Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Process Engg - Design Guide - Pumps

Caricato da

jwochTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Process Engg - Design Guide - Pumps

Caricato da

jwochCopyright:

Formati disponibili

GE

GUIDE DOCUMENT

PROCESS ENGINEERING DESIGN GUIDE

PART 1 SECTION 1

PROCESS MANUAL (DATA BOOK)

Issued

Book N

Chapter N

312

1.1.2.

VIII

S.S. 1.2 : Process Equipment

CHAPTER VIII Pumps

CONTENTS

1.

PUMP SELECTION

1.1.

1.2.

2.

Pump selection

Flow control

CENTRIFUGAL PUMPS

2.1.

Incidence of main operating parameters

2.1.1. Modification of impeller's speed (n, rpm)

2.1.2. Modification of impeller's diameter

2.1.3. NPSH

2.2.

Main features of centrifugal pumps

2.2.1.

2.2.2.

2.2.3.

2.2.4.

2.3.

2.4.

Pumps operating in parallel

Rating point

Minimum flow

Materials of construction

Selection of centrifugal pumps

Power estimation

2.4.1.

2.4.2.

2.4.3.

2.4.4.

2.4.5.

2.4.6.

2.4.7.

Shaft power

Pump efficiency

Viscosity correction factor

Electrical motor efficiency

Criteria for motor selection

Power at reduced capacity

Pump suction specific speed Nss

3.

OTHER TYPES OF PUMPS

4.

IMPACT OF DISSOLVED GASES ON THE NPSH

GE 1 - ANG - rev. 0

Rev. Page

1 2/22

GUIDE DOCUMENT

PROCESS ENGINEERING DESIGN GUIDE

PART 1 SECTION 1

PROCESS MANUAL (DATA BOOK)

1.

GE

Issued

Book N

312

1.1.2.

Chapter N

VIII

Rev. Page

1 3/22

S.S. 1.2 : Process Equipment

CHAPTER VIII Pumps

PUMP SELECTION

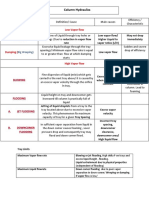

1.1.

Pump selection diagram

Refer to the selection chart enclosed overleaf.

The borderlines of the various areas are conservative. They may be exceeded after

Mechanical Department approval or based on Vendors data.

For reciprocating and rotary pumps, also refer to the tables given further in this

chapter.

As a general rule, centrifugal pumps should always be preferred whenever they can

be used, since they tend to be cheaper and more reliable.

They should generally not be considered in the following cases :

High viscosity (> 400 cSt)

High differential head at low flowrate.

1.2.

Flow control

Whatever the type of pump is, the flow can always be controlled by adjusting the

speed ; at a fixed speed, flow can be often adjusted through control valve, throttling

valve, etc.

GE 1 - ANG - rev. 0 - EG-312-1128.doc

GUIDE DOCUMENT

PROCESS ENGINEERING DESIGN GUIDE

PART 1 SECTION 1

PROCESS MANUAL (DATA BOOK)

GE

Issued

Book N

312

1.1.2.

S.S. 1.2 : Process Equipment

CHAPTER VIII Pumps

PUMP SELECTION DIAGRAM

GE 1 - ANG - rev. 0 - EG-312-1128.doc

Chapter N

VIII

Rev. Page

1 4/22

GUIDE DOCUMENT

PROCESS ENGINEERING DESIGN GUIDE

PART 1 SECTION 1

PROCESS MANUAL (DATA BOOK)

2.

GE

Issued

Book N

312

1.1.2.

Chapter N

VIII

Rev. Page

1 5/22

S.S. 1.2 : Process Equipment

CHAPTER VIII Pumps

CENTRIFUGAL PUMPS

2.1.

Incidence of main operating parameters

2.1.1.

Modification of impellers speed (n, rpm)

For a given geometry :

The flowrate is directly proportional to n

The head H is directly proportional to n2

The power P is directly proportional to n3 (at fixed efficiency)

The efficiency is not affected significantly by a speed modification, excepted for

very low speeds where it slightly decreases.

2.1.2.

Modification of impeller's diameter

At a given speed

The Impeller shape offers a constant cross sectional area (exit velocity triangles

remain similar) :

- The flowrate is directly proportional to D

- The head H is directly proportional to D2

- The power P is directly proportional to D3 (at fixed efficiency).

The cross sectional area through the impeller increases with the diameter :

The flowrate is directly proportional to D2

The head H is directly proportional to D2

The power P is directly proportional to D4 (at fixed efficiency)

The efficiency slightly decreases when the impeller's diameter is reduced.

2.1.3.

NPSH

It is directly proportional to n2, but does not vary with the diameter of the impeller

(provided that the diameter reduction is less than 20%). The use of inducers allows to

decrease the NPSH required.

n : Impeller speed (revolution per minute, rpm).

GE 1 - ANG - rev. 0 - EG-312-1128.doc

Issued

Book N

Chapter N

312

1.1.2.

VIII

GE

GUIDE DOCUMENT

PROCESS ENGINEERING DESIGN GUIDE

PART 1 SECTION 1

PROCESS MANUAL (DATA BOOK)

Rev. Page

1 6/22

S.S. 1.2 : Process Equipment

CHAPTER VIII Pumps

2.2.

Main features of centrifugal pumps

2.2.1.

Pumps operating in parallel

The performance curves should be drooping as much as possible to provide a good

operating stability. This can be achieved if the angle between impeller blades is less

than 18, which entails a slight reduction in pump efficiency.

2.2.2.

Rating point

The pump rating point shall be located as close as possible from the maximum

efficiency, but should not go beyond in terms of flowrate.

2.2.3.

Minimum flow

A minimum flow shall always be maintained in a centrifugal pump. This may require

a manual or automatic recirculation by-pass (restriction orifice, valve or "schroeder"

check valve).

The minimum flow is specified by the pump supplier. It is usually 20 to 30% of the

nominal flow, excepted for high-speed pumps, for which performance curves are

bell-shaped and the minimum flow can be up to 50% of normal flow.

2.2.4.

Materials of construction

Refer to the table enclosed overleaf.

2.3.

Selection of centrifugal pumps

The main characteristics of various types of centrifugal pumps are summarized in the

following table :

Centrifugal

pumps

Flowrate

Viscosity

(%)

NPSH

Required

(m)

Flow

control

(m3/h)

Single-stage pump

Single-stage pump

1500

10 to 80

1 to 4

Valve

Low

3000

10 to 80

1 to 5

Valve

Low

180

20000 max.

20 to 60

1 to 5

Valve

Moderate

< 500

35

3000

10 to 75

2 to 5

Valve

Moderate

< 500

140

3000

10 to 80

3 to 8

Valve

Moderate

Current

speed

(rpm.)

Efficiency

(cSt)

Differential

pressure

(bar)

2000

< 500

15

1500

< 500

35

Single-stage Sundyne

pump

90

< 500

Double-stage pump

250

Multi-stage pump

1500

GE 1 - ANG - rev. 0 - EG-312-1128.doc

Sensitivity

to solid impurities

GUIDE DOCUMENT

PROCESS ENGINEERING DESIGN GUIDE

PART 1 SECTION 1

PROCESS MANUAL (DATA BOOK)

GE

Issued

Book N

Chapter N

312

1.1.2.

VIII

Rev. Page

1 7/22

S.S. 1.2 : Process Equipment

CHAPTER VIII Pumps

MATERIAL SELECTION TABLE FOR CENTRIFUGAL PUMPS

G-2

GE 1 - ANG - rev. 0 - EG-312-1128.doc

API Standard 610

(8th Edition August 1995)

GUIDE DOCUMENT

PROCESS ENGINEERING DESIGN GUIDE

PART 1 SECTION 1

PROCESS MANUAL (DATA BOOK)

GE

Issued

Book N

Chapter N

312

1.1.2.

VIII

Rev. Page

1 8/22

S.S. 1.2 : Process Equipment

CHAPTER VIII Pumps

MATERIAL SELECTION TABLE FOR CENTRIFUGAL PUMPS

H-2

GE 1 - ANG - rev. 0 - EG-312-1128.doc

API Standard 610

(8th Edition August 1995)

GUIDE DOCUMENT

PROCESS ENGINEERING DESIGN GUIDE

PART 1 SECTION 1

PROCESS MANUAL (DATA BOOK)

GE

Issued

Book N

Chapter N

312

1.1.2.

VIII

Rev. Page

1 9/22

S.S. 1.2 : Process Equipment

CHAPTER VIII Pumps

MATERIAL SELECTION TABLE FOR CENTRIFUGAL PUMPS

H-3

GE 1 - ANG - rev. 0 - EG-312-1128.doc

API Standard 610

(8th Edition August 1995)

GUIDE DOCUMENT

PROCESS ENGINEERING DESIGN GUIDE

PART 1 SECTION 1

PROCESS MANUAL (DATA BOOK)

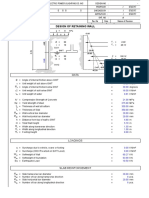

2.4.

Power estimation

2.4.1.

Shaft power

P (kW ) =

2.4.2.

GE

Issued

Book N

Chapter N

312

1.1.2.

VIII

Rev. Page

1 10/22

S.S. 1.2 : Process Equipment

CHAPTER VIII Pumps

Q (m3 / h x P (bar)

36 x (pump ' s efficiency )

Pump efficiency

It can be estimated based on the chart enclosed further on.

2.4.3.

Viscosity correction factor

It can be estimated based on the chart enclosed further on.

The impact on pump efficiency can be significant above 5 cSt, especially in the case of

low flow and low pump head.

2.4.4.

Electrical motor efficiency

It can be estimated based on the table enclosed further on.

The motor efficiencies are given for a 75% load (from maximum power), which is usually

the case.

For motors exceeding 15 kW, the efficiency increases by 0.5% at full load and decreases

by 2% at half load.

2.4.5.

Criteria for motor selection

A standard nominal power shall be selected for the motor. The nominal power will be the

standard nominal power immediately above the absorbed power at design conditions.

API 610 selection criteria shall be followed, i.e. the ratio of motor nominal power and

pump shaft power at rating point shall not be less than :

1.25 if the shaft power at rating point is < 22 kW

1.15 if the shaft power at rating point is from 22 to 55 kW

1.1 if the shaft power at rating point is > 55 kW.

GE 1 - ANG - rev. 0 - EG-312-1128.doc

GUIDE DOCUMENT

PROCESS ENGINEERING DESIGN GUIDE

PART 1 SECTION 1

PROCESS MANUAL (DATA BOOK)

GE

Issued

Book N

Chapter N

312

1.1.2.

VIII

Rev. Page

1 11/22

S.S. 1.2 : Process Equipment

CHAPTER VIII Pumps

When the pump is specified for open-valve start-up, the absorbed power at maximum

flow (end of the curve flow / head) shall be considered to select the motor, excepted for

high specific velocity pumps for which the maximum absorbed power corresponds to

minimum flow.

Practically, to calculate the power at maximum flow (end of the curve flow / head), the

Mechanical Department will consider 125% of the flow at B.E.P. (Best Efficiency Point).

The standard nominal powers of electric motors are given alongside with motor

efficiency values in the table enclosed further on.

Generally, low voltage motors (380 V) are used so long as the nominal power does not

exceed 132 kW and high voltage motors (5500 V) for higher values. However, the limit

between low and high voltage tends to increase, and a limit of 160 or even 200 kW may

be considered. This is usually defined in a Project general specification.

Examples of calculations :

The shaft power required for a pump at design conditions is equal to 7 kW. From the

table given further on, we obtain :

Motor efficiency : 85% for a 7.5 kW motor

Motor efficiency : 86% for a 11 kW motor.

For the 7.5 kW motor, the absorbed power is 7 / 0.85 = 8.2 kW. This motor is not

acceptable because the absorbed power (8.2) exceeds the nominal power (7.5).

For the 11 kW motor, the absorbed power is 7 / 0.86 = 8.1 kW. This motor is acceptable

because the absorbed power (8.1) is lower than the nominal power (11).

Checking of the API 610 criteria

For the 11 kW motor, the ratio (motor nominal power / pump shaft power) equals 11 / 7

i.e. 1.57 > 1.25. The criteria is met.

GE 1 - ANG - rev. 0 - EG-312-1128.doc

GE

GUIDE DOCUMENT

PROCESS ENGINEERING DESIGN GUIDE

PART 1 SECTION 1

PROCESS MANUAL (DATA BOOK)

Issued

Book N

Chapter N

312

1.1.2.

VIII

Rev. Page

1 12/22

S.S. 1.2 : Process Equipment

CHAPTER VIII Pumps

Example n 2

The shaft power required for a pump at design conditions is equal to 12.2 kW. From the

table given further on, we obtain :

Motor efficiency : 87 % for a 15 kW motor

Motor efficiency : 88 % for a 18.5 kW motor.

For the 15 kW motor, the absorbed power is 12.2 / 0.87 = 14 kW. This motor is

acceptable because the absorbed power (14) is lower than the nominal power (15).

For the 18.5 kW motor, the absorbed power is 12.2 / 0.88 = 13.9 kW. This motor is

acceptable because the absorbed power (13.9) is lower than the nominal power (18.5).

Checking of the API 610 criteria

For the 15 kW motor, the ratio (motor nominal power / pump shaft power) equals

5 / 12.2 = 1.22 < 1.25. The criteria is not met.

For the 18.5 kW motor, the ratio (motor nominal power / pump shaft power) equals

18.5 / 12.2 = 1.5 > 1.25. The criteria is met.

2.4.6.

Power at reduced capacity

The power at reduced capacity will be estimated by the following method :

w

w

Calculation of the power P at design flow Y

For a reduced flow x, the power P' will be :

x + Y

P' = P

2Y

2.4.7.

Pump suction specific speed nss

Nss = N x Q0.5 / (NPSH req3/ 4)

where :

N

Q

NPSHreq

: Rotating speed of the pump

: Flow by suction intake

: NPSH required for the pump

rpm.

m3/h

m

This criteria is used by the Mechanical Department for pump selection when a maximum

value is imposed by the Client ; If not, it is only used as a guideline.

GE 1 - ANG - rev. 0 - EG-312-1128.doc

GUIDE DOCUMENT

PROCESS ENGINEERING DESIGN GUIDE

PART 1 SECTION 1

PROCESS MANUAL (DATA BOOK)

GE

Issued

Book N

Chapter N

312

1.1.2.

VIII

Rev. Page

1 13/22

S.S. 1.2 : Process Equipment

CHAPTER VIII Pumps

The Nss is calculated for the flow giving the best efficiency with the impeller maximum

diameter. This means that for a same service, two pump suppliers will usually provide

different Nss depending on the position of the operating point.

In some particular cases, an increase of the NPSH required (consequently of the NPSH

available) can be desirable to get an acceptable Nss value. But this case is uncommon

because few suppliers can propose two NPSH for a same pump model (different wheels

for a same pump casing).

The Process Department does not have to verify this criteria ; It has to be done by the

Mechanical Department.

GE 1 - ANG - rev. 0 - EG-312-1128.doc

GUIDE DOCUMENT

PROCESS ENGINEERING DESIGN GUIDE

PART 1 SECTION 1

PROCESS MANUAL (DATA BOOK)

GE 1 - ANG - rev. 0 - EG-312-1128.doc

GE

Issued

Book N

Chapter N

312

1.1.2.

VIII

S.S. 1.2 : Process Equipment

CHAPTER VIII Pumps

Rev. Page

1 14/22

GUIDE DOCUMENT

PROCESS ENGINEERING DESIGN GUIDE

PART 1 SECTION 1

PROCESS MANUAL (DATA BOOK)

GE

Issued

Book N

Chapter N

312

1.1.2.

VIII

S.S. 1.2 : Process Equipment

CHAPTER VIII Pumps

Extract of Standard of the Hydraulic Institute, New York, USA 1955

GE 1 - ANG - rev. 0 - EG-312-1128.doc

Rev. Page

1 15/22

GUIDE DOCUMENT

PROCESS ENGINEERING DESIGN GUIDE

PART 1 SECTION 1

PROCESS MANUAL (DATA BOOK)

GE

Issued

Book N

Chapter N

312

1.1.2.

VIII

Rev. Page

1 16/22

S.S. 1.2 : Process Equipment

CHAPTER VIII Pumps

EFFICIENCY OF ELECTRICAL MOTORS AT 75% LOAD

380 V

Nominal P

kW

5500 V

Efficiency

%

0.75

1.1

1.5

2.2

3

4

7.5

11

15

18.5

22

30

37

45

55

75

90

110

132

GE 1 - ANG - rev. 0 - EG-312-1128.doc

70

73

74

77

79

80

85

86

87

88

89

90

90.5

91

91.5

92

92.5

93

93.5

Nominal P

kW

160

200

290

400

500

750

1 000

1 500

2 000

3 500

5 000

> 5000

Efficiency

%

91

92

93

93.5

94

94.5

95

95.5

96

96.5

97

97

GE

GUIDE DOCUMENT

PROCESS ENGINEERING DESIGN GUIDE

PART 1 SECTION 1

PROCESS MANUAL (DATA BOOK)

3.

Issued

Book N

Chapter N

312

1.1.2.

VIII

Rev. Page

1 17/22

S.S. 1.2 : Process Equipment

CHAPTER VIII Pumps

OTHER TYPES OF PUMPS

The main features of reciprocating and rotary pumps are summarized on the tables

enclosed further on.

Unless otherwise specified, the maximum flows indicated are limit values that may not be

compatible with the maximum differential heads. For border cases, the Mechanical

Department shall be consulted.

NPSH of reciprocating pumps

For reciprocating pumps, the pumped fluid is pulsed in the suction line. To produce this

acceleration, a certain amount of energy is required. This energy, which adds to the

frictional losses, is called "acceleration height". The NPSH available for a reciprocating

pump can subsequently be calculated by the following formula :

NPSHa = (HA HB) +

HA and HB

PA

TV

g

r

D PAB

HAB

GE 1 - ANG - rev. 0 - EG-312-1128.doc

( PA TV

(PAB )2 + (H AB )2

5

g x x 10

0.5

: Height in m

: Suction pressure in bar a

: Vapour pressure of the pumped liquid in bar a

: Gravity factor in m / s2

: Density in kg / m3

: Pressure drop due to friction in m

: Acceleration head

Equation 1 (Note 1)

GE

GUIDE DOCUMENT

PROCESS ENGINEERING DESIGN GUIDE

PART 1 SECTION 1

PROCESS MANUAL (DATA BOOK)

Issued

Book N

Chapter N

312

1.1.2.

VIII

Rev. Page

1 18/22

S.S. 1.2 : Process Equipment

CHAPTER VIII Pumps

For centrifugal pumps, HAB is nil and DPAB does not depend on the pump. The NPSHa is

independent of the selected pump.

For a reciprocating pump, HAB and DPAB depend on the pump, the NPSH available is

dependent on the selected pump :

D PAB : Pressure drop due to friction, is calculated for the maximum liquid velocity

HAB : Acceleration head, depends on the pumping rate.

During the preparation of the process specification, the characteristics of the pump are

unknown and the NPSHa (from equation 1) cannot be calculated. The NPSH given in the

process specification is the NPSHa for a non-pulsed flow, i.e. :

The NPSH available calculated is the one calculated as for a centrifugal pump, (HAB nil

and D PAB calculated for an average velocity which corresponds to the average flow

indicated in the specification).

Only after pump selection, provided that the piping layout at pump suction is defined, the

NPSH available for the selected pump can be given. Subsequently, the following note is

written on the process specification :

"The Mechanical Department must check with the supplier that the NPSH available

corresponding to the pump is compatible with its NPSH required."

D PAB calculation :

The pressure drop due to friction is calculated as for a centrifugal pump, but the

maximum liquid velocity, corresponding to the maximum instantaneous flow of the liquid

in the suction pipe, has to be considered. Depending on the type of pump selected, the

maximum instantaneous flow can be calculated by multiplying the average design flow

by the following factor :

Double-acting pump

Single-acting pump

Simplex

Duplex

Triplex

Quadruplex

Others

3

2

2

1.5

1.3

2

1.5

1.3

1.3

1.3

Note - If a pulsation dampener is installed on the suction line, the factor to consider is 1.2

whatever the type of pump is.

GE 1 - ANG - rev. 0 - EG-312-1128.doc

GUIDE DOCUMENT

PROCESS ENGINEERING DESIGN GUIDE

PART 1 SECTION 1

PROCESS MANUAL (DATA BOOK)

GE

Issued

Book N

Chapter N

312

1.1.2.

VIII

Rev. Page

1 19/22

S.S. 1.2 : Process Equipment

CHAPTER VIII Pumps

HAB Calculation :

H AB = 0.712 x K x

QxNxL

D2

Equation 2 (Note 2)

Where :

HAB

Q

N

D

L

K

:

:

:

:

:

:

In m

Average design flow in l/min

Number of rpm

Pipe diameter in mm

Pipe length in m

Factor depending on the type of the pump

Single-acting pump

Simplex

Duplex

Triplex

Quadruplex

Others

Double-acting pump

1.00

0.50

0.166

0.125

0.10

0.50

0.29

0.166

0.10

0.10

In case the suction line comprises several piping diameters, HAB must be calculated for

each section, and the results added.

The equation 2 above derives from the following assumptions :

The motion generated by the pump is assumed to be a harmonical one,

The fluid is assumed to be incompressible.

The first assumption is never realised. Usually, the motion generated by the connecting

rod-crank assembly exceeds the maximum values of the harmonic curve. This excess

depends on the ratio r = (length of the connecting rod / length of the stroke), which

commonly ranges from 1.5 to 2.

The maximum acceleration head must be increased by 25 to 35%.

The second assumption is checked when the suction pressure is close to the atmospheric

pressure, which is usually the case for reciprocating pumps.

GE 1 - ANG - rev. 0 - EG-312-1128.doc

GUIDE DOCUMENT

PROCESS ENGINEERING DESIGN GUIDE

PART 1 SECTION 1

PROCESS MANUAL (DATA BOOK)

GE

Issued

Book N

Chapter N

312

1.1.2.

VIII

Rev. Page

1 20/22

S.S. 1.2 : Process Equipment

CHAPTER VIII Pumps

Remark : When a pulsation dampener is installed on the suction line, the acceleration

head between the pulsation dampener and the pump must be calculated from equation 2.

The acceleration head between the drum and the pulsation dampener will be taken as 10%

of the calculated value from equation 2. The two heads have to be added to obtain the

total acceleration head.

Notes

4.

1.

There is a phase shift between the pressure drop due to friction D PAB and the

pressure drop caused by acceleration HAB (acceleration is maximum when the

velocity is minimum).

This phenomenon is taken into account by the term [(PAB)2 + (HAB)2]05 in

equation 1.

2.

Some sources indicate equation 2 as being unrealistic when the suction line is

very long.

IMPACT OF DISSOLVED GASES ON THE NPSH

The occurrence of dissolved gas in the liquids dramatically reduces the NPSH really

available at the pump suction.

It is then necessary to take some margins into account, deriving from past experience.

These margins shall be considered in the PDS and shall be clearly indicated to prevent

any misunderstanding with the Mechanical Department.

The following recommendations can be found in the literature :

BFW pumps :

Other pumps :

GE 1 - ANG - rev. 0 - EG-312-1128.doc

divide by 1.25

divide by 2 or consider liquid at bubble point.

GUIDE DOCUMENT

PROCESS ENGINEERING DESIGN GUIDE

PART 1 SECTION 1

PROCESS MANUAL (DATA BOOK)

GE

Issued

Book N

Chapter N

312

1.1.2.

VIII

Rev. Page

1 21/22

S.S. 1.2 : Process Equipment

CHAPTER VIII Pumps

MAIN FEATURES OF RECIPROCATING PUMPS

Type of

reciprocating pump

NPSH

Usual

Global

velocity efficiency required

%

m

rpm

Flow

Viscosity

m3/h

cSt

Direct acting steam

pump

100 (simplex)

250 (duplex)

1800

20 to 350 usually

700 and more possible

0-70

45-80

3-4

Speed adjustment by steam throttling.

Max. temperature: 400C

Controlled piston

pump (or plunger)

300 (multiplex)

1800

350 to 750 usually

2500 possible

20-450

55-85

4-5

Flow control : 0-100%

Max. temp. : about 500C

Diaphragm pump with

hydraulic control

20 by head

1000

350 usually

3000 possible (metal

diaphragm)

150-200

80

4-5

Max. temperature : 500C min.

Temperature : -70C

Very good tightness.

Flow control : 0-100% .

Typical use : loaded liquids.

High viscosities.

Diaphragm pump with

pneumatic control

50

1800

0-40

250000

500

3000

Possible

50-200

Dosing pump :

Maxi range

Usual range

0-10

0-3

Differential

pressure ( )

bar

2 to 4

20

4-5

(

) the maximum values indicated for flow and differential head may not be simultaneous.

GE 1 - ANG - rev. 0 - EG-312-1128.doc

Remarks

Max. temperature : 100C

Applicable to loaded liquids (up to

90%)

Extreme temperature :

- 5000C max.

- 2000C min.

Flow control : 0-100%

Flow accuracy : +/- 0.5%

Book N

Chapter N

312

1.1.2.

VIII

GE

GUIDE DOCUMENT

PROCESS ENGINEERING DESIGN GUIDE

PART 1 SECTION 1

PROCESS MANUAL (DATA BOOK)

Issued

Rev. Page

1 22/22

S.S. 1.2 : Process Equipment

CHAPTER VIII Pumps

MAIN FEATURES OF ROTARY PUMPS

Type of rotary

pump

Gear

Screw :

- 2 screws

- 3 screws

Vanes

Flow (1)

Viscosity

m3/h

cSt

Differential

pressure (1)

bar

Usual

velocity

rpm

Global

efficiency

%

NPSH

required

m

200

10 x 106

250

0-3000

50-90 (2)

3-4

1000-2000

1000

1 x 106

2 x 106

200

200

2000

up to 15000

50-90

50-90 (2)

3-4

3-4

400

1 x 106

25

0-1500

Remarks

Max. temperature : 3500C

Max. temperature : 3000C

Max. temperature : 2600C

Hydraulic pumps : 200 bar, 20 m3/h,

2000 rpm.

Pistons

up to 50

(3)

up to 700

2000-3000

Deformable rotor

20

20000

2-4

200-1800

10 to 30

Off centre Screw

200

1 to 200000

50

0-1500

50

1-5

Max. temp. : 80-900C

Can handle erosive particles.

Lobes

200

1 to 200000

5-20

< 700

30-40

1-5

Max. temperature : 1200C

Deformable stator

20

25000

5-15

0-200

30-50

Max. temperature : 950C

Can handle erosive particles.

Mouvex

120

3-5

250-1400

45-50

Max. temp. : 250-3000C

(1)

(2)

(3) These pumps are used in

hydraulic systems for which the

fluids have a 500/1000 cSt viscosity.

Max. temperature : 800C

The maximum values given may not be simultaneous.

These efficiencies commonly exceed 70% when the operating conditions (differential pressure + flow + viscosity) are in the

optimal range for the pump selected.

GE 1 - ANG - rev. 0 - EG-312-1128.doc

Potrebbero piacerti anche

- Printable Spencerian Practice Sheets PDFDocumento5 paginePrintable Spencerian Practice Sheets PDFjwochNessuna valutazione finora

- Engineering 0016 General Process Design RequirementsDocumento51 pagineEngineering 0016 General Process Design RequirementsagaricusNessuna valutazione finora

- 3.1 Turbine and GoverningDocumento90 pagine3.1 Turbine and GoverningYudo Heru PribadiNessuna valutazione finora

- Copperplate GuidelinesDocumento12 pagineCopperplate GuidelinesPanosPlacebo100% (2)

- Jacketed Piping Stress Analysis - HP 1978 PDFDocumento3 pagineJacketed Piping Stress Analysis - HP 1978 PDFim4uim4uim4uim4u100% (1)

- Simple DistillationDocumento6 pagineSimple DistillationA Arun100% (1)

- Guide For VesselDocumento72 pagineGuide For VesselFlorin Daniel AnghelNessuna valutazione finora

- Ge312-1121 Columns - DrumDocumento20 pagineGe312-1121 Columns - DrumDiarista Thoma SaputraNessuna valutazione finora

- Indra: SonatrachDocumento9 pagineIndra: SonatrachhichamNessuna valutazione finora

- Hydraulics Basis OPALDocumento13 pagineHydraulics Basis OPALGoutam GiriNessuna valutazione finora

- Process STD 103 PDFDocumento58 pagineProcess STD 103 PDFaliNessuna valutazione finora

- Elm Pul PR XXX 034 Agc FinalDocumento16 pagineElm Pul PR XXX 034 Agc Finaljagiprem123Nessuna valutazione finora

- Design and Simulation of Continuous Distillation Columns PDFDocumento33 pagineDesign and Simulation of Continuous Distillation Columns PDFnghiemta18Nessuna valutazione finora

- E-Pr-460 Process Design Flare and Blowdown VesselsDocumento37 pagineE-Pr-460 Process Design Flare and Blowdown VesselsAndy Sevordzi100% (1)

- SAMSUNG SEM-9471E - Process Design Manual - Health and Design Safety Specification Rev0 2004Documento7 pagineSAMSUNG SEM-9471E - Process Design Manual - Health and Design Safety Specification Rev0 2004d_mazieroNessuna valutazione finora

- Reboiler HydraulicDocumento3 pagineReboiler Hydraulic54yreyeNessuna valutazione finora

- Guide Document GE P312 4.1.2 I General ConsiderationsDocumento31 pagineGuide Document GE P312 4.1.2 I General ConsiderationsDiarista Thoma SaputraNessuna valutazione finora

- Junín Upgrader Hydrocracking Unit (14) Overall Material BalanceDocumento11 pagineJunín Upgrader Hydrocracking Unit (14) Overall Material BalancegarciahoNessuna valutazione finora

- D 103eDocumento19 pagineD 103eCivil FriendNessuna valutazione finora

- Process Design CriteriaDocumento23 pagineProcess Design CriteriaDoctorOberman100% (1)

- Assay BachaqueroDocumento12 pagineAssay BachaqueroGinis MrcNessuna valutazione finora

- Offsites and UtilitiesDocumento70 pagineOffsites and Utilitiesankitalalwani100% (1)

- E PR 460Documento37 pagineE PR 460khorzooNessuna valutazione finora

- (D-103) Fractionating Trays - Rev1 PDFDocumento10 pagine(D-103) Fractionating Trays - Rev1 PDFmihir_jha2Nessuna valutazione finora

- A10-A-DOC-VE-068274 - 00 离心泵 设计要求Documento14 pagineA10-A-DOC-VE-068274 - 00 离心泵 设计要求zhangNessuna valutazione finora

- Design of A Heat Exchanger Using HTRIDocumento4 pagineDesign of A Heat Exchanger Using HTRIcenter010% (1)

- EXXI 080 50 00 PI DPS 0001 0(特殊管架与图纸)Documento103 pagineEXXI 080 50 00 PI DPS 0001 0(特殊管架与图纸)1339979Nessuna valutazione finora

- Process Engineering Design GuideDocumento296 pagineProcess Engineering Design GuideNguyen Anh TungNessuna valutazione finora

- Pulsation Suppression Device Design For Reciprocating CompressorDocumento9 paginePulsation Suppression Device Design For Reciprocating CompressorFrancis LinNessuna valutazione finora

- Genesis Process Design Guidelines RDocumento96 pagineGenesis Process Design Guidelines RDavid Gustavo Duran TangoNessuna valutazione finora

- Oxy Enrich Process For Capacity Enhancement of Claus Based Sulfur Recovery UnitDocumento22 pagineOxy Enrich Process For Capacity Enhancement of Claus Based Sulfur Recovery Unitamitgoyal1972Nessuna valutazione finora

- 943025-806 Strainers Rev01Documento3 pagine943025-806 Strainers Rev01studyendlessNessuna valutazione finora

- Indus - PGD Process Design EngineeringDocumento2 pagineIndus - PGD Process Design EngineeringAmarjeet SandhuNessuna valutazione finora

- MTP Process DescriptionDocumento5 pagineMTP Process DescriptionW00WNessuna valutazione finora

- Chemical & Process Technology - Two-Third (2 - 3) Rule or Ten-Thirteen (10 - 13) RuleDocumento3 pagineChemical & Process Technology - Two-Third (2 - 3) Rule or Ten-Thirteen (10 - 13) RuleomeshchemNessuna valutazione finora

- Jump Start Aspen HYSYS V8Documento29 pagineJump Start Aspen HYSYS V8hayfronbsterNessuna valutazione finora

- Special Report: Design A Staggered Depressurization Sequence For Flare SystemsDocumento4 pagineSpecial Report: Design A Staggered Depressurization Sequence For Flare Systemsdigeca100% (1)

- Att2 Baretti InternalsDocumento36 pagineAtt2 Baretti InternalsAli MetinNessuna valutazione finora

- 1-Steady State Hydraulic Analysis ReportDocumento39 pagine1-Steady State Hydraulic Analysis ReportrajNessuna valutazione finora

- Mechanical Constraints On Thermal Design of Shell and Tube ExchangersDocumento26 pagineMechanical Constraints On Thermal Design of Shell and Tube Exchangersjdgh1986Nessuna valutazione finora

- Process Engineering Manual 005 IIDocumento29 pagineProcess Engineering Manual 005 IIzoeNessuna valutazione finora

- SPE-171415-MS Increasing Sales Gas Output From Glycol Dehydration PlantsDocumento7 pagineSPE-171415-MS Increasing Sales Gas Output From Glycol Dehydration Plantsnguyenphuoc258Nessuna valutazione finora

- Estimating Costs of Shell and Tube Heat Ex Changers by Purohit ComDocumento12 pagineEstimating Costs of Shell and Tube Heat Ex Changers by Purohit Comhwang2Nessuna valutazione finora

- Engineering Standard: IPS-E-PR-330Documento30 pagineEngineering Standard: IPS-E-PR-330Akmal ZuhriNessuna valutazione finora

- Equipment Design BasisDocumento4 pagineEquipment Design BasisAnjani GantiNessuna valutazione finora

- Surge Control Dynamic Simulation Centrifugal CompDocumento3 pagineSurge Control Dynamic Simulation Centrifugal CompAnil B YadavNessuna valutazione finora

- 11-3085 Energy Analyzer Jump StartDocumento26 pagine11-3085 Energy Analyzer Jump StartOmesh BoroleNessuna valutazione finora

- Hysys Liquid PumpingDocumento8 pagineHysys Liquid PumpingEkundayo JohnNessuna valutazione finora

- HTP - PRC.PRG.10010-Process Plant Steady State Simulation-Iulie 2009 PDFDocumento11 pagineHTP - PRC.PRG.10010-Process Plant Steady State Simulation-Iulie 2009 PDFFlorin Daniel Anghel100% (1)

- Wall Metal Temperature During Emergency DepressurizationDocumento7 pagineWall Metal Temperature During Emergency Depressurizationmihaileditoiu2010Nessuna valutazione finora

- Engineering Standar For Process Design of Solid Liquid Separators-IpsDocumento31 pagineEngineering Standar For Process Design of Solid Liquid Separators-Ipsdantorrelio89100% (1)

- Pd-Va.4 (1996)Documento15 paginePd-Va.4 (1996)Santiago GarciaNessuna valutazione finora

- Piping Arrangement LurgiDocumento42 paginePiping Arrangement Lurgienjoyguruji100% (3)

- CTBEST PVM 300 Process Design of Separation VesselsDocumento22 pagineCTBEST PVM 300 Process Design of Separation Vesselsrzepedac100% (2)

- Column Hydraulics NotesDocumento4 pagineColumn Hydraulics NotessatishchemengNessuna valutazione finora

- Process Design Course (From Exxon) PDFDocumento281 pagineProcess Design Course (From Exxon) PDFphantanthanhNessuna valutazione finora

- Process STD 400-1.2 PDFDocumento71 pagineProcess STD 400-1.2 PDFBassemNessuna valutazione finora

- Process STD 105 PDFDocumento50 pagineProcess STD 105 PDFMohamed100% (1)

- Process Engg Design Guide Matls Corrosion TechnipDocumento21 pagineProcess Engg Design Guide Matls Corrosion Techniplutfi awnNessuna valutazione finora

- Process STD 1104 PDFDocumento37 pagineProcess STD 1104 PDFAugusto ManuelNessuna valutazione finora

- Chemical Process Retrofitting and Revamping: Techniques and ApplicationsDa EverandChemical Process Retrofitting and Revamping: Techniques and ApplicationsGade Pandu RangaiahNessuna valutazione finora

- Manual BookDocumento154 pagineManual BookAnonymous nHT1rzjmcNessuna valutazione finora

- Hydraulic Turbines Od ThaperDocumento90 pagineHydraulic Turbines Od ThaperVeronica Naveda Espinoza100% (1)

- 3.1 GL For Selection of Turbine and GoverningDocumento96 pagine3.1 GL For Selection of Turbine and GoverningBehailu FelekeNessuna valutazione finora

- Spencerian - 2.5mm - 52 Degrees PDFDocumento1 paginaSpencerian - 2.5mm - 52 Degrees PDFjwochNessuna valutazione finora

- Spencer 2.5mm PDFDocumento1 paginaSpencer 2.5mm PDFjwochNessuna valutazione finora

- Spencerian Guide-2,5mm-Light-Ruled PDFDocumento1 paginaSpencerian Guide-2,5mm-Light-Ruled PDFjwochNessuna valutazione finora

- Spencerian - 2.5mm - 52 Degrees PDFDocumento1 paginaSpencerian - 2.5mm - 52 Degrees PDFjwochNessuna valutazione finora

- Spencerian 2.5mm PDFDocumento1 paginaSpencerian 2.5mm PDFjwochNessuna valutazione finora

- Lucy Edmonds - Modern Calligraphy - A Step-by-Step Guide To Mastering The Art of Creativity (2018, Orion) PDFDocumento98 pagineLucy Edmonds - Modern Calligraphy - A Step-by-Step Guide To Mastering The Art of Creativity (2018, Orion) PDFjwoch100% (13)

- DNV - RP - F109Documento28 pagineDNV - RP - F109Sylvia Delos SantosNessuna valutazione finora

- CAESAR II 2011 Applications GuideDocumento304 pagineCAESAR II 2011 Applications GuideTrietzeeNessuna valutazione finora

- PolyFlow BrochureDocumento6 paginePolyFlow BrochurejwochNessuna valutazione finora

- Pi Ec19412Documento1 paginaPi Ec19412jwochNessuna valutazione finora

- Pi-Ec19412 - 190619Documento1 paginaPi-Ec19412 - 190619jwochNessuna valutazione finora

- PolyflowDocumento2 paginePolyflowangel gabriel perez valdezNessuna valutazione finora

- PolyflowDocumento2 paginePolyflowangel gabriel perez valdezNessuna valutazione finora

- 27 May Greetings and FarewellsDocumento14 pagine27 May Greetings and FarewellsjwochNessuna valutazione finora

- Supersealer Sb10: Rotary Continuous Band SealerDocumento2 pagineSupersealer Sb10: Rotary Continuous Band SealerjwochNessuna valutazione finora

- Pipelines and Buried PipesDocumento22 paginePipelines and Buried PipesjwochNessuna valutazione finora

- Pipe Diameter Velocity GPMDocumento1 paginaPipe Diameter Velocity GPMLauren CaldwellNessuna valutazione finora

- 1988 - Kitching - Practical Guidelines For ReducingDocumento7 pagine1988 - Kitching - Practical Guidelines For Reducingpankajp17Nessuna valutazione finora

- Guide 4. The Essential Is Invisible To The Eye.Documento7 pagineGuide 4. The Essential Is Invisible To The Eye.jwochNessuna valutazione finora

- Mil F 24385FDocumento24 pagineMil F 24385FjwochNessuna valutazione finora

- Key Creator Administration GuideDocumento27 pagineKey Creator Administration GuideFadi W MoussaNessuna valutazione finora

- Boundary Layers PDFDocumento1 paginaBoundary Layers PDFjwochNessuna valutazione finora

- 9 Taylor DispersionDocumento1 pagina9 Taylor DispersionjwochNessuna valutazione finora

- 8 Turbulence ModelsDocumento1 pagina8 Turbulence ModelsjwochNessuna valutazione finora

- Determining Limits For Piping VibrationDocumento7 pagineDetermining Limits For Piping Vibrationsammar_10Nessuna valutazione finora

- Buoyant Plumes, Thermals, Etc.: Turbulent Flow and TransportDocumento1 paginaBuoyant Plumes, Thermals, Etc.: Turbulent Flow and TransportjwochNessuna valutazione finora

- Chapter 08 (Pumps) PDFDocumento21 pagineChapter 08 (Pumps) PDFjwochNessuna valutazione finora

- Sample Problem - ComsolDocumento4 pagineSample Problem - Comsolmayuri sritharanNessuna valutazione finora

- J2006 - Termodinamik 1 - UNIT0Documento12 pagineJ2006 - Termodinamik 1 - UNIT0Ahmas SyaakirNessuna valutazione finora

- (For Comprehensive Examination of BSME Program, IUBAT) : Prepared By: Rofail Miah (Id - 15207022)Documento25 pagine(For Comprehensive Examination of BSME Program, IUBAT) : Prepared By: Rofail Miah (Id - 15207022)ShakibNessuna valutazione finora

- Plastic Theory of Bending - Materials - Engg Reference With Worked ExamplesDocumento9 paginePlastic Theory of Bending - Materials - Engg Reference With Worked ExampleshoojzteNessuna valutazione finora

- Tablon Retaining Wall Ht. - Clark - With WindDocumento27 pagineTablon Retaining Wall Ht. - Clark - With WindclarkgaguiNessuna valutazione finora

- GATCHDocumento6 pagineGATCHsudhakarmnNessuna valutazione finora

- LP5 Arm 5150817 3 00Documento270 pagineLP5 Arm 5150817 3 00Jose Armando Lemus ManzanaresNessuna valutazione finora

- Lecture Xfem MeshfreeDocumento147 pagineLecture Xfem MeshfreemsyexploreNessuna valutazione finora

- Electromagnetic Phenomena in Resistance Spot Welding and Its Effects On Weld Nugget FormationDocumento5 pagineElectromagnetic Phenomena in Resistance Spot Welding and Its Effects On Weld Nugget FormationAlexandre CalixtoNessuna valutazione finora

- Computers and Geotechnics: G.S.P. Singh, U.K. SinghDocumento15 pagineComputers and Geotechnics: G.S.P. Singh, U.K. Singhkatta_sridharNessuna valutazione finora

- EX-0035 Drilling - English API Forumla SheetDocumento4 pagineEX-0035 Drilling - English API Forumla Sheetmohamed abbasNessuna valutazione finora

- Linear Vs Nonlinear Analysis in EarthquakeDocumento2 pagineLinear Vs Nonlinear Analysis in EarthquakeTejas DoshiNessuna valutazione finora

- Wing Wall Design-FinalDocumento25 pagineWing Wall Design-FinalRahulNessuna valutazione finora

- HVAC en CatalogueDocumento64 pagineHVAC en CataloguesafinditNessuna valutazione finora

- 1.1 Backwash Blowers 1.1.1 Design BasisDocumento2 pagine1.1 Backwash Blowers 1.1.1 Design BasisLusubilo MalakalingaNessuna valutazione finora

- Insight Into The Seismic Response of Earth Dams With An Emphasis On Seismic Coefficient Estimation PDFDocumento16 pagineInsight Into The Seismic Response of Earth Dams With An Emphasis On Seismic Coefficient Estimation PDFIonut PatrasNessuna valutazione finora

- 1.1 Review of Elementary Mechanics of Materials (Aka Strengths of Materials)Documento11 pagine1.1 Review of Elementary Mechanics of Materials (Aka Strengths of Materials)Boonme ChinnaboonNessuna valutazione finora

- Unit 2 Energy MethodDocumento10 pagineUnit 2 Energy MethodYokesvaran KNessuna valutazione finora

- Separation Process, Practice Test Questions and AnswersDocumento13 pagineSeparation Process, Practice Test Questions and AnswersEnaye MajiriNessuna valutazione finora

- Aspen Physical Property System Physical Property Methods - 2020Documento322 pagineAspen Physical Property System Physical Property Methods - 2020Ongki PurwantaNessuna valutazione finora

- NACA Technical Note 2440Documento58 pagineNACA Technical Note 2440lufabaoNessuna valutazione finora

- Conversion of Heat TransferDocumento2 pagineConversion of Heat TransferwagoheNessuna valutazione finora

- Feedwater Heater - Regeneration Analysis - HandbookDocumento19 pagineFeedwater Heater - Regeneration Analysis - HandbookAnonymous wIPMQ5rhNessuna valutazione finora

- H7 Friction LossDocumento4 pagineH7 Friction LossHoracio EspinosaNessuna valutazione finora

- MECHANICAL ENGINEERING 2019 Scheme S4 Syllabus Ktustudents - inDocumento91 pagineMECHANICAL ENGINEERING 2019 Scheme S4 Syllabus Ktustudents - inashnbNessuna valutazione finora

- Cooling Tower Basics PDFDocumento71 pagineCooling Tower Basics PDFMohamed TallyNessuna valutazione finora

- Measurement of Creep Crack Growth Times in Metals: Standard Test Method ForDocumento25 pagineMeasurement of Creep Crack Growth Times in Metals: Standard Test Method ForCristian DíazNessuna valutazione finora

- Specialty PumpsDocumento9 pagineSpecialty PumpsLorino BaldezamoNessuna valutazione finora

- Unit 3 One Marks QuestionsDocumento6 pagineUnit 3 One Marks QuestionsRahulNessuna valutazione finora