Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Success-Story PSG e

Caricato da

lakshmi321Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Success-Story PSG e

Caricato da

lakshmi321Copyright:

Formati disponibili

SUCCESS STORIES

PSG Plastic Service GmbH uses the complete product range

of the ISD Group

Consistent process optimisation with HiCAD, HELiOS, ERP-interface and HELiCON

From 2-D CAD to an optimised, consistent process chain with PDM system, ERP interface and product

configuration that is the technical progress the PSG has realised during the last years.

The PSG Group is a producer of hot runner systems

partner for the ISD. Today, PSG uses a solution consi-

and control technology. With its innovative solutions

sting of HiCAD, HELiOS and HELiCON that enables an

the company is ranked among the leading suppliers

optimal process control and ensures a permanent

for the plastics processing industry in Germany. As a

competitiveness.

specialist for customized hot runner systems the successful company offers a huge variety of nozzles for all

kinds of industries - from the smallest nozzle Nano

to the largest nozzle Big Shot. One of the most

important factors is the flexibility of the products, as a

great diversity of applications and innovations in the

field of technical plastics development require very

precise solutions.

Since 1994 the PSG Group has been using the CAD

system HiCAD for its product development tasks. This

was the basis for the gradual development of a com-

Customized solutions: Distributor with different geometries

and universally utilizable nozzles for a wide range of uses

(Image: PSG GmbH)

prehensive solution for the entire process chain

from sales to production. As a provider of complete

solutions, the ISD Group turned out to be the optimal

Keeping pace with the times

After working with a 2-D system in the nineties, we

IN BRIEF

switched to 3-D CAD with HiCAD. With the aim to optimise our document management, we also intensified

PSG Plastic Service GmbH

our utilisation of the PDM system HELiOS. In 2012,

Industry: Plastics industry

we implemented an interface to the ERP system

Software: HiCAD, HELiOS, ERP-interface,

HELiCON

Products: Hot runner systems, control systems,

cooling and temperature regulation systems

cess, the ISD staff had always assisted us with their

Headquarters: Mannheim

Walter, System administrator and Frank Gulde, chief

www.psg-online.de

designer at PSG.

ProALPHA. One year later, we decided to additionally

acquire HELiCON to automate the creation of standardized articles. During the implementation progreat expertise and competence", recall Christine

SUCCESS STORIES

on that is needed for the actual production, e.g. the

tolerances. HiCAD in conjunction with HELiOS enables us to realize our production concepts perfectly",

explains Christine Walter. PSG has developed an innovative concept for production strategies that allows an

optimal, lossless transfer of data between Engineering

and Process Planning. In this way, the high level of

quality required by the customers can be ensured on

a sustained basis for both standard products and

customized products.

Safer processes thanks to HELiOS

Over the years, the PSG Group has also intensified its

use of the PDM system HELiOS that had been used

for document and project management right from the

start. Whereas in the past, the working method at the

PSG was still drawing-oriented, it is now part masterConstructed with HiCAD: Nozzle from the Allround series

(Image: PSG Plastic Service GmbH)

oriented, including an automatic output of bills of

materials. And a modern, workflow-controlled release

system has been implemented, too.

In 2012, an interface to the ERP system ProALPHA

Optimised production processes with HiCAD

was created. ProALPHA had already been used in

Engineers working with HiCAD generally appreciate

various departments, e.g. in Sales and Purchasing.

the user-friendly, intuitive GUI, which also enables a

HELiOS workstations can be found in Engineering,

fast familiarisation for beginners. During the switching

Process Planning, Service, Quality Assurance and

to 3-D, the engineers at PSG greatly benefitted from

Project Planning. To prevent double entries and

HiCADs unique 2-D/3-D associativity: As the whole

manual entries of article masters in ProAlpha, the

process was performed gradually, a simultaneous wor-

PSG engineers and the ISD developed a concept for

king in 2-D and 3-D was required for a prolonged peri-

the ERP interface that allowed a controlled exchange

od. Even today, 2-D legacy data must sometimes still

of article master and structure data between HELiOS

be loaded and edited. PSG does not only combine 2-D

and ProAlpha. Furthermore, neutral formats of all rele-

and 3-D CAD, but also parametric and non-

vant production documents are generated and these

parametric modelling: In some cases, existing, partly

documents are then transferred to the ERP system for

parameterised models require quick changes applied

visualisation purposes. We are more than satisfied

by means of non-parametric modelling, in other

with the support we receive from the ISD. The know-

cases, customer data imported via STEP need to be

how of our cooperation partner and the precision of

processed further. Furthermore, PSG makes extensi-

their project planning greatly contributed to the suc-

ve use of HiCADs Design Variant technology, which is

cessful realisation of the interface, says Frank Gulde.

based on a combination of parametric and non-

The complete process chain could be optimised

parametric modelling. "We use the Design Variants

thanks to the described expansion of the software uti-

very often. Our variants already contain the informati-

lisation. New orders are stored in the ERP system by

UNLIMITED PERFORMANCE

SUCCESS STORIES

the Sales department, which automatically makes the

adjustments. During order processing, they often had

data available as HELiOS project as a part of the CAD

to deal with repetitive tasks. Smaller constructions

drawing. Controlled by the HELiOS workflow, the

with only minimal changes were often created several

whole product development process through to the

times. This resulted in longer lead times, a high con-

greenlighting by the customer for the actual produc-

sumption of resources and a lack of efficiency. On the

tion takes place via HELiOS, which has constant

one hand, PSG already controlled its parametric vari-

access to all relevant information.

ants via Excel, or made calculations on technical

product designs. But on the other hand, these procedures were very time-consuming and required programming skills. And the limits of the program soon

became evident: The biggest sources of error and

the most time-consuming tasks certainly consisted in

the manual data input and the repetitive routine tasks.

It was therefore important for us to find a program that

could spare us exactly these tasks, explains

Christine Walter, system administrator. She and her

Nozzle from the new Easy Shot series.

Rapidly and easily configurable in HELiCON.

(Image: PSG Plastic Service GmbH)

colleague Frank Gulde, chief designer, had soon realised the benefits that HELiCON offered: We were

sure that we could achieve our aims with the help of

HELiCON, says Christine Walter. The product

configurator enabled us to shorten lead times, mini-

Easy and efficient automation with HELiCON

Engineer

mize errors, increase product quality and reduce prod-

But thats not all: PSG additionally uses the product

create a standardized structure with consistent desig-

configurator HELiCON Engineer for an automation of

nations.

uct development costs. At the same time, we could

all standard products. HELiCON Engineer is a CAD

application that can be integrated into HiCAD and

Fast implementation of HELiCON

HELiOS and enables an automatic generation of tech-

HELiCON was then implemented at PSG within a few

nically perfect 3-D CAD models and specific draw-

weeks. First, the requirements concerning the soft-

ings. The program uses the data existing in HiCAD

ware were specified and the staff members of the PSG

and HELiOS and enables the definition of rules that

were trained appropriately by the ISD. After a short

ensure the validity of chosen product combinations.

test period of approximately five weeks, the first

The product know-how will be stored in HELiCON and

assembly could be generated via the configurator and

leads the user automatically to the creation of error-

transferred to the CAD drawing. Prior to this, all parts

free products, including the generation of CAD draw-

had to be converted to 3-D, and relations had to be

ings, bills of materials and PDM data. HELiCON allows

defined. These first steps were a little time-

a quick and easy product adjustment through auto-

consuming, but still manageable, reports Christine

mation of repetitive tedious routine tasks in

Walter. During this preparatory stage, an expert of the

Engineering. Before the introduction of HELiCON, the

ISD provided permanent support.

CAD engineers at PSG spent much time on the search

for matching parts in assemblies, or on manual

UNLIMITED PERFORMANCE

SUCCESS STORIES

More time for customized designs

this way, our staff was given enough time to get accus-

HELiCON generates the assembly, creates the article

tomed to the changes and realise their projects suc-

master, generates a product structure, creates part

cessfully.

and assembly drawings as well as an associated project. In this way, all double work is eliminated. All mod-

Progress and evolvement thanks to ISD products

ular products of the PSG and their individual variants

With HiCAD, HELiOS and HELiCON, PSG uses the full

can be visualised in HELiCON. Standard parts are

range of ISDs software products. The next planned

directly assembled in the configurator. Models of the

steps are a customisation of HELiCON, and the pur-

complete product can be created in a very short time.

chase of further HELiCON Studio licenses in order to

Each article that has been previously configured in

further promote the concept of product configuration

HELiCON will be recognized and re-used, preventing

at the PSG.

an inadvertent, repeated creation of the same article.

The finished product will always be created from

Long-term partnerships

existing components, which does not only save time,

Part of the PSG Groups company philosophy are

but also prevents an accumulation of identical single-

long-term partnerships and a long-standing, success-

part data. The different dependencies in a product

ful cooperation with its customers. A good example of

resulting from a general product diversity used to be

this philosophy is the year-long and fruitful partner-

possible sources of error, but have been eliminated

ship with the ISD: The PSG has always appreciated

now that the configurator had been introduced at

the ISD as an extremely competent partner. Their ser-

PSG. I am glad that we can now fully concentrate on

vices, such as training and consulting, in conjunction

our CAD models, says Frank Gulde. We do no lon-

with their high-performance software as part of a well

ger have to waste any time for the search of matching

conceived one-stop solution has significantly contrib-

components, or for manual adjustments. The time

uted to our success! says Frank Gulde with great sat-

savings due to the omission of such tedious routine

isfaction.

tasks are really enormous.

Customer-friendly consulting

In fact, PSG has already shown strong interest in

acquiring HELiCON around the time when the ERP

interface was introduced. After detailed consulting,

the advice of the ISD was to introduce the new systems successively, one by one, since experience has

shown that employees usually need some time to

familiarise themselves with their operation. In retrospect, Frank Gulde confirms: It was a good decision

to let one year pass by. In the end, the advice we got

A strong partner for your success:

ISD Software und Systeme GmbH

from the ISD proved very helpful. We first implemented the ERP interface, familiarized ourselves with

it, and fully concentrated on HELiCON afterwards. In

UNLIMITED PERFORMANCE

+49-(0)231-9793-0

+49-(0)231-9793-101

info@isdgroup.de

isdgroup.com

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- U.S. Civics TestDocumento11 pagineU.S. Civics TestPopeyeKahnNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- CMPM ReviewerDocumento8 pagineCMPM ReviewerRochel ClareteNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Job Order CostingDocumento6 pagineJob Order CostingJomar Teneza100% (1)

- ReviewofWearandGallingCharacteristicsofStainlessSteel 9006Documento0 pagineReviewofWearandGallingCharacteristicsofStainlessSteel 9006fahreezNessuna valutazione finora

- Cranes Today AprDocumento84 pagineCranes Today AprCarlos Ramón Plazaola Lorio100% (1)

- Everything You Need to Know About Ball MillsDocumento14 pagineEverything You Need to Know About Ball MillsLaxman Kumar100% (1)

- Supply Chain Strategy Study For Marks and SpencerDocumento9 pagineSupply Chain Strategy Study For Marks and SpencerSiva Kumar ArumughamNessuna valutazione finora

- Value Streeam Mapping in A Manufacturing CompanyDocumento11 pagineValue Streeam Mapping in A Manufacturing CompanyIsrael Urbina LugoNessuna valutazione finora

- In Situ Repair Welding of Steam Turbine ShroudDocumento7 pagineIn Situ Repair Welding of Steam Turbine ShroudClaudia MmsNessuna valutazione finora

- CE6130 現代作業系統核心 Modern Operating System Kernels Ph.DDocumento63 pagineCE6130 現代作業系統核心 Modern Operating System Kernels Ph.Dlakshmi321Nessuna valutazione finora

- C++ Notes: LIX, Ecole PolytechniqueDocumento35 pagineC++ Notes: LIX, Ecole PolytechniqueMahendranath RamakrishnanNessuna valutazione finora

- STD C++ Notes 03Documento77 pagineSTD C++ Notes 03Markel JohnNessuna valutazione finora

- On Ural Nab 06 AssessmentDocumento12 pagineOn Ural Nab 06 AssessmentNaresh DhandaNessuna valutazione finora

- No Silver BulletDocumento20 pagineNo Silver Bulletlakshmi321Nessuna valutazione finora

- 10 1 1 137 4976Documento11 pagine10 1 1 137 4976theplayer100Nessuna valutazione finora

- Lecture 22Documento2 pagineLecture 22Muhammad ShafiqNessuna valutazione finora

- Linked ListDocumento43 pagineLinked Listykudura2011Nessuna valutazione finora

- Essential PerlDocumento25 pagineEssential Perlcccc gggg oooNessuna valutazione finora

- Automated Generation of Hardware Accelerators With Direct Memory Access From ANSI/ISO Standard C FunctionsDocumento10 pagineAutomated Generation of Hardware Accelerators With Direct Memory Access From ANSI/ISO Standard C Functionslakshmi321Nessuna valutazione finora

- Pemrograman NCDocumento3 paginePemrograman NCPurwadyaziNessuna valutazione finora

- Cameron - CAMCHEC Riser Inspection - TC1484Documento4 pagineCameron - CAMCHEC Riser Inspection - TC1484jahehe2000Nessuna valutazione finora

- Kundan Switch Gear Private Limited Was Established in 2001Documento12 pagineKundan Switch Gear Private Limited Was Established in 2001vivek_jangir2007Nessuna valutazione finora

- Economic Engineering - Task XI - Dinda AdinaprajaDocumento4 pagineEconomic Engineering - Task XI - Dinda AdinaprajaAdinapraja DienNessuna valutazione finora

- By: Loy Lobo Aapa Angchekar Priyanka BendaleDocumento45 pagineBy: Loy Lobo Aapa Angchekar Priyanka BendaleLoy LoboNessuna valutazione finora

- Yd-134 TDSDocumento3 pagineYd-134 TDSMOHAMEDNessuna valutazione finora

- Asme Sa 106 Grade A PipesDocumento1 paginaAsme Sa 106 Grade A PipesFerroPipENessuna valutazione finora

- Waste Management in TokyoDocumento2 pagineWaste Management in TokyoPratiwi Natsir PutriNessuna valutazione finora

- Applications Guideline-Flashing (Water)Documento2 pagineApplications Guideline-Flashing (Water)strahor7492Nessuna valutazione finora

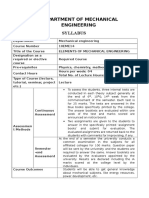

- SYLLABUSDocumento6 pagineSYLLABUSSyedZameerNessuna valutazione finora

- Section E Cooling SuppliesDocumento138 pagineSection E Cooling SuppliesalltheloveintheworldNessuna valutazione finora

- CH18題庫Documento5 pagineCH18題庫Lin RubyNessuna valutazione finora

- Pt. Duta Utama Tehnik Abadi: Daily ReportDocumento6 paginePt. Duta Utama Tehnik Abadi: Daily ReportMa'rifatullahNessuna valutazione finora

- Production Planning: It's Meaning and Objectives!Documento52 pagineProduction Planning: It's Meaning and Objectives!Gautam KocherNessuna valutazione finora

- Thermoplastic DescripsionDocumento72 pagineThermoplastic DescripsionDanang PrasetyoNessuna valutazione finora

- Differences between hardness and hardenability in steelsDocumento2 pagineDifferences between hardness and hardenability in steelsAmirul NorshahNessuna valutazione finora

- Agregat Plan Tugas PDFDocumento11 pagineAgregat Plan Tugas PDFNur Rahma Laila Rizki FauziahNessuna valutazione finora

- Productivity Improvement in Assembly Line of Automobile Industry by Reducing Cycle Time of OperationsDocumento5 pagineProductivity Improvement in Assembly Line of Automobile Industry by Reducing Cycle Time of OperationsMadeeha KhanNessuna valutazione finora

- 1202Documento1 pagina1202Duddi DennisukNessuna valutazione finora

- Role of Japanese ODA Loans in KoreaDocumento186 pagineRole of Japanese ODA Loans in KoreaLee Zhi KangNessuna valutazione finora

- FAQ Latascreed 100Documento2 pagineFAQ Latascreed 100Showri Raju AddagatlaNessuna valutazione finora

- PDS - NA - PRP Repair Data SheetDocumento2 paginePDS - NA - PRP Repair Data SheetHendra AwanNessuna valutazione finora