moldavskaya str., Moscow, 121 467, Russia, +7 (495) 411-7757, office@ogscomp.ru, www.oilgassystems.com

BALL VALVES FOR NATURAL GAS

Ball valves with manual operation, pneumatic actuator

or electric actuator

DN 50, 80/50, 80, 100 mm

PN 8.0, 10.0, 16.0 MPa

Ball valves are used as a shut-off device on processing lines carrying nonaggressive natural gas and other nonaggressive media with temperature

from -60 up to +80.

Leakproofness of obturator according to grade (GOST 9544-2005).

Connection to pipeline welding, flanged, flanged with mating flanges.

Climatic version:

mild (ambient temperature from -40 up to +50);

cold (ambient temperature from -60 up to +45).

Seismicity of areas as per 12-points scale MSK-64 up to 9 points.

Different modification of ball valves are available: with manual operation, pneumatic actuator and electric actuator. The ball valves may be completed with electric

actuators of various manufacturers.

Pneumatically actuated ball valves are completed with the following control units:

EPUU-7-4 (24 V) or EPUU-7-5 (110 V) for DN 50 mm, PN 8.0, 10.0 MPa;

EPUU-7-7 (24 V) or EPUU-7-8 (110 V) for DN 80, 100 mm, PN 8.0, 10.0 MPa;

EPUU-8 (24 V) or EPUU-8-1 (110 V) for DN 50 mm, PN 16.0 MPa;

EPUU-8-2 (24 V) or EPUU-8-3 (110 V) for DN 80, 100 mm, PN 16.0 MPa.

The valves may be completed with other control units.

The installation is aboveground. The ball valves of buried installation can be coated with anticorrosion polymer layer.

The ball valves are installed coaxially with the pipeline. The manually operated ball valves can be installed in any position, the pneumatically and electrically actuated

ball valves on horizontal portions of the pipeline with the actuator above.

Upon the customer request the ball valves may be manufactured with welding pups.

Materials

body

plug

stem

sealings

steel 09G2S

steel 09G2S + Cr30 mkm

steel 40H, 40HN, 20HN3 + r30 mkm

elastomer

Service life assigned 30 years.

The warranty life before retirement at least 40 years.

The warranty service life 18 months from the date of commissioning provided that the storage life does not exceed

24 months from the date of valve shipment to the customer.

Manufacture and supply as per TU 26-07-1435-95.

Ball valves MA39025 are manufactured as per standard API Spec 6D.

Design features and advantages:

body of valve consists of two stamped hemispheres and has one entry, which prevents the gas leakages

into the environment;

sealing of obturator is made from elastomer material characterized by high wear- and erosion- resistance;

high leakproofness of obturator is ensured by both seats constantly pressed to the ball;

the ball is trunnion mounted by using the bearings made of metal-fluoroplastic providing an easier operation

of ball valves;

the pneudraulically actuated ball valves are fitted out with manual stand-by;

the valve control units are fitted out with integrated terminal boxes and limit switches, and therefore they require

no additional wiring;

control voltage 24 or 110 V.

22

5, Moldavskaya str., Moscow, 121 467, Russia, +7 (495) 411-7757, office@ogscomp.ru, www.oilgassystems.com

Ball valves with manual operation, pneumatic or electric actuator,

for welding

DN 50, 80/50, 80, 100 mm

PN 8.0, 10.0, 16.0 MPa

Fig. 4

Fig. 5

The sizes D3 and D4

shall be defined more

precisely when ordering

for specific pipe size

Fig. 6

Fig. 7

Overall dimensions of valve with pups L and material of welding pups are to be agreed when ordering.

OVERALL AND MOUNTING DIMENSIONS

Designation

11ls60p

11ls60p1

11ls660p

11ls660p1

11ls60p7

11ls60p6

11ls660p7

11ls660p6

11ls960p

11ls960p1

Clim.

vers.

N1

F1

N1

F1

N1

F1

N1

F1

N1

F1

DN,

mm

The mass and the sizes are specified for reference

PN, OpeMPa rator

D0

D3

D4

50

8.0

10.0

B2

49

60

L2

175

255

175

477

392

49

60

160

600

L4

500

200

255

L1

160

pn

pn

H1

185

84

H2

H3

m,

Notes

kg

90

15

Fig. 4

mm

r

50

B1

200

76

291 145.5

410

84

184

31

Fig. 5

600

185

84

90

15

Fig. 4

410

84

184

31

Fig. 5

590

102

147

75

Fig. 6

500

291 145.5

576

362

76

23

5, Moldavskaya str., Moscow, 121 467, Russia, +7 (495) 411-7757, office@ogscomp.ru, www.oilgassystems.com

Designation

11s45p

11ls45p

11ls645p

11ls645p1

11s945p

11ls945p1

MA39025-01

MA39025-07

MA39025-10

11ls60p

11ls60p1

11ls660p

11ls660p1

11ls60p7

11ls60p6

11ls660p7

11ls660p6

11s45p

11ls45p

11ls645p

11ls645p1

MA39025-01

MA39025-07

MA39025-10

11ls60p

11ls60p1

11ls660p

11ls660p1

11ls60p7

11ls60p6

11ls660p7

11ls660p6

11ls960p

11ls960p1

11s45p

11ls45p

11ls645p

11ls645p1

11s945p

11ls945p

MA39025-01

MA39025-07

MA39025-10

11ls60p

11ls60p1

11ls60p8

11ls60p9

11ls660p

11ls660p1

24

Clim.

vers.

N1

F1

N1

F1

N1

F1

N1

N1

N1

N1

F1

N1

F1

N1

F1

N1

F1

N1

F1

N1

F1

N1

N1

N1

N1

F1

N1

F1

N1

F1

N1

F1

N1

F1

N1

F1

N1

F1

N1

F1

N1

N1

N1

N1

F1

N1

F1

N1

F1

DN,

mm

PN, OpeMPa rator

D0

D3

D4

16.0

pn

47

60

160

50

10.0

80/50*

8.0

pn

r

e

49

60

160

81

92

160

r

pn

r

80/50*

10.0

81

92

r

16.0

77

92

10.0

80

8.0

pn

r

e

81

92

160

81

92

234

80

80

10.0

16.0

100

10.0

8.0

L1

L2

L4

H1

185

84

410

84

590

102

410

185

590

84

84

102

185

84

H2

H3

m,

Notes

kg

405

325

477

392

255

477

175

392

600

200

353 176.5

576

292

500

90

15

Fig. 4

362

291 145.5

646 500

576 362

600

175

291 145.5

600

500

200

245

165

291 145.5

600

500

325

245

477

175

392

356

410

84

185

84

184

36

Fig. 5

147

75

Fig. 6

291 145.5

678 500

576 362

984

806

356

76

184

90

147

31

16

76

Fig. 5

Fig. 4

Fig. 6

90

17

Fig. 4

184

33

Fig. 5

90

17

Fig. 4

184

33

Fig. 5

90

17

Fig. 4

184

36

Fig. 5

184

90

147

33

18

78

Fig. 5

Fig. 4

Fig. 6

145

42

Fig. 4

76

410

84

185

84

353 176.5

80

76

200

405

500

200

255

80

410

84

410

185

590

84

84

102

292

125

76

117

pn

291

174

350

175

520

125

265

70

Fig. 5

984

806

292

125

145

42

Fig. 4

291

174

350

175

520

125

265

70

Fig. 5

533

416

572

388

696

148

208

106 Fig. 6

984

806

292

125

145

43

Fig. 4

365

248

370

185

541

125

265

77

Fig. 5

533

416

572

388

696

148

208

106 Fig. 6

291

533

174

416

350

984

572

175

806

388

520

292

696

125

125

148

265

145

208

70 Fig. 5

42 Fig. 4

106 Fig. 6

1220 1080

350

143

200

53

Fig. 4

350

216

350

211

51

490

158 132.5 216

70

Fig. 7

350

175

550

136

92

Fig. 5

pn

pn

81

77

92

92

234

234

80

160

pn

80/50*

160

pn

80/50*

B2

mm

r

50

B1

pn

r

e

r(r)

320

pn

81

100

92

110

234

265

335 202.5

356

356

356

280

117

117

117

246

5, Moldavskaya str., Moscow, 121 467, Russia, +7 (495) 411-7757, office@ogscomp.ru, www.oilgassystems.com

Designation

Clim.

vers.

11ls60p7

11ls60p6

11ls60p10

11ls60p11

11ls660p7

11ls660p6

11ls960p

11ls960p1

11s45p

11ls45p

11s45p4

11ls45p4

11ls645p

11ls645p1

11s945p

11ls945p

MA39025-01

MA39025-07

MA39025-10

N1

F1

N1

F1

N1

F1

N1

F1

N1

F1

N1

F1

N1

F1

N1

F1

N1

N1

N1

DN,

mm

100

100

PN, OpeMPa rator

D0

D3

D4

B1

B2

L1

L4

H1

1220 1080

350

143

350

51

490

158

H2

H3

m,

Notes

kg

200

53

Fig. 4

216

70

Fig. 7

Fig. 5

mm

r(r)

320

10.0

98

110

350

216

265

132.5

335 202.5

350

550 417.5

r(r)

320

16.0

94

110

350

216

265

211

280

pn

pn

L2

175

550

136

246

92

570 437.5

775

162

277

120 Fig. 6

1240 1120

350

143

200

56

Fig. 4

350

51

490

158

216

70

Fig. 7

Fig. 5

211

280

330 197.5

132.5

435 217.5

550

136

246

92

775

162

277

110 Fig. 6

550

490

775

136

246

158 132.5 216

162

277

92 Fig. 5

70 Fig. 7

120 Fig. 6

100

10.0

pn

r(r)

e

320

-

98

110

265

550 417.5

570 437.5

335 202.5

350 216 432

550 417.5

350

350

601

175

211

385

51

-

* Designation like 80/50 indicates that the nominal size of bore in the valve is reduced up to 50 mm.

Legend:

r with manual operation (handle);

r(r) with manual operation (gearbox);

pn with pneumatic actuator;

e with electric actuator;

N1 mild climatic version;

F1 cold climatic version.

25

5, Moldavskaya str., Moscow, 121 467, Russia, +7 (495) 411-7757, office@ogscomp.ru, www.oilgassystems.com

Ball valves with manual operation, pneumatic or electric actuator,

flanged

DN 50, 80/50, 80, 100 mm

PN 8.0, 10.0, 16.0 MPa

Fig. 8

Fig. 9

Fig. 10

Fig. 11

26

5, Moldavskaya str., Moscow, 121 467, Russia, +7 (495) 411-7757, office@ogscomp.ru, www.oilgassystems.com

OVERALL AND MOUNTING DIMENSIONS

Designation

11ls60p2

11ls60p3

11ls60p4

11ls60p5

11ls660p2