Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Sheedal, Shidal

Caricato da

sanzitTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Sheedal, Shidal

Caricato da

sanzitCopyright:

Formati disponibili

Indian Journal of Natural Products and Resources

Vol. 4(2), June 2013, pp. 170-177

Naturally evolved fermented fish products of Northeast India (Seedal and Shidal) A comparative study

A U Muzaddadi

Department of Fish Processing Technology, College of Fisheries, Central Agricultural University

Lembucherra, Tripura 799 210, India

Received 23 May 2012; Accepted 2 April 2013

The indigenous fermented fish products of Northeast India namely seedal and shidal were studied to record the

preparation processes and general biochemical and microbiological characteristics of the products. The production centers of

different states including Assam and Tripura were surveyed and the data were recorded through personal interview and on

the spot observation. The most common methods have been reported for the products including seedal and shidal from

Assam and Tripura, respectively. These solid products are prepared from small fish species belonging to the carp family

(Cyprinidae) by a combined process of drying and semi-fermentation which are then consumed with further elaborate

cooking. Seedal was found to contain better original organoleptic characteristics than shidal. The proximate composition of

moisture and protein showed significant changes (P<0.05), e.g. less moisture content in shidal (30%) than in seedal (36%);

however, more protein content was evident in shidal (39%) than in seedal (31%). The protein breakdown products such

alpha amino nitrogen, Total Volatile Bases (TVB-N) and Non-Protein-Nitrogen (NPN) showed minimal protein degradation

in both the products which is a major peculiarity of these products. The indices for lipid hydrolysis including Peroxide Value

(PV), Free Fatty Acid (FFA) and Thiobarbituric Acid number (TBA) showed significantly higher lipid oxidation in shidal

than in seedal. The pH also showed significantly higher value in seedal than in shidal. Total Plate Count (TPC) was

recorded significantly higher in shidal (7.2 log CFU/g) than in seedal (6.4 log CFU/g) having the Total Fungal Count (TPC)

almost negligible in both the products. Being produced in large scale, shidal contained more dry fish like characters than

seedal which had higher market value than the other.

Keywords: Fermented fish, Fish Products, Northeast India, Seedal, Shidal, Puntius spp.

IPC code; Int. cl. (2011.01)A23L 1/00, A23L 1/326

Introduction

The Northeastern region of India is a treasure of

natural products pertaining to agriculture, food,

medicine, and natural resources management1. The

region has over 100 tribes and communities, each

having their unique ethnic foods developed through

the ages. In recent years a number of ethnic foods and

food products traditionally prepared by different

tribes/communities of the region has been reported1-11

including fish products such as shidal/seedal5,6,

ngari1,11, hentak1,11, and tungtap5,11. The low-valued

small fish are dried, moistened, packed in oil smeared

earthen pots and kept at room temperature for about 6

months. These products are eaten after elaborate

cooking as a condiment with rice. These semifermented products retain almost original shape and

size of the fish that are used as raw material. These

____________

*Correspondent author:

E-mail: drarmaan@gmail.com, dr.armaan@hotmail.com

Telefax: +91-9611133444

non-salty solid products have no similarity with

classical fermented products of Southeast Asian

countries such as Patis of the Philippines, Nuac mum

of Korea, Taiwan and Vietnam which are mostly

paste or semi liquids with salt as a major component.

The fermented products probably came into

existence at least before the British Era in

Northeastern states of India [before 1824, The

Yandabu Agreement between British Govt. and

Burma (now Myanmar)] when the British first

introduced salt in the region. Interestingly, in all the

fermented fish products of this region no salt is used

as ingredient which is a major difference with the

other fish based fermented fish products of Southeast

Asian countries such as Nuac-mum of Vietnam, Budu

of Malaysia, Patis of the Philippines, etc. Even after

the British Era, people used to treat salt as a highly

valued and scarce commodity and they used to take an

alternative commodity, for example khar in Assam,

made from banana plant or papaya. Hence, they could

MUZADDADI: FERMENTED FISH PRODUCTS OF NORTH-EAST INDIA (SEEDAL AND SHIDAL)

not afford spending salt in fish preservation and they

were bound to preserve fish in their own cheaper and

easier way. As Saisithi (1994) suggested, it is quite

natural that the simple drying might have prolonged

due to frequent rainfall resulting in high humidity in

the atmosphere particularly during the peak fishing

seasons, i.e., monsoon and post-monsoon from May

to September12. Consequently, the experienced fishers

had to find out a method through which they could

preserve the instant heavy catches comprising of very

less valued small fishes like Puntius spp.,

Amblypharyngdodon sp., Trichogaster spp., Channa

spp., Mystus spp., Botia spp., Danio spp., Rasbora spp.,

Chanda spp., Nandus sp., etc. for the consumption and

sale in the dry seasons (November to April) when raw

fresh fish used to be scares in the market. Due to the

unavailability of ice and good road communication

facilities, fishers could not even transport this highly

perishable catch to the distant markets where they

could have received a profitable price. As a matter of

fact, the fishers would never earn good price in the

village markets through instant sale of these fish.

Furthermore, the people, perhaps, wanted to

change the taste and flavor of their daily rice-fish

dish, which had become bland and monotonous. As a

result, they invented the methods of preparation of

such fermented fish products. For instance, people

must have stored the semi-dried fish in earthen vats

(locally called mutkas) for months together which

eventually allowed the fermentation process to set in

and resulted in a semi-pasty and product with strong

smell seedal in Assam. People gradually acquired

the taste and aroma of such fermented products and

especially the disadvantaged economic conditions of

the people, perhaps, created compulsion for accepting

these products. The primary objectionable smell of

these products was taken care of while preparation of

the culinary dishes by adding hot spices including

green chili, ginger, garlic, onion, red pepper, salt and

oil and by frying or boiling with subsequent grinding

into pastes.

Mostly Puntius spp. or Setipinna phasa which are

abundantly available during monsoon and postmonsoon seasons in the water bodies of the region are

utilized as a means of preservation for future use

when fresh fish are scanty. The use of small economic

varieties of fish in fermented fish products and their

popularity in Northeast may be due to several reasons

such as: [1] Highly perishable nature of such fish did

not allow transport to the distant markets for better

171

price, thus compelling fishers to go for preservation,

[2] Variability of size and shape of individual species in

the whole catch, however, species wise uniformity in

size such as Puntius spp. made it easier to sort and

segregate this particular species for processing for

preparation of seedal. [3] The fish oil required for

product processing could be extracted sufficiently from

the same fish, hence no dependency on other oil source

and a low cost product. [4] The other options like

preparation of silage were not known to the fishers. [5]

Simple sun drying was difficult enough due to frequent

rain, infestation by pests and creation of unpleasant

atmosphere in the courtyard. [6] Believing such products

to be of medicinal value. [7] The culinary preparations

of these products used to be efficient appetizer and taste

enhancer to serve as condiment with rice.

These traditional methods are spontaneously

evolved by the people who have been actively

engaging themselves in fish related activities. The

products originated traditionally from time immemorial

and are the delicacies of tribes and non-tribes of the

region with amazingly high demand in the market. The

popular belief is, these products have pharmaceutical

values which may be proven in affirmative by

conducting organized scientific research.

Materials and Methods

The information was collected through extensive

field study and survey. The study area was Nagaon

district of Assam and West Tripura district of Tripura

(Plate 1). Three production centers from each district

were surveyed and the persons actively engaged in the

production were interviewed. From the many

variations of the preparation procedures adopted in

the study region, a common method of preparation of

the product has been worked out after eliminating

insignificant deviations having little bearing on the

finished product quality.

Plate 1 The study area (red circle mark) in Assam and Tripura

in the North-east states of India

INDIAN J NAT PROD RESOUR, JUNE 2013

172

The product quality characteristics were recorded

by sensory evaluation which was given by 10 judges

randomly selected from the regular consumers of

seedal and shidal and the scores were given in

10-point Hedonic scale such as 10-Excellent, 9-Very

good, 8-Good, 6-7-Average, 5-Lost property/

unacceptable. The mean value of the scores was taken

and the results were supplemented by information

provided by the fishers engaged in product preparation.

The samples of seedal and shidal were collected in

polyethylene bags immediately after opening the

mutka from the production centers of Assam and

Tripura respectively during a period of six months in

2011. Total 10 samples of each product were analyzed

in the laboratory of the Department of Fish Processing

Technology, College of Fisheries, Tripura. Moisture,

protein, ash, acid insoluble ash, total fat content, pH,

free fatty acid and non protein nitrogen (NPN) were

estimated following standard AOAC methods13.

Alpha-amino nitrogen was determined by the method

given by Pope and Stevens14. Total Volatile Base

Nitrogen (TVB-N) was determined by Conways

micro-diffusion method15, Peroxide Value (PV) by the

method given by Jacob16 and Thiobarbituric Acid

(TBA) number by method given by Tarladgis et al17.

Total Plate Count (TPC) and Total Fungal Count

(TFC) were done by spread plate techniques (APHA,

1995). Exactly 10 g of shidal sample was introduced

aseptically in a sterile stomacher bag (Seward

stomach BA6141CPG standard bags) and blended for

2 minutes with 90 mL of sterile diluents (0.85% NaCl

for TPC and 0.1% Peptone water for TFC) using a

stomacher (Seward stomacher 400 circulator,

England). Serial decimal dilution of 1/100 was

prepared using 9 mL sterile physiological saline and

1 mL homogenized sample and it was well mixed in

cyclomixer. For TPC, 0.1 mL portions of various

dilutions were spread on the surface of preset surfacedried Soybean Casein Digest Agar/Trypticase Soya

Agar (TSA) (MU290, Himedia, India) plates and for

Total Fungal Count (TFC) same portions were spread

on the surface of preset surface-dried Rose Bengal

Chloramphenical agar (M640, HIMEDIA) plates

using a sterile glass spreader. For TPC, plates were

incubated at 35C for 24-48 h while fungal plates were

incubated at 25C for 3-5 days. The plates containing

25-250 colonies were counted for TPC and plates with

15-150 colonies were selected for TFC. Representative

samples of the product were inoculated directly

(0.1 mL without dilution) onto replicate plates of brain

heart infusion (BHI) agar (M211, HIMEDIA) with

different concentrations of NaCl such as BHI + 5%

NaCl, BHI + 10% NaCl, and BHI + 20% NaCl in order

to see the growth halophilic/halotolerant bacteria.

These plates were incubated at 35C for 24-48 h.

Statistical analysis was done by performing one

way ANOVA (Post Hoc, Duncan) and students t-test

to compare the means using SPSS18.

Results and Discussion

Seedal (Product of Assam)

Seedal is a pasty and solid product in which the

shape of the fish (Puntius spp.) remains almost intact.

Instead of salt, as in many other indigenous fermented

fish product, extra oil is added here during product

preparation. Hence, rancidity is a must in seedal.

Puntius spp. is exclusively used for the preparation of

seedal (Table 1). The rural fishers procure them from

beels and rivers. Commercially it is prepared from dried

Puntius spp. which can be grouped into four groups in

Assam. The first group is Desi puthi, produced locally

and considered to be the best quality raw material for

seedal production. The dried Puntius spp. belonging to

the other groups come from Madras, Lucknow and

Gorakhpur, hence named as Madrasi Puthi, Luckhnowi

Puthi and Gorakhpuri Puthi. All these varieties are

procured from Jagiroad Fish Market (about 50 km east

to Guwahati City, Assam). As they are imported from

distant places through truck loadings, their quality

deteriorates during transportation due to the

unpredictable delay. However, due to the short supply of

Desi puthi, the imported varieties are used by the

commercial producers by compulsion which made the

producers able to produce seedal throughout the year

and maintain sustained supply to meet the high market

demand. Moreover, it made them independent of the

highly erratic availability of Deshi puthi.

Table 1 The major species of Puntius used in the preparation of seedal and shidal

S. No.

1.

2.

3.

4.

Scientific Name

Puntius chola (Hamilton, 1822)

P. sarana (Valenciennes, 1842)

P. sophore (McClelland, 1839)

P. ticto (Hamilton, 1822)

English common name

Swamp barb

Olive barb

Pool barb

Two spot barb

Assamese local name

Normal size range (cm)

Doloni puthi

Seni puthi

Soru puthi

Tita puthi

2-5

3-8

3-6

3-8

MUZADDADI: FERMENTED FISH PRODUCTS OF NORTH-EAST INDIA (SEEDAL AND SHIDAL)

Mutkas are round bottom and narrow necked

specially made earthen pots, the capacity of which

ranges from 8 to 40 kg (Plate 2). Mutkas can be used

for preparation of many batches of product until they

break. Older the mutkas better the product quality and

lesser the cost of production, the reason being the

older mutkas absorb very less amount of oil and

provide very good gas barrier property.

Fish oil extracted from the entrails of Puntius spp. or

other fresh water fish through an indigenous crude

method is used by the rural producers. Oil is used to

smear the mutkas, perhaps to increase gas barrier

property by filling the minute pores in the earthen pot.

Although fish oil is treated as the best oil for smearing

mutka, for the commercial production vegetable oil

such as mustard oil is used as an alternative of fish oil

due to its easy availability and inexpensiveness in

comparison to fish oil. Semi-dried or fully dried fish

are often crushed into powder and a paste is made from

it which is used to fill in the mouth portion of mutkas.

Any broad leaf of plants such as Colocasia or

banana leaves, bottle-guard leaves or a piece of

newspaper is used to seal the cover paste temporarily.

A thick mud is prepared from humus rich and fine

coarse soil, which is used to seal the mouth.

This procedure is popular among the rural fishers

where raw fresh fish are available in plenty. Fishers

173

extract fish oil from entrails of Puntius spp. and make

use of it in seedal preparation (The indigenous method

is illustrated in Fig. 1-Flow chart). This naturally

evolved procedure is most economic and climate

friendly and mostly practiced in the backyard of

fishers. Although the seedal produced by this method

(Plate 3) is considered to be the best, the commercial

producers do not normally follow this method, perhaps

due to inconsistent supply of raw material.

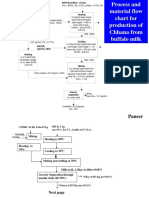

Shidal (product of Tripura)

Shidal, a seedal like product is prepared in Tripura

(one of the states of Northeast India) mainly from two

Plate 2 Earthen pots (mutka) used in seedal preparation

Fig. 1 (Flow chart)-Indigenous method of seedal preparation

174

INDIAN J NAT PROD RESOUR, JUNE 2013

species of fish such as Puntius spp. and Setipinna

phasa. Completely dry fish are used here and vegetable

oil is used instead of the fish oil for smearing of mutka.

The dried fish is further dried under sun after a thorough

sorting from the whole lot. The uniform sized fleshy fish

(not infested by maggots) are dried to reduce the

moisture level to about 15%. The fish are then washed

thoroughly and dipped into water 10-15 minutes in order

to make them slightly soft. These fish are then dried

under shade over night spreading under a drying shed.

In the very next morning, the mutkas are packed by

putting the fish in layers in a pre-processed mutka very

Plate 3 Good quality seedal with golden brown colour

tightly. Mutkas are processed by smearing with

mustard oil and repeatedly dried under sunlight until

they become saturated with oil (Plate 4). These mutkas

are kept under ventilated shade for 3-4 months for

fermentation (the method is illustrated in Fig. 2- Flow

chart). The fermentation time varies depending on the

texture of dry fish which is used as raw material. The

advantages of this method may be listed as:

Plate 4 Earthen pot (mutka) after oil processing used in shidal

preparation

Fig. 2 (Flow chart)- The method of shidal preparation

MUZADDADI: FERMENTED FISH PRODUCTS OF NORTH-EAST INDIA (SEEDAL AND SHIDAL)

i. No dependency on seasonally available fresh

fish, thus shidal can be prepared round the year.

ii. The large scale commercial production is

possible due to a sustained supply of raw material.

iii. The fish oil, with short supply, is replaced with

vegetable oil resulting in large scale production.

Table 2 summarizes the characteristics of seedal

and shidal. The acceptability of these products

depends on the post-fermentation organoleptic

qualities including the appearance, texture and

especially the typical shidal/seedal odour. The seedal

scored 10 points (excellent) under 10 point Hedonic

scale analysis when it had sticky surface, golden

brown colour, hard texture and strong ammoniacal

smell; whereas shidal with moderately dry surface,

silvery gray/light brown colour, hard texture and

moderate ammoniacal odour was given 10 points.

These characteristics decide the unit price of these

products in the market. In fact, seedal always fetches

better price than shidal due to its originality.

Although all types of small carps belonging to the

genera Puntius are used for preparation of quality

products, best quality product is prepared from the

matured fish of approximately 3-6 cm in length. The

rural fishers believe that the fish before bearing eggs

are best suited for seedal or shidal preparation.

175

Shidal is prepared in commercial scale to meet the

demand in the Northeast states of India. As a matter

of fact, the commercial producers modified the

traditional method to suit large scale production.

Hence, they compromised with the traditional

originality of the product and incorporated those raw

materials which have a constant supply for year round

production along with reduction of normal

fermentation time. Consequently, the product (shidal)

retained nearly the original shape of the raw material

(Plate 5) containing less organoleptic properties

compared to seedal.

Plate 5 Good quality shidal with shape nearly intact with

silvery grey colour

Table 2 General characteristics of best quality seedal and shidal

Sl. No.

Properties/

characteristics

Appearance

2

3

4

5

6

Colour

Texture

Odour

Raw material

Shape of Mutka

7

8

Mutka capacity

Cover leaf

Oil used in mutka

processing

Normal fermentation 4-6 months

period

Shelf life outside

Approx. 1 month [dusted with salt, packed

mutka

in polythene and stored under ambient

temperature (30C)]

10

11

Shidal*

Sensory

Score#

Retains the shape of raw material, structurally

looks like Puntius spp. or Setipinna phasa, firm

and moderately dry surface

Silvery gray or light brown

Hard texture but softer than dry fish

Moderate odour (ammoniacal and putrefied)

Puntius spp. and Setipinna phasa

Pointed bottom oval spherical with long neck,

made with red soil

15-40 kg

Polythene

10

Seedal*

Retains the shape of raw material,

structurally looks like Puntius spp., soft

and sticky surface

Golden brown with pale red tinge

Moderately hard texture

Strong odour (ammoniacal and putrefied)

Exclusively Puntius spp.

Round bottom spherical with short neck,

made with black soil

8-40 kg

A broad plant leaf, such as Colocassia or

banana plant

Fish oil extracted from fish

10

10

10

Mustard oil

3-4 months

Approx. 2 month [dusted with salt, packed in

polythene and stored under ambient temperature

(30C)]

*Characteristics are based on sensory evaluation by 10 judges (regular seedal and shidal eater) supplemented with the information

provided by the traditional seedal/shidal producers.

#In 10-Point Hedonic scale, 10-Excellent, 9- Very good, 8- Good, 6-7- Average, 5- Lost property/unacceptable

176

INDIAN J NAT PROD RESOUR, JUNE 2013

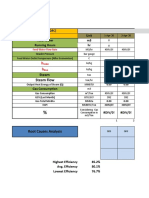

The biochemical properties of both the products are

summarized in Table 3. The moisture and protein

contents showed significant differences (P<0.05),

whereas all other parameters did not differ significantly.

Perhaps, the moisture content of shidal was less (30%)

due to loss of water holding capacity of protein of sundried fish which was used as raw material. On the other

hand, seedal prepared from fresh half-dried fish, its

muscle portion could hold more amount of moisture

resulting in less bulk density. Thus, the raw material

contained less protein and high moisture. Although ash

content was higher in shidal (14.8%), its acid insoluble

ash content (0.23%) was less than seedal, i.e. 13.8%

(total ash) and 0.53% (acid insoluble ash), which

indicates more sand contamination in seedal than in

shidal. The salt content in both the products was very

less, because no additional salt was used during

preparation. However, small amount of salt may come

from other cured fish which were handled in the same

processing shed. On the other hands, the lipid content

also was found to be less in shidal (15.77%) and that of

seedal (18.9%). The possible cause may be the oxidation

of lipids during sun-drying which is accelerated by heat

and impurities in water. Seedal contained more lipids

partly because of using fish oil for smearing raw fish

during packing. The NPN and alpha amino nitrogen

contents were almost similar in both the products with

small values showing similar protein degradation

process in muscle of fish. The reason may be the use of

dry or semi-dry fish with scales and skin on. The dried

Table 3 The biochemical properties of traditional seedal and

shidal, values are mean SD, n=10.

Biochemical properties

Moisture (w/w %)

Ash (w/w %)*

Protein (w/w %)

Lipid (w/w %)*

Acid-insoluble Ash (w/w %)

Salt (w/w %)*

Non-protein Nitrogen (w/w %)*

Free Alpha Amino Nitrogen

(w/w mg %)*

Total Volatile Base Nitrogen

(mg %)

Peroxide Value (milliequivallent

peroxide oxygen/1000g)

Free Fatty Acid (% as oleic acid)

Thiobarbituric Acid Number

(mg malonaldehyde/1000 g)

pH

scales and skin with high content of collagen protect fish

from undergoing excessive protein breakdown by

enzymatic or microbial activity. Moreover, due to the

use of gutted fish (entrails removed) in product

preparation, the gut enzymes are also not involved in the

protein degradation process leading to limited protein

hydrolysis and providing a special characteristic to the

products. The TVB-N content of seedal (223.67 mg %)

is significantly different (P<0.05) from that of shidal

(123.67), which indicates production of nitrogenous

volatile compounds such as ammonia and aliphatic

amines is more in seedal than in shidal. Perhaps, the

sun-dried fish as raw material in shidal might be the

reason for this. During long sun drying process fish

either lost most of the volatile compounds due to

evaporation or their precursors were denatured due to

the solar heat. Same may be the reason for which the

indices of lipid oxidation such as PV, FFA and TBA

showed greater lipid oxidation in shidal than in seedal.

The values of PV and FFA of shidal (27.2 and 42.6,

respectively) were almost double of the values of seedal

(14 and 20.6, respectively) which clearly indicates more

oxidative and hydrolytic rancidity in shidal than in seedal.

The TBA value too, which is 4 times greater in shidal

(8 mg malonaldehyde/1000 g) than in seedal (2 mg

malonaldehyde/1000 g) strongly supports high oxidative

rancidity in shidal than in seedal. The earlier study also

suggests that seedal has short shelf-life (10 days) outside

mutka due to lipid oxidation and loss of volatile

components that contribute to the typical flavour of

products6. The pH showed significant difference

(P<0.05) with a value of 6.3 in seedal and 4.5 in shidal.

The production of high content of nitrogenous bases in

seedal might have kept the pH high.

Total Plate Count of seedal (6.4 log CFU/g)

significantly differed from the count of shidal

(7.2 log CFU/g), while Total Fungal Count (TFC) was

negligible in both the products (Table 4). The

unhygienic rough handling, use of dry fish and pond

water for washing are some of the reasons that might

have contributed to the high bacteria count in shidal.

Seedal

Shidal

36.020.90

13.80.18

31.060.05

18.870.42

0.530.02

0.720.17

5.490.24

60.674.67

30.020.50

14.80.12

39.060.15

15.770.52

0.230.12

0.420.15

4.490.14

55.673.17

223.673.28

123.674.28

14.030.32

27.220.42

Microbiological property

Seedal

Shidal

20.620.17

2.210.64

42.620.47

8.110.34

6.30.2

4.50.2

Total Plate Count (log CFU/g)*

Total Fungal Count (log CFU/g)

Total Halophilic Count (log CFU/g)

Presence of anaerobic bacteria

6.40.9

3.40.1

UD

ND

7.20.5

3.50.3

UD

ND

*The biochemical properties with asterisks do not differ

significantly (P>0.05)

Table 4The microbiological properties of seedal and shidal,

values are mean SD, n=10.

*The microbiological properties with asterisks do not differ

significantly (P>0.05), UD- undetectable level, ND- Not detected

MUZADDADI: FERMENTED FISH PRODUCTS OF NORTH-EAST INDIA (SEEDAL AND SHIDAL)

Although many conditions are similar with process of

seedal production, the use of half-dried raw fish might

have reduced bacterial count in it. Almost anaerobic

packing of earthen pots probably reduced the growth

of fungi in the products. The halophilic bacteria were

in undetectable level in both the products. Analysis

for anaerobic bacteria such as Clostridium botulinum

was not carried out since its growth is unlikely. The

environment inside the earthen pot was not

completely anaerobic because of porous earthen pots

used as fermenting vessel. Moreover minute amount

of air remained in between fish layers inside the pot

making the internal environment unfavourable for the

growth of anaerobic bacteria.

Conclusion

Both the products are eaten after elaborate cooking

and preparation of chutney like preparations, mixed

curry with vegetables, making paste with bamboo

shoots. At present these products costs more than

rupees 500/- per kg in Tripura and Assam. However,

the price is still higher in hilly states including

Arunachal Pradesh, Manipur, Meghalaya and

Nagaland. In order to improve the quality of the

products, we recommend:

i. Use of hygiene practices during production

including use of cemented processing shed,

chlorinated washing water, regular disinfection

of the premises etc.;

ii. Use of accelerated and improved method for

increased production which has been developed

by College of Fisheries, Central Agricultural

University;

iii. Government intervention for undertaking more

research, awareness programmes and technology

upgradation and transfer. In order to throw light

on other aspects of these products, research

works are being conducted by the author under

sponsored projects.

Acknowledgements

The author is highly thankful to the Muslim Fisher

Community of Nagaon district of Assam and Hindu

fisher community of Tripura for providing the

valuable information about the products. The author is

also thankful to Central Agricultural University for

providing basic assistance in conducting the research.

177

References

1 Jeyaram K, Th Anand Singh, W Romi, A Ranjita Devi, W

Mohendro Singh, H Dayanidhi, N Rajmuhon Singh and

JP Tamang, Traditional fermented foods of Manipur, Indian

J Trad Knowledge, 2009, 8(1), 115-121.

2 Choudhry D, Sahu J K and Sharma G D, Bamboo shoot

based fermented food products: A review, J Sci Industr Res,

2011, 70, 199-203.

3 Dutta B K and Dutta P K, Potential of ethnomedicinal studies

in Northeast India: An overview, Indian J Trad Knowledge,

2005, 4(1), 7-14.

4 Mao A A and Odyuo N, Traditional fermented foods of Naga

tribes of Northeastern India, Indian J Trad Knowledge, 2007,

6(1), 37-41.

5 Murugkar D A and Subbulakshmi G, Preparation techniques

and nutritive value of fermented foods from the khasi tribes

of Meghalaya, Ecol Food Nutrition, 45, 27-38.

6 Muzaddadi A U and Basu S, An accelerated process for

fermented fish (seedal) production in Northeast region of

India, Indian J Animal Sc, 2012, 82(1), 98-106.

7 Muzaddadi A U and Basu S, Microbiological and sensory

changes during preparation of seedal- A fermented fish

product, in Seafood Safety, edited by P K Surendran, P T

Mathew, N Thampuran, V N Nambiar, J Joseph, et al (Society

of Fisheries Technologists (India), Cochin 2003, 35-40.

8 Muzaddadi A U and Basu S, Seedal-an indigenous fermented

fishery product of Northeast India, Fish Chimes, 2003, 23,

30-32.

9 Muzaddadi A U and Basu S, SHIDAL -A Traditional

fermented Fishery product of Northeast India, Indian J Trad

Knowledge, 2012, 11(2), 323-328.

10 Singh A, Singh R K and Sureja A K, Cultural significance

and diversities of ethnic foods of Northeast India, Indian J

Trad Knowledge, 2007, 6(1), 79-94.

11 Thapa N, Pal J and Tamang J, Microbial diversity in ngari,

hentak and tungtap, fermented fish products of North-East

India, World J Microbiol Biotech, 2004, 20, 599-607.

12 Saisithi P, Traditional fermented fish: fish sauce production,

In: Fisheries Processing- Biotechnological Applications

edited by Martin M A, Chapman and Hall, 1994, 111-131.

13 Association of Official Analytical Chemists (AOAC),

Official methods of analysis, 17th edn. Association of

Official Analytical Chemists, Washington, DC, USA, 2001.

14 Pope C G and Stevens M F, The determination of amino

nitrogen using a copper method, J Biochem, 1939, 33,

1070-1076.

15 Conway E J, Microdifusion analysis and volumetric error, 4th

edn, Van Nostrad Co. Inc., New York, USA, 1947.

16 Jacob M B, The chemical analysis of foods and food

products, Kreiger Publishing Co. Inc., New York, USA,

1958.

17 Tarladgis B G, Watts B M and Younathen M T, A distillation

method for the quantative determination of malonaldehyde in

rancid foods, J Am Oil Chem Soc, 1960, 37, 44-48.

18 Statistical Package for the Social Sciences (SPSS) (2005)

15.0 ver., SPSS Inc., Chicago: IL, Canada.

Potrebbero piacerti anche

- 4 5 65 704 PDFDocumento6 pagine4 5 65 704 PDFashisbhuniyaNessuna valutazione finora

- A Proposal On Study On The Histamine Content of Dried Fish in Some Districts of NepalDocumento8 pagineA Proposal On Study On The Histamine Content of Dried Fish in Some Districts of NepalPrashanta PokhrelNessuna valutazione finora

- Processing of Dried Anchovy (Stolephorus SP) in Teri Sebatik, Sebatik Island, Nunukan Regency, North KalimantanDocumento5 pagineProcessing of Dried Anchovy (Stolephorus SP) in Teri Sebatik, Sebatik Island, Nunukan Regency, North KalimantancrebotestNessuna valutazione finora

- Feeding Appropriate Formulated Diet For Improving Gonad Maturation and Spawning of Brooder of Some Native Fishes in IndonesiaDocumento9 pagineFeeding Appropriate Formulated Diet For Improving Gonad Maturation and Spawning of Brooder of Some Native Fishes in IndonesiaAdrians SAFNessuna valutazione finora

- Jurnal 2 EkpangDocumento9 pagineJurnal 2 EkpangMuhammad Aulia RahmanNessuna valutazione finora

- Indian Fishing IndustryDocumento21 pagineIndian Fishing IndustrygaurangNessuna valutazione finora

- The Biodiversity of Fish Fauna in GobardhanDas Pond (Saran District), North BiharDocumento4 pagineThe Biodiversity of Fish Fauna in GobardhanDas Pond (Saran District), North BiharresearchparksNessuna valutazione finora

- Anchovi Khedkar Reprint PDFDocumento8 pagineAnchovi Khedkar Reprint PDFZandrex S. AguillonNessuna valutazione finora

- Traditional Methods of Fish Drying An ExDocumento9 pagineTraditional Methods of Fish Drying An ExClyde Mae AmarillentoNessuna valutazione finora

- Food of JapanDocumento8 pagineFood of Japannhoclun274Nessuna valutazione finora

- Quality Characteristics and Functional and AntioxiDocumento14 pagineQuality Characteristics and Functional and AntioxiMed Lamine RabhiNessuna valutazione finora

- Jellyfish As Food PDFDocumento8 pagineJellyfish As Food PDFJezyll MarieNessuna valutazione finora

- Mariculture Development in IndonesiaDocumento15 pagineMariculture Development in IndonesiaRokhmadRofiqNessuna valutazione finora

- Dry Fish: January 2013Documento6 pagineDry Fish: January 2013Harshit RoyNessuna valutazione finora

- Foods: A Comprehensive Review On The Processing of Dried Fish and The Associated Chemical and Nutritional ChangesDocumento28 pagineFoods: A Comprehensive Review On The Processing of Dried Fish and The Associated Chemical and Nutritional ChangesShivam KalitaNessuna valutazione finora

- Koi Fish CultureDocumento26 pagineKoi Fish CulturefireflybarakaNessuna valutazione finora

- Paddy-Cum-Fish Culture in Ziro Valley: Arunachal PradeshDa EverandPaddy-Cum-Fish Culture in Ziro Valley: Arunachal PradeshNessuna valutazione finora

- Fermented FishDocumento13 pagineFermented FishAdrian StanNessuna valutazione finora

- Ipi134446 PDFDocumento6 pagineIpi134446 PDFKadriNessuna valutazione finora

- Comparative Study of Gold Fish (Carassius Auratus) Breeding Via Induced and Natural BreedingDocumento6 pagineComparative Study of Gold Fish (Carassius Auratus) Breeding Via Induced and Natural BreedingHamdi HamzaouiNessuna valutazione finora

- Evaluation of Integrated Fish-Rice Farming in The Nile Irrigation and Drainage Project Areas, South Gonder, EthiopiaDocumento4 pagineEvaluation of Integrated Fish-Rice Farming in The Nile Irrigation and Drainage Project Areas, South Gonder, EthiopiaSyahril FisNessuna valutazione finora

- The Utilization of Meat and Bones of Milkfish (Chanos Chanos) As High Protein and Calcium On SnackDocumento13 pagineThe Utilization of Meat and Bones of Milkfish (Chanos Chanos) As High Protein and Calcium On Snacksilvia100% (1)

- Issn 2094-1749Documento123 pagineIssn 2094-1749arianlyncaraldeNessuna valutazione finora

- Lona IlishDocumento6 pagineLona IlishAdrian StanNessuna valutazione finora

- Developing Culture Technology of Indigenous Small Fish Species Mola in Aquaculture Ponds in SunderbansDocumento15 pagineDeveloping Culture Technology of Indigenous Small Fish Species Mola in Aquaculture Ponds in SunderbansAnjan VarmaNessuna valutazione finora

- CitationDocumento9 pagineCitationmichaelllaNessuna valutazione finora

- Ansu FrevisedDocumento21 pagineAnsu Frevisedansuka bhattaraiNessuna valutazione finora

- Vannamei Experiment in TNDocumento5 pagineVannamei Experiment in TNVijay Varma RNessuna valutazione finora

- Effect of Potassium Salt Replacement On Physicochemical, Sensorial and Microbiological Properties of Mango PickleDocumento6 pagineEffect of Potassium Salt Replacement On Physicochemical, Sensorial and Microbiological Properties of Mango Pickle22phchvs101Nessuna valutazione finora

- Studies On Biodiversity of Selected Indigenous Fish Species, in Beels and Baors of South BengalDocumento5 pagineStudies On Biodiversity of Selected Indigenous Fish Species, in Beels and Baors of South BengalashisbhuniyaNessuna valutazione finora

- Comparing Different Fish Silage MethodDocumento15 pagineComparing Different Fish Silage Methodzihan.pohNessuna valutazione finora

- IJZAB ID No. 284 PDFDocumento10 pagineIJZAB ID No. 284 PDFIJZABNessuna valutazione finora

- Smoked and Dried Fish Products of North EastDocumento39 pagineSmoked and Dried Fish Products of North EastBahni DharNessuna valutazione finora

- Milkfish Culture: Alternative Revenue For Mandapam Fisherfolk, Palk Bay, Southeast Coast of IndiaDocumento15 pagineMilkfish Culture: Alternative Revenue For Mandapam Fisherfolk, Palk Bay, Southeast Coast of IndiaMike-Dave Madarang CastilloNessuna valutazione finora

- AsemSSingh Ngari AtraditionalfishDocumento6 pagineAsemSSingh Ngari AtraditionalfishNewtonNessuna valutazione finora

- Processing Sea Cucumbers Into Beche-De-mer - A Manual For Pacific Island FishersDocumento52 pagineProcessing Sea Cucumbers Into Beche-De-mer - A Manual For Pacific Island FishersEny DutaNessuna valutazione finora

- Asag 02 0180Documento7 pagineAsag 02 0180Ujjwal VlogsNessuna valutazione finora

- Pangasius Sp. - N.B. Rathod, Et Al PDFDocumento15 paginePangasius Sp. - N.B. Rathod, Et Al PDFDewi SetiyowatiNessuna valutazione finora

- Chapter 1-5-D&NDocumento64 pagineChapter 1-5-D&NMaclord GolvinNessuna valutazione finora

- 51 IFRJ 21 (06) 2014 Sarah 545Documento10 pagine51 IFRJ 21 (06) 2014 Sarah 545Ricardo Segura FloresNessuna valutazione finora

- Breeding and Development of Ornamental Hill Stream Fish Devario Aequipinnatus (McClelland) in CaptivityDocumento7 pagineBreeding and Development of Ornamental Hill Stream Fish Devario Aequipinnatus (McClelland) in CaptivityDR. BIJAY KALI MAHAPATRANessuna valutazione finora

- 2016 1 RJAVFS RasulDocumento7 pagine2016 1 RJAVFS Rasul020ANNISA NUR MAHARANINessuna valutazione finora

- FCR For Fish PDFDocumento30 pagineFCR For Fish PDFShekhar MitraNessuna valutazione finora

- Tilapia RRLDocumento10 pagineTilapia RRLZejkeara Imperial100% (2)

- Paper 19 PDFDocumento5 paginePaper 19 PDFAuna SandoNessuna valutazione finora

- Comparativestudyonqualityofdry Fish PuntiussppDocumento5 pagineComparativestudyonqualityofdry Fish PuntiussppShivam KalitaNessuna valutazione finora

- Tugas Pak Cipto TTHPDocumento14 pagineTugas Pak Cipto TTHPrendraNessuna valutazione finora

- Sp7-2 Surimi IndustryDocumento7 pagineSp7-2 Surimi IndustryNguyễn TiênNessuna valutazione finora

- AD21 - On Farm Fish CultureDocumento67 pagineAD21 - On Farm Fish CultureKenny CasillaNessuna valutazione finora

- Beddows, C.G. 1998. Fermented Fish and Fish Products. Microbiology of Fermented Foods, 416-440. Doi 10.1007slash978!1!4613-0309-1 - 13Documento25 pagineBeddows, C.G. 1998. Fermented Fish and Fish Products. Microbiology of Fermented Foods, 416-440. Doi 10.1007slash978!1!4613-0309-1 - 13Gaily Jubie HontiverosNessuna valutazione finora

- Tilapia VC Report 2012 - Final PDFDocumento26 pagineTilapia VC Report 2012 - Final PDFCharlene ManalastasNessuna valutazione finora

- Local Media6935855468758562925Documento5 pagineLocal Media6935855468758562925Gerad Kenneth BenoyaNessuna valutazione finora

- EXPERT TOPIC: Feed and Feeding Practices For Catfish in IndiaDocumento10 pagineEXPERT TOPIC: Feed and Feeding Practices For Catfish in IndiaInternational Aquafeed magazineNessuna valutazione finora

- FisheriesBy Products PDFDocumento9 pagineFisheriesBy Products PDFmanvi kaurNessuna valutazione finora

- Rismah Wahyu S.F.P - Essay Competition - Rismah Wahyu Salsabil Fadlilah PramuDocumento5 pagineRismah Wahyu S.F.P - Essay Competition - Rismah Wahyu Salsabil Fadlilah Pramudhary isNessuna valutazione finora

- Cooking with Jasmine; Fish Recipes: Cooking With Series, #3Da EverandCooking with Jasmine; Fish Recipes: Cooking With Series, #3Nessuna valutazione finora

- Australian Fish Farmer: A Practical Guide to AquacultureDa EverandAustralian Fish Farmer: A Practical Guide to AquacultureNessuna valutazione finora

- Creating An Open Supply ChainDocumento8 pagineCreating An Open Supply ChainsanzitNessuna valutazione finora

- A Guide To Reverse LogisticsDocumento4 pagineA Guide To Reverse LogisticssanzitNessuna valutazione finora

- A Multi-Objective Emergency Network Design Problem To Carry Out Disaster Relief Operations in Developing CountriesDocumento20 pagineA Multi-Objective Emergency Network Design Problem To Carry Out Disaster Relief Operations in Developing CountriessanzitNessuna valutazione finora

- Understanding Readiness Metrics For The Humanitarian Operations Through Literature ReviewDocumento25 pagineUnderstanding Readiness Metrics For The Humanitarian Operations Through Literature ReviewsanzitNessuna valutazione finora

- SOM LLDocumento10 pagineSOM LLsanzitNessuna valutazione finora

- Outsourcing of Humanitarian Logistics To Commercial Logistics Service ProvidersDocumento23 pagineOutsourcing of Humanitarian Logistics To Commercial Logistics Service ProviderssanzitNessuna valutazione finora

- Humanitarian LogisticsDocumento9 pagineHumanitarian LogisticssanzitNessuna valutazione finora

- Ssom2 1-TPDocumento3 pagineSsom2 1-TPsanzitNessuna valutazione finora

- Battery CalibrationDocumento3 pagineBattery CalibrationsanzitNessuna valutazione finora

- Digital MarketingDocumento6 pagineDigital MarketingsanzitNessuna valutazione finora

- Your Complete Online Marketing GuideDocumento11 pagineYour Complete Online Marketing GuidesanzitNessuna valutazione finora

- Supply Chain Management: Strategy, Planning, and Operation, 5/e Authors: Sunil Chopra, Peter Meindl and D. V. KalraDocumento42 pagineSupply Chain Management: Strategy, Planning, and Operation, 5/e Authors: Sunil Chopra, Peter Meindl and D. V. KalraMohammed AhmedNessuna valutazione finora

- SSOM2 3 PrefaceDocumento6 pagineSSOM2 3 PrefacesanzitNessuna valutazione finora

- Is Blockchain Technology Necessary or Even Possible For Supply ChainsDocumento5 pagineIs Blockchain Technology Necessary or Even Possible For Supply ChainssanzitNessuna valutazione finora

- Big Data Analytics For Investigating Taiwan Line Sticker Social Media MarketingDocumento19 pagineBig Data Analytics For Investigating Taiwan Line Sticker Social Media MarketingsanzitNessuna valutazione finora

- Ssom2 CH02Documento18 pagineSsom2 CH02sanzitNessuna valutazione finora

- SSOM2 Ch03Documento20 pagineSSOM2 Ch03sanzitNessuna valutazione finora

- Emerging Masculinities in ChinDocumento26 pagineEmerging Masculinities in ChinsanzitNessuna valutazione finora

- Big Data Analytics For Investigating Taiwan Line Sticker Social Media MarketingDocumento19 pagineBig Data Analytics For Investigating Taiwan Line Sticker Social Media MarketingsanzitNessuna valutazione finora

- The Challenges of ReplicatingDocumento118 pagineThe Challenges of ReplicatingsanzitNessuna valutazione finora

- Insights On The Adoption of Social Media Marketing in B2B ServicesDocumento41 pagineInsights On The Adoption of Social Media Marketing in B2B ServicessanzitNessuna valutazione finora

- Big Data Analytics For Investigating Taiwan Line Sticker Social Media MarketingDocumento19 pagineBig Data Analytics For Investigating Taiwan Line Sticker Social Media MarketingsanzitNessuna valutazione finora

- Social Media Marketing in Luxury Brands: A Systematic Literature Review and Implications For Management ResearchDocumento23 pagineSocial Media Marketing in Luxury Brands: A Systematic Literature Review and Implications For Management ResearchAkademis ArkaswaraNessuna valutazione finora

- Introduction: Services in The Economy: The Material in This Chapter Prepares Students ToDocumento12 pagineIntroduction: Services in The Economy: The Material in This Chapter Prepares Students ToAlbertoNessuna valutazione finora

- Emerging Masculinities in ChinDocumento26 pagineEmerging Masculinities in ChinsanzitNessuna valutazione finora

- HRM 1Documento22 pagineHRM 1sanzit100% (1)

- Distribution Network DesignDocumento32 pagineDistribution Network DesignsanzitNessuna valutazione finora

- An Integrated Model For Logistics Network DesignDocumento31 pagineAn Integrated Model For Logistics Network DesignsanzitNessuna valutazione finora

- Job AnalysisDocumento13 pagineJob AnalysissanzitNessuna valutazione finora

- Strategic ManagementDocumento173 pagineStrategic Managementjirufeleke1428100% (2)

- Theory Lm2500 Principios Basicos de Operacion PDFDocumento25 pagineTheory Lm2500 Principios Basicos de Operacion PDFamir8100Nessuna valutazione finora

- Practical Chemistry Voumetric EstimationDocumento9 paginePractical Chemistry Voumetric EstimationSanjay Shirodkar100% (2)

- Rate Law and The Eyring EquationDocumento11 pagineRate Law and The Eyring EquationManjunath.RNessuna valutazione finora

- COMEDK Important Topics and Revised SyllabusDocumento49 pagineCOMEDK Important Topics and Revised SyllabusVishal VermaNessuna valutazione finora

- Carbon Enrichment in Mo SteelDocumento50 pagineCarbon Enrichment in Mo SteelDhananjay ShimpiNessuna valutazione finora

- Quiz 1 With AnswerDocumento3 pagineQuiz 1 With AnswerAltra ZNessuna valutazione finora

- DDFC Boiler Effeciency AnalysisDocumento21 pagineDDFC Boiler Effeciency AnalysisPublic DemandNessuna valutazione finora

- IbandronateDocumento6 pagineIbandronateAashishThakurNessuna valutazione finora

- Pri STXDocumento2 paginePri STXМаксим ГрабовскийNessuna valutazione finora

- HVAC Cooling Load CalculationDocumento98 pagineHVAC Cooling Load CalculationVishnupriya B.100% (3)

- Chemistry Volumetric LabDocumento20 pagineChemistry Volumetric Labsunil venkataNessuna valutazione finora

- Terms in Pre-Stressed ConcreteDocumento3 pagineTerms in Pre-Stressed ConcreteKenneth100% (1)

- Salama YoussefDocumento1 paginaSalama YoussefYoussef SalamaNessuna valutazione finora

- Consolidation Theories of Soils: By: Alemayehu Teferra (Prof., Dr.-Ing.)Documento33 pagineConsolidation Theories of Soils: By: Alemayehu Teferra (Prof., Dr.-Ing.)ASAMENEWNessuna valutazione finora

- Raghavendra Bhat. GPUC High School Section, MegaravalliDocumento8 pagineRaghavendra Bhat. GPUC High School Section, Megaravallisyedyaseen39375Nessuna valutazione finora

- Chemistry Revision Guide For IGCSE Coordinated Science Chemistry Revision Guide For IGCSE Coordinated ScienceDocumento20 pagineChemistry Revision Guide For IGCSE Coordinated Science Chemistry Revision Guide For IGCSE Coordinated SciencekarlabrooksNessuna valutazione finora

- AWWA Manual M51 Air-Release, Air - Vacuum, and Combination Air Valves 2016Documento77 pagineAWWA Manual M51 Air-Release, Air - Vacuum, and Combination Air Valves 2016maguenhoyos100% (9)

- Class 11sc 2021 PaperDocumento10 pagineClass 11sc 2021 PaperAman KumarNessuna valutazione finora

- Basf Master BatchDocumento6 pagineBasf Master Batchapi-3842599100% (1)

- Determining An Optimum Catalyst For Liquid-Phase Dehydration of Methanol ToDocumento7 pagineDetermining An Optimum Catalyst For Liquid-Phase Dehydration of Methanol Toshaka9221Nessuna valutazione finora

- 6th SEM - Sep-22Documento4 pagine6th SEM - Sep-22Jay RanjanNessuna valutazione finora

- Deaerator Post MCQ'sDocumento50 pagineDeaerator Post MCQ'sEhtisham ul haqNessuna valutazione finora

- Ketaspire Peek Avaspire Paek: High-Performance PolyketonesDocumento2 pagineKetaspire Peek Avaspire Paek: High-Performance PolyketonesnhzaidiNessuna valutazione finora

- DOT Pipeline RepairsDocumento18 pagineDOT Pipeline RepairsSeng HeangNessuna valutazione finora

- Recommended MCQs - 123 Questions The Solid State Chemistry NEET Practice Questions, MCQS, Past Year Questions (PYQs), NCERT QuesDocumento1 paginaRecommended MCQs - 123 Questions The Solid State Chemistry NEET Practice Questions, MCQS, Past Year Questions (PYQs), NCERT QuesNeet 720Nessuna valutazione finora

- Method of Statement For FRP Lining TankDocumento5 pagineMethod of Statement For FRP Lining Tankmoytabura96100% (3)

- Process Flow Chart Dairy ProductsDocumento5 pagineProcess Flow Chart Dairy Productslokesh jainNessuna valutazione finora

- Light Dependent ResistorDocumento4 pagineLight Dependent ResistorantonerajNessuna valutazione finora

- Science q1 WK 2Documento3 pagineScience q1 WK 2Junior FelipzNessuna valutazione finora

- THK AFF GreaseDocumento3 pagineTHK AFF GreaseSidcley ReisNessuna valutazione finora