Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Geometric Dimensioning and Tolerancing

Caricato da

design12Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Geometric Dimensioning and Tolerancing

Caricato da

design12Copyright:

Formati disponibili

Geometric dimensioning and tolerancing (GD&T) is a system for defining and

communicating engineering tolerances. It uses a symbolic language on engineering drawings and

computer-generated

three-dimensional

solid

models

that

explicitly

describes

nominal geometry and its allowable variation. It tells the manufacturing staff and machines what

degree of accuracy is needed on each controlled feature of the part. GD&T is used to define the

nominal (theoretically perfect) geometry of parts and assemblies, to define the allowable

variation in form and possible size of individual features, and to define the allowable variation

between features.

Dimensioning specifications define the nominal, as-modeled or as-intended geometry.

One example is a basic dimension.

Tolerancing specifications define the allowable variation for the form and possibly the

size of individual features, and the allowable variation in orientation and location between

features. Two examples are linear dimensions and feature control frames using a datum

reference.

There are several standards available worldwide that describe the symbols and define the rules

used in GD&T.

Dimensioning and tolerancing philosophy

The purpose of geometric dimensioning and tolerancing (GD&T) is to describe the engineering

intent of parts and assemblies. The datum reference frame can describle how the part fits or

functions. GD&T can more accurately define the dimensional requirements for a part, allowing

over 50% more tolerance zone than coordinate (or linear) dimensioning in some cases. Proper

application of GD&T will ensure that the part defined on the drawing has the desired form, fit

(within limits) and function with the largest possible tolerances. GD&T can add quality and

reduce cost at the same time thru producability.

There are some fundamental rules that need to be applied (these can be found on page 7 of the

2009 edition of the standard):

All dimensions must have a tolerance. Every feature on every manufactured part is

subject to variation, therefore, the limits of allowable variation must be specified. Plus and

minus tolerances may be applied directly to dimensions or applied from a general tolerance

block or general note. For basic dimensions, geometric tolerances are indirectly applied in a

relatedFeature Control Frame. The only exceptions are for dimensions marked as minimum,

maximum, stock or reference.

Dimensions define the nominal geometry and allowable variation. Measurement and

scaling of the drawing is not allowed except in certain cases.

Engineering drawings define the requirements of finished (complete) parts. Every

dimension and tolerance required to define the finished part shall be shown on the drawing.

If additional dimensions would be helpful, but are not required, they may be marked as

reference.

Dimensions should be applied to features and arranged in such a way as to represent the

function of the features. Additionally, dimensions should not be subject to more than one

interpretation.

Descriptions of manufacturing methods should be avoided. The geometry should be

described without explicitly defining the method of manufacture.

If certain sizes are required during manufacturing but are not required in the final

geometry (due to shrinkage or other causes) they should be marked as non-mandatory.

All dimensioning and tolerancing should be arranged for maximum readability and

should be applied to visible lines in true profiles.

When geometry is normally controlled by gage sizes or by code (e.g. stock materials), the

dimension(s) shall be included with the gage or code number in parentheses following or

below the dimension.

Angles of 90 are assumed when lines (including center lines) are shown at right angles,

but no angular dimension is explicitly shown. (This also applies to other orthogonal angles of

0, 180, 270, etc.)

Dimensions and tolerances are valid at 20 C / 101.3 kPa unless stated otherwise.

Unless explicitly stated, all dimensions and tolerances are only valid when the item is in a

free state.

Dimensions and tolerances apply to the full length, width, and depth of a feature

including form variation.

Dimensions and tolerances only apply at the level of the drawing where they are

specified. It is not mandatory that they apply at other drawing levels, unless the

specifications are repeated on the higher level drawing(s).

Potrebbero piacerti anche

- Latest Report 2Documento13 pagineLatest Report 2Piyush BariNessuna valutazione finora

- Introduction To GDDocumento8 pagineIntroduction To GDCatalin FinkelsteinNessuna valutazione finora

- Six Sigma Is A Business Management Strategy Originally Developed by Motorola, USA in 1986Documento4 pagineSix Sigma Is A Business Management Strategy Originally Developed by Motorola, USA in 1986Manoj SinghNessuna valutazione finora

- Geometric Tolerance Class NotesDocumento6 pagineGeometric Tolerance Class NotesEngineernadeemshahidNessuna valutazione finora

- Six SigmaDocumento7 pagineSix SigmaGoudRaejshNessuna valutazione finora

- Geometric Dimensioning and TolerancingDocumento6 pagineGeometric Dimensioning and TolerancingPedro LeosNessuna valutazione finora

- Metrology 1CDocumento44 pagineMetrology 1CRadhaMadhavNessuna valutazione finora

- Your Source For GD&T Training and MaterialsDocumento6 pagineYour Source For GD&T Training and Materialskharsh23Nessuna valutazione finora

- Control ChartsDocumento72 pagineControl ChartsssimisimiNessuna valutazione finora

- Geometric Dimensioning and TolerancingDocumento7 pagineGeometric Dimensioning and TolerancingRamprasad T N100% (15)

- Surface Roughness: Surface Roughness Often Shortened To Roughness, Is A Component ofDocumento7 pagineSurface Roughness: Surface Roughness Often Shortened To Roughness, Is A Component ofcal2_uniNessuna valutazione finora

- Form and PositionDocumento54 pagineForm and PositionThangadurai Senthil Ram PrabhuNessuna valutazione finora

- GD&TDocumento6 pagineGD&Tdhruv001Nessuna valutazione finora

- UNIT-5 Gear Box DesignDocumento21 pagineUNIT-5 Gear Box DesignAnand vinayNessuna valutazione finora

- CHAP (35) 35 Engr Metrology & InstrumentationDocumento4 pagineCHAP (35) 35 Engr Metrology & InstrumentationfarizanNessuna valutazione finora

- ASSIGNMENT (Sliding Contact Bearing) PDFDocumento3 pagineASSIGNMENT (Sliding Contact Bearing) PDFRakesh Kumar Shukla KEC0% (1)

- New GD&TDocumento3 pagineNew GD&TvasantNessuna valutazione finora

- ComparatorsDocumento23 pagineComparatorsShashwat RaiNessuna valutazione finora

- Tolerance Stack Up Analysis What Is Stack Up Analysis?Documento25 pagineTolerance Stack Up Analysis What Is Stack Up Analysis?Venkadakrishnan ThiagarajanNessuna valutazione finora

- Statistical Quality ControlDocumento18 pagineStatistical Quality ControluzaimyNessuna valutazione finora

- Lecture 5 - Form TolerancesDocumento34 pagineLecture 5 - Form TolerancesSUNILNessuna valutazione finora

- Bt20mec104-Honoch MD Assignment 1Documento22 pagineBt20mec104-Honoch MD Assignment 1Y006 -HonochNessuna valutazione finora

- CH 2: Manufacturing AspectDocumento18 pagineCH 2: Manufacturing Aspectankit kumarNessuna valutazione finora

- Tensile Test (Zuhair)Documento4 pagineTensile Test (Zuhair)SaifAdamz'sNessuna valutazione finora

- Question BankDocumento7 pagineQuestion BankFlorence MercyNessuna valutazione finora

- BELT Lecture 01Documento56 pagineBELT Lecture 01mahaveer dasNessuna valutazione finora

- Datum Axis & Datum Center PlaneDocumento43 pagineDatum Axis & Datum Center Planegc_rama100% (1)

- Including Geometric Feature Variations in Tolerance Analysis of Mechanical AssembliesDocumento32 pagineIncluding Geometric Feature Variations in Tolerance Analysis of Mechanical AssembliesnaveenNessuna valutazione finora

- Analysis and Modeling of Roundness Error PDFDocumento6 pagineAnalysis and Modeling of Roundness Error PDFCarlosQuelartNessuna valutazione finora

- Springs 2nd-TermDocumento10 pagineSprings 2nd-TermCarl John MantacNessuna valutazione finora

- Intoduction: Tylor's Principle For Gauge DesignDocumento13 pagineIntoduction: Tylor's Principle For Gauge DesignDollar Daik100% (1)

- Comparator:: Essential Parts of A ComparatorDocumento5 pagineComparator:: Essential Parts of A ComparatorAnonymous bl0G8KNessuna valutazione finora

- Torque Defines As A Moment That Tends To Twist A Member About Its Longitudinal Axis - TheDocumento7 pagineTorque Defines As A Moment That Tends To Twist A Member About Its Longitudinal Axis - TheMUHAMMAD NURNAJMINessuna valutazione finora

- Statistical Constants FileDocumento12 pagineStatistical Constants FileAnandhi ChidambaramNessuna valutazione finora

- Paper Layout GaugingDocumento19 paginePaper Layout GaugingSadasivam Narayanan50% (2)

- GD&T CD PDFDocumento1 paginaGD&T CD PDFYogesh2323Nessuna valutazione finora

- Force MeasurementDocumento18 pagineForce MeasurementKali DasNessuna valutazione finora

- Statistical Process Control: Operations Management R. Dan Reid & Nada R. SandersDocumento32 pagineStatistical Process Control: Operations Management R. Dan Reid & Nada R. SandersM Afif Budi WicaksonoNessuna valutazione finora

- Conclusions: 7.1 ResultsDocumento4 pagineConclusions: 7.1 ResultsSunilkumar ReddyNessuna valutazione finora

- QuickGuide Roundtest PDFDocumento2 pagineQuickGuide Roundtest PDFArvin BabuNessuna valutazione finora

- Presentation On Jigs and Fixtures by Group G - 2Documento31 paginePresentation On Jigs and Fixtures by Group G - 2Michael Castro AbuduNessuna valutazione finora

- To Study and Design A Helical Spring.Documento6 pagineTo Study and Design A Helical Spring.Kartik BadalNessuna valutazione finora

- 1.1 Types of FixturesDocumento19 pagine1.1 Types of FixturesSrinivas DsNessuna valutazione finora

- ME 472 - Engineering Metrology and Quality Control: Linear and Angular MeasurementsDocumento19 pagineME 472 - Engineering Metrology and Quality Control: Linear and Angular MeasurementsAtul GaurNessuna valutazione finora

- Rules and Concepts of GD&T PDFDocumento31 pagineRules and Concepts of GD&T PDFMahender KumarNessuna valutazione finora

- Detc2016 59570Documento11 pagineDetc2016 59570Muhammad Uzair ShahNessuna valutazione finora

- RoundnessDocumento7 pagineRoundnessjacobian1810Nessuna valutazione finora

- Metrology and Measurements - Lecture Notes, Study Material and Important Questions, AnswersDocumento7 pagineMetrology and Measurements - Lecture Notes, Study Material and Important Questions, AnswersM.V. TVNessuna valutazione finora

- GD&TDocumento10 pagineGD&TShahed FacebookNessuna valutazione finora

- 4.failure Theories and Stress ConcentrationsDocumento21 pagine4.failure Theories and Stress ConcentrationsAmr El SaeedNessuna valutazione finora

- Tolerances FitsDocumento25 pagineTolerances FitsAnonymous E2oSW7Nessuna valutazione finora

- Angularity GD & TDocumento3 pagineAngularity GD & Tath-harNessuna valutazione finora

- GD&T 1Documento41 pagineGD&T 1Sai CharanNessuna valutazione finora

- DRAW10W - Geometric Dimensioning and TolerancesDocumento8 pagineDRAW10W - Geometric Dimensioning and TolerancesPaolo GochingcoNessuna valutazione finora

- GD&T StdsDocumento4 pagineGD&T StdsSri PupNessuna valutazione finora

- Geometric Dimensioning and Tolerancing: Navigation Search Citations Reliable and Independent SourcesDocumento8 pagineGeometric Dimensioning and Tolerancing: Navigation Search Citations Reliable and Independent SourcesDeepak LogesonNessuna valutazione finora

- Geometric Dimensioning and TolerancingDocumento4 pagineGeometric Dimensioning and TolerancingAshokNessuna valutazione finora

- Basic Dimensions Feature Control Block: Basic Rules of GD&TDocumento1 paginaBasic Dimensions Feature Control Block: Basic Rules of GD&Ttechsupport techsupportNessuna valutazione finora

- The Basics of Geometric Dimensioning and TolerancingDocumento9 pagineThe Basics of Geometric Dimensioning and TolerancingKishanNessuna valutazione finora

- App E - Dim RulesDocumento4 pagineApp E - Dim RulesIbadurrahman KahfiNessuna valutazione finora

- Vtu Mechanical EngineeringDocumento175 pagineVtu Mechanical Engineeringsbhalesh40% (5)

- MSMT Lab ManualDocumento28 pagineMSMT Lab Manualdesign12Nessuna valutazione finora

- Applied Thermodynamics June July 08Documento1 paginaApplied Thermodynamics June July 08design12Nessuna valutazione finora

- MicroscopeDocumento22 pagineMicroscopegaziahmad100% (1)

- Annexure-10 Faculty Details/Department of Mechanical Engineering (Ug)Documento4 pagineAnnexure-10 Faculty Details/Department of Mechanical Engineering (Ug)design12Nessuna valutazione finora

- Lingaraj Appa Engineering College, Bidar Mechanical Department 7 Sem Elgibility ListDocumento4 pagineLingaraj Appa Engineering College, Bidar Mechanical Department 7 Sem Elgibility Listdesign12Nessuna valutazione finora

- AEDocumento2 pagineAEdesign12Nessuna valutazione finora

- Applied Thermodynamics May June 10Documento2 pagineApplied Thermodynamics May June 10design12Nessuna valutazione finora

- DRDO RAC Recruitment Advt.Documento4 pagineDRDO RAC Recruitment Advt.Soni Mishra TiwariNessuna valutazione finora

- 02ME35 Basic Thermodynamics Dec Jan 2006Documento2 pagine02ME35 Basic Thermodynamics Dec Jan 2006design12Nessuna valutazione finora

- 9 2013 01 11814462Documento2 pagine9 2013 01 11814462design12Nessuna valutazione finora

- 10me33 2013 JulyDocumento2 pagine10me33 2013 Julydesign12Nessuna valutazione finora

- SPC Education Center: An Iso 9001:2008 Certified OrganisationDocumento3 pagineSPC Education Center: An Iso 9001:2008 Certified Organisationdesign12Nessuna valutazione finora

- Thermodynamic Problem SolvedDocumento3 pagineThermodynamic Problem SolvedfarshidianNessuna valutazione finora

- AmcDocumento2 pagineAmcdesign12Nessuna valutazione finora

- CH 15 The Laws of ThermodynamicsDocumento16 pagineCH 15 The Laws of ThermodynamicsJomar ManaoisNessuna valutazione finora

- Physics Syllabus NewDocumento2 paginePhysics Syllabus Newdesign12Nessuna valutazione finora

- Sheena HSMDocumento8 pagineSheena HSMdesign12Nessuna valutazione finora

- Steps To Prepare The Divine Golden BookDocumento2 pagineSteps To Prepare The Divine Golden Bookdesign12Nessuna valutazione finora

- Chapter 17Documento79 pagineChapter 17design12Nessuna valutazione finora

- Sheena HSMDocumento8 pagineSheena HSMdesign12Nessuna valutazione finora

- 2 ViscosityDocumento3 pagine2 Viscositytahera aqeelNessuna valutazione finora

- Gaurav Updated CV - NewDocumento5 pagineGaurav Updated CV - Newdesign12Nessuna valutazione finora

- 1-Opening and Welcome SpeechDocumento2 pagine1-Opening and Welcome SpeechNavneet K. PatilNessuna valutazione finora

- Para Medical CollegesDocumento21 paginePara Medical Collegesdesign12Nessuna valutazione finora

- Vtu Mechanical EngineeringDocumento175 pagineVtu Mechanical Engineeringsbhalesh40% (5)

- Chap 10 Science IX NCERTDocumento15 pagineChap 10 Science IX NCERTAmit Kumar MudgalNessuna valutazione finora

- Work & EnergyDocumento14 pagineWork & EnergyrjkmehtaNessuna valutazione finora

- 2.4first Angle ProjectionDocumento6 pagine2.4first Angle Projectiondesign12Nessuna valutazione finora

- Course Outline Principles of MarketingDocumento3 pagineCourse Outline Principles of MarketingKhate Tria De LeonNessuna valutazione finora

- FoundationDocumento98 pagineFoundationManognya KotaNessuna valutazione finora

- IFN 554 Week 3 Tutorial v.1Documento19 pagineIFN 554 Week 3 Tutorial v.1kitkataus0711Nessuna valutazione finora

- 9300AE 10-30kseis LDN 2005 PDFDocumento2 pagine9300AE 10-30kseis LDN 2005 PDFDoina ClichiciNessuna valutazione finora

- Focal Length of Convex LensDocumento5 pagineFocal Length of Convex LensHey AnuragNessuna valutazione finora

- Workplace Risk Assessment PDFDocumento14 pagineWorkplace Risk Assessment PDFSyarul NizamzNessuna valutazione finora

- Excavation Trench Permit Ex 1 F0206Documento5 pagineExcavation Trench Permit Ex 1 F0206emeka2012Nessuna valutazione finora

- AE HM6L-72 Series 430W-450W: Half Large CellDocumento2 pagineAE HM6L-72 Series 430W-450W: Half Large CellTaso GegiaNessuna valutazione finora

- Analysis and Design of Well FoundationDocumento40 pagineAnalysis and Design of Well Foundationdhanabal100% (1)

- Input and Output Statements PDFDocumento11 pagineInput and Output Statements PDFRajendra BuchadeNessuna valutazione finora

- AZ 103T00A ENU TrainerHandbook PDFDocumento403 pagineAZ 103T00A ENU TrainerHandbook PDFlongvietmt100% (2)

- Science, Technology and Society Module #1Documento13 pagineScience, Technology and Society Module #1Brent Alfred Yongco67% (6)

- Tools of Persuasion StudentsDocumento4 pagineTools of Persuasion StudentsBelén Revilla GonzálesNessuna valutazione finora

- Bio 104 Lab Manual 2010Documento236 pagineBio 104 Lab Manual 2010Querrynithen100% (1)

- AnimDessin2 User Guide 01Documento2 pagineAnimDessin2 User Guide 01rendermanuser100% (1)

- EE 8602 - Protection and Switchgear Unit I - MCQ BankDocumento11 pagineEE 8602 - Protection and Switchgear Unit I - MCQ Bankpoonam yadavNessuna valutazione finora

- Plane TrigonometryDocumento545 paginePlane Trigonometrygnavya680Nessuna valutazione finora

- Num Sheet 1Documento1 paginaNum Sheet 1Abinash MohantyNessuna valutazione finora

- DD 3334Documento2 pagineDD 3334FAQMD2Nessuna valutazione finora

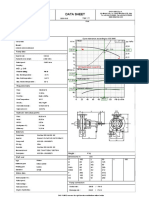

- Data Sheet: Item N°: Curve Tolerance According To ISO 9906Documento3 pagineData Sheet: Item N°: Curve Tolerance According To ISO 9906Aan AndianaNessuna valutazione finora

- Integration Plan Grade 9 Mapeh SeptemberDocumento3 pagineIntegration Plan Grade 9 Mapeh Septemberbernie evaristo bacsaNessuna valutazione finora

- High Performance Vector Control SE2 Series InverterDocumento9 pagineHigh Performance Vector Control SE2 Series InverterhanazahrNessuna valutazione finora

- The Role of Needs Analysis in Adult ESL Programme Design: Geoffrey BrindleyDocumento16 pagineThe Role of Needs Analysis in Adult ESL Programme Design: Geoffrey Brindleydeise krieser100% (2)

- Module 2 DIPDocumento33 pagineModule 2 DIPdigital loveNessuna valutazione finora

- Sai Deepa Rock Drills: Unless Otherwise Specified ToleranceDocumento1 paginaSai Deepa Rock Drills: Unless Otherwise Specified ToleranceRavi BabaladiNessuna valutazione finora

- Introduction To SCRDocumento19 pagineIntroduction To SCRAlbin RobinNessuna valutazione finora

- WAM ES Screw Conveyors Manual JECDocumento43 pagineWAM ES Screw Conveyors Manual JECabbas tawbiNessuna valutazione finora

- Grimm (2015) WisdomDocumento17 pagineGrimm (2015) WisdomBruce WayneNessuna valutazione finora

- INSTRUCTIONAL SUPERVISORY PLAN 1st Quarter of SY 2023 2024 Quezon ISDocumento7 pagineINSTRUCTIONAL SUPERVISORY PLAN 1st Quarter of SY 2023 2024 Quezon ISayongaogracelyflorNessuna valutazione finora

- Tutorial: MSBA7003 Quantitative Analysis MethodsDocumento29 pagineTutorial: MSBA7003 Quantitative Analysis MethodsAmanda WangNessuna valutazione finora