Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Mtechindusproins

Caricato da

Manoj BallaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Mtechindusproins

Caricato da

Manoj BallaCopyright:

Formati disponibili

DEPARTMENT OF INSTRUMENT TECHNOLOGY

A.U. COLLEGE OF ENGINEERING (A)

VISAKHAPATNAM

M.TECH INDUSTRIAL PROCESS INSTRUMENTATION

COURSE STRUCTURE, SCHEME OF EVALUATION AND SYLLABUS

M.Tech Degree Examinationa

Industrial Process Instrumentation

Course Structure and Scheme of Evaluation (Semester-wise)

Sl.

No.

Hrs./Week

Name of the Subject

Evaluation (Marks)

Credits

Int.

Written

Pract

.

Total

SEMESTER-I

1

Transducers and Measurements

30

70

100

Process Dynamics & Control

30

70

100

Computer Control of Process

30

70

100

Industrial Instrumentation

30

70

100

Analysis Instruments

30

70

100

Industrial Instrumentation lab

100

100

SEMESTER-II

1

Microprocessor based

Instrumentation

30

70

100

Electronic Instrumentation

30

70

100

Fibre Optics and Laser

Instrumentation

30

70

100

Power Electronics

30

70

100

Signal Processing

30

70

100

Seminar / Comprehensive Viva

100

100

26

100

100

SEMESTER-III

Thesis / Dissertation / Project

in the field of Instrumentation

M.TECH. I 1.1 TRANSDUCERS AND MEASUREMENTS

1.

Performance Characteristics Accuracy, Sensitivity, Precision,

Lizearity, resolution, hysterisis and dead zone, Inout and Output

impedance. Static and Dynamic characteristics.

2.

Resistance Transducers : Resistance Potentiometer, Stringauges

metallic and semi conducting, Thermistors, Photo transistors and

Photo resistors.

3.

Capacitance Transducers : Air gap and dielectric filled.

4.

Piezoelectric Transducers : Piezoelectric crystals and its properties,

configurations, sensitivity coefficients, ferro-electric materials,

biomorphs uses.

5.

Magnetostrictive

applications.

6.

Feedback Transducers : Application of negative feedback, advantages,

typical schemes.

7.

Elastic Transducers : Springs, billons, diaphragms, thin plates,

mombranos, bourdon tubes their special futures and applications.

8.

Hall Transducers, Flapper hozzle, A.C. Tachogenerators, Infra and U-V

Detectors, Ionizations gauges.

9.

Smart Transducers Optical & Hybrid Transducers.

Transducers

Materials,

Characteristics

and

Textbooks :

1.

Hormon, K.P. Neubert, Instrument Transducers An Introduction to

their performance and design 3rd Edn. Clarendon Press, Oxford.

2.

Earnest O.Doeblin, Measurement Systems, Application and Design,

McGraw-Hill, Kogakusha Ltd., New Delhi, 1983.

3.

C.S.Rangan, G.R.Sharma and V.S.Mani, Instrumentation Devices and

Systems, Tata McGraw-Hill Publishing Company Ltd., New Delhi,

1983.

4.

Barry E. Jone, Instrumentation, Measurement and Feedback, Tata

McGraw-Hill Publishing Company Ltd., New Delhi, 1983.

5.

Kurt S. Lion, Elements of Electrical and Electronic Instrumentation

McGraw-Hill, Kogakusha Ltd.

6.

D. Patranabis, Principles of Industrial Instrumentation, Tata McGrawHill Publishing, 1976.

M.TECH. I 1.2 PROCESS DYNAMICS AND CONTROL

1.

Dynamics of level, flow and thermal processes Modelling of

Processes Degrees of freedom Laws governing level, flow and

thermal proceses Formulation of mathematical models for simple

processes in each category.

2.

Basic control actions and controllers Various types of control

actions On-Off, Speed Floating-P, I D P+D and P+I+D control actions

Pneumatics and electronic controllers to realize above control

actions Tuning of controllers Performance indices Continuous

cycling method Reaction Curve method Evaluation of Process

Control Loop.

3.

Final Control Elements Pneumatic, hydraulic and electrical

actuators Control valves Characteristics Control Valve sizing

Cavitation and flashing in control valves Solenoid valves Motor

operated valves SCR as power control devices.

4.

Complex Control Systems Ratio control system Food forward

control Cascade control Adaptive control Selective Control

Averaging Control Systems with examples their advantages and

applications.

5.

Case Studies Various control loops in distillation column, steam

boiler, paper manufacturing plant.

References :

1.

P. Harriott, Process Control, Tata McGraw-Hill Publishing Co., Ltd.,

New Delhi, 1984.

2.

A. Pollard, Process Control, Heinemann Educational Books, London,

1981.

3.

T. Webber, An Introduction to Process Dynamics and Control, John

Wiley & Sons, New York, 1973.

4.

B.G. Liptak, Instrumentation in Processing Industries, Vol. II, Chilton

Book Co., 1973.

M.TECH. I 1.3 COMPUTER CONTROL OF PROCESSES

1.

Multivariable Systems State Variable representation of multi-input,

multi-output systems Solutions to state equations STM Food

forward control, ratio control, cascade control Interactive control

systems Controllability, observability State variable feedback.

2.

Introduction to Computer Control Systems Need for computer in a

control system Functional Block diagrams of Data Acquisition

Systems, Supervisory Control, Direct Digital Control, Programmable

Logic Control, Hierarchy Concept, Distributed Digital Control.

3.

Digital Controller and Algorithms Functional block of a Computer

Control System Digital Controller Algorithms Dead-beat, Dahlins

Kalmans, PID.

4.

Self-tuning Controllers Tuning of Controllers Performance indices

Adaptive Systems Self Tuners

5.

Distributed Digital Control System Significance of Distributed

Control System (DCS) Advantages Configuration Commercial

Systems.

6.

Process Control Computers Requirement of a computer for process

applications Peripheral devices analog & digital subsystems

Microprocessor based process systems Personal computers for

Processes.

References :

1.

C.M. Houpis, G.B. Lamont, Digital Control Systems, Theory,

Hardware, Software, International Student Edition, McGraw-Hill Book

Company, 1985.

2.

S.I Ashon, Microprocessors with Application in Process Control, Tata

McGraw-Hill Publishing Company Ltd., 1984.

3.

C.D. Johnson, Microprocessor based Process Control, Prentice Hall

Inc., 1984.

4.

C.L. Smith, Digital Computer Process Control, Intext Educational

Publishers, 1972.

5.

E.F. Johnson, Automatic Process Control, McGraw-Hill, 1967.

M.TECH. I 1.4 INDUSTRIAL INSTRUMENTATION I

1.

Design and fabrication of pressure measurement devices :

Piezo electric, Piezo resistive, capacitive and inductive pressure

pickups. Ionization, Alphatron gauge. High Pressure measurement

Piezo resistive and electro optic type. Force balance, Motion balance

type transmitters P/I and I/P convertors. IC pressure sensors and

current trends. Standards and calibration procedures.

2.

Flow Measuring Devices :

Installation and maintenance of different types of Head flow meters.

Variable area flowmeter Principle Rotameter glass and armour type

piston type bypass rotameter installation and maintenance

Inferential flow meters Propeller type turbine meter.

Electromagnetic flowmeter Principle DC AC and pulsed type

Ultrasonic flowmeter Principles transit time Doppler shift beam

deflection Tracer type flowmeter cross correlation NMR Mass

flowmeter transverse momentum Coriolis Pressure differential type

Thermal type Vortex shedding Principle fluid oscillating type

Swirl meter Sold flow measurement Capacitance type Force

sensing type standards and Calibration procedures.

3.

Design and fabrication of Level Measuring Devices :

Piezometric method using diaphragms and bellows Conductive and

Capacitive method electro mechanical method ultrasonic radiation

and microwave sensors use of light and thermistor as point sensors.

Solid level measurement Paddler method capacitance method for

powder level measurement.

4.

Design and fabrication of Density and Weight :

Load cell method Strain gage, LVDT, Piezoelectric Pneumatic and

hydraulic load coil null balance method conveyor belt weighing for

on line measurement.

References :

1.

N.P.Choromisionoff, Process Level

Marcel Dekkar Inc., New York, 1981.

Instrumentation

2.

Y.L.Arora,

Flow

measurement

Corporation, Bombay, 1978.

3.

R.K.Jain, Mechanical and

Publishers, Delhi, 1984.

4.

E.O. Doebelin, Measurement Systems, Application and Design,

McGraw Hill, Tokyo, 1983.

Techniques,

Industrial

and

Universal

Measurements,

Control

Book

Khanna

5.

R.S.Sirohi and H.C. Radhakrishna, Mechanical Measurements, Wiley

Eastern, 1980.

M.TECH. I 1.5 ANALYSIS INSTRUMENTS

1.

Fourier Transform Spectroscopy Emission spectroscopic

Instruments grating type instruments principle of operation and

constructional details Applications X-ray diffraction energy

dispersion analysis detectors X-ray absorption fluoroscene

spectrometry Radiation sources - , , , sources detectors

Geiger Mueller counter proportionalunters Ionization chamber

scintillation counter Solid State Detector rate meter Industrial

application of radiation measurement.

2.

Nuclear Magnetic Resonance (NMR) spectroscopy Principles of

operation and constructional details of NMR spectrophotometer

Broad band spectrometer Application principles and application of

Electron Spin Resonance (ESR) spectrometer. Mass spectrometry

principle of operation Co-analyser Commercial mass spectrometer.

3.

Flue Gas and Water Analysers :

Flue gas analysis using thermal conductivity principle Katharometer

Oxygen analyzer using paramagnetic, depolarization principles

Zirconium oxide cells Co Monitor combustibles analyzer Different

types of Dust and Smoke meter Visible Emissions Monitor Remote

sensing laser instruments Water purity meter Conductivity meters

Steam purity measurement Dissolved oxygen meter using

polarographic principle sodium analyzer Silica analyzer.

4a.

CHROMOTOGRAPHY : Basic Principle Gas Chromotography Liquid

Chromotograph Different types of columns Detectors Recorders

and associated equipment.

4b.

Salient features of liquid chromatography detectors used

application of high precision liquid chromatography p based

spectroscopic analysis current trends in analysis instrumentation.

References :

1.

D.A. Skoog and D.M. West, Principles of Instrumental Analysis, Holt

Saunders publication, Philodelphia, 1980.

2.

C.K. Mann, T.J. Vichers and W.H. Gulick, Instrumental Analysis,

Harper and Row Publishers, New York, 1974.

3.

H.A. Willard, L L Merrit and J.A. Dean, Instrumental Method of

Analysis D. Van Nostrand Co., New York, 1958.

4.

E.B.Jones, Instrument Technology, Vol.II, Instruments, Butterwork

Scientific Pub., London, 1956.

10

5.

E.G. Liptak, Instrumentation in Process Industries Suppl. To Vol.I and

II Chilton Book Co., 1974.

11

M.TECH. I 2.1 MICROPROCESSOR BASED INSTRUMENTATION

1.

Review of Microprocessors, Microprocessor architecture Intel 8085

Instruction set Assembly language programming IO Interrupts

16 Bit Processors.

2.

Input / Output Interface devices Review of A/D and D/A converters

Isolated I/O and memory mapped I/O + I/O Device selection.

Universal programmable peripheral interface 8255 and different

modes of operation. Serial and Parallel I/O ports RS 232 & IEEE

488 buses Asynchronous and Synchronous communication (8251).

LED and seven segment display interface Keyboard and display

controllers.

3.

Microprocessor measurement systems: Measurement and monitoring

of electrical and non-electrical quantities Analog and digital

multiplexers Sample and hold multi channel scanning,

Annunciation and data storage.

4.

Microprocessor control systems : Data acquisition systems

Supervisory Control Direct digital control Control algorithms

programmable logic control.

5.

Microprocessor applications in process control : Multipoint

temperature sensors Microprocessor based flow control loop,

temperature control loop- air fuel ratio control schemes for a boilers

UP based four (4) loop control system.

References :

1.

A.P. Mathur, Introduction to Microprocessors, Tata McGraw-Hill 1985.

2.

L.A. Leventhal, Introduction to Microprocessors Software hardware,

Programming, Prentice Hall of India (P) Ltd.

3.

S.I. Abson, Microprocessors with applications in Process Control, Tata

McGraw-Hill, 1984.

4.

C.D.Johnson and D. Curtis, Microprocessor based Process Control,

Prentice Hall Inc., 1984.

12

M.TECH. I 2.2 ELECTRONIC INSTRUMENTATION

1.

Review of analog and digital building blocks Different types of linear

and digital ICs Classification and specifications for UA 741, LM 108

series, 7400 TTL Series, 725 series.

2.

Power supplies : Types of IC power supplies functional blocks Fixed

and variable supply voltages Precision power supply ICs External

current boosting circuits Overload and short circuit protection

circuits Switch mode power supplies.

3.

Analog Instruments : Cathode ray oscilloscopes General purpose

and advanced types Sampling CRDs Basics of storage CRTs wide

band AC milli voltmeters Average reaching peak reading and true

RMS types Wave analyzers and FFT analyzers.

4.

Digital Instruments : Digital multimeters Dual slope and successive

approximation types of A/D conversion Digital counters Digital

storage CROs.

5.

Display and recording devices : Seven segment and dot matrix

displays X-Y recorders Magnetic type recorders.

References :

1.

E.O. Doebelin, Measurement Systems, Application and Design,

McGraw-Hill International Book Co., 3rd Edition, 1983.

2.

C.S. Rangan, G.R. Sarma, V.S.V. Mani, Instrumentation Devices and

Systems, Tata McGraw-Hill Pub. Co., New Delhi, 1985.

3.

C.B.Clayton, Linear Integrated Circuits and Application, Ruston

Publishing Co., 1975.

4.

W.D. Cooper, Electronic Instrumentation

Techniques, Prentice Hall, India, 1981.

5.

H.V. Malmstadt, C.M. Enke & S.R. Crouch, Instrumentation for

Scientist Series, Benjamin / Commings Pub., Co., 1974.

13

and

Measurement

M.TECH. I 2.3 FIBRE OPTICS AND LASER INSTRUMENTATION

1.

Theory of classification of fibre optics Different types of fibres

properties and considerations Fabrication of fibre components

2.

Fibre optic sensors Fibre optic communication and instrument

system Advantages of optical communications Different types of

Modulators Detectors Fibre optic communication setup

Applications in instrumentation.

3.

Characteristics and fundamentals of lasers Laser emission and light

amplification Properties of laser beams Laser modes Resonator

configuration Q-switching mode locking Single frequency

operation.

4.

Types of lasers Gas lasers Solid lasers liquid lasers

semiconductors lasers.

5.

Lasers for Analysis Laser application in holographic microscopy

holographic interferometry saturation spectroscopy.

6.

Industrial application of Lasers Measurement of distance and

length, velocity, acceleration, atmospheric effects, sonic boom,

pollutants, Material processing, laser heating, melting, scribing,

splicing, material removal, calculation of power requirement of laser

for material processing.

References :

1.

H.C. Allen, An Introduction

International Book Co., 1983.

2.

D. Reddy and J. Coolon, Electronic Communication, Prentice Hall,

1985.

3.

L.Allen, Esssentials of Lasers, Oxford University Press, 1969.

4.

D.C. Oshea and W.Russel Callen, Introduction to lasers and their

Applications, Addison Wesley, 1978.

5.

BS.. Wherrelt, Laser Advances and Applications, John Wiley, 1979.

6.

W.O.N. Guimarass and A.Mooradian, Lasers and Application Springer

Verlag, 1981.

14

to

Optical

Fibres,

McGraw-Hill

M.TECH. I 2.4 POWER ELECTRONICS

1.

Single Phase and three phase converters Sigle phase and three

phase Bridge type controlled rectifiers Single phase and three

phase - Expressions for DC output and ripple content Dual

converters.

2.

Inverters Line commutated and forced commutated inverters

Series converter Impulse commutated converter three phase

inverters.

3.

Cycle converters and Choppers Cycle converters and Cycle inverters

Frequency doublers and frequency triplers AC chopper DC

Chopper different types.

4.

DC and AC Motor Speed Control D.C. motor speed control using

SCRs Two quadrant and four quadrant speed control A.C. motor

speed control Slip-power recovery scheme.

5.

Thyristor Applications in Instrumentation Use of SCR as a final

control element in process loop Ramp and Pedestal control using

SCRs On-Off and Proportional control of level and thermal process

using thyristors Light control Switching mode voltage regulators.

References :

1.

F.F.Mazda, Thyristor Control, Newnes Butterworths, London, 1973.

2.

B.D.Bedford and R.G.Hoft, Principles of Inverter Circuits, John Wiley,

New York, 1964.

3.

M.Ramamoorthy, An Introduction to Thyristors

Applicatiions, East West Press, New Delhi, 1977.

4.

SCR Manual, General Electric Company, U.S.A., 1984.

15

and

their

M.TECH. I 2.5 SIGNAL PROCESSING

1.

Signal Representation Classification of Signals and their

mathematical representation step, impulse, ramp, periodic, nonperiodic and random signals Fourier series and Fourier transforms

Modifying signals, interfering signals, White-noise signal to noise

ratio.

2.

Signal Modulators Different types of modulators Amplitude and

frequency modulators Modulation and Demodulation techniques

and circuits Pulse modulation PPM, PWM, PCM Demodulators.

3.

Signal Converters Analog and Digital multiplexers, sample hold

devices, D/A and A/D converters, sampling, quantizing and encoding,

control logic and interfacing, output signal reconstruction.

4.

Active Filters Active filter circuits and design LP, BP, HP Special

filter mechanization Band rejection and notch filters.

5.

Digital filters Definition, Block diagram model Difference

equations z transforms Pulse transfer function Classification of

digital filters recursive and non-recursive Infinite Impulse

Response (IIR) and Finite Impulse Response Filters (FIR).

References :

1.

J.Millman and C.C.Halkias, Integrated Electronics Analog and Digital

Circuits and Systems, McGraw-Hill, Kogakusha Ltd., Tokyo, 1982.

2.

L.R. Rabniner and B.Gold, Theory and Application of Digital Signal

Processing, Prentice Hall, New Delhi, 1985.

3.

P.Gamett, Analog Systems for Microprocessors and Minicomputers,

Prentice Hall Pub. Co., 1985.

16

17

ANDHRA

UNIVERSITY

A.U.COLLEGE OF ENGINEERING (AUTONOMOUS)

ISO 9001 : 2000

Telephone No.0891-2844945 (O)

0891-2844946 (H)

Fax No.

0891-2525611

DEPARTMENT OF INSTRUMENT TECHNOLOGY

VISAKHAPATNAM,

Date : 06-11-2008.

From

HEAD OF THE DEPARTMENT

To

The Principal,

A.U. College of Engineering (A),

Visakhapatnam.

Sir,

Sub: Submission of IPI & B.Tech Syllabai Reg.

***

I am herewith sending CD containing the syllabai of

Industrial processing Instrument and B.Tech. Engineeringfor your

kind perusal.

Thanking you,

Yours faithfully,

(M.MARIYA DAS)

HEAD OF THE DEPARTMENT

19

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- CSWIP Welding Inspection Plate Section PracticalDocumento31 pagineCSWIP Welding Inspection Plate Section PracticalManoj Balla100% (3)

- Direct Conversion Receivers in Wide Band SystemsDocumento251 pagineDirect Conversion Receivers in Wide Band SystemsDaniel BarryNessuna valutazione finora

- Finisher q1 q3 PMDocumento62 pagineFinisher q1 q3 PMutilscNessuna valutazione finora

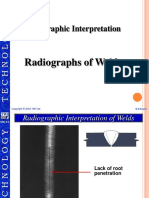

- Radiographic Interpretation: Radiographs of WeldsDocumento22 pagineRadiographic Interpretation: Radiographs of WeldsManoj BallaNessuna valutazione finora

- 8000E Service ManualDocumento66 pagine8000E Service ManualJuan Carlos Isaza Garcia100% (1)

- Is Iso 5349 2 2001Documento45 pagineIs Iso 5349 2 2001aldo3ab100% (1)

- Basics of 4-20ma Current LoopDocumento7 pagineBasics of 4-20ma Current LoopsandystaysNessuna valutazione finora

- Pipe Chart PDFDocumento2 paginePipe Chart PDFCarlos Rivera0% (1)

- Optical CommunicationDocumento10 pagineOptical CommunicationYashasvi MittalNessuna valutazione finora

- Ref 541Documento76 pagineRef 541Adrian PurcaroiuNessuna valutazione finora

- Seismic Processing 3Documento169 pagineSeismic Processing 3Temitayo Ologun100% (1)

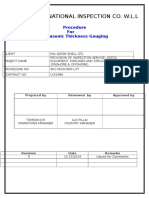

- UT Thickness ProcedureDocumento8 pagineUT Thickness ProcedureManoj Balla100% (3)

- Introduction To Marine AutomationDocumento46 pagineIntroduction To Marine AutomationHarvey Zabala60% (5)

- Huawei GSM Rru3008 Introduction 090420 Issue1.0 BDocumento42 pagineHuawei GSM Rru3008 Introduction 090420 Issue1.0 BEng Amr ElorbanyNessuna valutazione finora

- WeldingDocumento34 pagineWeldingManoj BallaNessuna valutazione finora

- 3rd Party-NDT-CCS-Post Weld Heat Treatement Procedure For SAPID Approval PDFDocumento11 pagine3rd Party-NDT-CCS-Post Weld Heat Treatement Procedure For SAPID Approval PDFManoj Balla100% (1)

- PUMA 761 762 Equipment ManualDocumento332 paginePUMA 761 762 Equipment ManualJackie SongNessuna valutazione finora

- En MultiBlockProgApplFW CDocumento274 pagineEn MultiBlockProgApplFW Cnhocp123Nessuna valutazione finora

- Multimedia Communication Vtu Unit 2Documento54 pagineMultimedia Communication Vtu Unit 2raghudatheshNessuna valutazione finora

- OFDM OpticalDocumento16 pagineOFDM OpticalAnh Nguyen100% (1)

- 1746sc-NI8u Manual 0300172 03DDocumento130 pagine1746sc-NI8u Manual 0300172 03Drfg21100% (1)

- International StandardDocumento10 pagineInternational StandardManoj BallaNessuna valutazione finora

- Rail Track Material Catalogue Nov17Documento44 pagineRail Track Material Catalogue Nov17Manoj BallaNessuna valutazione finora

- AsmeDocumento11 pagineAsmeManoj BallaNessuna valutazione finora

- API 510 Exam - 5C - Answer - KeyDocumento1 paginaAPI 510 Exam - 5C - Answer - KeyManoj BallaNessuna valutazione finora

- ASNT Level III MT Questions and Answers PDFDocumento20 pagineASNT Level III MT Questions and Answers PDFManoj Balla100% (5)

- Spectral Analysis of The Vedic Mantra OmkaraDocumento5 pagineSpectral Analysis of The Vedic Mantra OmkaraKiran RmvNessuna valutazione finora

- WP Namur PDFDocumento13 pagineWP Namur PDFIñaki EseberriNessuna valutazione finora

- 7RW600 Iec PDFDocumento4 pagine7RW600 Iec PDFsupermannonNessuna valutazione finora

- Vacon NXL Lift ALFIFF28 Application Manual UD00973Documento44 pagineVacon NXL Lift ALFIFF28 Application Manual UD00973TanuTiganuNessuna valutazione finora

- Revista ANSYSDocumento52 pagineRevista ANSYSEgar MtzNessuna valutazione finora

- Digital Comm Lecture5 SQRDocumento17 pagineDigital Comm Lecture5 SQRJehuNessuna valutazione finora

- MATLAB Communication Toolbox PrimerDocumento344 pagineMATLAB Communication Toolbox PrimerchalimisNessuna valutazione finora

- DIGITAL COMMUNICATION-unit 2 VTUDocumento75 pagineDIGITAL COMMUNICATION-unit 2 VTUraghudathesh100% (12)

- SOPDocumento5 pagineSOPKarthik V KalyaniNessuna valutazione finora

- The Physical Layer, Encoding Schemes:: - Physical Transmission of BitsDocumento13 pagineThe Physical Layer, Encoding Schemes:: - Physical Transmission of BitsPrinceRajDKilerNessuna valutazione finora

- AKS 41U Level Probe Data Sheet RD8AA502Documento12 pagineAKS 41U Level Probe Data Sheet RD8AA502Munkwok LeeNessuna valutazione finora

- Date Tehnice Control AccesDocumento32 pagineDate Tehnice Control AccesCornelCiorcanNessuna valutazione finora

- ECE220Documento13 pagineECE220Hackonymous WorldNessuna valutazione finora

- Infrasound Recording SystemDocumento7 pagineInfrasound Recording SystemarunpdnNessuna valutazione finora

- LAB MANUAL Updated PDFDocumento45 pagineLAB MANUAL Updated PDFTiff NguyenNessuna valutazione finora