Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Fabric Structures - Fabric Architecture

Caricato da

Khader Abu-daggaCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Fabric Structures - Fabric Architecture

Caricato da

Khader Abu-daggaCopyright:

Formati disponibili

3/15/2015

Fabric structures - Fabric Architecture

Fabric structures

Fabric Architecture | Sourcebook 2009

A fabric structures material selection, proper design, engineering, fabrication and installation all work together

to ensure a sound structure. The materials role in the structures performance makes the selection process

especially important. This is particularly true with tensile and air-supported structures because their

membranes, as well as their frames, carry the loads.

MEMBRANE MATERIALS

Most fabric structures use fabrics rather than meshes or films. The fabrics ty pically are coated and laminated with sy nthetic

materials for greater strength and/or env ironmental resistance. Among the most widely used materials are poly ester laminated

or coated with poly v iny l chloride (PV C), wov en fiberglass coated with poly tetrafluoroethy lene (PTFE) or silicone. Meshes, films

and other materials also hav e appropriate applications.

Polyesters

Poly ester is the most frequently used base material because of its strength, durability , cost and stretch. Poly esters laminated or

coated with PV C films generally are the least ex pensiv e for longer-term fabrications.

Laminates usually consist of v iny l films ov er wov en or knitted poly ester meshes (called scrims or substrates). Coated fabrics

ty pically use a high-count, high-tensile base fabric coated with a bondable substance for ex tra strength. One fabric

manufacturing method places poly ester fabric under tension before and during the coating processes. The result is that y arns in

both directions of the weav e hav e identical characteristics, giv ing the fabric increased dimensional stability .

Lighter fabrics (200 to 27 0g/m 2 ) commonly are used as acoustic and insulated liners suspended beneath a structures

env elope. For long-term ex terior use, heav ier materials are needed: 20- to 26-oz. (680 880gm) fabrics with topcoatings of

poly v iny l fluoride (PV F, of which Tedlar is an ex ample) or poly v iny lidene fluoride (PV DF, of which V idar, Fluorex and Ky nar

are ex amples). These topcoatings prov ide a protectiv e finish to withstand env ironmental degradation.

Vinyl-coated polyester

V iny l-coated poly ester is the most common fabric for producing flex ible structures, such as custom-designed awnings,

canopies, walkway s, tent halls, smaller air-supported structures and light member-framed structures.

http://fabricarchitecturemag.com/articles/0409_f2_structures.html

1/14

3/15/2015

Fabric structures - Fabric Architecture

V iny l-coated poly ester is composed of a poly ester scrim, a bonding or adhesiv e agent, and ex terior PV C coatings. The poly ester

scrim supports the coating (applied initially in liquid form) and prov ides the tensile strength, elongation, tear strength and

dimensional stability of the finished fabric. The scrim is made of high-tenacity , continuous-filament y arns, which hav e high

dimensional stability , and can be bent thousands of times without losing any tensile properties. The base fabrics tensile strength

is determined by the size (denier) and strength (tenacity ) of the y arns and the number of y arns per linear inch or meter. The

bigger the y arn and the more y arns per inch, the greater the finished products tensile strength. For architectural applications,

base fabrics ty pically weigh between 2.5 and 1 0 oz/y d 2 , with a tensile strength between 300 (2.662 N/5cm) and 650 lbs/in

(5.60 N/5cm), although fabrics intended only for tent use may hav e lower measurements.

The adhesiv e agent prov ides a chemical bond between the poly ester fibers and the ex terior coatings and prev ents wicking of

moisture into the fibers. Wicking is the capillary like action of fiber to absorb water, which could result in freeze-thaw damage.

The PV C coating liquid (v iny l Organisol or Plastisol) contains chemicals to achiev e desired properties regarding color, water

resistance, mildew resistance and flame retardancy . The fabrics also can be made with high lev els of light transmission or

complete opaqueness. After the coating is applied to the scrim, the fabric goes through a heating chamber to dry the liquid

coating.

Vinyl-laminated polyesters

V iny l-laminated poly esters are used for awnings, tents and low-tension frame structures. Technically , a laminated fabric

consists of a reinforcing poly ester scrim that is calendared between two lay ers of unsupported PV C film. In general use, it refers

to two or more lay ers of fabric or film joined by heat, pressure and an adhesiv e to form a single ply .

With an open-weav e or mesh poly ester scrim, the ex terior v iny l films bond to themselv es through the openings in the fabric.

Heav ier base fabrics, though, are too tightly constructed to permit this lamination process, so an adhesiv e must bond the

ex terior films to the base fabric.

A good chemical bond is important to prev ent delamination and is critical in dev eloping the proper seam strengths. The

adhesiv e enables the seam, created by welding v iny l-coated fabric to another piece of the same material, to meet a structures

shear forces and load requirements at all temperatures. By prev enting wicking of moisture into the scrims fibers, the adhesiv e

prev ents fungal growth or freezing that can affect the ex terior coatings adhesion to the scrim. In response to EPA regulations,

the adhesiv es are water-based.

Using an open-weav e scrim such as mesh might make these fabrics more economical, depending on the number and ty pe of

features required in the v iny l. What weight is necessary to withstand abrasion and wear? Is flame resistance needed? Is a

particular color required? What width? V irtually any color, plus UV resistance, abrasion resistance, and colorfastness can be

formulated into the v iny l, but the more of these features incorporated, the higher the cost.

Fiberglass

Another widely used base material is wov en fiberglass coated with PTFE (also known as Teflon) or silicone. The glass fibers are

drawn into continuous filaments, which are bundled into y arns. The y arns are wov en to form a substrate. The fiberglass has a

high ultimate tensile strength, behav es elastically and does not undergo significant stress relax ation or creep. The PTFE coating

http://fabricarchitecturemag.com/articles/0409_f2_structures.html

2/14

3/15/2015

Fabric structures - Fabric Architecture

is chemically inert, withstands temperatures from minus 1 00F to 450F (minus 7 3C to 232C), is immune to UV radiation and can

be cleaned with water.

PTFE-coated fiberglass is av ailable with as much as 25% translucency , prov iding diffused interior light. Its ability to prov ide

natural day time lighting and its highly reflectiv e surface for efficient nighttime interior lighting can reduce energy consumption.

For these and other reasons, fiberglass-based fabrics hav e been the material of choice for stadium domes (both air- and cablesupported) and many other permanent structures, particularly in the United States. Another reason some industry ex perts cite

for this is a perception among code officials that its high melting temperature and lack of creep, or long-term elongation, make it

superior to poly ester. Other industry insiders note that poly ester, like fiberglass, melts rather than burns at high temperatures,

and that properly constructed, poly ester structures may be equally durable.

Because of the differences in how poly ester and fiberglass perform in fire-resistance tests, PTFE-coated fiberglass is the only

membrane material that currently meets the U. S. model building codes definitions of a noncombustible material. (The three U.S.

model codes are currently being rev iewed and soon will be consolidated into one code.) This is a more accurate reason for the

PTFE-coated fiberglass preference, but it raises questions about whether standards applied to other building materials should be

applied to membranes.

Woven PTFE

This material is constructed of PTFE fibers wov en into a fabric. As of now, only one such material is av ailable. Wov en PTFE

combines the env ironmentally -resistant adv antages of the material with its ability to withstand repeated flex ing and folding, an

adv antage it has ov er coated-fiberglass fabrics. Such flex ibility makes it an especially good option for conv ertible structures;

howev er, it is a rather ex pensiv e material and is not as strong as either poly ester or glass.

ETFE foil

Perhaps the newest dev elopment in the fabric structures arena is the introduction of ETFE (ethy lene tetrafluoroethethy lene), a

transparent membrane with fabric like qualities and the adv antages of PTFE, such as a self-cleaning capability . Resistant to

atmospheric pollution and UV light, ETFE has a v ery long ex pected lifespan of more than 20 y ears. Effectiv e thermal

performance (av erage U v alue is 2.6W/m 2 K for a two-lay er sy stem) and high light transmission (95% v isible light, 85% UV light)

enable a range of applications where traditional materials, such as glass, would not be practical. It is more than 20 times lighter

than glass (0.35kg/m 2 for ETFE v s. 1 5kg/m 2 for glass) and is ecologically friendly and energy efficient as its constituent

materials are fluorspar, hy drogen sulphate and trichloromethane, all non petrochemical deriv ativ es. It is 1 00% recy clable.

Meshes, netting and film

These are the least-used materials for fabric structures. Mesh is a broad term for any porous fabric with open spaces between its

y arns. It can be made from almost any fiber by a v ariety of methods, including knitting, weav ing and ex trusion. In some cases it

acts as a substrate to beef up other fabrics or is coated to produce specific characteristics.

For architectural use, m eshes ty pically are av ailable as poly ester weav es lightly coated with v iny l or as knitted fabrics using

high-density poly ethy lene (HDPE), poly propy lene or acry lic y arns. Poly ester mesh dy es well, is strong, has a low water

absorption rate and can be economical. Ny lon often is used in industrial applications because of its strength and resistance to

http://fabricarchitecturemag.com/articles/0409_f2_structures.html

3/14

3/15/2015

Fabric structures - Fabric Architecture

chemicals, although it does hav e a high water absorption rate and may cost more than poly ester. Often used in agriculture,

recreation and containment, poly propy lene and HDPE are inert, so they cant be stained or dy ed, and are less ex pensiv e than

poly ester or ny lon. Poly propy lene, howev er, does hav e a comparativ ely low melting rate, a factor in some industrial

applications.

Meshes can prov ide shade as well as shelter from wind. Since they re porous, meshes are little good against rain. Still, they are

inex pensiv e and hav e been used for some low-cost membrane structure applications. For obv ious reasons, meshes are not used

in traditional air-supported structure design.

Netting is considered a ty pe of mesh, usually tight with small holes. Netting finds use in stadium interiors behind goals, golf

ranges and courses, play ground equipment and structures, horticulture, zoos, construction sites and other areas where

protection or containment is needed.

Netting consists of a ny lon, poly ester or poly propy lene with ex truded or spun y arns that is knotted or raschel knitted to form

the material. Each material has its adv antages and appropriate applications. Poly ester holds dy e better than ny lon but is more

ex pensiv e; ny lon is easier to coat, but has a higher water absorption rate and doesnt hold dy e as well. Poly propy lene floats on

water, is durable and chemically resistant, but cant be dy ed. Raschel knitting is a newer, faster manufacturing method than

knotting. One drawback is that the knitted material can unrav el, which can be thwarted by heat-setting the netting to shrink and

stabilize the fibers.

Film s are transparent poly mers ex truded in sheet form without a supporting substrate. They are not laminated or coated.

Ex amples include clear v iny l, poly ester or poly ethy lene. These films are cheaper than tex tiles, but they are neither as strong nor

as durable.

Films are much weaker in tension, though more elastic, than scrim-based fabrics. Films sometimes hav e application in airinflated structures. Air-inflated structures are composed of fabric tubes in which the air is pressurized, but the structures

interior itself is not. Some air-inflated roofs or building env elopes hav e been made using two or three lay ers of films to form air

pillows. The film lay ers are thermally welded and sealed, and the resulting pillows are inflated by small fans. The inflation

increases the internal pressure to prestress the surface, creating load resistance. Such film pillows are framed by an aluminum

ex trusion perimeter, which must accommodate some structural mov ement.

Films range in thickness from 30 to 200 microns and can be produced with lev els of translucency v ary ing from 25% to 95% light

transmission. Films are low weight, hav e a life ex pectancy of 20 to 25 y ears and highly resist dirt. The inflated pillows ex hibit

good thermal insulation v alues. More research needs to be done to dev elop a range of standard reliable, economical details, for

instance, to improv e the water seals and reduce wicking.

Blackout fabric

Blackout material, sometimes called blockout material, is an opaque or nontranslucent fabric. Primarily used for tents, the fabric

is a laminate that sandwiches a dark opaque lay er between two white ex terior lay ers. Because no light transmits through the tent

top or walls made with blackout material, lighting and heat can be controlled. In addition, any stains, dirt, repairs or slightly

mismatched panels on the tents ex terior will not be noticeable from the inside.

http://fabricarchitecturemag.com/articles/0409_f2_structures.html

4/14

3/15/2015

Fabric structures - Fabric Architecture

Blackout fabric also has its disadv antages. Heating may be necessary , as the tents interior may be colder than using nonopaque

fabric. Heating and lighting, of course, will increase the operating costs. The multiple lay ers make the fabric heav y and harder to

handle, and increase the possibility of delamination ov er time. The fabric is more ex pensiv e that other tent materials, pinholes

or snags in it are apparent to occupants, and often, the interior color does not ex actly match the ex terior color.

OTHER MATERIALS

Shadecloth, often a knitted fabric such as monofilament poly ethy lene, originally found use as agricultural crop protection. It

has been adapted for tension structures whose purpose is solar shading. Shadecloth can be manufactured in a v ariety of colors,

offers stretch and resiliency and remains flex ible without tensile-strength loss under a range of conditions. Light transmission

can v ary from 20% to 90% shade factor; its UV filter construction can range from 30% to 7 0%.

Ny lon, which may be laminated with v iny l films, is stronger and more durable than poly ester, but has a higher cost and more

stretch. It may be a good choice for some small jobs, but it stretches too much for use in large buildings.

Spandex is difficult to use in long-term ex terior applications because of the winds effect on its seams and construction, but its

stretch and splash of colors can contribute to interior spaces or temporary ex terior use, for instance, at festiv als and special

ev ents.

Solution-dy ed acry lic and m odacry lic hav e gained use, particularly for small shading structures. Their wide range of colors

and modacry lics flame retardancy make the materials attractiv e to designers (see the Awnings & Canopies section for more

information).

Kev lar is an ex cellent lightweight fabric for construction, but it is v ery ex pensiv e, it is rarely used for large structures, such as

dome roofs.

FABRIC PROPERTIES

Product test data is almost the only way to establish a measure of relativ e quality . Many v ariables enter into the process of

making fabrics, which may make one manufacturers product significantly different from its competitions in one or more

aspects. Test results prov ide the best indicator of such differences. Many suppliers hav e inv ested considerable money and time

to test and characterize their products, and routinely prov ide information about the properties of their fabrics, including:

strip tensile strength

grab tensile strength

trapezoidal tear strength

tongue tear strength

adhesion strength

flame resistance

http://fabricarchitecturemag.com/articles/0409_f2_structures.html

5/14

3/15/2015

Fabric structures - Fabric Architecture

finished weight

base fabric weight

av ailable topcoatings

resistance to cold cracking

dead load

structural properties

life ex pectancy

Tensile strength data is a basic indicator of relativ e strength. Its fundamental for architectural fabrics that function primarily in

tension.

T ear strength is im portant because if a fabric ruptures in place, it generally does so by tearing. This occurs when a

local stress concentration or local damage results in the failure of one y arn, which increases the stress on remaining y arns.

Adhesion strength is a measure of the strength of the bond between the base material and coating or film laminate that protects

it. The measure is useful for ev aluating the strength of welded joints for connecting strips of fabric into fabricated assembly .

Flam e retardancy is not the sam e as flam e proofing. Fabric with a flame-retardant coating can withstand a point source

ev en if it is v ery hot, but a flame-retardant material still will burn if a large ignition source is present. The larger the ignition

source, the more total heat energy is av ailable to the fabric fibers behind the protectiv e coating, The more heat energy gets in,

the faster and more successfully the fabric reaches a temperature at which it catches fire and burns from the inside out. Ty pical

tent fires, for ex ample, begin with small ignition sources, but ultimately the flammability of the tents contents contributes to the

fabrics response.

Flam e-retardancy tests measure the self-ex tinguishing feature of fabric when subjected to a flame. The industry has

dev eloped AF-1 and AF-2 classifications for architectural fabrics. Both ty pes must hav e a flame spread rating of 25 or less and

prov ide at least a Class C roof cov ering. In addition, AF-1 fabrics must pass tests related to resistance to ex ternal fire ex posure

and interior flame spread. In certain temporary or nonbuilding structures, fabrics that meet NFPA 7 01 (flame resistance), or

NFPA 7 01 in conjunction with a Class C classification, may suffice. Manufacturers should prov ide confirming information on

which of the NFPA or ASTM tests their products pass.

TOPCOATINGS

Most architectural fabrics hav e some form of topcoating applied to their ex terior coating to improv e cleanability . The topcoats

are acry lic solutions, poly urethane-acry lic solutions, PV DF solution coats or a PV F film lamination. The topcoat prov ides a hard

surface on the outside of the material and minimizes plasticizer migration. The barrier helps prev ent dirt from sticking to the

material and allows the fabric to be cleaned with water. As the material ages, the solution-coated top finishes will erode and the

material will collect more dirt and be harder to clean. Thicker-solution topcoats last longer than thin coats, but coatings that are

http://fabricarchitecturemag.com/articles/0409_f2_structures.html

6/14

3/15/2015

Fabric structures - Fabric Architecture

too thick will embrittle and crack when folded.

For permanent air structures and tensile structures, use of a 1 -mil (25.4 microns) PV F film, particularly if long-term cleanability

and appearance is an issue. The 1 -mil PV F film is 1 0 times as thick as the solution topcoats and will eliminate plasticizer

migration.

The fabrics top finish should relate to the structures long-term aesthetic requirements. Structures used for warehousing and

industrial applications generally dont require high lev els of cleanability . Air-supported structures for sports ev ents, tennis

courts or golf ranges require a moderate lev el of cleanability . Custom tensile structure for amusement parks and music pav ilions

generally require the highest lev el of cleanability .

STRUCTURAL PROPERTIES

A fabrics most fundamental properties are related to stress v ersus strain (unit load v ersus unit elongation), ex pected serv ice

life, the mechanisms of joining the material together (welding, gluing, etc.) and the behav ior of the material in or around a fire.

With this information, y ou are reasonably assured of being able to design a safe project.

For stress v ersus strain, data should be in the form of both uniax ial and biax ial information that characterizes the fabric in terms

of its stiffness, elasticity and plasticity . The information is essential to effectiv e modeling of the materials response under load in

a load-carry ing application. Shear strength, shear strain and Poissons ratios are more difficult to obtain, but are fundamental for

analy zing fabric as a structural material.

Fabric manufacturers should be able to prov ide ev idence of the fabrics long-term performance in a representativ e env ironment

based on testing aged samples.

Other properties come into play in ev aluating a fabrics v iability in a project. Finding information about these properties may be

more difficult to obtain, but worth asking about to gain a full picture of the fabrics performance in a project. Some properties

include:

shading coefficients

general solar, optical, thermal performance data

acoustical data

dimensional stability

colorfastness

cleanability

seam strength and stability

construction method

http://fabricarchitecturemag.com/articles/0409_f2_structures.html

7/14

3/15/2015

Fabric structures - Fabric Architecture

general handling ability , including abrasion resistance, foldability , etc.

Shading coefficients; solar, optical, thermal performance data

Building occupants thermal comfort depends on the air temperature surrounding them and the radiant temperature of the

surfaces enclosing them. The qualities that make fabric structures attractiv e their low mass and translucency also can

contribute to rapid temperature changes in response to ex ternal conditions. As a result, it can feel quite different at v arious

locations in the space, depending on prox imity to surfaces in contrasting thermal states caused by cloud cov er, wind speed or

the suns intensity . Ignoring this effect could result in uncomfortable and inefficiently maintained env ironments.

To understand a fabric membranes thermal behav ior, look to the properties information that its manufacturer supplies.

Specifically , it should offer summer and winter U-v alues and shading coefficients, and optical information about the fabrics

transmittance, absorptance and reflectance, ideally at all wav elengths of thermal radiation and all angles of incidence.

Acoustical properties

We generally think of fabric as absorbing sound but unfortunately , coated fabrics used for roofs and other structures are not

efficient sound-absorbing materials. Although it is true that fabrics will ex hibit reasonable sound-absorbing properties at lower

(bass) frequencies, at middle and high frequencies the fabrics sound absorption is low. (Some coated fabrics can be designed to

prov ide good sound absorption, but they are not imperv ious so they cannot be used in ex ternal roof or structure construction.)

Thus, other materials or installations must prov ide sound absorption when a coated fabric is used for an arena or stadium roof,

retail store, airport terminal or similar application. Coated sound-absorbing fabrics often are installed beneath the imperv ious

roof fabrics. T he distance between the ex terior roof fabric and the interior sound-absorbing fabric affects the

sound absorption and its relation to frequency . Av oid sm all spacing between the two fabrics since doing so

lim its sound absorption.

For large spaces, it often is not possible using coated fabrics alone to prov ide the required absorption for rev erberation control.

To take adv antage of a coated fabrics ability to reflect sound, the structures shape must play as great a role as the fabric itself.

Double-curv ed surfaces can reflect sound in m any directions. Since the fabric does not prov ide a 100%

acoustical barrier, the shape m ust be carefully designed.

Their sound reflectiv ity makes tensile structures especially suitable for acoustic music performances, in which its important for

sound to reflect back to the artists so they may hear themselv es. Properly designed saddle-shaped surfaces both reflect and

diffuse sound.

For amplified performances, the interior of the tensile structure may need fabric liners or other materials to absorb sound.

Because tensile structure fabrics reflect the middle- and high-range sounds, lower frequencies may go through the membrane,

making the sound too bright for amplified music. A v ariance may be needed for certain performances in which the sound bey ond

the structure ex ceeds municipal decibel-lev el requirements.

Colorfastness

http://fabricarchitecturemag.com/articles/0409_f2_structures.html

8/14

3/15/2015

Fabric structures - Fabric Architecture

With PV C-coated and PV C-laminated poly esters, color selection will affect the colorfastness and UV resistance of the finished

material. Certain bright colors and pastel shades will tend to fade with time. Highly translucent material also will not hav e the UV

light resistance as compared to materials with high lev els of titanium diox ide (white pigment) in the ex terior coatings.

Handling considerations

More so than with traditional construction, in the design of membrane structure, the materials properties must be taken into

consideration early in the design process. Only some fabrics, for instance, can accommodate a sharp edge on a four-point cov er.

In the case of a retractable structure, a designer must know whether the fabric can be folded, and the folding v olume. Fiberglass

y arns, for ex ample, lose tensile strength when folded. Speak directly with fabricators and installers to learn the materials

maintenance needs, whether it can be walked on during installation, and whether special tools and equipment are needed for

installation.

http://fabricarchitecturemag.com/articles/0409_f2_structures.html

9/14

3/15/2015

Fabric structures - Fabric Architecture

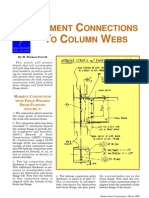

This look inside a v iny l tension-structure membrane shows the materials building blocksa wov en poly ester base fabric with a

v iny l coating.

http://fabricarchitecturemag.com/articles/0409_f2_structures.html

10/14

3/15/2015

Fabric structures - Fabric Architecture

A schematic illustration of the thermal behav ior of fabric membranes.

COMMENTS

Comments are the opinion of individual posters and do not reflect the view s of Fabric Architecture or Industrial Fabrics

Association International.

Wavy fabric - tentering issues ?

Dana pavia-Dunn

Feb 6, 2014

1:10 pm CST

I work with PVC coated poly ester and fiberglass wov en fabric for

window cov erings is sev eral openness factors. Lately we hav e

been seeing alot of wav es and ripples in the fabrics we are

purchaseing for som e suppliers but not others - When I say

wav y - I m ean they dont lay flat on the table to cut large

window shadesw. Do y ou know what could be causing this? And

how to adv ise to correct this? Seem s this fabric is m ost pliable in

the tentering and heating step. Is this som ething wrong in the

tentering process, unev en heat? Unev en tention? Som ething to

do with the cooling and heating tim es and tem peratures. I need

to figure out how to correct this issue. Please adv ise any insight

or experienc y ou hav e to this issue. My suppller say s it's how we

handle the m aterial after we reciev e it but we dont think so.

Please help.

http://fabricarchitecturemag.com/articles/0409_f2_structures.html

11/14

3/15/2015

Fabric structures - Fabric Architecture

Fiber Content

Tanya Sharma

Jan 14, 2014

1:37 am CST

Tanya Sharma

Jan 14, 2014

1:33 am CST

The fiber content of a fabric will determ ine the com fort of the

garm ent when y ou wear it. Usually , in a m arket store, the

fabric content will be on the end of the cardboard form that the

fabric is wrapped around. You m ust sure to ask the sales people,

as som etim es the form is re-used and does not m atch the fabric.

If y ou are purchasing fabric from a web site, the inform ation

should be display ed with the fabric. In case y ou find fabric that

the fiber content is unknown, it can be tested by burning it.

Great post, v ery knowledgeable. Here I am m entioning few

words in contest of fiber content:- The fiber content of a fabric

will determ ine the com fort of the garm ent when y ou wear it.

Usually , in a m arket store, the fabric content will be on the end

of the cardboard form that the fabric is wrapped around. You

m ust sure to ask the sales people, as som etim es the form is reused and does not m atch the fabric. If y ou are purchasing fabric

from a web site, the inform ation should be display ed with the

fabric. In case y ou find fabric that the fiber content is unknown,

it can be tested by burning it. You can get m ore inform ation

here www.shahlon.com . Good luck!

novice needs ideas

Jennie

Dec 21, 2013

4:42 pm CST

Hi, I'm needing to hide the internal roof of a large shed roof.

Main reason is to prev ent flaking insulation from falling on

item s below and im prov e 'look' of the space. I am worried about

tension and heat im plications of m y choice of fabric. Any ideas

appreciated. Jennie

PTFE thickness

S Krishnan

A ug 8, 2013

3:23 am CDT

Hello, I am a doctoral student at the Univ ersity of Illinois. My

research is on tension dom es. I would like to know the thickness

of a ty pical PTFE m em brane used in long span structures. I will

appreciate all properties that will be needed in the structural

m odeling and analy sis of the m em brane. Regards, Krishnan

im try ing to find a cloth that lets in m ost of the air and light

and also has good water retention properties like towels....does it

ev en exist?? because it seem s kind of im possible

Khyati C

Jun 13, 2013

2:31 am CDT

http://fabricarchitecturemag.com/articles/0409_f2_structures.html

12/14

3/15/2015

Fabric structures - Fabric Architecture

bajirao patil

Dec 30, 2012

8:44 am CST

Mara Whitten

Looking for m ore details of base fabric used for car seating

chairs, interlinings, ty pe of coating, new trends and sty les in

car interlining and seating arrangem ent. Also looking for m ore

details on new dev elopm ents and ty pe of fabric used in all ty pes

of bags m anufacturing.

Try searching our Buy er's Guide

(http://fabricarchitecturem ag.com /buy ersguide) for "PTFEcoated." It should bring up sev eral com panies for y ou. Good

luck!

A ug 20, 2012

8:51 am CDT

Searching for manufacturers of woven fiberglass coated with

PTFE(Teflon)

Piyush Parekh

Hi, could please help m e locate the m anufacturers of wov en

fiberglass coated with PTFE(Teflon) worldwide. Thanks.

A ug 17, 2012

12:17 pm CDT

Dara

Jun 13, 2012

1:19 pm CDT

Julian, y our next best m ov e m ay be to v isit Fabric Structure

Association's website (http://fabricstructuresassociation.org/)

and check out the m em ber directory . You m ay well find an

engineer who can help y ou with the calculations. All the best to

y ou as y our div e into y our project.

Structural properties

Julian Brummitt

Jun 6, 2012

5:09 pm CDT

I'm working on an inflatable design, in the m aterial research

phase of the design, and I'm try ing to get an idea of how I will be

able to analy ze the structural properties of the fabric when

placed in tension as a result of com pression v alues. I will be

sealing the fabric around a tube and filling the tube with air to

the appropriate com pression lev el. I'm not sure how to estim ate

the required com pression which will be needed to lift the fabric

up and I further need to calculate how m uch additional load it

can bear. (I will also be placing about 1 2 00 lbs of infrastructure

on top of it.)

http://fabricarchitecturemag.com/articles/0409_f2_structures.html

13/14

3/15/2015

Fabric structures - Fabric Architecture

Copy right 2015 Industrial Fabrics A ssociation International. A ll rights reserv ed.

http://fabricarchitecturemag.com/articles/0409_f2_structures.html

14/14

Potrebbero piacerti anche

- Fabric Structurefabric StructureDocumento61 pagineFabric Structurefabric Structurerichuricha100% (1)

- FRP Sandwich Panel Properties Uses AdvantagesDocumento21 pagineFRP Sandwich Panel Properties Uses AdvantagesNaag RajNessuna valutazione finora

- Tensile Fabric StructuresDocumento26 pagineTensile Fabric StructuresUdz Velez100% (2)

- Structure and Mechanical Properties of WoodDocumento21 pagineStructure and Mechanical Properties of WoodMohammed Amin100% (1)

- Bar ScheduleDocumento2 pagineBar SchedulearctusharNessuna valutazione finora

- GRP and Buildings: A Design Guide for Architects and EngineersDa EverandGRP and Buildings: A Design Guide for Architects and EngineersNessuna valutazione finora

- Elastane FabricDocumento8 pagineElastane FabricMaria MirandaNessuna valutazione finora

- Insulation Roofs P11 40Documento30 pagineInsulation Roofs P11 40Jennifer NavarroNessuna valutazione finora

- Sheet Forming Process of Carbon Fiber Reinforced Plastics For Lightweight Parts PDFDocumento4 pagineSheet Forming Process of Carbon Fiber Reinforced Plastics For Lightweight Parts PDFlolycanoNessuna valutazione finora

- Carbon FibreDocumento33 pagineCarbon FibrePrasad NbNessuna valutazione finora

- Counter Top SpecsDocumento12 pagineCounter Top Specsapi-3797031100% (3)

- Sandwich Panel SP2D PU For External WallDocumento5 pagineSandwich Panel SP2D PU For External WallMujjo SahbNessuna valutazione finora

- Structural Pro™ Laminated Glass Load Resistance Report: Project Details Report DetailsDocumento1 paginaStructural Pro™ Laminated Glass Load Resistance Report: Project Details Report DetailsShafeeq KTNessuna valutazione finora

- PVC SpecificationDocumento17 paginePVC SpecificationDavid Ruelas50% (2)

- Autocad Tutorial: Calculate Scale and Sheet SizeDocumento31 pagineAutocad Tutorial: Calculate Scale and Sheet SizeSamantha NacionNessuna valutazione finora

- Thermal Insulation Materials Made of Rigid Polyurethane FoamDocumento33 pagineThermal Insulation Materials Made of Rigid Polyurethane FoamAdrian MorarNessuna valutazione finora

- Glass Fibre Reinforced Plastic and Its Architectural ApplicationsDocumento27 pagineGlass Fibre Reinforced Plastic and Its Architectural ApplicationsVipul UttamchandaniNessuna valutazione finora

- Standard U ValuesDocumento5 pagineStandard U Valueshello3232Nessuna valutazione finora

- BarChip Fibres Replace Steel in Chilean HousingDocumento2 pagineBarChip Fibres Replace Steel in Chilean HousingPedro Augusto Delgado NascimentoNessuna valutazione finora

- Zipper Testing MethodsDocumento5 pagineZipper Testing MethodsNikita JainNessuna valutazione finora

- Grab and Strip Tensile Strengths For Woven FabricsDocumento8 pagineGrab and Strip Tensile Strengths For Woven Fabricsarobin23Nessuna valutazione finora

- Caravan Frame Materials - Timber, Aluminum or CompositeDocumento12 pagineCaravan Frame Materials - Timber, Aluminum or CompositeAnonymous 3idACuNessuna valutazione finora

- Lower cost FRP baffle panel for structural wallsDocumento2 pagineLower cost FRP baffle panel for structural wallsLoay Al-SabbaghNessuna valutazione finora

- Composites World Thermoformable Composite PanelsDocumento26 pagineComposites World Thermoformable Composite PanelsSunilBhandariNessuna valutazione finora

- Tensile StructuresDocumento29 pagineTensile StructuresPratyush Mishra100% (1)

- Timber 1Documento36 pagineTimber 1CHIRAG SNessuna valutazione finora

- O Line KTS KatalogDocumento152 pagineO Line KTS KatalogJohan ConradieNessuna valutazione finora

- Facades and InterfacesDocumento22 pagineFacades and InterfaceshkatniwalaNessuna valutazione finora

- Glass FibreDocumento14 pagineGlass Fibresofiahabib100% (2)

- Indian Standard: Qualjty Systefds - Model For Quality Assurance in Final Inspection and Te STDocumento13 pagineIndian Standard: Qualjty Systefds - Model For Quality Assurance in Final Inspection and Te STproxywar100% (1)

- Successful Curtain Wall Attachment DesignDocumento4 pagineSuccessful Curtain Wall Attachment DesignTony ZapantaNessuna valutazione finora

- Fit Tolerance For Plastic PartsDocumento16 pagineFit Tolerance For Plastic PartsA_JANNESNessuna valutazione finora

- Timber A Wood Prepared For The Engineering Purpose Is A TimberDocumento21 pagineTimber A Wood Prepared For The Engineering Purpose Is A TimberMohit VermaNessuna valutazione finora

- Seminar on Architectural & Constructional TextilesDocumento33 pagineSeminar on Architectural & Constructional TextilesMusa EltayebNessuna valutazione finora

- Mechanical Characterization of NanocelluloseJute Fiber Based CompositesDocumento4 pagineMechanical Characterization of NanocelluloseJute Fiber Based CompositesInternational Journal of Innovative Science and Research TechnologyNessuna valutazione finora

- Technical Sheet and Installation Guide for Autoclaved Aerated Concrete PropertiesDocumento12 pagineTechnical Sheet and Installation Guide for Autoclaved Aerated Concrete PropertiessubhaschandraNessuna valutazione finora

- 2808-084413 - Glazed Aluminum Curtain WallsDocumento52 pagine2808-084413 - Glazed Aluminum Curtain WallsAmro Ahmad AliNessuna valutazione finora

- Fsi Window SystemsDocumento144 pagineFsi Window SystemsFrederico FerreiraNessuna valutazione finora

- Textile Structures For Technical Textiles Part IDocumento9 pagineTextile Structures For Technical Textiles Part IEdison BittencourtNessuna valutazione finora

- Ply Orientation of Carbon Fiber ReinforcDocumento3 paginePly Orientation of Carbon Fiber ReinforcTopstar2Nessuna valutazione finora

- Metals Extrusion and Drawing Processes ExplainedDocumento26 pagineMetals Extrusion and Drawing Processes ExplainedArvind BhosaleNessuna valutazione finora

- Failure Studies in Materials - ch8Documento47 pagineFailure Studies in Materials - ch8tamailhamNessuna valutazione finora

- Cellular BeamsDocumento4 pagineCellular BeamsSeifeldin Ali MarzoukNessuna valutazione finora

- Bison Panel Layout PDFDocumento48 pagineBison Panel Layout PDFRohan Kulkarni100% (1)

- Infinity PipeDocumento22 pagineInfinity PipeBarlian WidaryantoNessuna valutazione finora

- Soetens 2008Documento37 pagineSoetens 2008jvs11021102Nessuna valutazione finora

- Avjeet Gur Prashad Harpreet Mehar Nikhil ShantanuDocumento20 pagineAvjeet Gur Prashad Harpreet Mehar Nikhil ShantanuProf Dr Kathirrvelu SubramanianNessuna valutazione finora

- Tensile Membrane Structure PDFDocumento25 pagineTensile Membrane Structure PDFAbed Genaim100% (1)

- Build TechDocumento13 pagineBuild Techila030% (1)

- Trosifol® - World of Interlayers - Glass Calculator112mm PVBDocumento2 pagineTrosifol® - World of Interlayers - Glass Calculator112mm PVBwaweng22Nessuna valutazione finora

- S BeamDocumento1 paginaS Beammanu_giteNessuna valutazione finora

- Basic Types Plastic Pipes ProductionDocumento4 pagineBasic Types Plastic Pipes ProductionLeo MilosevNessuna valutazione finora

- A Review On Use of FRP Mesh and Bamboo Fiber Composite Material For AAC Block Masonry Wall Strengthening and WaterDocumento5 pagineA Review On Use of FRP Mesh and Bamboo Fiber Composite Material For AAC Block Masonry Wall Strengthening and WaterIJRASETPublicationsNessuna valutazione finora

- Roofing Profile GuideDocumento192 pagineRoofing Profile Guideghetto_bmx_boyNessuna valutazione finora

- Fabric ArchitectureDocumento6 pagineFabric ArchitectureVarun SanthoshNessuna valutazione finora

- Fiberglass: Glass Wool Glass FiberDocumento8 pagineFiberglass: Glass Wool Glass FibernimigirlzNessuna valutazione finora

- Alternative Building Systems - Tensile Structures MaterialsDocumento6 pagineAlternative Building Systems - Tensile Structures MaterialsJoshua C. JosonNessuna valutazione finora

- FiberglassDocumento17 pagineFiberglassHemali Shah100% (1)

- FiberglassDocumento9 pagineFiberglassJennifer CharlesNessuna valutazione finora

- Makkah Royal Tower ClockDocumento2 pagineMakkah Royal Tower ClockKhader Abu-daggaNessuna valutazione finora

- Analytically Derived Fragility Relationships For The Modern High-Rise Buildings in The UAEDocumento20 pagineAnalytically Derived Fragility Relationships For The Modern High-Rise Buildings in The UAEKhader Abu-daggaNessuna valutazione finora

- Arup Journal 3 2009Documento60 pagineArup Journal 3 2009Deac CristianNessuna valutazione finora

- ADSBS Case StudyDocumento2 pagineADSBS Case StudyKhader Abu-daggaNessuna valutazione finora

- Burj KhalifaDocumento20 pagineBurj KhalifasonukuldeepNessuna valutazione finora

- Watergen Prezentation PDFDocumento24 pagineWatergen Prezentation PDFKhader Abu-dagga100% (1)

- Sound Insulation - NRCDocumento372 pagineSound Insulation - NRCKhader Abu-daggaNessuna valutazione finora

- Moment Connections to Column WebsDocumento3 pagineMoment Connections to Column WebsAmro Ahmad AliNessuna valutazione finora

- Optimization Design of Tall Buildings Under Multiple Design CriteriaDocumento14 pagineOptimization Design of Tall Buildings Under Multiple Design CriteriaKhader Abu-daggaNessuna valutazione finora

- Twofour54 Guideline2018 V28cDocumento60 pagineTwofour54 Guideline2018 V28cKhader Abu-daggaNessuna valutazione finora

- Buildex Self Drilling ScrewDocumento40 pagineBuildex Self Drilling ScrewKhader Abu-dagga100% (1)

- Arup Journal 3 2009Documento60 pagineArup Journal 3 2009Deac CristianNessuna valutazione finora

- Joints in Concrete SlabsDocumento2 pagineJoints in Concrete SlabsmutyokaNessuna valutazione finora

- Watergen Prezentation PDFDocumento24 pagineWatergen Prezentation PDFKhader Abu-dagga100% (1)

- Roofing Product OptionsDocumento8 pagineRoofing Product OptionsKhader Abu-daggaNessuna valutazione finora

- Joints in Concrete SlabsDocumento2 pagineJoints in Concrete SlabsmutyokaNessuna valutazione finora

- Articleaircrafthangarsuperstructures03 PDFDocumento2 pagineArticleaircrafthangarsuperstructures03 PDFSuhail SiddiquiNessuna valutazione finora

- Joints in Concrete SlabsDocumento2 pagineJoints in Concrete SlabsmutyokaNessuna valutazione finora

- Articleaircrafthangarsuperstructures03 PDFDocumento2 pagineArticleaircrafthangarsuperstructures03 PDFSuhail SiddiquiNessuna valutazione finora

- New Buildings: Green Building Guidelines, UAEDocumento131 pagineNew Buildings: Green Building Guidelines, UAEAli AteeqNessuna valutazione finora

- Catalogue 2014Documento227 pagineCatalogue 2014Khader Abu-daggaNessuna valutazione finora

- Shinglev 2Documento4 pagineShinglev 2Khader Abu-daggaNessuna valutazione finora

- Catalogue Exp 100202 PDFDocumento166 pagineCatalogue Exp 100202 PDFKhader Abu-daggaNessuna valutazione finora

- Empowering Solar Across the Middle EastDocumento31 pagineEmpowering Solar Across the Middle EastacidcocoaNessuna valutazione finora

- SikasilBrochure FINAL - High Res 4.5.11Documento3 pagineSikasilBrochure FINAL - High Res 4.5.11Khader Abu-daggaNessuna valutazione finora

- Resilmount Clip - Installation GuideDocumento8 pagineResilmount Clip - Installation GuideKhader Abu-daggaNessuna valutazione finora

- Milano Mixers PDFDocumento8 pagineMilano Mixers PDFKhader Abu-daggaNessuna valutazione finora

- NRC Rc-Ir-761 PDFDocumento371 pagineNRC Rc-Ir-761 PDFKhader Abu-daggaNessuna valutazione finora

- Kimmco Building Roll (KBR) : Kimmco Duct Insulation (Kdi)Documento8 pagineKimmco Building Roll (KBR) : Kimmco Duct Insulation (Kdi)Khader Abu-daggaNessuna valutazione finora

- Resilmount Clip - Data SheetDocumento2 pagineResilmount Clip - Data SheetKhader Abu-daggaNessuna valutazione finora

- SDS Body Mist GenericDocumento4 pagineSDS Body Mist Genericsabuyexpress.worldwideNessuna valutazione finora

- Venturi TubeDocumento2 pagineVenturi TubeQing JyulyanNessuna valutazione finora

- Kartu Stock Obat: Apotek EmpangDocumento17 pagineKartu Stock Obat: Apotek EmpangKlinik EmpangNessuna valutazione finora

- S&T Roofing Solutions Product Guide Mar2018-DP1 0Documento12 pagineS&T Roofing Solutions Product Guide Mar2018-DP1 0sattar12345Nessuna valutazione finora

- Building electricity vocabularyDocumento9 pagineBuilding electricity vocabularyChan PhakkdeyNessuna valutazione finora

- Chemical and Physical Prop of PetroleumDocumento35 pagineChemical and Physical Prop of Petroleumshivam tiwari100% (1)

- Chapter 14Documento11 pagineChapter 14Marco LuigiNessuna valutazione finora

- Surface Preparation StandardsDocumento4 pagineSurface Preparation StandardsjasmineammaNessuna valutazione finora

- 1995Documento283 pagine1995Robert BataraNessuna valutazione finora

- Zak SystemDocumento10 pagineZak SystemSlavisa BjelicNessuna valutazione finora

- SRS 400 A 475 GPMDocumento12 pagineSRS 400 A 475 GPMrhusseinpos4765Nessuna valutazione finora

- MSDS ScaleChem SI-7022Documento5 pagineMSDS ScaleChem SI-7022Muaz Haziq MusaNessuna valutazione finora

- EXPERIMENT A2: Determination of The Formula of A HydrateDocumento5 pagineEXPERIMENT A2: Determination of The Formula of A HydrateTessi SeokoloNessuna valutazione finora

- Fire cable performance standardsDocumento3 pagineFire cable performance standardsRajan Varghese100% (1)

- The Fundamental Building Block: The CellDocumento12 pagineThe Fundamental Building Block: The CellTanish JenaNessuna valutazione finora

- Vaporizer DesignDocumento18 pagineVaporizer DesignEngr Abuzar Khan100% (1)

- Transpiration: Prepared By: Concepcion, Ada - Trinidad, Lester - Tolon, ChristianDocumento17 pagineTranspiration: Prepared By: Concepcion, Ada - Trinidad, Lester - Tolon, ChristiannimhaNessuna valutazione finora

- GSAP - Shell HelixDocumento16 pagineGSAP - Shell HelixJoseph Rubyanto SudrajadNessuna valutazione finora

- Sudharshan Seneviratne 1995Documento41 pagineSudharshan Seneviratne 1995darshanieratnawalliNessuna valutazione finora

- Storage ProteinDocumento3 pagineStorage ProteinprincessicyjulietNessuna valutazione finora

- 02-1 Sampling Challenges in Laterite - Waheed AhmadDocumento31 pagine02-1 Sampling Challenges in Laterite - Waheed AhmadDinanNessuna valutazione finora

- New Natron NXT Series Screen and Pad Printing Ink For Neoprene, Nitrile, EVA and EPDM Rubber From Boston Industrial Solutions, Inc.Documento2 pagineNew Natron NXT Series Screen and Pad Printing Ink For Neoprene, Nitrile, EVA and EPDM Rubber From Boston Industrial Solutions, Inc.PR.comNessuna valutazione finora

- Atmospheric Water GeneratorDocumento3 pagineAtmospheric Water GeneratorKhusnil MujibNessuna valutazione finora

- Gems Psi Paper 2004Documento14 pagineGems Psi Paper 2004biophr34kNessuna valutazione finora

- Using Pumps As Power Recovery TurbinesDocumento4 pagineUsing Pumps As Power Recovery TurbinesKali CharanNessuna valutazione finora

- 72 Had DadDocumento6 pagine72 Had DadthestupiddogNessuna valutazione finora

- Carbomer 940: Information SheetDocumento3 pagineCarbomer 940: Information SheetrendyNessuna valutazione finora

- Application of Nanoparticles in AgricultureDocumento11 pagineApplication of Nanoparticles in AgricultureShetti Swamy PatelNessuna valutazione finora

- Reactivity Series Worksheet - 8B and 8CDocumento6 pagineReactivity Series Worksheet - 8B and 8CHighlightNessuna valutazione finora

- Flash Point StandardsDocumento177 pagineFlash Point Standardsgreat_triskelionNessuna valutazione finora