Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Module 2 Lec 1,2

Caricato da

Ashrav Gupta0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

13 visualizzazioni3 pagineNPTEL NANOTech quiz

Titolo originale

module2lec1,2

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoNPTEL NANOTech quiz

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

13 visualizzazioni3 pagineModule 2 Lec 1,2

Caricato da

Ashrav GuptaNPTEL NANOTech quiz

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 3

Nano structured materials-synthesis, properties, self assembly and applications

by Prof. A.K. Ganguli, Chemistry Department,

IIT Delhi, New Delhi.

MODULE 2 (LECTURE 1 & 2): SOL-GEL

Problem:

1. What are the two basic approaches for synthesis of nanomaterials.

2. What is sol-gel method.

3. Advantages of sol-gel route.

4. What are the steps involved in a typical sol-gel process.

5. What is a sol.

6. What do you understand by PZC.

7. Define gel.

8. PZC depends on which parameters.

9. Define Oswald ripening.

10. Condensation process influenced by what parameters.

11. What are the different drying process of gel.

12. Difference between colloidal vs polymeric route.

13. What are the internal and external parameters affecting sol-gel process.

14. Applications of sol-gel process.

15. How to control the size of particles using sol-gel process.

MODULE 2 (LECTURE 1 & 2): SOL-GEL

Solution:

1. Top down and bottom up approach

2. Sol-gel: process in which solid particles are dispersed in a liquid (a sol) and agglomerate

together to form a continuous three dimensional network extending throughout the liquid

(a gel)

3. Product morphology can be controlled, cheap and low operating temperature, shaping is

simple, homogenous compound can be achieved

4. Hydrolysis, condensation, gelation, ageing, drying and densification

5. Sol: consists of a liquid with colloidal particles which are not dissolved, but do not

agglomerate or sediment

6. PZC: point of zero change, pH where the particle is neutral

PZC > pH, particle surface negatively charged

PZC < pH, particle surface positively charged

7. Gel: dilute cross-linked system, which exhibits no flow when in the steady-state.

8. PZC depends on pH, size of particle and degree on condensation.

9. Ostwald ripening: process of ageing where small particles dissolve and add on to the

large particles to grow bigger particles.

10. Condensation process influenced by type of precursor, ratio between alkoxide and water,

type of catalyst, type of solvent, temperature and pH

11. Different drying process of gels: Cryogel, Aerogel and xerogel

12.

Colloidal

polymeric

Metal alkoxide or metal salt

Metal alkoxide

Solvent = alcohol or water

Solvent = alcohol

Precipitation

[alkoxide]<<[water]

Precipitation

[water]/[alkoxide] = 1-4

Gel as a result of electrostatic effects

Gel as a result of further polymerization

13. Internal parameters: nature of the metal atom and alkyl/oxide group, structure of metal

precursor

External parameters: water/alkoxide ration, catalyst(acid or base), concentration of

solvent/precursor, solvent, temperature

14. Optical coatings, ceramics, thin films, fibres

15. Low temperature process advantageous for controlling particle size. Rate of hydrolysis

and condensation under basic and acidic condition influences the particle size

Potrebbero piacerti anche

- Storyboard 1 - States and GovernmentDocumento10 pagineStoryboard 1 - States and GovernmentAshrav GuptaNessuna valutazione finora

- Lovemarks Academic Module 3 Tools of The TradeDocumento35 pagineLovemarks Academic Module 3 Tools of The TradeAshrav GuptaNessuna valutazione finora

- Martin Luther King JRDocumento9 pagineMartin Luther King JRAshrav GuptaNessuna valutazione finora

- Letter To Finance MinisterDocumento2 pagineLetter To Finance MinisterAshrav GuptaNessuna valutazione finora

- Direct Cash Transfer - Section BDocumento16 pagineDirect Cash Transfer - Section BAshrav GuptaNessuna valutazione finora

- Bang On Target - IMT Ghaziabad - Round 1Documento13 pagineBang On Target - IMT Ghaziabad - Round 1Ashrav GuptaNessuna valutazione finora

- Godfrey Philips FinancialsDocumento14 pagineGodfrey Philips FinancialsAshrav GuptaNessuna valutazione finora

- Paper Manufacturing Case PDFDocumento2 paginePaper Manufacturing Case PDFAshrav GuptaNessuna valutazione finora

- Negative Feedback Over MailDocumento4 pagineNegative Feedback Over MailAshrav GuptaNessuna valutazione finora

- Decision Trees SolutionDocumento24 pagineDecision Trees SolutionAshrav GuptaNessuna valutazione finora

- Alaska Retailers L1StartDocumento7 pagineAlaska Retailers L1StartAshrav GuptaNessuna valutazione finora

- Feedback That Works PDFDocumento5 pagineFeedback That Works PDFAshrav GuptaNessuna valutazione finora

- ME 01 ElasticityDocumento31 pagineME 01 ElasticityAshrav GuptaNessuna valutazione finora

- KaveriDocumento1 paginaKaveriAshrav GuptaNessuna valutazione finora

- Project-Effect of Monetary Policy On Business Environment Imf Working Paper On Monetary Policy Coordination and The Role of Central Banks Submitted by Ashrav Gupta (11108009)Documento2 pagineProject-Effect of Monetary Policy On Business Environment Imf Working Paper On Monetary Policy Coordination and The Role of Central Banks Submitted by Ashrav Gupta (11108009)Ashrav GuptaNessuna valutazione finora

- SM UK ManagingIndirectServicesDocumento13 pagineSM UK ManagingIndirectServicesAshrav GuptaNessuna valutazione finora

- Atomic BondsDocumento16 pagineAtomic BondsAshrav GuptaNessuna valutazione finora

- Le Ecture II I: HistoryDocumento8 pagineLe Ecture II I: HistoryAshrav GuptaNessuna valutazione finora

- PVD and CVDDocumento2 paginePVD and CVDAshrav GuptaNessuna valutazione finora

- Introduction To LITHOGRAPHYDocumento7 pagineIntroduction To LITHOGRAPHYAshrav GuptaNessuna valutazione finora

- Lecture 2Documento3 pagineLecture 2Ashrav GuptaNessuna valutazione finora

- Mett.7th SemDocumento9 pagineMett.7th SemLokesh DahiyaNessuna valutazione finora

- Kevlar - Wikipedia, The Free EncyclopediaDocumento11 pagineKevlar - Wikipedia, The Free EncyclopediaAshrav GuptaNessuna valutazione finora

- Module 1Documento2 pagineModule 1Ashrav GuptaNessuna valutazione finora

- 1Documento6 pagine1Ashrav GuptaNessuna valutazione finora

- ArcweldingbasicsDocumento61 pagineArcweldingbasicsapi-302554558Nessuna valutazione finora

- XLRI-Interview Questions and GD Topics Interview QuestionsDocumento4 pagineXLRI-Interview Questions and GD Topics Interview QuestionsfundoNessuna valutazione finora

- Project-Effect of Monetary Policy On Business Environment Imf Working Paper On Monetary Policy Coordination and The Role of Central Banks Submitted by Ashrav Gupta (11108009)Documento2 pagineProject-Effect of Monetary Policy On Business Environment Imf Working Paper On Monetary Policy Coordination and The Role of Central Banks Submitted by Ashrav Gupta (11108009)Ashrav GuptaNessuna valutazione finora

- Magnetic Inspection Testing - 11108009Documento4 pagineMagnetic Inspection Testing - 11108009Ashrav GuptaNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- FAJASDocumento891 pagineFAJASCecilia GilNessuna valutazione finora

- Comparative Performance of Some Cattle Breeds Under Barani Conditions of PakistanDocumento4 pagineComparative Performance of Some Cattle Breeds Under Barani Conditions of PakistanMasood HassanNessuna valutazione finora

- 09 Passport 7K 15K Performance Guidelines PCR 3 0Documento44 pagine09 Passport 7K 15K Performance Guidelines PCR 3 0thed719Nessuna valutazione finora

- Biomediacal Waste Project FinalDocumento43 pagineBiomediacal Waste Project Finalashoknr100% (1)

- Abnormalities of Placenta, Amniotic Fluid and Cord: Prepared By, B. Ezhilarasi, Nursing TutorDocumento21 pagineAbnormalities of Placenta, Amniotic Fluid and Cord: Prepared By, B. Ezhilarasi, Nursing TutorGopala KrishnanNessuna valutazione finora

- Chapter 04 Product and ServDocumento43 pagineChapter 04 Product and ServAlireza AlborziNessuna valutazione finora

- SP 73Documento105 pagineSP 73Rodrigo Vilanova100% (3)

- Donna Hay Magazine 2014-10-11 PDFDocumento172 pagineDonna Hay Magazine 2014-10-11 PDFlekovic_tanjaNessuna valutazione finora

- Southwest Airlines Final ReportDocumento16 pagineSouthwest Airlines Final Reportapi-427311067Nessuna valutazione finora

- ME 352 Design of Machine Elements: Lab ReportDocumento5 pagineME 352 Design of Machine Elements: Lab ReportKeshav VermaNessuna valutazione finora

- Understanding Bernoulli's Principle Through Simulations PDFDocumento4 pagineUnderstanding Bernoulli's Principle Through Simulations PDFIoannis GaroufalidisNessuna valutazione finora

- Kuiz1 210114Documento12 pagineKuiz1 210114Vincent HoNessuna valutazione finora

- Datasheet Ark XH Battery System EngDocumento2 pagineDatasheet Ark XH Battery System EngLisa CowenNessuna valutazione finora

- ReviewerDocumento3 pagineReviewerKristine SantominNessuna valutazione finora

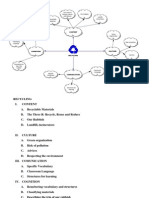

- Recycling Mind MapDocumento2 pagineRecycling Mind Mapmsole124100% (1)

- Basses: Pricelist March 2019Documento3 pagineBasses: Pricelist March 2019zhaihaijunNessuna valutazione finora

- Brief Summary of Catalytic ConverterDocumento23 pagineBrief Summary of Catalytic ConverterjoelNessuna valutazione finora

- Dizziness - Vertigo and HomoeopathyDocumento38 pagineDizziness - Vertigo and HomoeopathyDr. Rajneesh Kumar Sharma MD HomNessuna valutazione finora

- JHS 182Documento137 pagineJHS 182harbhajan singhNessuna valutazione finora

- Hot Topic 02 Good Light Magazine 56smDocumento24 pagineHot Topic 02 Good Light Magazine 56smForos IscNessuna valutazione finora

- Apcotide 1000 pc2782Documento1 paginaApcotide 1000 pc2782hellmanyaNessuna valutazione finora

- Army Aviation Digest - Nov 1978Documento52 pagineArmy Aviation Digest - Nov 1978Aviation/Space History Library100% (1)

- Module in Pe 103Documento79 pagineModule in Pe 103Kym Dacudao100% (1)

- Exercise 9 Two Factor Factorial Experiments and Derivation of Expected Mean SquaresDocumento14 pagineExercise 9 Two Factor Factorial Experiments and Derivation of Expected Mean SquaresHasmaye PintoNessuna valutazione finora

- Intel Stratix 10 Avalon - MM Interface For PCI Express Solutions User GuideDocumento173 pagineIntel Stratix 10 Avalon - MM Interface For PCI Express Solutions User Guideenoch richardNessuna valutazione finora

- LPG GasDocumento39 pagineLPG Gasv prasanthNessuna valutazione finora

- 40 RT-flex Control-System Rev01Documento68 pagine40 RT-flex Control-System Rev01Mayvon Botelho100% (2)

- Killer Kohler Part I IDocumento17 pagineKiller Kohler Part I Irusyn100% (1)

- Motor CAT C13 AcertDocumento3 pagineMotor CAT C13 AcertJosé Gonzalez100% (4)

- Generalized Anxiety DisorderDocumento24 pagineGeneralized Anxiety DisorderEula Angelica OcoNessuna valutazione finora