Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Core Sample Processing

Caricato da

Adhia Prenata Putra HuzaCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Core Sample Processing

Caricato da

Adhia Prenata Putra HuzaCopyright:

Formati disponibili

SAMPLE CATCHING AND PROCESSING

SAMPLE BAGS

-sample bags and vials are labeled with

1) location and event number (possibly licence number)

2) well operator and field name

3) depth

-print labels with indelible ink and if possible, especially for invert wells, a

perforating printer

-dry government fractions as soon as possible to prevent oxidation of ferric

compounds and tie sample bags into 10 bag bundles

RIG DOGHOUSE

-post a notice in the doghouse informing driller in writing

-of basic sample washing requirements

-listing anticipated bottoms up times for the well (times can be altered to

adapt to changing hole conditions as drilling proceeds)

-an estimate of sample lag:

1)dividing the depth by 33 gives a rough starting sample lag

2)using formulas to calculate bottoms up times using pump

strokes/pipe and hole diameter etc

3)refine estimate with gas detector as coal or reservoir gas shows

are drilled

4)consult with the drilling foreman as they often have a good

estimate of annular velocities.

SAMPLE PROCESSING AT RIG

-place a pail in front of shaker positioned to fill with a representative sample

from the entire sample interval

-during slow drilling with very little sample dribbling over the shaker the pail

should be moved to catch as much sample as possible

-when a lot of solids are coming over the shaker and threatening to overfill the

bucket, it should be moved to catch as little sample as possible

-sample is transferred to a pail with 5mm holes drilled into the bottom and

washed into a fine meshed sieve (80) or casing protector lined with fine 222

shaker screen

-oversized cuttings left in the pail, being predominantly cavings, are discarded

-the sample is washed with a 1 rig hose or if drilled with invert mud washed

with clean diesel or kerosene.

PROCESSING SAMPLE BY GEOLOGIST

Drilling mud systems, especially diesel or crude oil based contain a mixture of

potentially harmfull chemicals and should be handled with good ventilation,

nitrile gloves, a dust or preferably a carbon filter mask, eye protection and a

rubberized apron.

Mechanical wash systems provide good sample quality and homogeneity.

WATER BASED MUD SYSTEM

-sieve the sample into a small light fry pan and swish water over until clean.

-an air drying procedure using a vacuum cleaner suction system with the sample

in a fine sieve is least damaging to the colour and hydrocarbon show potential.

-as a poor alternative dry the washed sample in an aluminum tart pan gently on

a stove or under heat lamps (heat above 39C damages hydrocarbon shows)

-clean only as much sample as will be required for describing samples and filling

vials in order to speed drying.

-refrain from agitating drying samples, leaving a dust coating on wet cuttings.

-sample can be sieved through a colander with 10 or more 3mm holes in its

screen in order to further separate drilled cuttings from cavings. This is best

done after the whole sample, brought from rig, has been washed, dried and all

fractions inspected for usefulness.

INVERT MUD SYSTEMS

-invert mud systems require soap and degreasers to clean diesel and crude oil

from the sample

-on the rig as a final step, have sample rinsed with clean diesel or kerosene.

-the prewashed sample is processed either by:

1) processing in a mechanical washer with washing, rinsing and drying

stations built into the system

2) shaking in a jar with detergent or degreaser

3) processing in a blender with detergent and warm water

-aggressive mechanical agitation is an important component in all three systems

in order to remove polymer and rock flour from unbalanced or old invert systems

-presoak in degreaser or detergent for 5min helps to remove much of the diesel

-some geologists use only solvents such as varsol for cleaning invert samples as

any exposure of an invert drilled sample to water during the processing destroys

the colour and integrity of many shales and clay constituents of reservoir rocks

-this procedure should be conducted outside or with good ventilation

using the precautions listed above

-in a fine 80-mesh sieve sample is rinsed in a bucket of varsol to remove

the fines, transfer cuttings to a small frying pan and swish clean varsol

from a second bucket over the sample until it is clean

-transport and store bags with invert samples in sealed 5gal/20 litre plastic pails

Potrebbero piacerti anche

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Dave Graham Literature CatalogDocumento640 pagineDave Graham Literature CatalogPierce PetersonNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Nursing Practice Skills: Adult Intensive Care Unit PatientsDocumento10 pagineNursing Practice Skills: Adult Intensive Care Unit PatientsMona Doria67% (3)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Basic Resistance Training GP5Documento20 pagineBasic Resistance Training GP5matt.tubieron23Nessuna valutazione finora

- Sale of Property When - KP AstrologyDocumento2 pagineSale of Property When - KP Astrologyprajishvet100% (1)

- Web Based Bus Tracking SystemDocumento4 pagineWeb Based Bus Tracking SystemKrishna EelaNessuna valutazione finora

- Vein Type DepositDocumento7 pagineVein Type DepositHarisArmadiNessuna valutazione finora

- Methodology of Static Pile Load TestDocumento33 pagineMethodology of Static Pile Load Testraju_420034520100% (1)

- WST Macros Add-In FeaturesDocumento1 paginaWST Macros Add-In FeaturesTrader CatNessuna valutazione finora

- Pruebas y Mantenimiento Automático Centralizado para Detectores de Humo Direccionales Vesda VeaDocumento50 paginePruebas y Mantenimiento Automático Centralizado para Detectores de Humo Direccionales Vesda Veasanti0305Nessuna valutazione finora

- Sample Paper English: Kendriya Vidyalaya SangathanDocumento7 pagineSample Paper English: Kendriya Vidyalaya SangathanVines and ScienceNessuna valutazione finora

- Bleeding Disorders and Periodontology: P V & K PDocumento13 pagineBleeding Disorders and Periodontology: P V & K PAdyas AdrianaNessuna valutazione finora

- Kingspan 30 GSNDocumento1 paginaKingspan 30 GSNNoella AguiarNessuna valutazione finora

- Federal Bylaw 12 Air Pollution 2006 English Translation v2 OCRDocumento63 pagineFederal Bylaw 12 Air Pollution 2006 English Translation v2 OCRIsmail SultanNessuna valutazione finora

- Strength of Materials: 2. Assume Missing Data, If Any, SuitablyDocumento2 pagineStrength of Materials: 2. Assume Missing Data, If Any, SuitablynvnrevNessuna valutazione finora

- RB in Poultry Feed - 3Documento17 pagineRB in Poultry Feed - 3Vishwanath HebbiNessuna valutazione finora

- XVI - Magneticpropertiesofmanganese ContainingsolidsolutionsofbismuthorthoniobateBiNiO4Documento7 pagineXVI - Magneticpropertiesofmanganese ContainingsolidsolutionsofbismuthorthoniobateBiNiO4Chukwuebuka UgochukwuNessuna valutazione finora

- Las Mapeh 9 q2 w6 HealthDocumento8 pagineLas Mapeh 9 q2 w6 HealthJemalyn Hibaya Lasaca100% (1)

- Catalogo Smartline Transmitter Family Ferrum Energy 变送器Documento12 pagineCatalogo Smartline Transmitter Family Ferrum Energy 变送器peng chaowenNessuna valutazione finora

- Accesorios Del Lamborghini VenenoDocumento31 pagineAccesorios Del Lamborghini VenenoVicente Gil PalopNessuna valutazione finora

- Final Tana Beles - pdf2222Documento72 pagineFinal Tana Beles - pdf2222Tiruneh Yeneneh100% (1)

- PTFE HZ-2 HoerbigerDocumento2 paginePTFE HZ-2 HoerbigerТатьяна ВасильеваNessuna valutazione finora

- Philippine Airlines Reservation New Timings Dep - 230314 - 193643Documento7 paginePhilippine Airlines Reservation New Timings Dep - 230314 - 193643sophia buiserNessuna valutazione finora

- Transient Stability of A Multi Machine Power System: Devender Kumar, Balwinder Singh SurjanDocumento4 pagineTransient Stability of A Multi Machine Power System: Devender Kumar, Balwinder Singh SurjanVerruumm AmineNessuna valutazione finora

- Fire AlarmDocumento18 pagineFire AlarmgauriNessuna valutazione finora

- Manual de Servico Samsung Sgh-I677-Eplis-11Documento10 pagineManual de Servico Samsung Sgh-I677-Eplis-11Anselmo Antunes0% (1)

- IJHIM 6 - Nur Husnina (36 SD 42)Documento7 pagineIJHIM 6 - Nur Husnina (36 SD 42)RSU Sayang BundaNessuna valutazione finora

- Government Schemes: Ministry of Agriculture and Farmers' WelfareDocumento29 pagineGovernment Schemes: Ministry of Agriculture and Farmers' WelfareDushyant MudgalNessuna valutazione finora

- Part 7 Mean Field TheoryDocumento40 paginePart 7 Mean Field TheoryOmegaUserNessuna valutazione finora

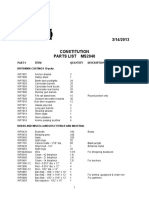

- MS2040 Constitution Parts ListDocumento6 pagineMS2040 Constitution Parts ListTemptationNessuna valutazione finora

- Middle East ManufacturerDocumento6 pagineMiddle East Manufacturerhsco rdNessuna valutazione finora