Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Automatic Solar Irrigation Pump Control System Based On Soil Moisture Sensor

Caricato da

Srinivas Reddy MandaDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Automatic Solar Irrigation Pump Control System Based On Soil Moisture Sensor

Caricato da

Srinivas Reddy MandaCopyright:

Formati disponibili

AUTOMATIC SOLAR IRRIGATION PUMP CONTROL SYSTEM BASED ON SOIL MOISTURE SENSOR

CHAPTER 1

INTRODUCTION

This project aims in providing a user friendly, reliable and automated irrigation

pump controlling system for illiterates. Now a days technology is running with time, it

completely occupied the life style of human beings. Even though there is such an

importance for technology in our routine life there are even people whose life styles are

very far to this well known term technology. So it is our responsibility to design few

reliable systems which can be even efficiently used by them. This basic idea gave birth to

the project soil moisture sensor based irrigation pump controller and this project aims in

introducing the automation technology into the lives of the illiterates.

The purpose of this project is to monitor soil moisture and control a irrigation

pump using microcontroller powered by solar. This can be achieved by the use of soil

moisture sensor, which senses the water content in the soil. This sensor output is given to a

Microcontroller based control system for further data processing.

This project also consists of relays are used to control the pump motor. Whenever

the soil moisture content goes below some predefined level, and then this information is

sent to Microcontroller based control system. Based on the command received the

Microcontroller switches ON or OFF the irrigation pump motor. This system uses relay

which are controlled by the starter.

Dept. of EEE

Tech. Knr

Trinity College of Engg. &

AUTOMATIC SOLAR IRRIGATION PUMP CONTROL SYSTEM BASED ON SOIL MOISTURE SENSOR

The features of the project are:

1.

Automatic Soil moisture sensing system.

2.

Irrigation motor control.

The major building blocks of this project

1.

Regulated Power Supply.

2.

Microcontroller.

3.

Soil moisture sensor.

4.

Electromagnetic relay with driver.

5.

Crystal oscillator.

6.

Reset.

7.

Pump Motor (for water pumping).

8.

LCD.

Dept. of EEE

Tech. Knr

Trinity College of Engg. &

AUTOMATIC SOLAR IRRIGATION PUMP CONTROL SYSTEM BASED ON SOIL MOISTURE SENSOR

Regulated Power Supply:

Fig.1: Regulated Power Supply

Block Diagram:

Dept. of EEE

Tech. Knr

Trinity College of Engg. &

AUTOMATIC SOLAR IRRIGATION PUMP CONTROL SYSTEM BASED ON SOIL MOISTURE SENSOR

Fig: 2: Block diagram

Dept. of EEE

Tech. Knr

Trinity College of Engg. &

AUTOMATIC SOLAR IRRIGATION PUMP CONTROL SYSTEM BASED ON SOIL MOISTURE SENSOR

CHAPTER II

SOLAR PANEL

Solar panel refers either to a photovoltaic module, a solar hot water panel, or to a

set of solar photovoltaic (PV) modules electrically connected and mounted on a

supporting structure. A PV module is a packaged, connected assembly of solar cells. Solar

panels can be used as a component of a larger photovoltaic system to generate and supply

electricity in commercial and residential applications. Each module is rated by its DC

output power under standard test conditions (STC), and typically ranges from 100 to 320

watts. The efficiency of a module determines the area of a module given the same rated

output an 8% efficient 230 watt module will have twice the area of a 16% efficient 230

watt module. There are a few solar panels available that are exceeding 19% efficiency. A

single solar module can produce only a limited amount of power; most installations

contain multiple modules. A photovoltaic system typically includes a panel or an array of

solar modules, an inverter, and sometimes a battery and/or solar tracker and

interconnection wiring.

Solar panels are devices that convert light into electricity. They are called "solar"

panels because most of the time, the most powerful source of light available is the Sun,

called Sol by astronomers. Some scientists call them photovoltaics which means, basically,

"light-electricity."

A solar panel is a collection of solar cells. Lots of small solar cells spread over a

large area can work together to provide enough power to be useful. The more light that

hits a cell, the more electricity it produces, so spacecraft are usually designed with solar

panels that can always be pointed at the Sun even as the rest of the body of the spacecraft

moves around, much as a tank turret can be aimed independently of where the tank is

going.

These panels are designed with solar cells composed of semiconductor materials.

The main function of Solar panels is, it converts solar energy into DC electrical energy

generally of 12V, which is further used for the rest of the circuit. The number of cells

required and their size depends on the rating of the load. The collection of solar cells can

Dept. of EEE

Tech. Knr

Trinity College of Engg. &

AUTOMATIC SOLAR IRRIGATION PUMP CONTROL SYSTEM BASED ON SOIL MOISTURE SENSOR

produce maximum electricity. But, the solar panel must place exactly at right angles to the

sun rays.

Fig.3 Block Diagram of Solar energy Conversion

Solar Water Pump

A solar water pump has a mini power house at its heart and consists of a calibrated

and matching solar array of modules tuned with the equivalent power of pump for that

particular application. The solar water pumping system is capable of running all types of

electrical water pumps with applications varying from irrigation to household demands.

Irrigation pumps such as submersible, surface or deep well can also be coupled with drip

irrigation systems to enhance the returns from this configuration.

A typical solar water pumping system is known by the sum total of solar array size

that is required to run the attached pump. A 1000 Wp solar water pump is capable of

drawing and pumping approximately 40,000 litres of water per day from a source that is

up to 10 meters deep. This is sufficient to irrigate about 2 acres of land with regular crops.

A 1000 Wp solar water pump helps save up to Rs 45,000 when compared to equivalent

use of a diesel-operated pump over a year.

Dept. of EEE

Tech. Knr

Trinity College of Engg. &

AUTOMATIC SOLAR IRRIGATION PUMP CONTROL SYSTEM BASED ON SOIL MOISTURE SENSOR

CHAPTER III

COMPONENTS DESCRIPTION

Liquid Crystal Display

Liquid crystal displays (LCD) are widely used in recent years as compares to

LEDs. This is due to the declining prices of LCD, the ability to display numbers,

characters and graphics, incorporation of a refreshing controller into the LCD, their by

relieving the CPU of the task of refreshing the LCD and also the ease of programming for

characters and graphics. HD 44780 based LCDs are most commonly used.

OP-AMP

An operational amplifier ("op-amp") is a DC-coupled high-gain electronic

voltage amplifier with a differential input and, usually, a single-ended output. An op-amp

produces an output voltage that is typically hundreds of thousands times larger than the

voltage difference between its input terminals. Operational amplifiers are important

building blocks for a wide range of electronic circuits. They had their origins in analog

computers where they were used in many linear, non-linear and frequency-dependent

circuits. Their popularity in circuit design largely stems from the fact that characteristics

of the final op-amp circuits with negative feedback are set by external components with

little dependence on temperature changes and manufacturing variations in the op-amp

itself.

The Submersible Pump

This solar system contains a submersible pump, a water tank, an irrigation pump,

associated water pumps. In the site trial the submersible pump is kept in a stainless steel

case, and that is placed in a well pit at the junction of the open channel and the natural

stream course. The pump controller pumps water to the water tank at a particular time

period as set in the control unit. This system is designed with 450W of power and that is

able to pump 2000 liters of water within 60minutes.This power capacity takes account of

the height difference b/n the water tank and the solar submersible pump.

The PV Panels

Dept. of EEE

Tech. Knr

Trinity College of Engg. &

AUTOMATIC SOLAR IRRIGATION PUMP CONTROL SYSTEM BASED ON SOIL MOISTURE SENSOR

The photo voltaic cells depend on the size of the pump. A panel is esteemed in

watts of power it can produce. This solar submersible pumping system should be operated

with a PV array capacity in the range of 200 to 500 watts peak, and measured under some

standard test conditions. Plenty number of modules in series & parallel could be used to

get the necessary PV power array power o/p. The o/p power of the PV modules which are

used in the PV array under standard test conditions, that should be a min of 74 watts peak.

Charge Controller

A solar charge controller is very important device in any solar power system. It is

used to maintain proper charging voltages of the batteries. The charge controller controls

current and voltage from the solar panel and charges the battery, and also stops the

charging of the battery from over and undercharging conditions.

Battery

The Battery is an electric device, that is used to store current which is produced

from the solar panel and supplies to the corresponding loads. The number of batteries

required depend on the load requirement.

Inverter

The main function of the inverter is, it converts the batterys voltage to AC voltage

in order to activate then loads. Therefore, it helps us to run many electronic devices, home

appliances and computers. There are numerous types of inverters available in the market

today.The characteristics of typical inverters like high switching frequency, high

conversion frequency and less harmonic content, and so on.

Dept. of EEE

Tech. Knr

Trinity College of Engg. &

AUTOMATIC SOLAR IRRIGATION PUMP CONTROL SYSTEM BASED ON SOIL MOISTURE SENSOR

CHAPTER IV

SOIL MOISTURE SENSOR

The moisture sensor is buried in the ground at required depth. The working of the

moisture sensor is simple and straightforward. The moisture sensor just senses the

moisture of the soil. The change in moisture is proportional to the amount of current

flowing through the soil.

Fig.4. Circuit Diagram of Soil Moisture Sensor

Most soil moisture sensors are designed to estimate soil volumetric water content

based on the dielectric constant (soil bulk permittivity) of the soil. The dielectric constant

can be thought of as the soil's ability to transmit electricity. The dielectric constant of soil

increases as the water content of the soil increases. This response is due to the fact that the

dielectric constant of water is much larger than the other soil components, including air.

Thus, measurement of the dielectric constant gives a predictable estimation of water

content.

Bypass type soil moisture irrigation controllers use water content information from

the sensor to either allow or bypass scheduled irrigation cycles on the irrigation timer

(Figures 1 and 2). The SMS controller has an adjustable threshold setting and, if the soil

water content exceeds that setting, the event is bypassed. The soil water content threshold

is set by the user. Another type of control technique with SMS devices is on-demand

where the controller initiates irrigation at a low threshold and terminates irrigation at a

high threshold.

Dept. of EEE

Tech. Knr

Trinity College of Engg. &

AUTOMATIC SOLAR IRRIGATION PUMP CONTROL SYSTEM BASED ON SOIL MOISTURE SENSOR

A moisture sensor is used to sense the level of moisture content present in the

irrigation field. It has a level detection module in which we can set a reference value. This

circuit can be used with analog probes that produce a voltage proportional to soil moisture

such as VG400 probe . The moisture content of the soil is found by using the soil moisture

sensor such as VG400 which produces an equivalent output voltage proportional to the

conductivity between the two probes.

Fig. 5: Soil Moisture Sensor probe.

Moisture sensor module

The prongs should be oriented horizontally, but rotated onto their side like a

knife poised to cut food so that water does not pool on the flat surface of the prongs. The

horizontal orientation of the sensor ensures the measurement is made at a particular soil

depth. The entire sensor can be placed vertically, but because soil moisture of ten varies by

depth, this is not usually the desired orientation. To position the sensor, use a thin

implement such as a trenching shovel to make a pilot hole in the soil. Place the sensor into

the hole, making sure the entire length of the sensor is covered. Press down on the soil

along either side of the sensor with your fingers. Continue to compact the soil around the

sensor by pressing down on the soil with your fingers until you have made at least five

passes along the sensor. This step is important, as the soil adjacent to the sensor surface

has the strongest influence on the sensor reading. Removing the sensor when removing the

sensor from the soil, do not pull it out of the soil by the cable! Doing so may break

internal connections and make the sensor unusable

Dept. of EEE

Tech. Knr

10

Trinity College of Engg. &

AUTOMATIC SOLAR IRRIGATION PUMP CONTROL SYSTEM BASED ON SOIL MOISTURE SENSOR

4.1. RELAY

The electromagnetic relay consists of a multi-turn coil, wound on an iron core, to

form an electromagnet. When the coil is energised, by passing current through it, the core

becomes temporarily magnetised. The magnetised core attracts the iron armature. The

armature is pivoted which causes it to operate one or more sets of contacts. When the coil

is de-energised the armature and contacts are released. The coil can be energised from a

low power source such as a transistor while the contacts can switch high powers such as

the mains supply. The relay can also be situated remotely from the control source. Relays

can generate a very high voltage across the coil when switched off. This can damage other

components in the circuit. To prevent this a diode is connected across the coil.

A relay is an electrical switch that opens and closes under the control of another

electrical circuit. In the original form, the switch is operated by an electromagnet to open

or close one or many sets of contacts. A relay is able to control an output circuit of higher

power than the input circuit.

The above diagram shows the representation of a relay. By default when there is no

excitation in the coil the NC (Normally Closed) and C (Common Terminal) are connected

through the contact internally. When the coil is excited by providing the required coil

voltage, the contact switches from the NC to NO (Normally Open) side. In this case, the C

and NC terminals are connected internally.

Dept. of EEE

Tech. Knr

11

Trinity College of Engg. &

AUTOMATIC SOLAR IRRIGATION PUMP CONTROL SYSTEM BASED ON SOIL MOISTURE SENSOR

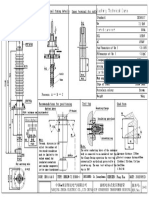

Fig.6. Circuit Diagram of Relay

The main operation of a relay comes in places where only a low-power signal can

be used to control a circuit. It is also used in places where only one signal can be used to

control a lot of circuits. The application of relays started during the invention of

telephones. They played an important role in switching calls in telephone exchanges. They

were also used in long distance telegraphy. They were used to switch the signal coming

from one source to another destination. After the invention of computers they were also

used to perform Boolean and other logical operations. The high end applications of relays

require high power to be driven by electric motors and so on. Such relays are called

contactors.

TYPES OF RELAYS

1. Latching Relay

Latching relays are also called impulse relays. They work in the bistable mode, and

thus have two relaxing states. They are also called keep relays or stay relays because as

soon as the current towards this relay is switched off, the relay continues the process that it

was doing in the last state. This can be achieved only with a solenoid which is operating in

a ratchet and cam mechanism. It can also be done by an over-centre spring mechanism or

a permanent magnet mechanism in which, when the coil is kept in the relaxed point, the

over-centre spring holds the armature and the contacts in the right spot of a remanent core.

power consumption occurs only for a particular time.

2. Reed Relay

These types of relays have been given more importance in the contacts. In order to

protect them from atmospheric protection they are safely kept inside a vacuum or inert

gas. Though these types of relays have a very low switching current and voltage ratings,

they are famous for their switching speeds.

3. Polarized Relay

This type of relay has been given more importance on its sensitivity. These relays

have been used since the invention of telephones. They played very important roles in

early telephone exchanges and also in detecting telegraphic distortion. The sensitivity of

Dept. of EEE

Tech. Knr

12

Trinity College of Engg. &

AUTOMATIC SOLAR IRRIGATION PUMP CONTROL SYSTEM BASED ON SOIL MOISTURE SENSOR

these relays are very easy to adjust as the armature of the relay is placed between the poles

of a permanent magnet.

4. Buchholz Relay

This relay is actually used as a safety device. They are used for knowing the

amount of gas present in large oil-filled transformers. They are designed in such a way

that they produce a warning if it senses either the slow production of gas or fast

production of gas in the transformer oil.

5. Overload protection Relay

As the name implies, these relays are used to prevent the electric motors from

damage by over current and short circuits. For this the heating element is kept in series

with the motor. Thus when over heat occurs the bi-metallic strip connected to the motor

heats up and in turn releases a spring to operate the contacts of the relay.

6. Mercury Wetted Relay

This relay is almost similar to the reed relay explained earlier. The only difference

is that instead of inert gases, the contacts are wetted with mercury. This makes them more

position sensitive and also expensive. They have to be vertically mounted for any

operation. They have very low contact resistance and so can be used for timing

applications..

7. Machine Tool Relay

They are mainly used for the controlling of all kinds of machines. They have a

number of contacts with easily replaceable coils. This enables them to be easily converted

from NO contact to NC contact. Many types of these relays can easily be setup in a

control panel. Though they are very useful in industrial applications, the invention of PLC

has made them farther away from industries.

8. Contactor Relay

This is one of the most heavy load relay ever used. They are mainly used in

switching electric motors. They have a wide range of current ratings from a few amps to

hundreds. The contacts of these relays are usually made with alloys containing a small

Dept. of EEE

Tech. Knr

13

Trinity College of Engg. &

AUTOMATIC SOLAR IRRIGATION PUMP CONTROL SYSTEM BASED ON SOIL MOISTURE SENSOR

percentage of silver. This is done so as to avoid the hazardous effects of arcing. These type

of relays are mainly categorized in the rough use areas. So, they produce loud noises while

operated and hence cannot be used in places where noise is a problem.

9. Solid State relay

SSR relays, as its name implies are designed with the help of solid state

components. As they do not have any moving objects in their design they are known for

their high reliability.

10. Solid State Contactor Relay

These relays combine both the features of solid state relays and contactor relays.

As a result they have a number of advantages. They have a very good heat sink and can be

designed for the correct on-off cycles. They are mainly controlled with the help of PLC,

micro-processors or microcontrollers.

4.2. SELECTION OF MOTOR DRIVE SYSTEM

The selection criteria of electrical motors depend on the cost and compatibility at

which the motors work. In this project the induction motor is chosen, as the AC motors are

more advantageous than DC motors. The comparison of electrical motors and drawbacks

with DC motors .The most common and simple industrial motor is the three phase AC

induction motor. The various aspects at which the three phase AC induction motor was

selected is also listed.

DC MOTORS

AC MOTORS

The commutator and brushes makes the motor Not bulky and heavy

bulky, costly and heavy

Costly

It requires frequent maintenance

Requires battery or inverter

Expensive

Less maintenance

They can be used in all locations, as

the supply is AC

Table 1: Comparison between AC Motors and DC Motors

Thus the three phase induction motor is:

Self-starting.

Dept. of EEE

Tech. Knr

14

Trinity College of Engg. &

AUTOMATIC SOLAR IRRIGATION PUMP CONTROL SYSTEM BASED ON SOIL MOISTURE SENSOR

Less armature reaction and brush sparking because of the absence of commutators and

brushes that may cause sparks.

Robust in construction.

Economical.

Easier to maintain.

According to Faradays law an emf induced in any circuit is due to the rate of

change of magnetic flux linkage through the circuit. As the rotor winding in an induction

motor are either closed through an external resistance or directly shorted by end ring, and

cut the stator rotating magnetic field, an emf is induced in the rotor copper bar and due to

this emf a current flows through the rotor conductor. The relative velocity between the

rotating flux and static rotor conductor is the cause of current generation; hence as per

Lenzs law the rotor will rotate in the same direction to reduce the cause i.e. the relative

velocity.

From the working principle of three phase induction motor it may observed

that the rotor speed should not reach the synchronous speed produced by the stator. If the

speeds equals, there would be no such relative velocity, so no emf induction in the rotor, &

no current would be flowing, and therefore no torque would be generated. Consequently

the rotor cannot reach at the synchronous speed. The difference between the stator

(synchronous speed) and rotor speeds is called the slip. The rotation of the magnetic field

in an induction motor has the advantage that no electrical connections need to be made to

the rotor.

Dept. of EEE

Tech. Knr

15

Trinity College of Engg. &

AUTOMATIC SOLAR IRRIGATION PUMP CONTROL SYSTEM BASED ON SOIL MOISTURE SENSOR

CHAPTER - V

WORKING OF PROJECT

The deficiency of water in the field is sensed by the op-amp based sensor.

Whenever there is need of water in the particular field, the high signal(1) appears on the

output pin of the sensor of that particular field. The output pins of all the sensors are

connected to the PORT 2 of microcontroller. The high signs(logic 1) from the sensor are

entertained by the microcontroller at a particular pin. By knowing the position of the pin

on which signal appears , the microcontroller rotates the water funnel type cup at the

desired angle (i.e. 90 ,180 ,270) by using stepper motor connected at PORT 0 in clockwise

direction. & switch ON the RELAY (i.e. Water pump) connected at port 0. Now water

starts flowing into the required field . after completion of watering the sensor sends low

signal (logic 0) to microcontroller. When uc receives this signal , it switches OFF the

water pump & rotates the stepper motor in anticlockwise direction to the previous angle to

bring the funnel cup in its initial position . now uc starts sensing the signal at PORT 2.

Whenever there is signal at any pin the uc repeats the above process. So this process

continues & we get the automatic irrigation the fields by using intelligent device uc 8051.

5.1. SYSTEM PRINCIPLE

The principles of solar powered intelligent drip irrigation system is based on

control module with sensor data availability to the irrigation system on the difference of

threshold limit of soil moisture content of the irrigated crops, and real-time soil moisture

content. When the soil moisture content of the crop is below the permissible limit, the

sensors will message to control system and irrigation system to start the irrigation until the

soil moisture content reaches the desired limit.

5.2 SYSTEM DESCRIPTION

Proposed irrigation system mainly consists of two modules- Solar pumping modul

and automatic irrigation module. In solar pumping module a solar panel of required

specification is mounted near the pump set.

Dept. of EEE

Tech. Knr

16

Trinity College of Engg. &

AUTOMATIC SOLAR IRRIGATION PUMP CONTROL SYSTEM BASED ON SOIL MOISTURE SENSOR

Fig. 7: Block diagram of solar pumping module.

Then using a control circuit it is used to charge a battery. From the battery using a

Converter circuit it gives power to the water pump which is submerged inside the well.

Then the water is pumped into an overhead tank for storing water temporarily before

releasing the water into the field. In automatic irrigation module the water outlet valve of

the tank is electronically controlled by a soil moisture sensing circuit. The sensor is placed

in the field where the crop is being cultivated. The sensor converts the moisture content in

the soil into equivalent voltage. This is given to a sensing circuit which has a reference

voltage that can be adjusted by the farmer for setting different moisture levels for different

crops.

The amount of water needed for soil is proportional to the difference of these two

voltages. A control signal was given to a stepper motor whose rotational angle is

proportional to the difference in voltage. The stepper motor in turns controls the

crosssectional area of the valve to be opened controlling flow of water. Therefore the

amount of water flowing is proportional to the moisture difference.

Dept. of EEE

Tech. Knr

17

Trinity College of Engg. &

AUTOMATIC SOLAR IRRIGATION PUMP CONTROL SYSTEM BASED ON SOIL MOISTURE SENSOR

Water Pump

Irrigation Field

Moisture Sensor

Actuator

Fig. 8: Block diagram of automatic irrigation module.

5.3 COST ANALYSIS

With over nine hundred thousand tube wells being used in every state of India,

around Rs.18 Million of energy is used for pumping water for irrigation. This amount of

money used for Electricity can be saved with the help of solar water pump. Annually the

cost of nearly five million kilo watt hour of energy can be spared. That is around Rs.27

Million per annum can be redeemed which comes around 40% of the total amount of

investment. Even though the initial investment is high, it can be earned back in 2 and a

half years time. If we assume the cost of power is Rs. 1.5 Million per kilo watt hour,

Rs.18 Million is used for pumping water alone in a year. By using the solar water pump,

we can save up to 4.8 million KWh of energy annually which saves a lot of energy. The

excess energy can also be given to the grid with small modifications and investments in

the circuit, which can add to the revenue of the farmer.

Cost analysis

Component

Unit Cost

Solar Panel (1.4m2)

Converter Circuit

Battery 24V,100Ah

24000

400

8250

Quantity

4

1

1

Overall cost

Total Cost

Rs.96000

Rs.400

Rs.8250

Rs.104650

Table2: Cost analysis

Dept. of EEE

Tech. Knr

18

Trinity College of Engg. &

AUTOMATIC SOLAR IRRIGATION PUMP CONTROL SYSTEM BASED ON SOIL MOISTURE SENSOR

ADVANTAGES

An advantage of using direct solar radiation as a power source for irrigation is that

it is available at the site of application without the employment of a distribution system

It helps in saving Energy.

There is no fuel cost - as it uses available free sun light.

No electricity required.

Can be operated lifelong.

It is highly reliable and durable.

Easy to operate and maintain

It is also useful for clean, drinking water sanitation and also irrigation.

It reduces the dependence on rain is reduced.

It creates wealth for farmers by increasing no of crops.

Dept. of EEE

Tech. Knr

19

Trinity College of Engg. &

AUTOMATIC SOLAR IRRIGATION PUMP CONTROL SYSTEM BASED ON SOIL MOISTURE SENSOR

DIS ADVANTAGES

That disadvantage is that the sun doesnt shine 24 hours a day. When the sun goes

down or is heavily shaded, solar PV panels stop producing electricity. If we need

electricity at that time, we have to get it from some other source.

In other words, we couldnt be 100% powered by solar panels. At the very least,

we need batteries to store electricity produced by solar panels for use sometime

later.

However, there are a couple of key things to note regarding this solar power

disadvantage. Firstly, the sun actually does shine when we need electricity most.

As humans (not vampires), our days more or less follow the movement of the sun.

Society more or less wakes up when the sun rises.

At the time of the suns greatest height and visibility, humans tend to be most

active. At this time, we are of course using much more electricity than in the

middle of the night, so electricity is in greater demand. (This also makes electricity

more expensive in the middle of the day, making electricity produced from solar

panels more valuable.

Dept. of EEE

Tech. Knr

20

Trinity College of Engg. &

AUTOMATIC SOLAR IRRIGATION PUMP CONTROL SYSTEM BASED ON SOIL MOISTURE SENSOR

APPLICATIONS

Solving needs of rural population.

Town and City Water Supply

Livestock Watering

Irrigation

Dept. of EEE

Tech. Knr

21

Trinity College of Engg. &

AUTOMATIC SOLAR IRRIGATION PUMP CONTROL SYSTEM BASED ON SOIL MOISTURE SENSOR

CONCLUSION

This paper managed to stumble upon the fact that the largest advantage of solar

energy is its attribute as being free and unlimited source of energy. We have also found out

that the research of the development of solar irrigation system requires vast knowledge

and familiarity about renewable energy, as well as other parameters of control. The

parameters of the system that have been used in the project are soil moisture sensor, light

detecting sensor and level sensors. The design of SCADA system is meant for adding an

operator on automatic irrigation system. Through SCADA system, the operator can read

and write data from the controller (PLC) in addition to this there is a report of the system

in excels form and that can be printed. After continuous work and effort, it was

manageable to test the system by making it function properly. This project is very vital for

all systems that deal with liquid monitoring and controlling specially in the irrigation

field . The SCADA system helps administrators to control an d monitor irrigation system.

As stated, the project can be expanded to oil and gas monitoring system and greenhouse

implementation system. Based on the result obtained from measurement, the system

performance is quite reliable and accurate. The system has successfully overcome quite a

few failings of the existing system by reducing the power consumption, maintenance and

automatic system interface with SCADA system.

Dept. of EEE

Tech. Knr

22

Trinity College of Engg. &

AUTOMATIC SOLAR IRRIGATION PUMP CONTROL SYSTEM BASED ON SOIL MOISTURE SENSOR

REFERENCES

[1] Harris 2009 Solar Powered Automated Greenhouse Irrigation System (LumiTech

International Limited)

[2] Morris And Lynne 2008 Solar-Powered Livestock Watering Systems (ATTRA)

[3] B.L.S. Lui 2006 Trial Use of Solar Power Automatic Irrigation System 7-11

[4] Noko And Road 2005 Solar International Botswana (Pty) Ltd. (InWEnt)

[5] B. Eker 2005 Solar Powered Water Pumping Systems 3 7-11

[6] Vick And Almas 2008 Developing Wind And/ Or Solar Powered Crop Irrigation

Systems For The Great Plains 27 235-245

[7] Helikson ,Haman And Baird 2009 Pumping Water For Irrigation Using Solar Energy

(Florida Energy Extension Service)

Dept. of EEE

Tech. Knr

23

Trinity College of Engg. &

Potrebbero piacerti anche

- Lightning Arrester: BY, Jachin JosesDocumento17 pagineLightning Arrester: BY, Jachin JosesBase CleanerNessuna valutazione finora

- Solar Irrigation SystemDocumento18 pagineSolar Irrigation SystemHarishwar ReddyNessuna valutazione finora

- Solar EnergyDocumento30 pagineSolar EnergyJatin Sharma cse 20Nessuna valutazione finora

- Hydropower ProjectDocumento5 pagineHydropower Projectapi-2931348240% (1)

- V S DDocumento17 pagineV S DveguruprasadNessuna valutazione finora

- Electrical Drives NotesDocumento6 pagineElectrical Drives Noteskaushik9595Nessuna valutazione finora

- EE 249 Lecture 0 Orientation PDFDocumento6 pagineEE 249 Lecture 0 Orientation PDFOnofre Algara Jr.Nessuna valutazione finora

- Optimal PlacementDocumento21 pagineOptimal PlacementSunnyJoelNessuna valutazione finora

- Lec CH 17 Symmetric FaultsDocumento16 pagineLec CH 17 Symmetric FaultsMajdi M. AbabnehNessuna valutazione finora

- Mahnoor Rashid (15EL02) M.Imran (15EL23) Usama Shehzad (15EL31)Documento10 pagineMahnoor Rashid (15EL02) M.Imran (15EL23) Usama Shehzad (15EL31)MahnoorRashidNessuna valutazione finora

- Presentation 1Documento109 paginePresentation 1keethanNessuna valutazione finora

- DC GeneratorDocumento38 pagineDC GeneratorAshwini ChaurasiaNessuna valutazione finora

- Solar Power SatelliteDocumento28 pagineSolar Power SatelliteInduchoodan Rajendran100% (2)

- Sample 22289 PDFDocumento16 pagineSample 22289 PDFVarun DuggalNessuna valutazione finora

- Design of A Mobile Phone Charging Station Utilizing PV Renewable Energy SystemDocumento17 pagineDesign of A Mobile Phone Charging Station Utilizing PV Renewable Energy SystemMaria Blessie NavarreteNessuna valutazione finora

- 04 - Wind Turbine Power, Energy and TorqueDocumento54 pagine04 - Wind Turbine Power, Energy and Torquebiosbg100% (1)

- Review Paper On Three Phase Fault AnalysisDocumento6 pagineReview Paper On Three Phase Fault AnalysisPritesh Singh50% (2)

- Dual Axis Solar Radiation Tracking System: Pamantasan NG Lungsod NG MaynilaDocumento12 pagineDual Axis Solar Radiation Tracking System: Pamantasan NG Lungsod NG MaynilamgoldiieeeeNessuna valutazione finora

- Abebe HandoutDocumento113 pagineAbebe HandoutFasika Tegegn100% (1)

- DC GeneratorDocumento14 pagineDC GeneratorGlen DangaranNessuna valutazione finora

- Chapter 13 PduDocumento57 pagineChapter 13 Pduarslan khalidNessuna valutazione finora

- LD College of Engineering: Gujarat Technological UniversityDocumento18 pagineLD College of Engineering: Gujarat Technological UniversityVathsal MehtaNessuna valutazione finora

- Chapter 1 Appeal DraftDocumento10 pagineChapter 1 Appeal DraftJessie JulongbayanNessuna valutazione finora

- Tese Grid Connected PV 2001Documento124 pagineTese Grid Connected PV 2001chauhan303Nessuna valutazione finora

- Report On Solar PV TechnologiesDocumento16 pagineReport On Solar PV Technologiessagar paneliyaNessuna valutazione finora

- Ecological RelationshipDocumento3 pagineEcological RelationshipNikel CanNessuna valutazione finora

- Outline of The ProblemDocumento3 pagineOutline of The ProblemAnonymous IaLz7L100% (1)

- Solar Water PumpDocumento10 pagineSolar Water PumpSOLARC GREEN ENERGY SOLUTIONSNessuna valutazione finora

- Hybrid Power Generation by Solar - WindDocumento27 pagineHybrid Power Generation by Solar - WindUday Wankar100% (1)

- Sabaq Details of NaqshbandiDocumento3 pagineSabaq Details of Naqshbandiimaad100% (1)

- Solar Powered Water Pumping System: Department of Electrical and Electronics EngineeringDocumento20 pagineSolar Powered Water Pumping System: Department of Electrical and Electronics EngineeringAnonymous bau06xStTNessuna valutazione finora

- Solar Micro ControllerDocumento18 pagineSolar Micro ControllerElangovanNessuna valutazione finora

- Chapter - 1 1.1 OverviewDocumento21 pagineChapter - 1 1.1 OverviewTirumalarao PechettyNessuna valutazione finora

- Advancements in Inverter TechnologyDocumento9 pagineAdvancements in Inverter TechnologyAyush KumarNessuna valutazione finora

- Transmission Line ConstantsDocumento74 pagineTransmission Line ConstantsEr Ashish BahetiNessuna valutazione finora

- Design of A Mobile Phone Charging Station Utilizing PV Renewable Energy SystemDocumento6 pagineDesign of A Mobile Phone Charging Station Utilizing PV Renewable Energy SystemMaria Blessie NavarreteNessuna valutazione finora

- Lightning ArresterDocumento18 pagineLightning ArresterDinesh Prasad SenapatiNessuna valutazione finora

- Curve Graphing in MS Excel and ApplicationsDocumento23 pagineCurve Graphing in MS Excel and ApplicationsShashi TapsiNessuna valutazione finora

- 12 Distribution SystemDocumento27 pagine12 Distribution SystemPao Castillon100% (1)

- WindmillDocumento23 pagineWindmillManav KohliNessuna valutazione finora

- Study of Over Current Earth Fault RelayDocumento1 paginaStudy of Over Current Earth Fault RelayVirender RanaNessuna valutazione finora

- Solar Mobile ChargerDocumento16 pagineSolar Mobile ChargerAshis karmakarNessuna valutazione finora

- Spec Info Mechanical Data Cooling Data Motor Starting Curve Open Circuit Curve Zero Power Factor Curve Reactive Capability Chart General InformationDocumento11 pagineSpec Info Mechanical Data Cooling Data Motor Starting Curve Open Circuit Curve Zero Power Factor Curve Reactive Capability Chart General Informationrupesh1000Nessuna valutazione finora

- Automatic Sun Tracking System (ASTS)Documento18 pagineAutomatic Sun Tracking System (ASTS)mayank bishtNessuna valutazione finora

- PVC Bladed Wind TurbineDocumento12 paginePVC Bladed Wind Turbineainer navalNessuna valutazione finora

- Wireless Mobile Charger Using Inductive Coupling: October 2017Documento17 pagineWireless Mobile Charger Using Inductive Coupling: October 2017Jerin TasnimNessuna valutazione finora

- Types of Bus and ArrangementsDocumento9 pagineTypes of Bus and ArrangementsAlex asherNessuna valutazione finora

- Zambia Chapter 4 CDocumento22 pagineZambia Chapter 4 Cdoud98Nessuna valutazione finora

- RSTU EEE Syllabus With Name VER1Documento32 pagineRSTU EEE Syllabus With Name VER1AhmedEEENessuna valutazione finora

- Grid Connected Photovoltaic SystemDocumento18 pagineGrid Connected Photovoltaic SystemAbu SalmanNessuna valutazione finora

- Automatic Solar Submersible Pump Control For IrrigationDocumento5 pagineAutomatic Solar Submersible Pump Control For Irrigationrohan aijazNessuna valutazione finora

- Jurnal SellDocumento4 pagineJurnal SellfarizalNessuna valutazione finora

- Renewable Energy - SolarDocumento40 pagineRenewable Energy - SolarArthurmie Jr CaitorNessuna valutazione finora

- AGRICULTURAL MOTOR PUMP RUNNING USING Solar PowerDocumento76 pagineAGRICULTURAL MOTOR PUMP RUNNING USING Solar PowerKalai SelvanNessuna valutazione finora

- 1.1 Water Pumping Systems and Photovoltaic PowerDocumento54 pagine1.1 Water Pumping Systems and Photovoltaic Powerthawpeek2006100% (1)

- AGRICULTURAL MOTOR PUMP RUNNING USING Solar PowerDocumento75 pagineAGRICULTURAL MOTOR PUMP RUNNING USING Solar PowerMechWindNaniNessuna valutazione finora

- Design of Solar Power Based Water Pumping SystemDocumento7 pagineDesign of Solar Power Based Water Pumping SystemprasannachvNessuna valutazione finora

- Solar Based Auto Irrigation System: Guided By: Prof. Rakesh B. VasaniDocumento18 pagineSolar Based Auto Irrigation System: Guided By: Prof. Rakesh B. Vasanisandhya AlaneNessuna valutazione finora

- Design and Development of Solar Powered Agriculture Water Pump Irrigation SystemDocumento11 pagineDesign and Development of Solar Powered Agriculture Water Pump Irrigation SystemAin KaloiNessuna valutazione finora

- PDFDocumento27 paginePDFSrinivas Reddy MandaNessuna valutazione finora

- Notification Indian Air Force LDC MTS and Other Posts PDFDocumento3 pagineNotification Indian Air Force LDC MTS and Other Posts PDFSrinivas Reddy MandaNessuna valutazione finora

- Julary ShopDocumento2 pagineJulary ShopSrinivas Reddy MandaNessuna valutazione finora

- Solved Paper: ReasoningDocumento8 pagineSolved Paper: ReasoningSrinivas Reddy MandaNessuna valutazione finora

- Digital Signal Processing QuantumDocumento332 pagineDigital Signal Processing QuantumSudhir MauryaNessuna valutazione finora

- Voltage Reference Modifications - Replacing The LM336Z 5.0V ReferenceDocumento1 paginaVoltage Reference Modifications - Replacing The LM336Z 5.0V ReferenceMoseley MirandaNessuna valutazione finora

- Fault Location On A Transmission Line Using High Frequency TraveDocumento6 pagineFault Location On A Transmission Line Using High Frequency TraveAlexNessuna valutazione finora

- JK400A Fixed ManualDocumento48 pagineJK400A Fixed ManualMohammad Adnan TariqNessuna valutazione finora

- Islanding SystemDocumento22 pagineIslanding SystemSahil Sankalp PatelNessuna valutazione finora

- Asco Avtron 2000 Series With Sigma LT User Manual PDFDocumento43 pagineAsco Avtron 2000 Series With Sigma LT User Manual PDFfernandoNessuna valutazione finora

- Type B Ground-Fault Protection On Adjustable Frequency Drives PDFDocumento6 pagineType B Ground-Fault Protection On Adjustable Frequency Drives PDFRajuNessuna valutazione finora

- NORA-W10 DataSheet UBX-21036702Documento36 pagineNORA-W10 DataSheet UBX-21036702comercialNessuna valutazione finora

- 81381C Plastic Machinery Eng PDFDocumento76 pagine81381C Plastic Machinery Eng PDFEvandro Amaral RodriguesNessuna valutazione finora

- 06-Carrier Aided Protection of Transmission LineDocumento17 pagine06-Carrier Aided Protection of Transmission LineranaNessuna valutazione finora

- PT50010 eDocumento28 paginePT50010 eVlad AdrianNessuna valutazione finora

- Wireless and Mobile NetworksDocumento15 pagineWireless and Mobile NetworksKumar MuruganNessuna valutazione finora

- Electrical StandardsDocumento2 pagineElectrical StandardsKrishna KumarNessuna valutazione finora

- Mira 3 User ManualDocumento23 pagineMira 3 User ManualCenk ErdincNessuna valutazione finora

- Error Inicio SAR-ADocumento5 pagineError Inicio SAR-ANathalyNessuna valutazione finora

- The Common-Emitter Amplifier: Basic CircuitDocumento5 pagineThe Common-Emitter Amplifier: Basic CircuitNicolas Mora RestrepoNessuna valutazione finora

- Miniphor Test and Calibration ProgramDocumento14 pagineMiniphor Test and Calibration ProgramWolaé Mathurin Edmond AmegandjinNessuna valutazione finora

- Distance Relays NewDocumento24 pagineDistance Relays NewShashankMishra100% (1)

- EDAIC Question Paper - 10th December, 2021Documento4 pagineEDAIC Question Paper - 10th December, 2021Tota OtaharadaNessuna valutazione finora

- Particle Swarm Optimization Based Capacitor Placement On Radial Distribution SystemsDocumento37 pagineParticle Swarm Optimization Based Capacitor Placement On Radial Distribution SystemsMudavath ChandramNessuna valutazione finora

- 854 ATG Servo Level Gauge: Kelvin KhooDocumento48 pagine854 ATG Servo Level Gauge: Kelvin KhooVraja KisoriNessuna valutazione finora

- MCS-012 (2022-23) Solved AssignmentDocumento43 pagineMCS-012 (2022-23) Solved AssignmentTanishq MaherNessuna valutazione finora

- Kenstel Communications Pvt. LTDDocumento5 pagineKenstel Communications Pvt. LTDKamitkumar PatelNessuna valutazione finora

- SM5ce - V3 SawDocumento9 pagineSM5ce - V3 SawBryan DixNessuna valutazione finora

- Wacker Neuson - FUH20 - Single Outlet ConverterDocumento3 pagineWacker Neuson - FUH20 - Single Outlet ConverterMolie1979Nessuna valutazione finora

- Vacon 10 User Manual DPD00717E1 EN PDFDocumento110 pagineVacon 10 User Manual DPD00717E1 EN PDFRamesh Singh DawanNessuna valutazione finora

- Numerical Analysis and Computer ProgrammingDocumento39 pagineNumerical Analysis and Computer ProgrammingAbhishekNessuna valutazione finora

- Service Manual: DVD ReceiverDocumento50 pagineService Manual: DVD ReceiverDavid Montecillo LopezNessuna valutazione finora

- Ahanix MCE601: User's ManualDocumento12 pagineAhanix MCE601: User's ManualajtikhanoffNessuna valutazione finora

- BR4144A.8 英 (conector)Documento1 paginaBR4144A.8 英 (conector)Victor GuzmanNessuna valutazione finora