Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Denim Fabric Supplier Details

Caricato da

PuneethSrinivasTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Denim Fabric Supplier Details

Caricato da

PuneethSrinivasCopyright:

Formati disponibili

FASHION EXPORT MERCHANDISING & EXIM DOCUMENTATION

CONTENTS

INTRODUCTION

HISTORY

PRODUCTION TECHNIQUE

TYPES OF DENIM

INTERNATIONAL SOURCING

NATIONAL SOURCING

LEAD TIME & PRICE RANGE

LATEST DENIM DEVELOPMENT

REFERENCES

2

3

5

7

11

15

19

20

22

FASHION EXPORT MERCHANDISING & EXIM DOCUMENTATION

INTRODUCTION TO DENIM

Denim is a sturdy cotton warp-faced twill textile in which the weft passes

under two or more warp threads. This twill weaving produces the familiar

diagonal ribbing of the denim that distinguishes it from cotton duck.

A coarse, twilled cotton fabric, often blue, traditionally used for overalls an

d work-clothes

and now used for jeans and casual wear. Denims Pants or another garmen

t made of this

fabric.

A similar but finer fabric used in draperies and upholstery.

It is a characteristic of most indigo denim that only the warp threads are

dyed, whereas the weft threads remain plain white. As a result of the

warp-faced twill weaving, one side of the textile then shows the blue warp

threads and the other side shows the white weft threads. This is why

blue are white on the inside. The indigo dyeing process, in which the core

of the warp threads remains white, creates denim's fading characteristics,

which are unique compared to every other textile.

Denims durability is due to the weave, called a twill weave. Twill weaves

have great abrasion resistance, meaning the fabric will absorb a lot of

friction before it breaks apart. The reason for such great durability is the

way the yarns are woven together: one set of yarns floats over another 2

4 set of yarns at regular intervals to create a diagonal textured fabric

surface. It is these yarn floats that absorb the abrasion. When the

floating yarns are worn away, there are still more yarns underneath to

hold the fabric together. Take a look at a pair of worn jeans, and look for

places when the float yarns have worn away, exposing the white yarns

underneath. Denim has always been used for very durable outdoor work

clothing. Because of its weight, rigidity, and thickness, denim is chosen for

casual jackets, skirts, and jeans. Now that so many garment-finishing

techniques are applied to denim, its use has broadened into different

lifestyles. Denim apparel can command high prices, depending on the fit,

finishing, and brand name. Denim is still mostly used for jackets and

pants, with most attention focused on interesting jeans. Spandex yarn is

added to denim to make the denim elastic. Denim without spandex tends

to hold the body. A 25% spandex blend with cotton will stretch the

fabric over the body for a more comfortable fit.

Denim is a woven fabric commonly made with a blue cotton warp yarn

and a white cotton filling yarn. When it was first designed, denim was

primarily used to make work clothes and tough clothing like overalls, but

today it is used for everything from purses and skirts to denim jackets and

other fashionable clothes. Denim is so popular in the twenty-first century

2

FASHION EXPORT MERCHANDISING & EXIM DOCUMENTATION

that you can hardly walk into a store without seeing it on racks and

displays. In fact, its difficult to imagine a time when 9 out of 10 people

were NOT wearing jeans as casual everyday attire. If youre a fan of jeans

and youre curious about how denim is made, then prepare to find out.

HISTORY OF DENIM

The denim fabric originated in the French town of Nimes and owes its

name to the location, which was quickly known as denim abroad.

Spunky Genoese Navy sailors first strutted around in denim back in the

1500s but it wasnt until the 1870s in the gold rush boom that denim

took off. This was when Levi Strauss a name now synonymous with

denim - created a strong style of workers pants with rivets that was

quickly adopted by Californian coal miners. Originally made from

uncomfortable hemp, Strauss eventually discovered and started using the

twilled cotton cloth that originated from the French town of Nimes and

denim, as we know it, was born.

For a long time, it was largely worn by workers but become popular in

American Pop Culture when jeans became symbolic of protest against

conformity. Worn by teenagers and young adults they were often refused

admission to movies, restaurants and other everyday haunts when

wearing them. But the trend grew and during the 1960s wearing blue

jeans become more acceptable and by the 1970s they were truly

established as a fashion trend. The 80s brought with it designer jeans

and denim took to the catwalks. Today jeans are a staple of everybodys

wardrobe and often a key element in seasonal trends and fashion around

the world. Each season brings with it new cuts, features, treatments and

embellishments.

Denim is more than just a cotton fabric; it inspires strong opinions within

the hearts of historians, designers, teenagers, movie stars, reporters and

writers. Interest bordering on passion can be found among textile and

costume historians today, especially in the debate over the true origins of

denim. These experts have put decades of work into their research; here

is a summary of the prevailing opinions about the birth of denim, followed

by a discussion of the way Levi Strauss & Co. has helped to contribute to

denims movement around the world. In 1969 a writer for

FASHION EXPORT MERCHANDISING & EXIM DOCUMENTATION

American Fabrics magazine declared, Denim is one of the worlds oldest

fabrics, yet it remains eternally young. If continuous use of and interest

in an item makes it eternally young, then denim certainly qualifies. From

the 17th century to the present, denim has been woven, used and

discarded; made into upholstery, pants and awnings; found in museums,

attics, antique stores and archaeological digs; worn as the fabric of hard,

honest work and as the expression of angry rebellion; used for the sails of

Columbus ships in legend; and worn by American cowboys in fact. Legend

and fact are also interwoven when scholars discuss the origin of the name

denim itself.

Most reference books say that denim is an English corruption of the French

serge de Nimes; a serge fabric from the town of Nimes in France.

However, some scholars have begun to question this tradition. There are a

few schools of thought with regard to the derivation of the word denim.

Pascale Gorguet-Ballesteros, of the Musee de la Mode et du Costume in

Paris, has done some interesting research on both of these issues. A fabric

called serge de Nimes, was known in France prior to the 17th century. At

the same time, there was also a fabric known in France as nim. Both

fabrics were composed partly of wool.

There are various theories about the origin of the term "denim." The most

common theory is that the fabric was originally produced during the

Middle Ages in Nmes, France (under the name of "serge de Nmes") and

that America shortened it to "denim" in the 1800s. Another theory claims

the fabric originated in England.

The term "jeans" or "jean" is has become synonymous with "denim" in

todays terminology, but the terms werent always interchangeable. Jeans

actually originated in Genoa, Italy, and were made from fustian (a cotton,

linen and/or wool blend) instead of denim. Denim was slightly more

expensive than jean and was woven from one colored thread and one

white thread (jean was woven from two threads of the same color).

Levi Strauss is credited with making the first denim jeans. Strauss was a

young German immigrant who went to California in 1853, during the gold

rush, to sell a rough canvas to make tents and wagon covers. Prospectors

complained that what they really needed were pants that were strong

enough to last in the mines; so, Strauss made his first jeans from the

rough canvas and then began using denim when the miners complained

that the canvas pants chafed. The official birthday of "blue jeans" did not

FASHION EXPORT MERCHANDISING & EXIM DOCUMENTATION

come until 1873, when Strauss and a Nevada tailor named Jacob Davis copatented the idea of using rivets to add strength to the jeans.

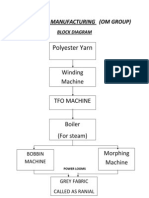

PRODUCTION TECHNIQUE

The term "Denim" has originated from the city of Nimes in France where

"serge de Nimes" was manufactured. Denim is made from a vat dye,

the Indigo dye, which is applied to cotton fabricin loosely held form in

layers. As far as manufacturing process of denim is concerned, it is similar

to that of Grey fabric up to the process of weaving with the only difference

that in case of Denim Fabric, it is dyed at the stage of sizing where as in

case of Grey Fabric, the decision regarding dyeing stage depends upon

the

finished

product..

SPINNING

The initial processes of denim manufacturing consist of the regular

activities of opening and blending of cotton fibers. Carding is done to

remove any foreign matter and the short fibers so that cotton takes the

form of a web which is then converted into a rope-like form, the sliver.

Then drawing process produces a single, uniform sliver from a number of

carded slivers. Yarn is then spun through Open-End Spinning or Ring

Spinning. Roving is also carried on, if the spinning has to be done through

Ring Spinning. Generally, denim fabric are 3/1 warp-faced twill fabric

made from a yarn dyed warp and an undyed weft yarn. Normally dyed and

Grey ring or open- end yarns are used in warp and weft respectively.

Traditionally speaking, the warp yarn is indigo dyed.

FASHION EXPORT MERCHANDISING & EXIM DOCUMENTATION

Warp Preparation - Dyeing and Sizing Processes

Warp yarns are indigo dyed and sized with the help of two

methods.

(i) Threads from several back beams are

combined to form a warp sheet and dyed and

same machine.

sized on the

(ii) Threads, about 350-400 in number are

formed into

ropes. 12-14 ropes run adjacent to each other through the continuous

dyeing unit. After dyeing, the ropes are dried on drying cylinders and then

collected in a can. After that, a worker's beam is prepared. Sizing is then

done in the conventional manner.

There are various dyeing and sizing processes, which can be classified into

four categories.

o

Continuous Indigo-Rope dyeing and sizing.

Continuous Indigo dyeing and sizing.

Indigo-back beam dyeing and sizing.

Continuous dyeing and sizing.

WEAVING

The weaving process interlaces the warp, which are the length-wise indigo

dyed yarn and the filling, which are the natural-colored cross-wise yarn.

The warp thread is in the form of sheet. The weft thread is inserted

between two layers of warp sheets by means of a suitable carrier, such as

Shuttle, Projectile, Rapier, Air current, Water current, etc. The selection of

carrier depends upon the type of weaving machinery used. The two

different technologies available for weaving machines are - Conventional

Shuttle Weaving System which is done by Ordinary Looms or Automatic

Looms; and the Shuttle less Weaving System which is done by Airjet,

Waterjet,

Rapier,

or

a

Projectile

weaving

machine.

The

Conventional Shuttle loom results in lesser production due to slow speed

and excessive wear and tear of machinery. As such, now denim is

generally woven through Shuttle less Weaving System namely, Airjet

looms, rapier looms or projectile looms.

FASHION EXPORT MERCHANDISING & EXIM DOCUMENTATION

FINISHING

The final woven fabric, wound on a cloth roll, is

taken out from weaving machines at particular

intervals and checked on inspection machines so

that any possible weaving fault can be detected.

In this quality control exercise, wherever any fault

is seen, corrective measures are taken then and

there only. The woven Denim Fabrics then goes

through various finishing processes, such as brushing, singeing, washing,

impregnation for dressing and drying. Brushing and singeing eliminate

impurities and help to even the surface of denim fabric. Dressing

regulates the hand and rigidity of the fabric while compressive shrinking

manages its dimensional stability. The standard width denim fabrics is

then sent for making up. In this process, the fabric is cut into the desired

width according to the size required. The made- up denim fabric is then

thoroughly checked for defects such as weaving defects, uneven dyeing,

bleaching and dyeing defects, oil stains, or patches. After inspection, the

final product is categorized quality-wise. The fault less fabrics are sent to

the packaging department while the defective ones are sent for further

corrections.

TYPES OF DENIM FABRICS

ORDINARY DENIM

This basic jean is an all-time favorite. The weft is left undyed and it is wrap

faced and dyed in indigo. The best part of using indigo is that, it bleeds

when washed.

7

FASHION EXPORT MERCHANDISING & EXIM DOCUMENTATION

ECRU DENIM

Ecru refers to the color of undyed denim and is the natural hue of cotton.

Jeans that have not been dyed with indigo are called ecru jeans; however,

they are more difficult to find.

STRECH DENIM

Stretch denim incorporates an elastic component, such as spandex. This

creates a certain amount of "give" in garments made from stretch denim.

Only a small percentage (about 3%) of spandex is required within the

fabric to create a significant stretching capacity of about 15%. However,

this feature will shorten the wearing life of the garment. It has a Lycra

content.

SOFT DENIM

It is basically a twill weave runs diagonally from right to left, which

produces denim that is a bit softer also called as Left Hand Twill providing

FASHION EXPORT MERCHANDISING & EXIM DOCUMENTATION

soft texture after washing. However it is more difficult to produce because

it requires more attention in the finishing stages.

REUSED DENIM

It is a technology developed technique which contains 50 percent cotton

and 50 percent reclaimed denim.

SODA POP DENIM

It has been developed from 100 percent recycled plastic pet bottles.

Developed by an US-based company Fortel Ecospun, this denim is already

being used by Levi Strauss and Reebok.

OVERDYED DENIM

Overdyeing is a process where the fabric is either dyed for too long or

dyed a second time. It is most often used on denim to add an overtone of

color to the indigo. No longer are the denims conventional indigo blue.

The market is now flooded with denim available in many different shades.

Over dyed with sulfur:

9

FASHION EXPORT MERCHANDISING & EXIM DOCUMENTATION

MERCERISED BLACK

This variety of fabric involves a pretreatment process that uses a special

technique to cause swelling of the fabric, thus improving the density of

the dye in the fabric. This process also imparts the denim fabric extra

strength particularly useful when the fabric has to undergo intensive

washing or abrading.

RING DENIM

Ring-ring, or dual-ring spun, denim is created from ring-spun yarn, a type

of yarn created by rolling rather than pressing the fibers into shape. It has

an uneven look surface appearance and feel and is considered more

valuable and unique than open end denim. Stone washing can be used to

enhance the irregularities. Coarse ring denim has prominent streaks on its

surface. Fine ring denim is more subdued. Ring-ring denim differs from

ring-spun denim in that the ring-spun yarn is used for both the warp and

weft during the weaving process rather than just the warp threads. It is

the most expensive choice out of ring-ring, ring-spun, and open end

denim.

Uneven thickness of ring-ring denim:

NATURAL DYED DENIM

Conventional cotton requires either bleaching to make it white or

bleaching and dyeing to add colour. Both processes release a large

amount of toxic chemicals into the environment. But coloured cotton

requires neither bleaching nor dyeing. Natural dyed denim is made from

10

FASHION EXPORT MERCHANDISING & EXIM DOCUMENTATION

coloured cotton grown primarily to manufacture denim. The colour of the

denim unlike others actually intensifies with more washing.

RAMIE-DENIM

Denim is also sometimes blended with the plant fiber ramie, which

reduces wrinkling and gives the fabric a softer feel. Ramie fiber is pure

white in colour, lustrous, moisture absorbent, and readily dyed. The fibre

is stronger than flax, cotton, or wool. Fabric made from ramie fibre is

easily laundered, increasing in strength when wet, and does not shrink or

lose its shape. It dries quickly and becomes smoother and more lustrous

with repeated washings. Ramie is resistant to mildew and other types of

micro-organism attack and good fastness to sun. Because ramie is brittle,

spinning it is difficult and weaving is complicated because ramie has a

very hairy yarn surface.

A visual of ramie cloth:

POLY-DENIM

Poly-denim blends look like a dressier denim, and are more lightweight,

which makes them more convenient to wash and dry. They also are more

resistant to wrinkling. A type of fibre known for its strength, dye affinity

and high luster. Polyester is derived from coal, air, water and oil. Polyester

is well known for being blended with cotton to create a fabric (polyestercotton blend) that is used in many different materials today including

denim.

Originally called Terylene, polyester was first discovered by the British

company ICI in 1941. It is produced from petroleum by-products such as

PET, and can even be created from recyclable materials such as soda

bottles (polar fleece is produced in this way). Polyester is the most popular

synthetic fiber in the world and is often used in blends to increase a

fabrics strength, durability, wrinkle resistance, and water resistance. Jean

manufacturers sometimes use polyester instead of spandex to make their

denim stretchier.

11

FASHION EXPORT MERCHANDISING & EXIM DOCUMENTATION

SOURCING

INTERNATIONAL SOURCING

The sourcing hubs have evolved in the South East Asia over the year in

the oriental countries like China, India, Bangladesh, Pakistan & Indonesia

Chemitex is the largest Textile Trading Company in Europe, with its

sourcing hubs in Pakistan, China, India, Indonesia, Africa, etc.,. They

specialized in all types of woven & denim fabrics.

Their consistent quality & competitive prices have made it possible for

them to sell 700,000 Meters Fabric per Day.

A&A TEXTILES

7F., No.53, Dongsing Rd., Sinyi District,

Taipei City 110, Taiwan (R.O.C.)

TEL:+886 2 8768 1133

FAX:+886 2 8768 1212

E-MAIL:Dollen@aatextile.com.tw

ABSOLUTE DENIM

12

FASHION EXPORT MERCHANDISING & EXIM DOCUMENTATION

No.99, Absolute Denim Room P6a Fl.

Sukhumvit Soi 6, Klongtoey,

BKK - 10110

Thailand

Tel : +66 2 255 4999

Fax : +66 2 255 4999 ext. 188

info @absolutedenim.com

ADM DENIM

Plot No. 5-9, 23-26, Sector-16,

Korangi Industrial Area,

74900 Karachi, Pakistan.

Tel: +92 21 111-236-236

Fax: +92 21 3505 4652

sales@admdenim.com

ADVANCE DENIM

Address: #3 Xinyoudong Road, Ronggui High-tech

Development Park of Shunde Foshan City,

Guangdong Province, P.R.C. 528306

Telephone: +86-757-29322698

Fax: +86-757-28385198

Email: qjjeans@advancedenim.com

ANANTA DENIM

Ananta Plaza

136, Elephant Road

Dhaka 1205, Bangladesh

Phone: +88-02-9660159-60

Fax: +88-02-8615738

E-mail: info@ananta-bd.com

ARGONDENIMS

REGISTERED OFFICE

Plot-33, section 7, Mirpur.

Dhaka-1216, Bangladesh.

Phone: +88 02 9020491-5, +88 02 9004405

Fax: +88 02 9020490.

BEXTEX LIMITED

Beximco Industrial Park

Sarabo, Kashimpur, Gazipur

Bangladesh

Phone: 8618220-7,8611891-5

Email: sardar@beximet.com

BLUEDIP GMBH

Fockenstegge 3 48683 Ahaus

Fon: +49 (0) 2561 429295

13

FASHION EXPORT MERCHANDISING & EXIM DOCUMENTATION

Fax: +49 (0) 2561 429296

E-mail :info@bluedip.de

CHITTAGONG DENIM MILLS LTD

Chittagong Denim Mill Ltd

House# B-123,Road# 21

New D.O.H.S , MohaKhali

Dhaka-1206

Telephone : 88-02 9886131, 88-02 9886247 88-02 8713508

Email : sales@chittagongdenim.com

HAMEEM DENIM

198/A,TEJGAON I/A

DHAKA-1208, BANGLADESH

Tel: +88-02-9889628

Email : sales@hameemdenim.com

INDIGO DENIM

Suite 214, the Cotton Exchange I.I.

Chundrigar Road, P.O.Box No. 4124,

Karachi, 74000, Pakistan.

Phone: (92-21) 3241-3204-5

Fax: (92-21) 3242-7647

Email:info@indigo.com.pk

JAMUNA GROUP

KA-244, Kuril, Progoti Sharani, Baridhara, Dhaka, Bangladesh.

Phone : 88-02-8413760-4, Fax : 88-02-8416050

E-mail : info@jamunagroup.com.bd

sales@jamunagroup.com.bd

marketing@jamunagroup.com.bd

MAHMUD GROUP

House - 25, Road - 10, Sector - 6,Uttara Model Town,

Dhaka- 1230, Bangladesh

Hotline number : +88-02-8961594

Hotline number : +88-02-8961652

Fax number : +88-02-8961508

EMAIL : info@mahmudgroup-bd.com

MARFANI DENIM

14

FASHION EXPORT MERCHANDISING & EXIM DOCUMENTATION

Plot No.26, Sector 15

Korangi Industrial Area,

Karachi, Sindh, Pakistan

Phone: 9221-5070373 / 5070371 / 5057996.

Fax: 9221-5058091

Email: info@marfanidenim.com ,

Email: marfanidenim@cyber.net.pk

SHASHA DENIM

Head Office:

Mascot Plaza (10th Floor)

Plot-107/A, Sonargaon Janapath Road. Sector 7,

Uttara C/A, Dhaka 1230

Phone: +88 (02) 8952801-3

Fax: +88 (02) 8952748

Email : info@shashabd.com

SIDDIQSONS

7th Floor- Siddiqsons Towers Plot # 3, Block

D-53 S.I.T.E, Karachi, Pakistan

(92-21) 3257-7480-9

Fax: (92-21) 3256-4613

UAN: 111-111-001

Email: siddiqsons@siddiqsons.com

SOORTY DENIM

Plot Survey : 332, Deh Landhi

Bin qasim, National Highway

Karachi Pakistan

T: + 92 21 34102633

15

FASHION EXPORT MERCHANDISING & EXIM DOCUMENTATION

NATIONAL SOURCING

In India, Surat, Ahmedabad & Tirpur has emerged over the period of time

as the Manchester of the East and taken over the market as the sourcing

hub for most of the fabrics and trims. Noida IS also upcoming centers for

sourcing of Denim fabric.

AARVEE DENIM & EXPORTS LIMITED

188/2, Ranipur Village,

Opp. CNI Church, Narol,

Ahmedabad 382 405 Gujarat, India.

Tel : +91-079-30417000, +91-079-40707000 (Central Boardline Number)

Fax : +91-079-30417070 (Central Boardline Number)

Mobile No : +91-9825600689, +91-9825600690

Mail : info@aarvee-denims.com

ADVANCE MULTITECH LTD

Regd office:

36, Kothari Market,

Opp. Hirabhai Market, Diwanballubhai Road,

Ahmedabad : 380 022.

Phone : + 91 79 - 25450609, 25454795

Fax : 079 25454586

E-mail : advance93@hotmail.com

E-mail: info@advancemulti.com

16

FASHION EXPORT MERCHANDISING & EXIM DOCUMENTATION

ANUBHA INDUSTRIES

Registered office address

104, mahade complex, ghb road, fatehnagar

Surat 394221

Gujarat, india

info@anubhaindustries.com

ARVIND MILL

The Arvind Mills Limited

Naroda Road

Ahmedabad 380025

Gujarat ,India

Tel: +91-79-22203030

Fax: +91-79-22201270

BEST TEXTILE LTD

B-85, Okhla Phase-II,

New Delhi -110020,

INDIA

Email: customercare@besttextiles.in

Email: sales@besttextiles.in

ASHIMA

Texcellence Complex

Khokhra Mehmedabad

Ahmedabad - 380 021.

INDIA

Tele. : 91-79-6777 7000

Fax. : 91-79-2277 3061

BLUE BLENDS (INDIA) LTD.

DENIM DIVISION

603, Sahajanand, Shaibaug Road,

Ahmedabad - 380 004,

Gujarat (India)

Tele : +91-79-25622141, 91-79-25622571, 91-79-25625481

Email ID: blueblends@dataone.in

ETCO DENIM

142, Andheri Industrial Estate, Nr Janki Centre,

Off. Veera Desai Road, Andheri (west)

Mumbai - 400 053.

Tel.: (022) 4238 2800/49 Fax.: (022) 2673 0130.

Email.: marketing2@etco.in , info2@etco.in

17

FASHION EXPORT MERCHANDISING & EXIM DOCUMENTATION

GINNI INTERNATIONAL LIMITED

2nd floor, Shanti Chamber,

11/6b pusa road,

New delhi-110005(india)

phone :+91-11-40088000

email : plant@ginnniint.com

JINDAL TEXTILES

Jindal House" Opp. D-Mart,

IOC Petrol Pump Lane, Shivranjani

Shyamal 132 Ft Ring Road, Satellite,

Ahmedabad 380015

Tele: +91 - 079 71001500

KANCHAN INDIA

Registered office:19-20,

Bhilwara Textile Market, Pur Road,

Bhilwara (Rajasthan) 311001 India

Phone:+91-1482-247001

Email: info@kanchanindia.com

KG DENIM LIMITED

Then Thirumalai

Coimbatore - 641302

India

Phone: +91 4254 235401

Fax : +91 4254 235400

Email: custrel@kgdenim.in

MAFATLAL INDUSTRIES LTD

Kaledonia, 6th Floor, Sahar Road, Andheri (E), Mumbai 400069

Telephone: +91-22-6771 3800 / 3900

Fax No: +91-22-6771 3924 / 25

Email: marketing@mafatlals.com, sales@mafatlaldenim.com

LNJ DENIM

Bhilwara tower, A-12 sector 1

Nodia- 201301 (NCR DELHI)

INDIA

18

FASHION EXPORT MERCHANDISING & EXIM DOCUMENTATION

Tel:+91 120 4390000/300

Rohit.menon@lnjbhilwara.com

NAHAR

Nahar Tower Industrial Area-A

Ludhiana-141003 (india)

Tel:+91-161-2600701

E-mail : nahar@owmnahar.com

RAINDOW DENIM

#51-52, free press house,

215, Nariman point,

Mumbai, pin 400021

INDIA

Phone:+91 22 2283 4123

RAYMOND UCO DENIM

#C-1, MIDC, LOHAR,

Yavatmal-445001,

Maharashtra

Phone: 91-7232-304570

19

FASHION EXPORT MERCHANDISING & EXIM DOCUMENTATION

LEAD TIMES & PRICE RANGES OF CURRENT DENIM

FABRICS WHICH ARE IN TREND

LATEST DENIM DEVELOPMENTS

SILK DENIM:

20

FASHION EXPORT MERCHANDISING & EXIM DOCUMENTATION

Denim/jeans have made their way into our everyday lifestyle, diluting its

association as a working class garment. Recent development of silk

denims which are soft, light and comfortable in all seasons, have added a

new dimension to the denim and fashion world.

In the present global economy, the future of silk will increasingly depend

on the industrys ability to relentlessly innovate new range of products.

Product development has been a pressing need of the Indian silk industry

and diversification into casual wear to address the changing market needs

is critically important.

Central Silk Technological Research Institute (CSTRI), Bangalore has been

engaged in product development in silk and silk blends. The Cocoona

Product Design, Development and Diversification (P3D) Cell under the

institute, established with broader objectives of quality upgradation,

investment

generation,

technology

upgradation,

productivity

improvement and employment generation, is involved in revival of

traditional products as well as development of innovative silk products,

meeting the consumer preferences and market needs. The product range

includes eri fleece fabrics, eri dress materials, eri shawls, silk non-wovens,

silk stretch fabrics, silk-knits, eri silk and wool blends, silk x cotton/linen

union fabrics etc.

Silk denim is another such successful

effort in this direction giving a new

dimension to both denim and silk

segments of the textile sector. The initial

attempt by the institute to develop silk

denim using eri silk has been reported

earlier (Indian Silk, July, 2005

Development of silk denim fabrics

Natural silk has been one of the most popular fabrics because of its

unique properties like, softness, suppleness and strength. Silk is preferred

for its lightness with warmth, sheerness with strength and delicacy with

resiliency. Silk fabrics retain their shape and resist wrinkling rather well.

Silk has pliability and suppleness that aided by elasticity and resilience,

give it excellent drapability. Also, silk being fine and strong, can be woven

into light weight denim fabrics.

The denim is a coarse twill weave

cotton

fabric, also commonly

known as blue jeans/jeans. Taking

clue from the history that denims/

jeans were originally made of silk,

wool, cotton and linen, an attempt has been made to develop different

combinations of silk denim fabrics. The mulberry silk of 20/22 denier in 6

and 12 ply organize twisted and eri silk of 2/60s, 2/80s and 2/ 120s were

21

FASHION EXPORT MERCHANDISING & EXIM DOCUMENTATION

used in warp. The warp yarn was dyed to indigo blue shade with acid

dyes. The mulberry silk in 6 and 12 ply tram twisted and eri silk of 2/60s,

2/80s and 2/120s grey yarns were used in weft for development of 100%

silk denim fabric. The cotton yarn of 2/60s, 2/ 100 Ne and linen yarns of

40s, 50s Le were also used in weft on the silk warp. Further, mulberry raw

silk of 20/22 denier that can be doubled and twisted in the required plies

and eri mill spun silk yarn available in the counts of 2/40s,2/60s,2/80s,

2/100s and 2/120s Nm and 20s Ne noil yarn can also be used for

development of different varieties of silk denim fabrics.

22

FASHION EXPORT MERCHANDISING & EXIM DOCUMENTATION

REFERENCES

DENIM A BOOK FOR ALL

VOUGE MAGZINE

www.denimclub.com

www.fiber2fashion.com

The information regarding suppliers, Price, Lead time,

MOQ & monthly mill capacity were collected by the Fabric

Merchandisers of Gokaldas Exports & Shahi Exports.

23

Potrebbero piacerti anche

- The History and Types of Denim FabricDocumento9 pagineThe History and Types of Denim FabricTorikul Islam SajibNessuna valutazione finora

- Jeans Business PlanDocumento34 pagineJeans Business PlanNancy Goel ッ67% (3)

- Production Process and Material Handling of Jeans.Documento26 pagineProduction Process and Material Handling of Jeans.Sandeep Guneshwar100% (1)

- Eco Friendly Denim ProcessingDocumento8 pagineEco Friendly Denim ProcessingMajid_Latif_721850% (2)

- Pre-Feasibility Study for Denim Jeans Stitching UnitDocumento25 paginePre-Feasibility Study for Denim Jeans Stitching Unitfibref100% (3)

- National Institute of Fashion Technology Hyderabad Fabric and garment finishing : Basic washes in denim fabricDocumento13 pagineNational Institute of Fashion Technology Hyderabad Fabric and garment finishing : Basic washes in denim fabricSundaramoorthy ManickamNessuna valutazione finora

- What Is Denim? Why It's Called Denim?: Properties of Denim FabricDocumento21 pagineWhat Is Denim? Why It's Called Denim?: Properties of Denim Fabricrahmanshanto623100% (1)

- Delighting in Denim - A Wonder FabricDocumento53 pagineDelighting in Denim - A Wonder Fabricrajivranjan3490Nessuna valutazione finora

- Denim Washing - Basic Steps and GuideDocumento13 pagineDenim Washing - Basic Steps and GuideMahbubor Rahman JulhazzNessuna valutazione finora

- Introduction To FabricsDocumento10 pagineIntroduction To FabricsP. LakshmanakanthNessuna valutazione finora

- Fiber, Yarn, Fabrics 3Documento18 pagineFiber, Yarn, Fabrics 3Mahadi HabibNessuna valutazione finora

- Knit Factory of BD - Problem & ProsfectDocumento37 pagineKnit Factory of BD - Problem & ProsfectShams Uddin Prodhan100% (4)

- DEnim Stitching Unit FeasibilityDocumento14 pagineDEnim Stitching Unit FeasibilitySateesh BalaniNessuna valutazione finora

- Presentation On Denim and Their Manufacturing ProcessDocumento37 paginePresentation On Denim and Their Manufacturing ProcessTulika RajNessuna valutazione finora

- Knit CostingDocumento2 pagineKnit CostingSanjana Islam Nilima67% (3)

- GP Report QC 1Documento50 pagineGP Report QC 1Rohan JetlingNessuna valutazione finora

- Arvind IntershipDocumento52 pagineArvind IntershipAnurag MosanNessuna valutazione finora

- Apparel Internship at Orient Craft LimitedDocumento81 pagineApparel Internship at Orient Craft LimitedBaabul Singh50% (6)

- Denim Dry ProcessDocumento9 pagineDenim Dry ProcessZaman Parvez0% (1)

- All Trims Are Accessories But All Accessories Are Not Trims (Assignment)Documento14 pagineAll Trims Are Accessories But All Accessories Are Not Trims (Assignment)Sadi Sheikh67% (6)

- Denim Washing ThesisDocumento76 pagineDenim Washing Thesistoki-00767% (3)

- Understanding Textile Production ProcessesDocumento48 pagineUnderstanding Textile Production ProcessesVaisistha BalNessuna valutazione finora

- ReportDocumento45 pagineReportabhijith msNessuna valutazione finora

- Thread Consumption GuideDocumento6 pagineThread Consumption GuideMohammad Saleh MusaNessuna valutazione finora

- Garment MerchandisingDocumento16 pagineGarment MerchandisingaontuNessuna valutazione finora

- Plant Layout - IDocumento16 paginePlant Layout - ITanya rajNessuna valutazione finora

- Kesarinandan Knit FabsDocumento42 pagineKesarinandan Knit Fabsmk_bothraNessuna valutazione finora

- Denim Quality ControlDocumento10 pagineDenim Quality ControlEhsan HameedNessuna valutazione finora

- Process of Manufacturing TrouserDocumento15 pagineProcess of Manufacturing TrouserAAKASH AAKASHNessuna valutazione finora

- Formal Trouser: Feasibility Report PresentationDocumento64 pagineFormal Trouser: Feasibility Report Presentationbolaaajiii100% (1)

- Denim Bottom: Textile Merchadising and Marketing Akmal JavedDocumento9 pagineDenim Bottom: Textile Merchadising and Marketing Akmal JavedAkmal JavedNessuna valutazione finora

- Fusing TechnologyDocumento59 pagineFusing TechnologyShreyasiSaxena100% (2)

- Basics Denims - Style Spec: Wash CommentDocumento9 pagineBasics Denims - Style Spec: Wash CommentAnonymous kTEAR8k2YNessuna valutazione finora

- APPAREL INTERNSHIP Final PDFDocumento107 pagineAPPAREL INTERNSHIP Final PDFAnonymous EPCN6WNessuna valutazione finora

- YarnsDocumento38 pagineYarnsAbhinav VermaNessuna valutazione finora

- Disha Kapil (11) Stanley SayoniDocumento12 pagineDisha Kapil (11) Stanley Sayonisahu_dishaNessuna valutazione finora

- Introduction To TextileDocumento30 pagineIntroduction To Textileumar.niift3049100% (1)

- Container Fabric Cost AnalysisDocumento1 paginaContainer Fabric Cost Analysissubhankhan45Nessuna valutazione finora

- Textile InternshipDocumento62 pagineTextile InternshipNeetek SahayNessuna valutazione finora

- Shahi ExportDocumento18 pagineShahi ExportPrachi JaiswalNessuna valutazione finora

- Denim Finishing: Full Jeans Trend Bleaching Washing RippingDocumento16 pagineDenim Finishing: Full Jeans Trend Bleaching Washing RippingRajib DasNessuna valutazione finora

- Internship ReportDocumento20 pagineInternship Reportveenaos0% (1)

- R101 Lesson 7 Fabrics, Finishes and FurnishingsDocumento44 pagineR101 Lesson 7 Fabrics, Finishes and FurnishingsAman KeltaNessuna valutazione finora

- Product Specification of Terry TowelsDocumento2 pagineProduct Specification of Terry TowelsAbhishek SrivastavaNessuna valutazione finora

- Denim Present and Future of Bangladesh (For Selim)Documento12 pagineDenim Present and Future of Bangladesh (For Selim)shohagh12133% (3)

- YarnsDocumento27 pagineYarnsnitishkohli75% (4)

- Pad Harshita Kartik PPT Assignment 1Documento23 paginePad Harshita Kartik PPT Assignment 1kaarthikayaNessuna valutazione finora

- 01 Denim Fabric and Garments PDFDocumento12 pagine01 Denim Fabric and Garments PDFabul hossain100% (3)

- Grey Cloth Manufacturing ProcessDocumento8 pagineGrey Cloth Manufacturing ProcessPriya JainNessuna valutazione finora

- Denim Fabric ManufacturingDocumento22 pagineDenim Fabric ManufacturingFazley Elahi100% (2)

- Textile IndustryDocumento59 pagineTextile IndustryBruce AlphansoNessuna valutazione finora

- Apparel Merchandising & Costing DocumentDocumento21 pagineApparel Merchandising & Costing DocumentPooja GuptaNessuna valutazione finora

- Sewing Machine Beds: - Prepared by - P.Lakshmana Kanth, Senior Faculty - IFTKDocumento9 pagineSewing Machine Beds: - Prepared by - P.Lakshmana Kanth, Senior Faculty - IFTKP. Lakshmanakanth100% (1)

- Carr and Latham's Technology of Clothing ManufactureDa EverandCarr and Latham's Technology of Clothing ManufactureDavid J. TylerValutazione: 4 su 5 stelle4/5 (1)

- Denim: Shahrukh ShahbazDocumento22 pagineDenim: Shahrukh ShahbazShahrukhNessuna valutazione finora

- Project of Denim DyeingDocumento111 pagineProject of Denim Dyeingdani100% (1)

- History of DenimDocumento2 pagineHistory of DenimMuhammad Iqbal ShaikhNessuna valutazione finora

- A Short History of DenimDocumento7 pagineA Short History of Denimapi-3838281100% (1)

- A Short History of Denim: (C) Lynn Downey, Levi Strauss & Co. HistorianDocumento11 pagineA Short History of Denim: (C) Lynn Downey, Levi Strauss & Co. HistorianBoier Sesh PataNessuna valutazione finora

- Fashion Retail and Mall ManaementDocumento19 pagineFashion Retail and Mall ManaementPuneethSrinivasNessuna valutazione finora

- Denim Fabric Supplier DetailsDocumento23 pagineDenim Fabric Supplier DetailsPuneethSrinivasNessuna valutazione finora

- Basta GM PlanDocumento21 pagineBasta GM PlanPuneethSrinivasNessuna valutazione finora

- Rolex Vs CartierDocumento28 pagineRolex Vs CartierPuneethSrinivas100% (3)

- Fashion Retail and Mall ManaementDocumento19 pagineFashion Retail and Mall ManaementPuneethSrinivasNessuna valutazione finora

- Rolex Vs CartierDocumento28 pagineRolex Vs CartierPuneethSrinivas100% (3)

- Quality Assurance ProceduresDocumento100 pagineQuality Assurance ProceduresPuneethSrinivas50% (2)

- ScarrDocumento45 pagineScarrPuneethSrinivasNessuna valutazione finora

- Ob Case StudyDocumento18 pagineOb Case StudyPuneethSrinivasNessuna valutazione finora

- Label Box ObatDocumento145 pagineLabel Box ObatIrwandi SuhermanNessuna valutazione finora

- Evolution of A Process The Manufacture of Diphenyl OxideDocumento2 pagineEvolution of A Process The Manufacture of Diphenyl OxideAshwini SwamiNessuna valutazione finora

- 1.2 JP2021195344A - TranslationDocumento4 pagine1.2 JP2021195344A - TranslationNilesh PatelNessuna valutazione finora

- Important questions on alcohols, phenols and ethersDocumento9 pagineImportant questions on alcohols, phenols and ethersrajNessuna valutazione finora

- Module 6 Revision 2Documento42 pagineModule 6 Revision 2Ysharath ChandramouliNessuna valutazione finora

- CSS Yarn Indentification GuideDocumento7 pagineCSS Yarn Indentification GuideteryNessuna valutazione finora

- Standard Astm d1646-04Documento12 pagineStandard Astm d1646-04Huỳnh TG50% (2)

- Astm 4458-94Documento3 pagineAstm 4458-94Roberto Eduardo Salvador MonteroNessuna valutazione finora

- Seismic Acquisition Seismic AcquisitionDocumento70 pagineSeismic Acquisition Seismic AcquisitionGhassen LaouiniNessuna valutazione finora

- Fiber Analysis: Quantitative: AATCC Test Method 20A-2017Documento9 pagineFiber Analysis: Quantitative: AATCC Test Method 20A-2017Milagros Wieczorek50% (2)

- 05 Molecular Tools For Studying Genes and Gene ActivityDocumento15 pagine05 Molecular Tools For Studying Genes and Gene Activityفقوش عبودNessuna valutazione finora

- An Introduction To Flute PadsDocumento10 pagineAn Introduction To Flute PadsLuis M GonzálezNessuna valutazione finora

- Knitting Capacity & Booking StatusDocumento7 pagineKnitting Capacity & Booking StatussaidurtexNessuna valutazione finora

- Astman NPG Glycol: Powder Coating Resin PC-17-4N Based OnDocumento4 pagineAstman NPG Glycol: Powder Coating Resin PC-17-4N Based OnRAZA MEHDINessuna valutazione finora

- Screener Troubleshooting: Diagnosing and Solving Screen ProblemsDocumento4 pagineScreener Troubleshooting: Diagnosing and Solving Screen ProblemsEduardo GoyhenecheNessuna valutazione finora

- SafeSpec Permeation GuideDocumento99 pagineSafeSpec Permeation GuideWellington BV Wellington A A BvNessuna valutazione finora

- Pivotal Role of Fillermatrix Interface in Dental Composites ReviewDocumento12 paginePivotal Role of Fillermatrix Interface in Dental Composites ReviewAlex KwokNessuna valutazione finora

- D 5417 - 99 - Rdu0mtctotkDocumento3 pagineD 5417 - 99 - Rdu0mtctotkMorched TounsiNessuna valutazione finora

- Poly Water Tank (Completed) PDFDocumento2 paginePoly Water Tank (Completed) PDFSopi LabuNessuna valutazione finora

- Schmidt 2016Documento9 pagineSchmidt 2016Rob Robbie RabuelNessuna valutazione finora

- Biodegradable PolymersDocumento16 pagineBiodegradable PolymersAnonymous oSJ15KEc100% (1)

- Conveyor Idler Rollers - Waminco - Industrial Rubber & Polymer Products - Perth WADocumento1 paginaConveyor Idler Rollers - Waminco - Industrial Rubber & Polymer Products - Perth WACarlos Ediver Arias RestrepoNessuna valutazione finora

- PolyesterDocumento432 paginePolyesterkhuongdaihuynh75% (4)

- AminesDocumento31 pagineAminesJoseph YayenNessuna valutazione finora

- SI R10 Ch07Documento11 pagineSI R10 Ch07Carlos Javier PérezNessuna valutazione finora

- THERMOFORMINGDocumento98 pagineTHERMOFORMINGShubham ChaudharyNessuna valutazione finora

- Pharmacognosy of Alkaloidal DrugsDocumento67 paginePharmacognosy of Alkaloidal DrugsDharun RanganathanNessuna valutazione finora

- Wikipedia OrgfDocumento2 pagineWikipedia OrgfBrandon TimmNessuna valutazione finora

- Designing New Vanillin Schiff Bases and Their Antibacterial StudiesDocumento4 pagineDesigning New Vanillin Schiff Bases and Their Antibacterial StudiesAvinash PurohitNessuna valutazione finora

- Chemistry (Hydrocarbons) : Question 1: An Isomer of CDocumento30 pagineChemistry (Hydrocarbons) : Question 1: An Isomer of CDhruv KuchhalNessuna valutazione finora