Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

JP3 Notes Condensate

Caricato da

haritec2Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

JP3 Notes Condensate

Caricato da

haritec2Copyright:

Formati disponibili

Application Note: Verax Analyzer

Condensate RVP and TVP

Introduction

Condensate has been coming in from gathering

systems for years and has been handled in different

ways. However, the industrys focus on liquids-rich

resource plays has elevated the focus on condensates

and how they should be handled. Numerous factors

varying from economical to environmental drivers

have contributed to this change in priorities, but U.S.

condensate production has increased in step with

activity in shale plays.

Condensate is lighter than crude oil, but heavier than

natural gas liquids. The issue with condensate in

its natural form is that the lighter hydrocarbons can

make it dangerous to store and transport. Therefore,

stabilizing is required to allow the condensate to meet

specifications. Often, the condensate is pumped

to a sales storage tank, where it will flash off its

lighter hydrocarbon components. These are usually

captured through vapor recovery compression in

order to prevent venting to the atmosphere, which

results in lost revenues and potential emission issues.

In many cases, however, liquids pricing makes it

advantageous to further process the demethanized

condensate to produce a saleable condensate

product with a target Reid Vapor Pressure (RVP) or

True Vapor Pressure (TVP). To accomplish this, a

second stabilizer is placed in the process immediately

downstream of the first. The demethanized liquids are

sent to another liquid/liquid exchanger to be warmed,

and are then fed to the top tray of the RVP control

stabilizer. (Fig1)

at 100F (for RVP), which is well below the condensing

point of the paraffin present in the typical condensate

stream. This will cause plugging of sample lines and

measurement cells in a traditional RVP analyzer which

will cause failure of the device.

Solutions

The JP3 Verax analyzer utilizes NIR spectroscopy

to identify the components in the condensate that

will directly determine the RVP or TVP and model

the actual RVP of the stabilized condensate. The

Verax also has the ability to report the actual hydrocarbon composition along with the vapor pressure

information, making a significantly more powerful tool

for midstream process control.

The Verax has two optical probes that are in contact

with the process and will usually have a heater blanket

on them to prevent them from being the heat sink

for the paraffin that is typically in these condensate

streams. The optical probes can be mounted directly

on the stabilizer outlet while the process is still at the

higher temperatures which will keep the paraffin in a

liquid phase.

Measuring the RVP of stabilized condensate in the

midstream gathering and stabilization facilities of the

more recent shale oil fields has proven to be a very

difficult analysis due to the amount of paraffin in the

condensate stream. Conventional ASTM methods

have proven mostly unsuccessful.

Measurement Problems

Making this analysis with a conventional ASTM

method requires the sample stream to be measured

Fig.1 Typical Stabilizer

Application Note: Verax Analyzer

Condensate Vapor Pressure

NGL (Y-Grade) Stream

The Verax can speciate the C2-C3 hydrocarbon split and also monitor the

potential C1 contaminant.

9 psi RVP Stabilized Condensate

The Verax is successfully measuring stabilized condensate RVP in both the

Eagle Ford and the Marcellus shale fields.

Vapor Recovery Unit

The Verax can report composition of the hydrocarbon stream and report C6+

and BTU of the recovered gases.

Verax 75 Analyzer

SPECIFICATIONS

Fluid Streams (Max 8 per Analyzer) Type: natural gas, NGLs, LPG, condensate, crude oil; Phase: liquid or gas

Composition & Property Analyses C1-C6+ Mol% 0.5% repeatability ; RVP & TVP 0.5 psi ; API Gravity or BTU 0.5% repeatability

Moisture(H2O) >1%

Carbondioxide (CO2) >1%

Sample System None

Calibration Gas None

Verification Fluid Varies by application

Line Pressure 0-1500 psig

Line Temperature -10to 150F

Line Flow Rate 1.0 gpm minimum; no maximum

Response Time 10-30 seconds per analysis point

Detection Method NIR spectroscopy with inline optical probes

ELECTRICAL

Input Power 3.5A @ 24VDC standard; 100-240 VAC optional

Communications TCP/IP, MODBUS TCP and Serial (others available upon request)

Outputs 8 solid state relays for process control; 2 analog 4-20 mA /0-10 VDC outputs standard;

configurable alarms/controls

PHYSICAL

Enclosures NEMA 4X IP 67 powder coated aluminum

Dimensions Top Control Panel: 24W x 30H x 10D; Bottom Control Panel: 24W x 24H x 10D

Weight Combined Top & Bottom Control Panels:90 lbs.; Probe Assembly: 5 lbs.

Ambient -20to 50C (-4to 122F). No environmental control required; sunshade required if >90F

Classification Control Panel with Z-Purge: Class 1 Div2; Control Panel without Purge: General Purpose;

Probe Assembly: Intrinsically Safe /Class 1 Div1

4109 Todd Lane, Suite 200

Austin, Texas 78744

www.jp3measurement.com

For more information:

512.537.8450

sales@jp3measurement.com

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Cooling Load UERM CANTEENDocumento52 pagineCooling Load UERM CANTEENHenry San PedroNessuna valutazione finora

- Cement Additives PDFDocumento64 pagineCement Additives PDFfaheemqcNessuna valutazione finora

- Abstract (Lab 2) Ionization ConstantDocumento12 pagineAbstract (Lab 2) Ionization Constantmirdza94Nessuna valutazione finora

- Diary Trends Foods Profile: Description Amount Unit CaloriesDocumento2 pagineDiary Trends Foods Profile: Description Amount Unit Caloriesharitec2Nessuna valutazione finora

- CSHM 2016 - FinalDocumento9 pagineCSHM 2016 - Finalharitec2Nessuna valutazione finora

- 1200 Cal DietDocumento2 pagine1200 Cal Dietharitec2Nessuna valutazione finora

- CSHM 2016 - FinalDocumento9 pagineCSHM 2016 - Finalharitec2Nessuna valutazione finora

- Phase Fluorimetric OxygenDocumento12 paginePhase Fluorimetric Oxygenharitec2Nessuna valutazione finora

- 2011 IFPAC - Dinosaurs Among Us - 01!20!11Documento21 pagine2011 IFPAC - Dinosaurs Among Us - 01!20!11haritec2Nessuna valutazione finora

- Dubois - IsA - Myths and Mistakes - Oct 6c, 2010 - IsA AW - CPAC ReleaseDocumento19 pagineDubois - IsA - Myths and Mistakes - Oct 6c, 2010 - IsA AW - CPAC Releaseharitec2Nessuna valutazione finora

- Phase Fluorimetric OxygenDocumento12 paginePhase Fluorimetric Oxygenharitec2Nessuna valutazione finora

- JP3 Notes Plant BalancingDocumento4 pagineJP3 Notes Plant Balancingharitec2Nessuna valutazione finora

- JP3 Notes FractionationDocumento2 pagineJP3 Notes Fractionationharitec2Nessuna valutazione finora

- Corporate Presentation - December 2014Documento47 pagineCorporate Presentation - December 2014haritec2Nessuna valutazione finora

- En-211 CrackSpreadHandbook SRDocumento16 pagineEn-211 CrackSpreadHandbook SRharitec2Nessuna valutazione finora

- On LineAnalyzerUsesAndApplications PDFDocumento11 pagineOn LineAnalyzerUsesAndApplications PDFharitec2Nessuna valutazione finora

- Isa Paper 2011 Sample LinesDocumento12 pagineIsa Paper 2011 Sample Linesharitec2Nessuna valutazione finora

- Resolution Effects - SpectrosDocumento13 pagineResolution Effects - Spectrosharitec2Nessuna valutazione finora

- Btu Analysis Using A Gas ChromatographDocumento5 pagineBtu Analysis Using A Gas Chromatographlutfi awnNessuna valutazione finora

- PAC ReviewDocumento20 paginePAC Reviewharitec2Nessuna valutazione finora

- PGA ANO C2plus Turbine ControlDocumento2 paginePGA ANO C2plus Turbine Controlharitec2Nessuna valutazione finora

- Lord Kelvin QuoteDocumento1 paginaLord Kelvin Quoteharitec2Nessuna valutazione finora

- Design of UV SpectrometersDocumento13 pagineDesign of UV Spectrometersharitec2Nessuna valutazione finora

- Beginning PullupsDocumento18 pagineBeginning Pullupsharitec2Nessuna valutazione finora

- Acid Gas ManagementDocumento2 pagineAcid Gas Managementharitec2Nessuna valutazione finora

- Jimenez PHD ThesisDocumento360 pagineJimenez PHD Thesisharitec2Nessuna valutazione finora

- SulfuricDocumento21 pagineSulfuricharitec2Nessuna valutazione finora

- E. Loewen Diffraction Grating Handbook (2005)Documento271 pagineE. Loewen Diffraction Grating Handbook (2005)haritec2Nessuna valutazione finora

- SulfuricDocumento21 pagineSulfuricharitec2Nessuna valutazione finora

- Nafion DryersDocumento25 pagineNafion Dryersharitec2Nessuna valutazione finora

- Liquid Millionaire FreeDocumento311 pagineLiquid Millionaire FreeikramuNessuna valutazione finora

- (Sex Seduction Dating) Thunder Cat - Art of ApproachingDocumento94 pagine(Sex Seduction Dating) Thunder Cat - Art of ApproachingDavid Herbert Lawrence100% (6)

- Jawad, 2020 - Mesoporous Iraqi Red Kaolin Clay As An Efficient Adsorbent For Methylene Blue Dye Adsorption Kinetic, Isotherm and Mechanism Study PDFDocumento7 pagineJawad, 2020 - Mesoporous Iraqi Red Kaolin Clay As An Efficient Adsorbent For Methylene Blue Dye Adsorption Kinetic, Isotherm and Mechanism Study PDFLorranaVietroNessuna valutazione finora

- Exercise 1 Lab Manual Chem 117Documento4 pagineExercise 1 Lab Manual Chem 117EJ FelisildaNessuna valutazione finora

- Insulation Thickness ChartDocumento9 pagineInsulation Thickness ChartPartha Pratim GhoshNessuna valutazione finora

- Types of Exapnsion Devices in RAC SystemsDocumento4 pagineTypes of Exapnsion Devices in RAC SystemsNishit ParmarNessuna valutazione finora

- Class X Test Electrolysis and MetullargyDocumento4 pagineClass X Test Electrolysis and MetullargyToshiGMaheshwariNessuna valutazione finora

- P4 Oct Nov 21Documento11 pagineP4 Oct Nov 21Aini Munirah Muhamad ShudNessuna valutazione finora

- Pipeline Cathodic Protection Design - Compress PDFDocumento20 paginePipeline Cathodic Protection Design - Compress PDFBadi100% (1)

- 9 Chem Unit 3 NewDocumento5 pagine9 Chem Unit 3 NewRizwan HameedNessuna valutazione finora

- ChE212 Topic 04 A NotesDocumento4 pagineChE212 Topic 04 A NotesGino Paul MarasiganNessuna valutazione finora

- Nanoemulsions and Their Potential Applications in Food IndustryDocumento21 pagineNanoemulsions and Their Potential Applications in Food IndustrySiapa HayoNessuna valutazione finora

- Notes - Acids Bases and SaltsDocumento2 pagineNotes - Acids Bases and SaltsantonyNessuna valutazione finora

- Phyy 5Documento24 paginePhyy 5Sajjad FaisalNessuna valutazione finora

- Highly Luminescent N-Doped Carbon Quantum Dots From Lemon JuiceDocumento8 pagineHighly Luminescent N-Doped Carbon Quantum Dots From Lemon JuiceJoaquim RodriguezNessuna valutazione finora

- Xii Physics NotesDocumento170 pagineXii Physics Notesiamyasirali68Nessuna valutazione finora

- European Patent Specification C23F 11/10, C02F 5/12: Printed by Jouve, 75001 PARIS (FR)Documento11 pagineEuropean Patent Specification C23F 11/10, C02F 5/12: Printed by Jouve, 75001 PARIS (FR)mini2018Nessuna valutazione finora

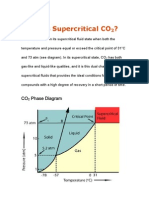

- What Is Super Critical CO2Documento42 pagineWhat Is Super Critical CO2kesaco100% (2)

- Chapter 4 Ionic EquilibriumDocumento61 pagineChapter 4 Ionic EquilibriumSuraj BhattaraiNessuna valutazione finora

- Journal of The Taiwan Institute of Chemical Engineers: Tawfik A. Saleh, Gaddafi I. DanmalikiDocumento9 pagineJournal of The Taiwan Institute of Chemical Engineers: Tawfik A. Saleh, Gaddafi I. DanmalikiPrativa BeheraNessuna valutazione finora

- Errata For Atkins' Chemical Principles 5th EditionDocumento2 pagineErrata For Atkins' Chemical Principles 5th EditionRonald LNessuna valutazione finora

- One Dimensional Steady State Conduction: By: Taz 1Documento52 pagineOne Dimensional Steady State Conduction: By: Taz 1Adam AndualemNessuna valutazione finora

- THC SigmaDocumento2 pagineTHC SigmaPinoteDiegoNessuna valutazione finora

- Dehydration of Ethanol On Zeolite Based MediaDocumento11 pagineDehydration of Ethanol On Zeolite Based MediaHasan AbuyNessuna valutazione finora

- Topic 1 Quantitative Chemistry (New)Documento42 pagineTopic 1 Quantitative Chemistry (New)ma hiuming100% (1)

- Organic Chemistry Carbonyls, Carboxylic Acids and ChiralityDocumento22 pagineOrganic Chemistry Carbonyls, Carboxylic Acids and ChiralityMer CyNessuna valutazione finora

- Physical Science Paper 1 November 2010Documento23 paginePhysical Science Paper 1 November 2010BRANDON TINASHENessuna valutazione finora

- LPG Standards PDFDocumento115 pagineLPG Standards PDFhandoyo_eko20017573Nessuna valutazione finora

- Synthetic RubbersDocumento3 pagineSynthetic RubbersKamal KishoreNessuna valutazione finora