Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Select Actuator Damper Retrofit

Caricato da

Aditya B. RyantoCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Select Actuator Damper Retrofit

Caricato da

Aditya B. RyantoCopyright:

Formati disponibili

Retrofit and Replacement

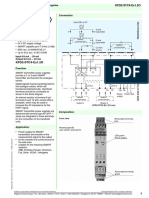

How to Select an Actuator for Damper Retrofit

The 10 questions method for sizing and selection shown below is

recommended as the best method for your actuation requirements.

Use the Application Data column in this chart as a worksheet to help

in the selection process.

Is fail-safe

actuation

required?

Consider the application. Is the

actuator and/or damper exposed to

outside air? If yes, use spring return.

L x W = Total sq

inches/144 = total sq feet

What is

the supply

voltage to

the actuator?

24 VAC/DC

Opposed Blade

w/o seals 3 in-lbs/sq feet*

120 VAC

Opposed Blade

230 VAC

single phase

Opposed Blade

w/ seals 5 in-lbs/sq feet

Parallel Blade

w/o seals 4 in-lbs/sq feet

Parallel Blade

w/ seals 7 in-lbs/sq feet

Are there blade

and edge seals

on the damper?

This will impact

the proper

selection as the

seals add resistance

requiring more torque.

If unknown, use

a worst case

scenario, parallel

blade with seals.

What is the air

velocity, static

pressure, or

design CFM?

Yes

No

10

in-lbs/sq.ft.

On/Off

Floating Point

Modulating

2-10 VDC

Sequencing

Directcoupling has

become the

industry

standard.

Some retrofit

applications

do not allow direct coupling. Refer to

the Belimo Mounting & Methods

Guide for application details.

Are there

additional

accessories

required?

K4-2 US

_______FPM

0-10 VDC

4-20 mA

PWM____

range

Other (MFT)

Yes

No, see

accessories

page

KH-AF US

KH-AF-1 US

No

PA

SA

For example, some applications require

the addition of an auxiliary switch for

proof of position; a retrofit application

may require an additional mounting

bracket and linkage kit. We advise that

you identify these needs prior to leaving

the job site or ordering products.

_______CFM

230 VAC

Floating point

This will be a critical component to

the selection of an actuator. Consider

the MFT actuator product range and

the flexibility of its application.

Can you direct

couple to a

damper shaft?

120 VAC

2 position

Non-standard

voltage signals

_______W.G.

Systems above 1,000 FPM

require additional actuator torque

If replacing an oil

immersed gear

train actuator, is the transformer in the

defective actuator? You may need to

purchase one.

Parallel Blade

If this information

is not available

refer to the

typical damper

requirements and

sizing chart

below.

For the damper

in question,

what does the

manufacturer

specify as the

torque rating?

24 VAC

What is

the control

signal to the

actuator?

*Less than 1,000 feet per

minute

Do you need

a step down

transformer?

Yes, see

accessories

section or

actuator

series for

details

TYPICAL DAMPER REQUIREMENTS AND SIZING

Square Damper (with square shape): ft2 = h x w /144; (h= height, w= width, in inches)

EXAMPLE: Damper Area (8 ft ) x Rated Torque Loading of Damper (4 in-lbs/ft2) = Total in-lbs Required (32 in-lbs) Belimo LF 35 in-lbs/ LM 45 in-lbs actuators

SQUARE

Damper Blade Type

Parallel blade/edge seals

Opposed blade/edge seals

Parallel blade/no edge seals

Opposed blade/no edge seals

Round

800-543-9038 USA

< 1000 FPM

7 (Typical)

5 (Typical)

4

3

10

Torque Loading in-lbs/ft2

1000-2500 FPM

10.5

7.5

6

4.5

14

866-805-7089 CANADA

2500-3500 FPM

14

10

8

6

20

203-791-8396 LATIN AMERICA/CARIBBEAN

P10406 - 04/13 - Subject to change. Belimo Aircontrols (USA), Inc.

Opposed blade

or Parallel

blade control

construction?

Yes

No

What is the

total area of

the damper?

sq.ft.

APPLICATION DATA

APPLICATION DATA

APPLICATION INFO

ACTUATOR REQUIREMENTS

Retrofit and Replacement

How to Select an Actuator

TYPICAL DAMPER REQUIREMENTS AND SIZING EXAMPLE:

APPLICATION REQUIREMENTS

Damper Length

Damper Width

Damper (Round)

Blade Type

Edge Seals

Design CFM

Fail-Safe

Supply Voltage

Control Signal

CALCULATIONS

Damper Area (sq inches)

Damper Area (sq feet)*

Velocity

Rated Torque Loading (in-lbs/ft2)**

SQUARE DAMPER

24"

12"

ROUND DAMPER

12"

Round

Opposed

Edge Seals

1800 CFM

Yes

24 Volt

2-10 VDC

700 CFM

Yes

24 Volt

2-10 VDC

24" x 12" = 288 in2

288 in2 x 1ft/12 in x 1ft/12 in = 2 ft2

1800 ft3/min / 2 ft2 = 900 ft/min

See chart under <1000 FPM (ft/min)

Select 5 in-lbs/ft2 for Opposed Blade/Edge Seals

r =113.04 in2

113.04 in2 / 1ft/12in x 1ft/12in= 0.785 ft2

700 ft3/min / .785 ft2 = 892 ft/min

See chart under <1000 FPM (ft/min)

Select 10 in-lbs/ft2 for Round Damper

*Damper Area (sq ft) x **Rated Torque Loading of Damper (in-lbs/ft2) = Total in-lbs Required

EXAMPLE EQUATION

2 ft2 x 5 in-lbs/ft2 = 10 in-lbs

Belimo LF24-SR US @ 35 in-lbs

0.785 ft2 x 10 in-lbs/ft2 = 7.85 in-lbs

Belimo LF24-SR US @ 35 in-lbs

CONTROL SIGNAL OVERVIEW

Belimo actuators are compatible with many control inputs and all direct digital control (DDC) systems. There are many signals to select from

with todays controllers.

P10406 - 04/13 - Subject to change. Belimo Aircontrols (USA), Inc.

On/Off or Open-Close: The actuator is able to drive either to its full

clockwise (CW) position, or to its full counter-clockwise (CCW)

position. The same indication is used for spring return type

actuators. Where the actuator will drive to its full CW position and

spring return to its CCW position. This can also be reversed.

Phasecut: An actuator drives depending on the power result of a

remaining wave. This signal type cuts the amplitude of the wave and

the actuator recognizes this signal as a proportional movement.

3-point, Tri-State, Floating Point: The actuator has both clockwise

(CW) and counter-clockwise (CCW) control inputs. One drives the

actuator to its CW, the other to its CCW position. If there is no signal

(Null point) on either input the actuator simply stays in its last

position.

Proportional Control: The actuator drives proportional to its control

input and modulates throughout its angle of rotation. This control

type is usually a variation of VDC. Common values are:

0-10 VDC

2-10 VDC

It is common to also have a 0-20/4-20 mA output from a controller.

This can be very easily converted to 0-10 VDC or 2-10 VDC with a

500 resistor.

Pulse Width Modulation (PWM): The actuator drives to a specified

position according to a pulse duration, the length of signal. The

pulse can originate from a dry contact closure or a triac sink or

source controller. An example of PWM control:

Multi-Functional Technology (MFT): This technology was

developed by Belimo for incorporation into our damper and valve

actuators. MFT provides the ability to program certain characteristics

of the actuators. Some of the key characteristics to change are:

CONTROL INPUT

Selectable on/off, VDC, PWM or floating point

MOTION VALUES

Selectable running time adjustment

FEEDBACK

Selectable feedback values

Time base: 0 to 10 seconds

Output pulse: 5 seconds

Actuator position: 50%

800-543-9038 USA

866-805-7089 CANADA

203-791-8396 LATIN AMERICA/CARIBBEAN

Potrebbero piacerti anche

- Belman Wafer Check Lug VelanDocumento2 pagineBelman Wafer Check Lug VelanAditya B. Ryanto100% (1)

- General Service Solenoid Valves: ConstructionDocumento3 pagineGeneral Service Solenoid Valves: ConstructionAditya B. RyantoNessuna valutazione finora

- DatasheetDocumento3 pagineDatasheetAditya B. RyantoNessuna valutazione finora

- Manual Topworx D Series Discrete Valve Controller Hart Protocol Topworx en 82604Documento20 pagineManual Topworx D Series Discrete Valve Controller Hart Protocol Topworx en 82604Aditya B. RyantoNessuna valutazione finora

- Ico3s Iom ManualDocumento2 pagineIco3s Iom ManualAditya B. RyantoNessuna valutazione finora

- Introduction To The Incoterms 2010Documento3 pagineIntroduction To The Incoterms 2010Dani RebahuNessuna valutazione finora

- Gate Valve CataogueDocumento4 pagineGate Valve CataogueAditya B. RyantoNessuna valutazione finora

- Material EquivalentsDocumento25 pagineMaterial EquivalentsAditya B. Ryanto100% (6)

- Material EquivalentsDocumento25 pagineMaterial EquivalentsAditya B. Ryanto100% (6)

- Kwik-Clamp Sizing Chart for Sanitary FerrulesDocumento1 paginaKwik-Clamp Sizing Chart for Sanitary FerrulesAditya B. RyantoNessuna valutazione finora

- B16-34 Clarifications 2009Documento77 pagineB16-34 Clarifications 2009RobertReinboldNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Aksin Et Al. - The Modern Call Center - A Multi Disciplinary Perspective On Operations Management ResearchDocumento24 pagineAksin Et Al. - The Modern Call Center - A Multi Disciplinary Perspective On Operations Management ResearchSam ParkNessuna valutazione finora

- Touch Screen TechnologyDocumento18 pagineTouch Screen TechnologySmîlērNessuna valutazione finora

- Saint Louis University Baguio City Principal'S Recommendation FormDocumento1 paginaSaint Louis University Baguio City Principal'S Recommendation FormnidzNessuna valutazione finora

- Slurry Flo BrochureDocumento4 pagineSlurry Flo BrochureChristian Andres Campa HernandezNessuna valutazione finora

- Smart Lighting Market Analysis and Forecast 2025 by Global Marketing InsightsDocumento5 pagineSmart Lighting Market Analysis and Forecast 2025 by Global Marketing InsightsEko Hadi Susanto100% (1)

- Tugas 1Documento8 pagineTugas 1Muhammad Robby Firmansyah Ar-RasyiedNessuna valutazione finora

- LTE Advanced - Leading in Chipsets and Evolution: August 2013Documento33 pagineLTE Advanced - Leading in Chipsets and Evolution: August 2013Muneeb JavedNessuna valutazione finora

- Admin Interview Questions and Answers - Robert HalfDocumento2 pagineAdmin Interview Questions and Answers - Robert HalfWaqqas AhmadNessuna valutazione finora

- Circular Tank Radius CalculationDocumento25 pagineCircular Tank Radius CalculationQamar AbbasNessuna valutazione finora

- Advances in Remediation-eBookDocumento88 pagineAdvances in Remediation-eBookalinerlfNessuna valutazione finora

- ISO 128-25 Technical Drawings - General Principles of Presentation - Lines On Shipbuilding Drawings (1999)Documento16 pagineISO 128-25 Technical Drawings - General Principles of Presentation - Lines On Shipbuilding Drawings (1999)SantoshNessuna valutazione finora

- Disney Channel JRDocumento14 pagineDisney Channel JRJonna Parane TrongcosoNessuna valutazione finora

- Volume 1 Drafting Design and Presentation StandardsDocumento328 pagineVolume 1 Drafting Design and Presentation StandardsAntonio Herrera PérezNessuna valutazione finora

- Stock Register StoreDocumento1.218 pagineStock Register StoreSantanu Kumar SahuNessuna valutazione finora

- Rising Stem Ball ValveDocumento6 pagineRising Stem Ball ValveAnupam A. GandhewarNessuna valutazione finora

- Managing ImapDocumento408 pagineManaging ImapPriya RaoNessuna valutazione finora

- PD 957 AND BP 220 HOUSING DESIGN STANDARDSDocumento5 paginePD 957 AND BP 220 HOUSING DESIGN STANDARDSGeraldine F. CalubNessuna valutazione finora

- TN 46Documento23 pagineTN 46Khalil AhmadNessuna valutazione finora

- 1HD-T - 1 Land Cruiser Engine Service ManualDocumento26 pagine1HD-T - 1 Land Cruiser Engine Service ManualMichael Dzidowski86% (7)

- SIS - Plano Hidráulico de Motoniveladora 140H CATDocumento9 pagineSIS - Plano Hidráulico de Motoniveladora 140H CATRoy Huaripata100% (1)

- ALTERNATOR - ST170741: Parts ListDocumento2 pagineALTERNATOR - ST170741: Parts Listkaswade BrianNessuna valutazione finora

- Plett DawsonDocumento270 paginePlett DawsonRaghu0% (1)

- MS 01 182Documento5 pagineMS 01 182kicsnerNessuna valutazione finora

- UAV Course SyllabusDocumento3 pagineUAV Course Syllabushindaputra374100% (3)

- MNDOT Distress Identification ManualDocumento51 pagineMNDOT Distress Identification ManualcrojastNessuna valutazione finora

- Sample Cover Letter: No Work ExperienceDocumento4 pagineSample Cover Letter: No Work ExperienceMaya ElvisaNessuna valutazione finora

- Services Marketing: Consumer Behavior in Services Unit 2Documento78 pagineServices Marketing: Consumer Behavior in Services Unit 2mpsrishaNessuna valutazione finora

- Assessment of Groundwater Quality Using GIS - A Case Study of The Churu District of RajasthanDocumento9 pagineAssessment of Groundwater Quality Using GIS - A Case Study of The Churu District of RajasthanSivaShankarNessuna valutazione finora

- Counter List HuaweiDocumento14 pagineCounter List Huaweiwedewe02Nessuna valutazione finora

- Tur C PDFDocumento86 pagineTur C PDFWilliam LambNessuna valutazione finora