Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Centrifugal Feeder Design

Caricato da

Juan Jose Barrios SanchezCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Centrifugal Feeder Design

Caricato da

Juan Jose Barrios SanchezCopyright:

Formati disponibili

Centrifugal Feeder Design

Tutorial

A centrifugal feeder, or rotary feeder, has a conical central driven rotor

surrounded by a circular bowl wall. The feeder separates parts utilizing

centrifugal force and the parts revolve with high speed and are pulled to the

outside of the bowl.

The design shown in this tutorial is a more sophisticated concept where an

inclined revolving disc brings the parts to the rim of a revolving bowl. This

concept allows for a series of qualifiers to gently orient the parts for transfer to a

downstream process.

Warning This tutorial is to

serve as a guide covering most

design areas. User is to

consult and respect local

government regulations where

the unit is to operate.

Phase 1: General geometry

Phase 2: Drive design

Phase 3: Structure / Tooling

www.packexone.com

Phase 1 General geometry (1)

Operation:

Parts are metered from a prefeeder on the rotating disc.

The disc carries the parts to the rim of the rotating bowl in a single lane.

Fixed mechanical or pneumatic qualifiers orient and qualify the parts.

Improperly oriented parts are ejected from the rim to the disc for recirculation.

Properly oriented parts moved out of the rim and out of the feeder.

Feed rate is affected mainly by:

The part size, its natural orientation and the desired orientation.

The disc and bowl speeds.

Part speed shall not exceed 100 meters/min to prevent damages.

BOWL RIM

DISC

BOWL

www.packexone.com

Phase 1 General geometry (2)

Calculated rate:

The feed rate, R, can be approximated using:

L : the part longest dimension.

V : the part speed (or the bowl rotating speed x 3.14 x bowl rim diameter).

P : the percentage of parts that will be in the desired orientation.

R=PV/L

A large bowl rim diameter will give time and space for the parts to be qualified

and oriented. So bigger bowl means higher rate.

www.packexone.com

Phase 1 General geometry (3)

Components (exploded view)

Tooling support

Tooling backup ring

Outer shell

Cone

Rotating disc

Disc hub

Rotating bowl

Bowl hub

Shell attachment

Base

Leveling foot

www.packexone.com

Phase 1 General geometry (4)

Components (section view)

The bowl has a spherical inner

surface. This allows the disc to rotate

in an inclined orientation and

maintains a small gap with the bowl

around its perimeter

Static hub fixed on base

Ball bearings

Roller chain & sprocket

www.packexone.com

Phase 1 General geometry (5)

Components (section view)

Roller chain & sprocket

Bowl gearmotor

Torque limiter

Disc gearmotor

Chain tensioner

www.packexone.com

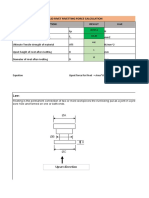

Phase 2 Drive design (1)

Drive

The drive is the assembly of components which rotates the disc and the bowl.

The disc rotates within the bowl at a speed that may be equal, higher or lower

than the bowl speed.

A speed difference between bowl and disc is used to improve loading of the

bowl rim.

Chain tensioner

Torque limiter

Bowl gearmotor

Torque limiter

Chain tensioner

Disc gearmotor

www.packexone.com

Phase 2 Drive design (2)

Drive

The static hub is bolted on the base.

The bowl is bolted on the bowl hub which rotates over the static hub.

A large sprocket drives the bowl hub.

Through the static hub, the drive shaft rotates the disc.

Disc hub

Steel: UNS G10200

Ball bearing

Static hub

Steel: UNS G10200

Bowl hub

Steel: UNS G10200

Ball bearing

Large

sprocket

Base

Torque limiter

Small

sprocket

Drive shaft

Steel: UNS G86200

www.packexone.com

Phase 2 Drive design (3)

Disc drive

The gearmotor drives in rotation all items listed below and the parts carried by

the disc.

Gearmotor output speed, Sd = (maximum part speed) / (3.14 x disc diameter) = {rpm}

Gearmotor output torque, Td = (Id + (Wp D2 / 4)) Ad + Tf = {N*m or lbs-in}

where:

Id : total rotational inertia of the items listed below

Wp : weight of the parts carried by the disc.

D : disc diameter

Ad : required disc acceleration after a complete stop.

Ad = 3.14 Sd / (30 td )

td : time to accelerate (below 2 sec.)

Tf : frictional torque in the bearings

Torque limiter and roller chain are to be selected using this data.

Cone

PVC

Disc hub

Disc

PVC

Driveshaft

Torque

limiter

Sprocket

Gearmotor

www.packexone.com

Phase 2 Drive design (4)

Bowl drive

The gearmotor drives in rotation all items listed below and the parts carried by

the bowl.

Gearmotor output speed, Sd = (maximum part speed) / (3.14 x bowl diameter) = {rpm}

Gearmotor output torque, Td = (Id + (Wp D2 / 4)) Ad + Tf = {N*m or lbs-in}

where:

Id : total rotational inertia of the items listed below

Wp : weight of the parts carried by the bowl.

D : bowl diameter

Ad : required disc acceleration after a complete stop.

Ad = 3.14 Sd / (30 td )

td : time to accelerate (below 2 sec.)

Tf : frictional torque in the bearings

Torque limiter and roller chain are to be selected using this data.

Bowl

Cast aluminum

Bowl hub

Bowl floor

Aluminum: UNS

A96061

Sprocket

Gearmotor

www.packexone.com

10

Phase 3 Structure/Tooling (1)

Structure

The structure supports all the rotating components and the outside shell. Its

construction is made of painted carbon steel (UNS K02600). The triangular

geometry allows easy mounting for most components.

Shell attachment

Base plate

Post

Leveling foot

www.packexone.com

11

Phase 3 Structure/Tooling (2)

Tooling

The tooling is all the components that qualify/orient the parts: mechanical

stoppers, air jets, pneumatic actuators, rotating wheel, . These components

are mounted on the tooling backup wall which serves also as an external guide.

This wall is mounted to the tooling support, and the tooling support is mounted

on top of the outer shell.

Tooling support

Outer shell

Tooling backup

wall

www.packexone.com

12

Potrebbero piacerti anche

- Machine Design Elements and AssembliesDa EverandMachine Design Elements and AssembliesValutazione: 3.5 su 5 stelle3.5/5 (2)

- Rocker Bogie CalculationsDocumento13 pagineRocker Bogie Calculationsravi100% (2)

- Overhead Conveyor Products PDFDocumento16 pagineOverhead Conveyor Products PDFPierre Hopkins100% (1)

- Solid Rivet Upset Force CalculationDocumento7 pagineSolid Rivet Upset Force CalculationVenkateswaran venkateswaranNessuna valutazione finora

- Calculation of v-BeltTensions and Shaft LoadsDocumento21 pagineCalculation of v-BeltTensions and Shaft Loadsbackvlacko100% (1)

- 6 Acceleration PolygonDocumento10 pagine6 Acceleration Polygonalibaba011Nessuna valutazione finora

- Rivet Joint Plate Tear - Tensile Strength CalculationDocumento6 pagineRivet Joint Plate Tear - Tensile Strength CalculationvenkateswaranNessuna valutazione finora

- BLDC Motor: 4 Pole 2 Phase Motor OperationDocumento10 pagineBLDC Motor: 4 Pole 2 Phase Motor OperationG.R.AzhaguvelSaranya Professor MechanicalNessuna valutazione finora

- Unit I DME I 13 09 2021Documento68 pagineUnit I DME I 13 09 2021Vaibhav JainNessuna valutazione finora

- Involute Spur Gear Geometry Calculations: Input DataDocumento11 pagineInvolute Spur Gear Geometry Calculations: Input DataNILESH YADAVNessuna valutazione finora

- HW4 PDFDocumento11 pagineHW4 PDFJonathan MorNessuna valutazione finora

- Shigley Machine Design 9th EditionDocumento43 pagineShigley Machine Design 9th EditionHerinda WijayaNessuna valutazione finora

- Servo Motor SelectionDocumento11 pagineServo Motor Selectionanandparasu100% (1)

- MAE 162A Project ReportDocumento18 pagineMAE 162A Project ReportJames Edward BennettNessuna valutazione finora

- Gears PresentationDocumento33 pagineGears PresentationNaveen YadavNessuna valutazione finora

- Options:: Useful Formulas Formulas Transformer FormulasDocumento5 pagineOptions:: Useful Formulas Formulas Transformer FormulasDileep SettyNessuna valutazione finora

- Valid and Invalid Isomers of Four Bar and Six Bar MechanismDocumento8 pagineValid and Invalid Isomers of Four Bar and Six Bar MechanismUZAIR MANSOORNessuna valutazione finora

- Hard+drive+motor+driver+schematic: Read/DownloadDocumento2 pagineHard+drive+motor+driver+schematic: Read/DownloadKapaleeswaran KapaleeswaranNessuna valutazione finora

- 38 Design of Flat Belt DrivesDocumento9 pagine38 Design of Flat Belt DrivesPRASAD326100% (1)

- NURBS SurfacesDocumento53 pagineNURBS Surfacessubha_aeroNessuna valutazione finora

- Ball - Screw - Calculations - As Per THK and PmiDocumento5 pagineBall - Screw - Calculations - As Per THK and PmiDharmeshPatelNessuna valutazione finora

- Practical Rotordynamics For Centrifugal PumpsDocumento52 paginePractical Rotordynamics For Centrifugal PumpsRavi Shankar100% (1)

- Gorki 3Documento26 pagineGorki 3Shushay GebreyesusNessuna valutazione finora

- 9A03401 Kinematics of MachineryDocumento8 pagine9A03401 Kinematics of MachinerysivabharathamurthyNessuna valutazione finora

- Runout TollerancesDocumento1 paginaRunout Tollerancesbiranchi satapathyNessuna valutazione finora

- Chapter 4 SolutionsDocumento5 pagineChapter 4 SolutionsTinozivasheNessuna valutazione finora

- Mece307 - Sertaç ŞimşekDocumento18 pagineMece307 - Sertaç ŞimşekErtürk ErdiNessuna valutazione finora

- 353 35435 ME357 2011 4 2 1 Sheet MD2Documento10 pagine353 35435 ME357 2011 4 2 1 Sheet MD2adel nabhanNessuna valutazione finora

- Engineering Drawing II Tutorial PDFDocumento38 pagineEngineering Drawing II Tutorial PDFskumaranspNessuna valutazione finora

- Fitting & ToleranceDocumento2 pagineFitting & Tolerancenama sayaNessuna valutazione finora

- 8 MC StructureDocumento26 pagine8 MC StructureNitesh KumarNessuna valutazione finora

- Building Technologies: HVAC ProductsDocumento7 pagineBuilding Technologies: HVAC Productsshivv230Nessuna valutazione finora

- Grashof's LawDocumento10 pagineGrashof's LawMihir MehanNessuna valutazione finora

- FormulasDocumento7 pagineFormulastthy kNessuna valutazione finora

- MEG373 CHP05 Forces ProblemsDocumento4 pagineMEG373 CHP05 Forces ProblemsDavorinBazijanacNessuna valutazione finora

- Non - InvoluteDocumento10 pagineNon - InvolutePushparaj VigneshNessuna valutazione finora

- รายการคำนวณถังน้ำมันกลมIKEA PDFDocumento3 pagineรายการคำนวณถังน้ำมันกลมIKEA PDFGooddayBybs0% (1)

- ME 363 - Fluid MechanicsDocumento5 pagineME 363 - Fluid MechanicsMostafa Mohamed0% (1)

- 5.2 Flanged Bolt CouplingDocumento11 pagine5.2 Flanged Bolt CouplingShayneBumatay0% (1)

- 12-3 Energy in SHM (P304) : Take A Spring Oscillator As An ExampleDocumento19 pagine12-3 Energy in SHM (P304) : Take A Spring Oscillator As An Exampletuikbe100% (1)

- Belt Drive Data BookDocumento2 pagineBelt Drive Data BookPappujiNessuna valutazione finora

- Thesis On PneumaticDocumento87 pagineThesis On PneumaticKhaled AbdelfattahNessuna valutazione finora

- CFturbo enDocumento184 pagineCFturbo enDefinal ChaniagoNessuna valutazione finora

- DOM ProblemsSolvedinClassDocumento129 pagineDOM ProblemsSolvedinClassrukmini_ramkiNessuna valutazione finora

- El34 Sed2002Documento2 pagineEl34 Sed2002Emerson EsquinaziNessuna valutazione finora

- Lug Analysis MechaniCalcDocumento29 pagineLug Analysis MechaniCalcOSCARDELTANessuna valutazione finora

- Z M B (MM) N H (Hours) : Gear Design (Is-4460) (Spur or Helical)Documento16 pagineZ M B (MM) N H (Hours) : Gear Design (Is-4460) (Spur or Helical)Babu RajamanickamNessuna valutazione finora

- 4 Bar Linkage AnalysisDocumento12 pagine4 Bar Linkage AnalysisKhuong VuNessuna valutazione finora

- Muff Coupling & Split Muff CouplingDocumento19 pagineMuff Coupling & Split Muff CouplingRamanathan DuraiNessuna valutazione finora

- CTA Remote TestDocumento20 pagineCTA Remote TestganyuanNessuna valutazione finora

- BLDC Motor Catalogue 15-01-2015Documento6 pagineBLDC Motor Catalogue 15-01-2015nitin9860Nessuna valutazione finora

- Longitudinal Pin For Shaft-Hub ConnectionDocumento6 pagineLongitudinal Pin For Shaft-Hub Connectionmet-calcNessuna valutazione finora

- Lecture 5 Shaft Design With SolutionsDocumento38 pagineLecture 5 Shaft Design With Solutionsgatoradeqazwsx100% (2)

- Technical Analysis of BakerDocumento27 pagineTechnical Analysis of BakerManu KhodNessuna valutazione finora

- Grundfos Gear ChallengeDocumento11 pagineGrundfos Gear ChallengeNicu TruicaNessuna valutazione finora

- Project Description S14Documento13 pagineProject Description S14behinddaplate9Nessuna valutazione finora

- D 0836 RadilicaDocumento12 pagineD 0836 Radilicadzadza2Nessuna valutazione finora

- Shaft Diameter PDFDocumento8 pagineShaft Diameter PDFrusruleti100% (1)

- Me6612 Design &fabrication Project: Design and Fabrication of Automotive Side Stand Retrieve SystemDocumento18 pagineMe6612 Design &fabrication Project: Design and Fabrication of Automotive Side Stand Retrieve SystemBlessly PrinceNessuna valutazione finora

- New Gearbox DesignDocumento16 pagineNew Gearbox DesignIAN MIGOTNessuna valutazione finora

- Nestle IndiaDocumento74 pagineNestle IndiaKiranNessuna valutazione finora

- Product Management Software Director in Austin TX Resume Chad ThreetDocumento2 pagineProduct Management Software Director in Austin TX Resume Chad ThreetChad ThreetNessuna valutazione finora

- Hyperinflation of Zimbabwe and The Lesson For Zimbabwe: Foreign Trade University Faculty of Banking and FinanceDocumento38 pagineHyperinflation of Zimbabwe and The Lesson For Zimbabwe: Foreign Trade University Faculty of Banking and FinancePham Việt AnhNessuna valutazione finora

- Viva Questions For Even SemestersDocumento22 pagineViva Questions For Even SemestersSiddhanta DuttaNessuna valutazione finora

- Management of Odontogenic Infection of Primary Teeth in Child That Extends To The Submandibular and Submental Space Case ReportDocumento5 pagineManagement of Odontogenic Infection of Primary Teeth in Child That Extends To The Submandibular and Submental Space Case ReportMel FANessuna valutazione finora

- Curtis Mathes CM25020S by Samsung - Owner's ManualDocumento49 pagineCurtis Mathes CM25020S by Samsung - Owner's ManualpadawerNessuna valutazione finora

- OMNI OptixDocumento4 pagineOMNI OptixFelipe MoyaNessuna valutazione finora

- Revised Implementing Rules and Regulations Ra 10575Documento79 pagineRevised Implementing Rules and Regulations Ra 10575Rodel D. LuyaoNessuna valutazione finora

- Drive Engineering - Practical Implementation SEW Disc Brakes 09202218 - G1Documento90 pagineDrive Engineering - Practical Implementation SEW Disc Brakes 09202218 - G1Anonymous ntE0hG2TPNessuna valutazione finora

- Research InstrumentsDocumento28 pagineResearch InstrumentsAnjeneatte Amarille AlforqueNessuna valutazione finora

- Review Women With Moustaches and Men Without Beards - Gender and Sexual Anxieties of Iranian Modernity PDFDocumento3 pagineReview Women With Moustaches and Men Without Beards - Gender and Sexual Anxieties of Iranian Modernity PDFBilal SalaamNessuna valutazione finora

- Lattner HRT Power Plus Operations ManualDocumento42 pagineLattner HRT Power Plus Operations Manualsabir_munnaNessuna valutazione finora

- Circular Railway Revival Project - Signaling PDFDocumento151 pagineCircular Railway Revival Project - Signaling PDFpoketupiNessuna valutazione finora

- The Art of Starting OverDocumento2 pagineThe Art of Starting Overlarry brezoNessuna valutazione finora

- Piezometers: Types, Functions, & How It Works?Documento38 paginePiezometers: Types, Functions, & How It Works?Encardio RiteNessuna valutazione finora

- InvoiceDocumento1 paginaInvoiceKidambi SureshNessuna valutazione finora

- MNHS Annex G10 Q4 LC1Documento10 pagineMNHS Annex G10 Q4 LC1angelinebianesNessuna valutazione finora

- Ingles - 1 - Bach - Modulo - 2 (20 - 21)Documento32 pagineIngles - 1 - Bach - Modulo - 2 (20 - 21)John Alex Almeida50% (2)

- PCI20107, Overview of Boiler Commissioning and Startup PDFDocumento17 paginePCI20107, Overview of Boiler Commissioning and Startup PDFMarc AnmellaNessuna valutazione finora

- How To Deliver A Good PresentationDocumento9 pagineHow To Deliver A Good PresentationGhozi Fawwaz Imtiyaazi LabiibaNessuna valutazione finora

- Generic NdaDocumento2 pagineGeneric NdalataminvestmentsNessuna valutazione finora

- Product Management Mcnaughton - 0Documento4 pagineProduct Management Mcnaughton - 0Andrey MatusevichNessuna valutazione finora

- Recruitment of Officers in Grade B' (General) - DR - By-2019Documento2 pagineRecruitment of Officers in Grade B' (General) - DR - By-2019Shalom NaikNessuna valutazione finora

- Restricted Earth Fault RelayDocumento5 pagineRestricted Earth Fault Relaysuleman24750% (2)

- Nava LunchDocumento3 pagineNava LuncheatlocalmenusNessuna valutazione finora

- Personal Tutor: 11 + MATHS Test 6Documento10 paginePersonal Tutor: 11 + MATHS Test 6siddhant4uNessuna valutazione finora

- 2002PCDFCADocumento78 pagine2002PCDFCATin NguyenNessuna valutazione finora

- Lotte Advanced Materials Co., LTD.: ISO 9001:2015, KS Q ISO 9001:2015Documento2 pagineLotte Advanced Materials Co., LTD.: ISO 9001:2015, KS Q ISO 9001:2015Tayyab KhanNessuna valutazione finora

- Congenital Abnormalities of The Female Reproductive TractDocumento14 pagineCongenital Abnormalities of The Female Reproductive TractMary SheshiraNessuna valutazione finora

- O RTIZDocumento2 pagineO RTIZKhimberly Xylem OrtizNessuna valutazione finora