Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Min Flow

Caricato da

ashrafDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Min Flow

Caricato da

ashrafCopyright:

Formati disponibili

What is the Purpose of

Minimum Flow?

Over the years use of the term minimum flow has evolved.

Decades ago industrial centrifugal pump manufacturers quoted a

single, relatively low value for minimum flow intended to prevent

users from running their pumps to destruction. The term minimum

flow generally meant the lowest continuous flow the pump was

permitted to operate, without reference to duration, vibration level or

other criteria. Today we have minimum flow values for continuous

operation, for intermittent operation and for permissible temperature

rise.

Pump phenomena and minimum flows

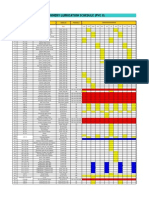

The accompanying chart Pump phenomena and minimum

flows shows the relationships among the various off-design pump

phenomena and minimum flow conditions. The head versus rate of

flow curve with indicated phenomena is a variation of S.

Gopalakrishnans from his well-cited paper titled, A New Method for

Computing Minimum Flow, Proceedings of the Fifth International

Pump Users Symposium; Texas A&M University, May 1988, pp. 4147. As an aside, I recall Gopal (everyone knew him by that name)

had made a local technical presentation using the now well-known

chart, before it was published. Evidently the chart was copied from a

handout of the overhead slides and was quickly pirated by another,

and then others. Copies or variants of this chart are now found

widely in papers and presentations on pumps.

The quoted minimum flow for continuous operation is usually called

Minimum Continuous Stable Flow or its more common abbreviation

MCSF. It is the flow below which the pump should not be operated

continuously. The usual purpose of MCSF is to achieve satisfactory

bearing and seal life; however MCSF may be based on other

considerations. Any of the following factors may be considered in

establishing the MCSF:

manufacturers experience

rule of thumb

calculated onset of suction recirculation or discharge

recirculation

radial thrust

temperature rise

cavitation erosion intensity

maximum permissible pressure rise (for system purposes)

maximum permissible power rise (high specific speed and axial

flow pumps)

a combination of the above factors or others not listed

For hydrocarbon process industry API 610 specification pumps, the

value of MCSF is normally coincident with the lower flow limit of the

Acceptable Operating Range (refer to chart titled Vibration limits for

Allowable Operating Range and Preferred Operating Range) where

a specified vibration limit is not to be exceeded.

Vibration limits for Allowable Operating Range and Preferred Operating

Range

MCSF is a value that can range from roughly 10% to 80% of Best

Efficiency Point flow depending on pump size and type, operating

speed, impeller suction geometry, liquid density, and other factors.

A size 2 (50mm) discharge single-stage process pump may have an

MCSF as low as 10% of BEP flow. MCSF is often in the range of

30% to 60% of BEP flow for process pumps with discharge sizes 3

(75 mm) and larger. Large mixed flow vertical pumps and very high

head-per-stage centrifugal pumps may have an MCSF greater than

60% of BEP flow. Axial flow pumps have a power curve that rises

toward shutoff and minimum flow may be limited by the power rating

of its driver.

On certain high energy pumps the minimum flow is governed by

cavitation erosion damage. Minimum continuous flow for 40,000hour impeller erosion life is where the system NPSH Available curve

intersects the pumps NPSH Required curve, at lower-than-BEP flow.

Intermittent minimum flow, when specified, is usually given as a

percentage of MCSF. On some applications the governing value may

be based on temperature rise. On large high energy pumps the

value of intermittent minimum flow could be, for example, 70% of

MCSF and not to exceed 100 hours per year.

For some applications a thermal minimum flow or Minimum

Continuous Thermal Flow is specified based on permissible liquid

temperature rise. MCTF is usually, but not necessarily, lower than

MCSF. While a pump thermal minimum flow is not always specified,

the end user can readily calculate its value based on input

mechanical power heating up the liquid. The limiting temperature

rise is based on a safe margin to prevent flashing of the pumped

liquid to vapor, potentially causing pump seizure.

Thermal minimum flow is not normally a concern at pump start-up as

long as the closed discharge valve is set to begin opening right

away. If the margin of system NPSHA above pump NPSHR is

minimal, then the temperature rise conditions at pump start-up should

be checked carefully.

A few pump applications, such as a vertical turbine jockey pump for

maintaining pressure in a large fire sprinkler system, can potentially

operate continuously at shutoff while pump suction recirculation

mixes with the water in the sump in which it operates. The sump acts

as a heat sink and a minimal water temperature rise is not a

problem. This example is a rare exception to an almost invariable

stricture on operating the pump continuously at shutoff.

The purpose of minimum flow is generally to prevent undue wear and

tear or damage to the pump. In the real environment of a process or

utility plant, a pump is operated at just about any condition demanded

by the situation at hand. Thus there are different pump minimum

flows for different purposes.

Potrebbero piacerti anche

- Defining Off Peak Pump Performance AOR and PORDocumento9 pagineDefining Off Peak Pump Performance AOR and PORhellwigtobiNessuna valutazione finora

- 3-Axles Semi Trailer Fuel Tank 45000 m3 StandardDocumento3 pagine3-Axles Semi Trailer Fuel Tank 45000 m3 StandardashrafNessuna valutazione finora

- PEB Brochure PDFDocumento12 paginePEB Brochure PDFBrian AbbottNessuna valutazione finora

- Centrifugal Pump FundamentalsDocumento140 pagineCentrifugal Pump FundamentalsLizbeth CamachoNessuna valutazione finora

- Chapter (5) Pump System CurveDocumento27 pagineChapter (5) Pump System Curvekarioke mohaNessuna valutazione finora

- Compressor Calculations: Polytropic CalculationDocumento1 paginaCompressor Calculations: Polytropic CalculationChirag DarjiNessuna valutazione finora

- Class Xii Chemistry Students Support MaterialDocumento95 pagineClass Xii Chemistry Students Support MaterialDivyam GargNessuna valutazione finora

- Pump System Efficiency: A Pumps & Systems E-BookDocumento14 paginePump System Efficiency: A Pumps & Systems E-BookAthiphap SrisupareerathNessuna valutazione finora

- Minimum Stable FlowDocumento3 pagineMinimum Stable Flowdk4monjureNessuna valutazione finora

- Minimum Thermal Flow in Centrifugal PumpsDocumento3 pagineMinimum Thermal Flow in Centrifugal Pumpsmnt6176Nessuna valutazione finora

- Pipe SizingDocumento4 paginePipe SizingTen Dye MungwadziNessuna valutazione finora

- NPSH PT 244Documento4 pagineNPSH PT 244mazzam75Nessuna valutazione finora

- Concrete Technology HandoutDocumento21 pagineConcrete Technology HandoutsainathNessuna valutazione finora

- Fluid Mechanics Tutorial 8C Pumped Piped Systems: Let's Start by Examining The Meaning of Specific Speed of PumpsDocumento17 pagineFluid Mechanics Tutorial 8C Pumped Piped Systems: Let's Start by Examining The Meaning of Specific Speed of Pumps12Nessuna valutazione finora

- PumpDocumento9 paginePumpNguyen ChuyenNessuna valutazione finora

- Positive Displacement PumpsDocumento5 paginePositive Displacement PumpssikuetNessuna valutazione finora

- Condensate PumpsDocumento1 paginaCondensate Pumpstricky11Nessuna valutazione finora

- Stress Relief Boreback BoxDocumento3 pagineStress Relief Boreback BoxDaisuke Numata100% (1)

- Calculate Bottom Hole Pressure With The Cullender and Smith MethodDocumento2 pagineCalculate Bottom Hole Pressure With The Cullender and Smith Methodprateek_bhoirNessuna valutazione finora

- Pressure DropDocumento54 paginePressure DropAbu Abdullah AlkaffNessuna valutazione finora

- Cylindrical Horizontal Tank Volume CalculationDocumento21 pagineCylindrical Horizontal Tank Volume CalculationashrafNessuna valutazione finora

- Multiphase Flow 1995Da EverandMultiphase Flow 1995A. SerizawaNessuna valutazione finora

- Pump NotesDocumento9 paginePump NotesGauravNessuna valutazione finora

- Book-Condensed Hydraulic PDFDocumento66 pagineBook-Condensed Hydraulic PDFbratkpNessuna valutazione finora

- Dimethyl AnilineDocumento68 pagineDimethyl Anilinemikelycan100% (1)

- Pressure Loss CorrelationsDocumento57 paginePressure Loss Correlationseandresmar100% (1)

- NASA CC3 ImpellerDocumento22 pagineNASA CC3 ImpellerPaul BarlowNessuna valutazione finora

- Paints Pigments and Industrial CoatingsDocumento10 paginePaints Pigments and Industrial CoatingsRaymond FuentesNessuna valutazione finora

- ML For Dummies TotalDocumento167 pagineML For Dummies TotalNataša ZekaNessuna valutazione finora

- 10 1016@j Jngse 2016 01 016Documento37 pagine10 1016@j Jngse 2016 01 016saiful bahriNessuna valutazione finora

- Pressure Drop Calculation - ExampleDocumento1 paginaPressure Drop Calculation - ExampleBandi ThaguruNessuna valutazione finora

- A Centrifugal Pump Converts The Input Power To Kinetic Energy in The Liquid by Accelerating The Liquid by A Revolving DeviceDocumento6 pagineA Centrifugal Pump Converts The Input Power To Kinetic Energy in The Liquid by Accelerating The Liquid by A Revolving DeviceAudrey Patrick KallaNessuna valutazione finora

- Pressure Drop in PipelineDocumento13 paginePressure Drop in PipelineNilambar BarihaNessuna valutazione finora

- 5.7 Centrifugal PumpsDocumento8 pagine5.7 Centrifugal PumpsSaleem Chohan100% (1)

- Eductor SizingDocumento2 pagineEductor SizingbudiprasNessuna valutazione finora

- Info RASCHIG Column Internals-1101Documento100 pagineInfo RASCHIG Column Internals-1101Frits32100% (3)

- Flow and Pressure Drop in Valves and Fittings. Valve Resistance Coefficient and DiameterDocumento21 pagineFlow and Pressure Drop in Valves and Fittings. Valve Resistance Coefficient and Diameterjroman33Nessuna valutazione finora

- ABS Fire Extinguisher CatalogueDocumento56 pagineABS Fire Extinguisher CatalogueqwertyNessuna valutazione finora

- Centrifugal Pump - What Is The Purpose of Minimum FlowDocumento3 pagineCentrifugal Pump - What Is The Purpose of Minimum Flowjesus_manrique2753Nessuna valutazione finora

- Centrifugal Pumps NPSHDocumento6 pagineCentrifugal Pumps NPSHSubrata MukherjeeNessuna valutazione finora

- AWDM 10 CH04 Water - Consumption PDFDocumento49 pagineAWDM 10 CH04 Water - Consumption PDFEdward BeleñoNessuna valutazione finora

- Electrical Load Data Sheet: Facility Name: Date: Address: City/State/Zip: Directions or Nearest Intersecting StreetDocumento1 paginaElectrical Load Data Sheet: Facility Name: Date: Address: City/State/Zip: Directions or Nearest Intersecting Streetgag aaNessuna valutazione finora

- Selección de CompresoresDocumento23 pagineSelección de CompresoresjowarNessuna valutazione finora

- Lube Oil Plan PVC2Documento10 pagineLube Oil Plan PVC2daxNessuna valutazione finora

- Residential and Commercial High StrengthDocumento36 pagineResidential and Commercial High StrengthNiong DavidNessuna valutazione finora

- Lecture 5 2Documento15 pagineLecture 5 2IbrahimDewaliNessuna valutazione finora

- Design Criteria 2019 PDFDocumento64 pagineDesign Criteria 2019 PDFngronau124545Nessuna valutazione finora

- Viscous Incompressible FlowDocumento72 pagineViscous Incompressible FlowEduardo LaloNessuna valutazione finora

- C3 Recovery StudyDocumento15 pagineC3 Recovery StudyengmohosmanNessuna valutazione finora

- Orifice SizingDocumento2 pagineOrifice SizingXheikhKaleemNessuna valutazione finora

- Performance Thermo CompressorsDocumento8 paginePerformance Thermo CompressorsclintoncNessuna valutazione finora

- Crane Vs Eqvlnt Length Method For FittingsDocumento177 pagineCrane Vs Eqvlnt Length Method For FittingsSamuel OnyewuenyiNessuna valutazione finora

- 4.2 Design of The Pump According To The Installation Baseplated Pumps AdvantagesDocumento3 pagine4.2 Design of The Pump According To The Installation Baseplated Pumps AdvantagesSandi AslanNessuna valutazione finora

- PumpLab Book 1 PreviewDocumento11 paginePumpLab Book 1 Previewcorey6Nessuna valutazione finora

- Compress Air Golden RulesDocumento1 paginaCompress Air Golden Rulesmymail0808Nessuna valutazione finora

- Reading A Pump Curve: Pump Name and SpeedDocumento4 pagineReading A Pump Curve: Pump Name and SpeedganeshanNessuna valutazione finora

- Compressible Flow Bench: Yeditepe University Department of Mechanical EngineeringDocumento5 pagineCompressible Flow Bench: Yeditepe University Department of Mechanical EngineeringAhmad AbukhashabehNessuna valutazione finora

- Sizing of Steam Lines PDFDocumento4 pagineSizing of Steam Lines PDFsakalidhasavasanNessuna valutazione finora

- Orifice MeterDocumento9 pagineOrifice MeterEran LopezNessuna valutazione finora

- Pump Design Data Design Curve Data: Design Parameter Units Value Design TDH/Power vs. CapacityDocumento1 paginaPump Design Data Design Curve Data: Design Parameter Units Value Design TDH/Power vs. CapacitydaveNessuna valutazione finora

- Vent Sizing For Fire Considerations For External Fire Duration Diers Users Group Ers Design For Fire CommitteeDocumento19 pagineVent Sizing For Fire Considerations For External Fire Duration Diers Users Group Ers Design For Fire CommitteekglorstadNessuna valutazione finora

- Pressure Drop in Gas PipelinesDocumento38 paginePressure Drop in Gas PipelinesDarshan Patel100% (1)

- 1a.calibration of OrificemeterDocumento7 pagine1a.calibration of OrificemeterArjun P PNessuna valutazione finora

- 14 Draw Off Nozzle Hydraulics PDFDocumento12 pagine14 Draw Off Nozzle Hydraulics PDFMohsin EhsanNessuna valutazione finora

- System OneDocumento4 pagineSystem OnerasottoNessuna valutazione finora

- Mehran University of Engineering and Technology SZAB Campus Khairpur Mir'sDocumento64 pagineMehran University of Engineering and Technology SZAB Campus Khairpur Mir'sMarcusHuynh88Nessuna valutazione finora

- Fluid MechanicsDocumento19 pagineFluid MechanicsengNessuna valutazione finora

- High Pressure Phase Behaviour of Multicomponent Fluid MixturesDa EverandHigh Pressure Phase Behaviour of Multicomponent Fluid MixturesNessuna valutazione finora

- Chemical Reactor Design, Optimization, and ScaleupDa EverandChemical Reactor Design, Optimization, and ScaleupNessuna valutazione finora

- Article On Pump Minimum FlowDocumento5 pagineArticle On Pump Minimum Flowarunima04100% (1)

- Simple Patterns for Developing Part19Documento2 pagineSimple Patterns for Developing Part19ashrafNessuna valutazione finora

- My First AbccDocumento1 paginaMy First AbccashrafNessuna valutazione finora

- Simple_Patterns_for_Developing_Part3Documento2 pagineSimple_Patterns_for_Developing_Part3ashrafNessuna valutazione finora

- Ready for School Grades Prek to 1 Part24Documento1 paginaReady for School Grades Prek to 1 Part24ashrafNessuna valutazione finora

- My First ADocumento1 paginaMy First AashrafNessuna valutazione finora

- DocumentDocumento1 paginaDocumentashrafNessuna valutazione finora

- Registry Entries For VSTO Add-Ins - Visual Studio (Windows) - Microsoft LearnDocumento7 pagineRegistry Entries For VSTO Add-Ins - Visual Studio (Windows) - Microsoft LearnashrafNessuna valutazione finora

- Dynamic HysysDocumento1 paginaDynamic HysysashrafNessuna valutazione finora

- My First AbcDocumento1 paginaMy First AbcashrafNessuna valutazione finora

- Pages From Applied Process Design C Hemical Petrochemical Plants1Documento1 paginaPages From Applied Process Design C Hemical Petrochemical Plants1ashrafNessuna valutazione finora

- Pages From AppliedProcessDesignChemicalPetrochemicalPlants1-3Documento1 paginaPages From AppliedProcessDesignChemicalPetrochemicalPlants1-3ashrafNessuna valutazione finora

- Compatibility With Plastics and Elastomers: TitleDocumento2 pagineCompatibility With Plastics and Elastomers: TitleashrafNessuna valutazione finora

- Text MIN MAX FIX Cost Group SPG LGA NAP PRO ETH : Table BuyDocumento4 pagineText MIN MAX FIX Cost Group SPG LGA NAP PRO ETH : Table BuyashrafNessuna valutazione finora

- Star - Wars.the - last.Jedi.2017.720p.bluray.H264.AAC RARBGDocumento74 pagineStar - Wars.the - last.Jedi.2017.720p.bluray.H264.AAC RARBGashrafNessuna valutazione finora

- Kali Linux 2.0 Top 10 Post Install TipsDocumento1 paginaKali Linux 2.0 Top 10 Post Install TipsashrafNessuna valutazione finora

- BBC.shock.and.Awe.the.Story.of.Electricity.2of3.the.age.of.invention.pdtv.XviD.mp3.MVGroup.orgDocumento85 pagineBBC.shock.and.Awe.the.Story.of.Electricity.2of3.the.age.of.invention.pdtv.XviD.mp3.MVGroup.orgashrafNessuna valutazione finora

- Carl Sagan's cosmOS Part I The Shores of The CosmicDocumento62 pagineCarl Sagan's cosmOS Part I The Shores of The CosmicashrafNessuna valutazione finora

- Introduction To Boolean AlgebraDocumento6 pagineIntroduction To Boolean AlgebraashrafNessuna valutazione finora

- Carl Sagan's cosmOS Part IV Heaven and HellDocumento2 pagineCarl Sagan's cosmOS Part IV Heaven and HellashrafNessuna valutazione finora

- VelocityDocumento1 paginaVelocityashrafNessuna valutazione finora

- Autocad Plant3d Quick Reference GuideDocumento2 pagineAutocad Plant3d Quick Reference GuideashrafNessuna valutazione finora

- BBC Shock and AweDocumento64 pagineBBC Shock and AweashrafNessuna valutazione finora

- Rheology and Hydraulics: Rheology Is The Science of Deformation and Flow of MatterDocumento36 pagineRheology and Hydraulics: Rheology Is The Science of Deformation and Flow of Matterhassan haddadiNessuna valutazione finora

- Periodic Classification of ElementsDocumento101 paginePeriodic Classification of Elementsmrpulkit20Nessuna valutazione finora

- Subject: Chemistry Chapter #: 6: Quantitative Chemistry - How Much? (Moles)Documento26 pagineSubject: Chemistry Chapter #: 6: Quantitative Chemistry - How Much? (Moles)Haider Ali100% (2)

- Mucosal Drug Delivery SystemDocumento34 pagineMucosal Drug Delivery SystemDebjani Baidya100% (1)

- Persediaan 2017, 2018Documento1.061 paginePersediaan 2017, 2018Selly RianiNessuna valutazione finora

- Fire-Specifications For Fire Free Coatings-Manu Spec FF88Documento6 pagineFire-Specifications For Fire Free Coatings-Manu Spec FF88smartman35Nessuna valutazione finora

- Chapter 1 Introduction To The Study of GeneticsDocumento31 pagineChapter 1 Introduction To The Study of GeneticsCassieGrecoNessuna valutazione finora

- ME 6301 Engineering Thermodynamics QB - BY Civildatas - Com 12 PDFDocumento62 pagineME 6301 Engineering Thermodynamics QB - BY Civildatas - Com 12 PDFAjay JNessuna valutazione finora

- Msds Colateric Jbs (16 Section)Documento6 pagineMsds Colateric Jbs (16 Section)mndmattNessuna valutazione finora

- Slab-On-Grade Reinforcing DesignDocumento9 pagineSlab-On-Grade Reinforcing DesignAdam GreenlawNessuna valutazione finora

- Electrical Fuse HRC Fuse High Rupturing Capacity - Electrical EngineeringDocumento5 pagineElectrical Fuse HRC Fuse High Rupturing Capacity - Electrical EngineeringAmit DebnathNessuna valutazione finora

- 科莱恩塑料颜料宝旭化工Documento12 pagine科莱恩塑料颜料宝旭化工Ashesh ShahNessuna valutazione finora

- Enthusiast Score-I 2021-22Documento1 paginaEnthusiast Score-I 2021-22Aarya Vardhan ShandilyaNessuna valutazione finora

- Spons Encyclopaedia of The Industrial Arts, Manufactures, and Commercial Products, Part 3Documento396 pagineSpons Encyclopaedia of The Industrial Arts, Manufactures, and Commercial Products, Part 3Books for the lotNessuna valutazione finora

- Fuels and Combustion: - Calorific Value - Significance and Comparison Between LCV andDocumento44 pagineFuels and Combustion: - Calorific Value - Significance and Comparison Between LCV andanurag prernaNessuna valutazione finora

- Home Made Soap: Using Glitz Caustic SodaDocumento1 paginaHome Made Soap: Using Glitz Caustic Sodaabeiasa_biomedNessuna valutazione finora

- Theory Papers Odd Semester 2008-2009 Civil Engineering Theory Papers Odd-SemesterDocumento47 pagineTheory Papers Odd Semester 2008-2009 Civil Engineering Theory Papers Odd-SemesterVijay KumarNessuna valutazione finora

- 全棉⾯料(100%Cotton Fabric): Item Comp Yarn Weight (G/SM) Width RemarkDocumento11 pagine全棉⾯料(100%Cotton Fabric): Item Comp Yarn Weight (G/SM) Width RemarkI'm BuddyNessuna valutazione finora

- Production and Characterization of Heterogeneous Catalyst (CaO) From Snail Shell For Biodiesel Production Using Waste Cooking OilDocumento4 pagineProduction and Characterization of Heterogeneous Catalyst (CaO) From Snail Shell For Biodiesel Production Using Waste Cooking OilAbdul azizNessuna valutazione finora

- Kandhal Lecture 3 On Aggregate For Bituminous Road Construction - Handouts OnlyDocumento8 pagineKandhal Lecture 3 On Aggregate For Bituminous Road Construction - Handouts OnlyProf. Prithvi Singh KandhalNessuna valutazione finora

- Infrared Physics & Technology: Luca QuaroniDocumento6 pagineInfrared Physics & Technology: Luca QuaroniAlejandro QuintanaNessuna valutazione finora

- Extraction of Copper and Gold From Anode Slime of Sarcheshmeh Copper Complex by M.H.Dehghanpoor PDFDocumento5 pagineExtraction of Copper and Gold From Anode Slime of Sarcheshmeh Copper Complex by M.H.Dehghanpoor PDFFerudun AkyolNessuna valutazione finora