Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

M# 36 Cop#6 Univer Copl Remov

Caricato da

wessamalexDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

M# 36 Cop#6 Univer Copl Remov

Caricato da

wessamalexCopyright:

Formati disponibili

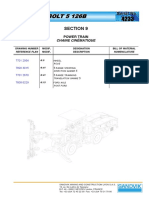

COLD WORK SAFETY PROCEDURES

DATE:

LOCATION:______________

RESPONSIBLE SUPERVISOR:_____

PLANT/EQUIPMENT:

July, 08 ,2002

____M.#36 ___________ __________

Eng. ABD EL AZIZ MOH.

COP. # 6

DESCRIPTION OF WORK: REMOVE THE UNIVERSAL JOINT FOR REPAIR & REINSTALL

___________________________________________________________________

SAFETY PRECAUTIONS

Lock out Tag out procedures must be applied before commencing work

Cold work permit should be issued and signed daily.

Safety meeting will be held on location daily, with all personnel involved in the task

Keep all walkways, stairs and access doors clear of obstructions.

Clean up any spillage of oil/chemicals immediately.

All tools must be in good condition, and the correct tools for the work

Use only correctly color coded lifting equipment (blue) universal weight 60kg

All workers must wear correct PPE at all times

Inspect All Lifting Tools And Check For Color Coded

ICC should be issued

A copy of procedure should be on work site

Gas free check should be applied before starting the job

Remove any source of ignition at work place

Fire extinguisher and trained person should be valid during the work

Good communication between performing authority OIM before and during the job to ensure every body

understand the written proced. And risk assis. For the job

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

Isolation Procedures :1. Close main Fuel valve install spade out fuel line & Open the vent valve of the fuel filter to

ensure the fuel pressure become zero

LOTO

( MM )

2.

Disconnect magneto cable list on isolation certificate

3.

Close air starter air valve LOTO

4.

Close suction & discharge valve of the pump & Open drain valve LOTO

(Prod.)

5. Isert spade on suction & discharge valves of the pump to comply with recommended standard

isolation ( SVI + Spade )

( Prod. )

6. Make sure by monitoring the pressure gauge on suction and discharge line of the pump that

the reading of the gauges are zero and there is no pressure build up in the system (if there is

leak from the valves causing pressure build up dont resume the job)

Procedures: 7. Remove the safe guard around the universal joint.

(MM)

8. Disconnect the universal joint from the pump end first then the engine flywheel end

(MM)

9. Repair The Defective Joint

(MM)

10. After repairing the joint and before reinstalling make sure first that the isolation procedures are

Still applied.

(MM)

11. susbend a chain hoist on the beam above the engine ( I-beam must be tested)

12. Reinstall the repaired joint

13. Reinstall the safe guard around the joint

(MM)

(MM)

14. Remove the isolation from the pump & engine

(MM)

15. Start the engine and check for any problems

(MM)

Date

Mech. Maint,

Asst.Gen. mgr.

Gen.Maint.

Gen.mgr.

Production

Gen.mgr

HSE

Gen.mgr.

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- 3-Cent Pump Construction IDocumento36 pagine3-Cent Pump Construction IwessamalexNessuna valutazione finora

- 4-Cent - Pump Construction IIDocumento22 pagine4-Cent - Pump Construction IIwessamalexNessuna valutazione finora

- 8-Pumps General ClasificationDocumento62 pagine8-Pumps General ClasificationwessamalexNessuna valutazione finora

- CMT TP Fi02 V1.0Documento75 pagineCMT TP Fi02 V1.0wessamalexNessuna valutazione finora

- Part 2 Instrumentation and Control Dr. Ahmed Kamel 505Documento23 paginePart 2 Instrumentation and Control Dr. Ahmed Kamel 505wessamalex100% (2)

- 2-General Intro. of PumpDocumento45 pagine2-General Intro. of PumpwessamalexNessuna valutazione finora

- CMT TM MM02 V1.0Documento149 pagineCMT TM MM02 V1.0wessamalexNessuna valutazione finora

- ASME Brochure - Sept 2014 - June 2015Documento4 pagineASME Brochure - Sept 2014 - June 2015wessamalexNessuna valutazione finora

- Introduction To Bearing and Seals in Rotordynamics: The Most Commonly Recurring Problems in Rotordynamics AreDocumento15 pagineIntroduction To Bearing and Seals in Rotordynamics: The Most Commonly Recurring Problems in Rotordynamics ArewessamalexNessuna valutazione finora

- Asset Inspection Procedures PDFDocumento100 pagineAsset Inspection Procedures PDFwessamalexNessuna valutazione finora

- 6th Central Pay Commission Salary CalculatorDocumento15 pagine6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- High Speed and Long Life Double-Row Cylindrical Roller BearingsDocumento4 pagineHigh Speed and Long Life Double-Row Cylindrical Roller BearingswessamalexNessuna valutazione finora

- Broch 2196Documento3 pagineBroch 2196wessamalexNessuna valutazione finora

- Suez Oil Company: Zeit Bay Field OriginatorDocumento1 paginaSuez Oil Company: Zeit Bay Field OriginatorwessamalexNessuna valutazione finora

- Suez Oil Company: B-2501A/C LP Compression Train B-2501B/D HP Compression TrainDocumento1 paginaSuez Oil Company: B-2501A/C LP Compression Train B-2501B/D HP Compression TrainwessamalexNessuna valutazione finora

- Proc 0603E001Documento1 paginaProc 0603E001wessamalexNessuna valutazione finora

- Suez Oil Company: B-2501A/C B-2501B/DDocumento1 paginaSuez Oil Company: B-2501A/C B-2501B/DwessamalexNessuna valutazione finora

- Suez Oil Company: Zeit Bay Field OriginatorDocumento2 pagineSuez Oil Company: Zeit Bay Field OriginatorwessamalexNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Schneider EngineeringDocumento1 paginaSchneider EngineeringT.J. MayesNessuna valutazione finora

- Alloys DensityDocumento4 pagineAlloys DensityArnold Melissa CollettNessuna valutazione finora

- Philips Aquatrio FC7070 - 01 Esploso ManualeDocumento9 paginePhilips Aquatrio FC7070 - 01 Esploso ManualeRocco Mangione0% (1)

- Educational Solutions From Schneider ElectricDocumento164 pagineEducational Solutions From Schneider ElectricfaneeeeeeNessuna valutazione finora

- ElectronicsDocumento3 pagineElectronicsashishkumar218Nessuna valutazione finora

- Zaroulas Mies Fullpaper 2020 05 21Documento9 pagineZaroulas Mies Fullpaper 2020 05 21sidgonzoNessuna valutazione finora

- Car DeerDocumento2 pagineCar DeerNEGameandParksNessuna valutazione finora

- Meai Mar 2010Documento36 pagineMeai Mar 2010Daneshwer VermaNessuna valutazione finora

- Skytrain Avia Services: Emergency Procedures ManualDocumento32 pagineSkytrain Avia Services: Emergency Procedures ManualEndro RastadiNessuna valutazione finora

- RequirementsDocumento18 pagineRequirementsmpedraza-1Nessuna valutazione finora

- 4.10) Arch Shaped Self Supporting Trussless Roof SpecificationsDocumento11 pagine4.10) Arch Shaped Self Supporting Trussless Roof Specificationshebh123100% (1)

- Aeroshell Fluid 41 PdsDocumento2 pagineAeroshell Fluid 41 Pdsja.moreno930Nessuna valutazione finora

- Bio-Sensors and Bio-Devices: Spring 2020Documento22 pagineBio-Sensors and Bio-Devices: Spring 2020barristertoto99 chanNessuna valutazione finora

- Bazele Matematice Ale Calculatoarelor - Florian Mircea BoianDocumento132 pagineBazele Matematice Ale Calculatoarelor - Florian Mircea BoiannimsocNessuna valutazione finora

- TechSpec MistralDocumento4 pagineTechSpec MistralScarab SweepersNessuna valutazione finora

- Grundfos S Pump 5 - 29 KW Super VortexDocumento20 pagineGrundfos S Pump 5 - 29 KW Super Vortexdalveerchoudhary100% (1)

- Glass Inspection CriteriaDocumento4 pagineGlass Inspection CriteriabatteekhNessuna valutazione finora

- GMP Male BearingDocumento3 pagineGMP Male BearingMahdi HajizadehNessuna valutazione finora

- The Reef Wayfinding Plan and Signage Design Concept 28 August 2019Documento51 pagineThe Reef Wayfinding Plan and Signage Design Concept 28 August 2019Michele MontoloNessuna valutazione finora

- Manual PC Soundcard Scope 1.4.5Documento17 pagineManual PC Soundcard Scope 1.4.5NatashaKillerNessuna valutazione finora

- Pioneer XDP - 30R ManualDocumento213 paginePioneer XDP - 30R Manualmugurel_stanescuNessuna valutazione finora

- Trial Manufacture of A Fluid-Type Static Induction TransistorDocumento4 pagineTrial Manufacture of A Fluid-Type Static Induction TransistorStanley ClermontNessuna valutazione finora

- Semantic and Frames PDFDocumento20 pagineSemantic and Frames PDFsyncasterNessuna valutazione finora

- Optimasi Blending Pertalite Dengan Komponen Reformate Di PT. XYZ BalikpapanDocumento7 pagineOptimasi Blending Pertalite Dengan Komponen Reformate Di PT. XYZ BalikpapanFrizki AkbarNessuna valutazione finora

- Bubbling Kun NiDocumento7 pagineBubbling Kun NiBelen CRNessuna valutazione finora

- Methods of Tube Expansion in Tube To TubDocumento19 pagineMethods of Tube Expansion in Tube To Tubkurcek100% (1)

- Antikythera MechanismDocumento25 pagineAntikythera MechanismchetansergiurazvanNessuna valutazione finora

- SinxbyxDocumento9 pagineSinxbyxGreeshmaNessuna valutazione finora

- S09 Power TrainDocumento90 pagineS09 Power TrainPLANEAMIENTO MDRILLNessuna valutazione finora