Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Food Processor Ž

Caricato da

Andrei Și Mihaela GeantăCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Food Processor Ž

Caricato da

Andrei Și Mihaela GeantăCopyright:

Formati disponibili

Service Documentation

Market Release 4/97

Braun CombiMax

K 650

3205

3205

BINC Rev: 4/97

Service Documentation

Exploded Drawing

3205

BAG Rev: 11/96

3205 - 2

BINC Rev: 4/97

Service Documentation

Spare Parts List

3205

BAG Rev: 1/97

Pos. No.

Part Description

1

2

3

4

5

7

9

10

11

12

13

14

15

Cover

Return spring

Leg spring

Lever

Switching PCB

Coupling

Housing K 650

Setting knob

Switch knob

Button

Pressure spring

Spring

O-ring

3205 - 3

Part Number

3205627

3205029

3202014

3205017

3205641

3205053

3205636

3205629

3202628

3202012

3210004

3205016

3205055

BINC Rev: 4/97

Service Documentation

Exploded Drawing

3205

BAG Rev: 11/96

3205 - 4

BINC Rev: 4/97

Service Documentation

Spare Parts List

3205

BAG Rev: 1/97

Pos. No.

Part Description

16

17

18

19

20

20

20

20

20

21

22

23

24

25

28

29

30

31

32

33

34

35

36

37

38

Spring

Carbon brush

Motor cpl.

Ferrite tube

Wiring, black

Wiring, brown

Wiring, orange

Wiring, red

Wiring, blue

Cable support

Washer

Damper

Supporting frame

Screw

Gear wheel with shaft

Toothed belt

Screw

Cable clamp

Mains lead

Base

Rubber foot

Screw

Switch-PCB

Switch cam

Insulating tube

3205 - 5

Part Number

4227016

4227034

3205634

3205155

3205935

3205936

3205937

3205938

3205939

3205002

0111410

3205038

3205625

0033423

3202626

3205030

0028012

4206149

3205879

3205621

3205025

0033419

3205642

3205078

0818182

BINC Rev: 4/97

Service Documentation

Exploded Drawing

3205

BAG Rev: 11/96

3205 - 6

BINC Rev: 4/97

Service Documentation

Spare Parts List

3202

BAG Rev: 11/96

Pos. No.

Part Description

60

61

62

64

66

67

68

70

71

72

73

74

75

76

77

Pusher

Lid

Blade

Kneading hook

Safety cover

Whipping attachment

Bowl

Grating insert

Coarse slicing insert

Fine slicing insert

Coarse shredding insert

Fine shredding insert

Julienne insert

Insert carrier

French fries system

3205 - 7

Part Number

3200032

3200640

3200636

3200635

4293067

3200645

3200630

3200151

3200153

3200152

3200155

3200154

3200158

3200633

3200634

BINC Rev: 4/97

Service Documentation

Service Information

3205

BAG Rev: 2/97

Technical Data

Nominal voltage/frequency:

120V 60 Hz

Driving motor:

DC motor B2-DC

Nominal power:

approx. 600 W (load dependent)

No-load power:

approx. 100 - 140 Watts

No-load speed position 2:

No-load speed position 14:

approx. 240 - 300 r.p.m. at the bowl coupling

approx. 1850 - 2200 r.p.m. at the bowl coupling

Overload protection:

electronic controls, see use instructions

Mixing arm rotation:

approx. 14 - 130 r.p.m. mixing arm into the bowl

approx. 144 - 1320 r.p.m. whisk into the mixing arm

Length of mains lead:

approx. 1.30 m

Note about the screws

The special screws (25/35), can only be removed with a screw

driver furnished with a special blade insert. These special blade

inserts for the screwdriver can be ordered from the parts department.

Because of approval-board requirements and reasons of safety, only

the special screws (35) into the base plate must be used to avoid

tampering by un-authorized persons.

Note about the PCB

Attention, charging capacitor on the PCB (36) is charged, use a

resistor of 10-50 Ohms to discharge.

Note about the wiring

All connecting cables are provided with self-securing plugs. In order

be bent down slightly. These pins must not be deformed or broken

off. In case that the plug does not snap in correctly to the connecting

contact, a completely new cable must be used.

Note about the speed

It is not possible to adjust the speed. In case that the number of

revolutions does not correspond to the technical data, the device is

defective.

3205 - 8

BINC Rev: 4/97

Service Documentation

Service Information

3205

BAG Rev: 11/96

Dismantling Remove all supplementary parts from the device and turn the switch to the 0

position.

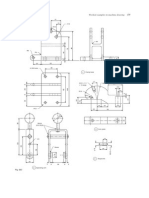

Exchangeable parts assembled in the housing upper part

Remove the cover (1) by means of a dismantling fork (already existing for K 1000),

see sketch 1.

Now, the leg spring (3), the lever (4) and the switching-PCB (5) can be reached.

Exchangeable Parts assembled in the housing lower part

For the sake of a better dismantling, the parts in the housing upper part must be

dismantled.

Take off the setting knob (10) and the switch knob (11) to the front. Remove the

button (12) and the pressure spring (13) to the front.

Place the supporting plate underneath the corresponding coupling shaft by inserting

the supporting bolt from the lower side into the small long hole (8 x 3 mm) in the

base plate, see sketch 2. Now, cleave the coupling (7) with an appropriate tool (e.g.

screwdriver size 4 - 5.5 mm) in the center of the top and remove it from the shaft.

Unscrew the screws (35) in the base (33) and remove the base.

The completely assembled carrier with motor can be removed from the housing.

All remaining parts which are as well shown in the exploded drawing can be dismantled and exchanged.

Before dismantling the gear wheel (28), the tension roller (27) and the motor (18)

the toothed belt (29) must be removed.

The safety lock (8) is inserted in the housing by means of two snap-in pins.

Reassembly To be performed in reversed order. However, attention must be paid to the

following points:

After reassembling the gear wheel (28) and the motor (18) the toothed belt must be

orderly positioned and the tension must be reapplied.

3205 - 9

BINC Rev: 4/97

Service Documentation

Service Information

3205

BAG Rev: 11/96

Attention must be paid to the reassembling position of the motor and to the cable

connection (+/-), see sketch 3.

Tension of the toothed belt: Slightly loosen the motor securing screws and displace the

motor (18) on the carrier. If the toothed belt is correctly tensioned, the motor securing

screws (25) will be tied. Please refer to sketch 4 for the tension value of the toothed

belt.

The both washers (22) must be attached to the shafts. The O-rings (15) must be

inserted into the housing.

Attach all dampers (23) for the carrier.

Insert the completely reassembled carrier into the housing (9).

Connect the leads to the switch-PCB (36), see sketch 3.

Insert the switch-PCB into the guides of the base plate and the switch cams (37), see

sketch 6.

Attach the base (33) and the rubber feet (34).

Place the supporting plate underneath the corresponding coupling shaft. Then, press

the coupling onto the shaft by slightly tapping against the embossing spike. The axial

free space of the coupling shafts must be 0.4 mm - 0.6 mm, see sketch 5 (symbolic

illustration). A smaller or larger axial free space may cause a defect of the appliance.

Insert the setting knob (10), and make sure that the potentiometer for the setting knob

axis is placed in the correct position.

Insert the spring (14) into the housing front.

Assemble the pressure spring (13), the button (12) and the switch knob (11), see

sketch 6.

Connect the leads to the switching-PCB (5) and insert the switching-PCB into the

housing upper part.

Insert the lever (4) and the leg spring (3), see sketch 7 (symbolic illustration).

Attach the cover (1) to the housing upper part until it snaps in.

3205 - 10

BINC Rev: 4/97

Service Documentation

Service Information

3205

BAG Rev: 2/97

Measuring points PCB

Function Check

In case the switching contacts on the PCBs (5 and 36) are closed and

a connecting wire at the motor (for example +) is taken off for the

measuring process.

N

Mains voltage

165-170 Volts DC voltage (intermittent 6-10 kHz)

165-170 Volts DC voltage (constant)

Mains voltage

Check the appliance in all switching positions and, if necessary,

attach the available supplementary parts.

Check the security locks with and without the complete bowl.

3205 - 11

BINC Rev: 4/97

Service Documentation

Reference Drawing

3205

BAG Rev: 11/96

3205 - 12

BINC Rev: 4/97

Service Documentation

Reference Drawing

3205

BAG Rev: 11/96

3205 - 13

BINC Rev: 4/97

Service Documentation

Service Information

3205

BAG Rev: 11/96

3205 - 14

BINC Rev: 4/97

Service Documentation

Reference Drawing

3205

BAG Rev: 11/96

3205 - 15

Potrebbero piacerti anche

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideDa EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideValutazione: 4.5 su 5 stelle4.5/5 (8)

- Engine Mechanical PDFDocumento115 pagineEngine Mechanical PDFAndrey GladyshevNessuna valutazione finora

- ZF6 Gen2 Zip PDFDocumento8 pagineZF6 Gen2 Zip PDFHumberto Cadori Filho100% (1)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceDa EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNessuna valutazione finora

- 3408E and 3412E Crankshaft Main Bearings - InstallDocumento6 pagine3408E and 3412E Crankshaft Main Bearings - InstallalonsoNessuna valutazione finora

- Montagem C7.1 Engine 320D2 L ExcavatorDocumento9 pagineMontagem C7.1 Engine 320D2 L ExcavatorRafa SantosNessuna valutazione finora

- Clio Sport Manual 3286aDocumento149 pagineClio Sport Manual 3286aOctavio LópezNessuna valutazione finora

- Service Bulletin: SUBJECT: 19XR Split Ring Diffuser Assembly and SetupDocumento18 pagineService Bulletin: SUBJECT: 19XR Split Ring Diffuser Assembly and SetupANGEL MURILLO100% (1)

- Piping Design Philosophy: Essar Oil Limited Vadinar Refinery ExpansionDocumento20 paginePiping Design Philosophy: Essar Oil Limited Vadinar Refinery ExpansionSami ThirunavukkarasuNessuna valutazione finora

- 2RZ 3RZ SCDocumento21 pagine2RZ 3RZ SCDiego Pillco0% (1)

- Construction and Manufacture of AutomobilesDa EverandConstruction and Manufacture of AutomobilesValutazione: 5 su 5 stelle5/5 (1)

- Wiring Diagram - C3Documento3 pagineWiring Diagram - C3dardo100% (1)

- Injector Installation 107 EngineDocumento5 pagineInjector Installation 107 EnginevalterripNessuna valutazione finora

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementDa EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNessuna valutazione finora

- Visual Inspection of The PistonDocumento53 pagineVisual Inspection of The Pistondonsallus100% (3)

- Machine Drawing Worked ExamplesDocumento2 pagineMachine Drawing Worked Exampleseuclidl75% (4)

- Steam TrapsDocumento10 pagineSteam Trapsmaninder_khasria100% (1)

- Braun Km32 Part ListlDocumento29 pagineBraun Km32 Part ListlNickolaos Mourikis100% (3)

- Cam Belt (M40)Documento11 pagineCam Belt (M40)Metin OmerNessuna valutazione finora

- MH5 Series Service ManualDocumento33 pagineMH5 Series Service Manualronald0% (1)

- Eaton: Model 74318 and 74348 Piston Motors Fixed Displacement, Valve Plate DesignDocumento9 pagineEaton: Model 74318 and 74348 Piston Motors Fixed Displacement, Valve Plate Designluisbravo1264Nessuna valutazione finora

- Solution Manual For Mechanical Vibration - William PalmDocumento20 pagineSolution Manual For Mechanical Vibration - William PalmAfshar Arabi0% (1)

- Food Processor ©Documento17 pagineFood Processor ©pukymottoNessuna valutazione finora

- Instructions: Replacement 5 In. Electronic Speedometer KitsDocumento6 pagineInstructions: Replacement 5 In. Electronic Speedometer KitsEddie SpeghettyNessuna valutazione finora

- Instruction Firefly Fitting J RangeDocumento12 pagineInstruction Firefly Fitting J RangeСергей сергеевичNessuna valutazione finora

- Swing Rack - InstallDocumento7 pagineSwing Rack - InstallGilney FreitasNessuna valutazione finora

- Fuel Injection Pump - InstallDocumento5 pagineFuel Injection Pump - InstallMaria PazNessuna valutazione finora

- Piston & Rod RemovalDocumento5 paginePiston & Rod RemovalsxturboNessuna valutazione finora

- c2152 GuideDocumento5 paginec2152 Guidevisual619Nessuna valutazione finora

- Engine Assembly Engine Assembly Removal and Installation: (QR25DE)Documento33 pagineEngine Assembly Engine Assembly Removal and Installation: (QR25DE)Ioana BocaniciuNessuna valutazione finora

- 5330 New Carriage Drive Motor ReplacementDocumento15 pagine5330 New Carriage Drive Motor ReplacementBrenda ClayNessuna valutazione finora

- Tech Bulletin 0112 - Creaking Clicking of FrameDocumento8 pagineTech Bulletin 0112 - Creaking Clicking of FrameRichard HagleyNessuna valutazione finora

- Recall Inspect/Replace HLA (Hydraulic Lash Adjusters)Documento10 pagineRecall Inspect/Replace HLA (Hydraulic Lash Adjusters)lionellin83Nessuna valutazione finora

- Install Cylinder Head on 3176C EngineDocumento7 pagineInstall Cylinder Head on 3176C EngineCésar PérezNessuna valutazione finora

- Pistons and Connecting Rods - DisassembleDocumento4 paginePistons and Connecting Rods - Disassembleeshopmanual limaNessuna valutazione finora

- Muncie PtoDocumento12 pagineMuncie Ptoneil superNessuna valutazione finora

- Removal Refitting Variable Geometry Turbocharger GARETTDocumento6 pagineRemoval Refitting Variable Geometry Turbocharger GARETTiliecNessuna valutazione finora

- Desmonte de Bomba de Inyeccion 3406cDocumento5 pagineDesmonte de Bomba de Inyeccion 3406cAnderson CamachoNessuna valutazione finora

- Cylinder Head - Install: Desmontagem e MontagemDocumento10 pagineCylinder Head - Install: Desmontagem e MontagemTatiano BrolloNessuna valutazione finora

- DR Service InstructionsDocumento4 pagineDR Service InstructionsCentral HydraulicsNessuna valutazione finora

- How To Fix Ignition Key / Heater Blower Problem On Xsara PicassoDocumento6 pagineHow To Fix Ignition Key / Heater Blower Problem On Xsara PicassoGoran Kosic100% (2)

- Throttle Valve With Actuator ReassemblyDocumento5 pagineThrottle Valve With Actuator ReassemblySreepriodas RoyNessuna valutazione finora

- Chapter 18 BrakeSystemsDocumento7 pagineChapter 18 BrakeSystemsMark Evan SalutinNessuna valutazione finora

- Service Manual Konica 1015Documento24 pagineService Manual Konica 1015Colesniuc Alin50% (2)

- How to Optimize Your Website for Search EnginesDocumento49 pagineHow to Optimize Your Website for Search EnginestfphoenixNessuna valutazione finora

- Torque Converter, Transmission and Bevel Pinion: Bottom Removal (Preferred Method)Documento12 pagineTorque Converter, Transmission and Bevel Pinion: Bottom Removal (Preferred Method)ait mimouneNessuna valutazione finora

- Pautas de Reutilización y Recuperación de Las Bombas Hidráulicas de VanesDocumento38 paginePautas de Reutilización y Recuperación de Las Bombas Hidráulicas de VanesJoel RodríguezNessuna valutazione finora

- 320D2 Excavator XBA00001-UP (MACHINE) POWERED BY C7.1 Engine (M0065912 - 13) - Systems & ComponentsDocumento8 pagine320D2 Excavator XBA00001-UP (MACHINE) POWERED BY C7.1 Engine (M0065912 - 13) - Systems & ComponentsYudi setiawanNessuna valutazione finora

- Radiator - Assemble: Previous ScreenDocumento8 pagineRadiator - Assemble: Previous ScreenKusuma JayaNessuna valutazione finora

- 2012 Dorado Pro Service ManualDocumento29 pagine2012 Dorado Pro Service ManualSea RidersNessuna valutazione finora

- Disassembling and Reassembling - Fixing Unit - TP07-168Documento9 pagineDisassembling and Reassembling - Fixing Unit - TP07-168shamilbasayevNessuna valutazione finora

- Coffeemaker ©Documento18 pagineCoffeemaker ©pukymottoNessuna valutazione finora

- 34-1 Shift Linkage ServiceDocumento18 pagine34-1 Shift Linkage Servicemefisto06cNessuna valutazione finora

- 3S AWD Trans Service ManualDocumento103 pagine3S AWD Trans Service ManualMatt BushnellNessuna valutazione finora

- HONDA2Documento8 pagineHONDA2Taller PNCNessuna valutazione finora

- Linotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeDa EverandLinotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeNessuna valutazione finora

- Motorcycle, Solo (Harley-Davidson Model WLA)Da EverandMotorcycle, Solo (Harley-Davidson Model WLA)Nessuna valutazione finora

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDa EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNessuna valutazione finora

- Hybrid Systems Based on Solid Oxide Fuel Cells: Modelling and DesignDa EverandHybrid Systems Based on Solid Oxide Fuel Cells: Modelling and DesignNessuna valutazione finora

- Rotavapor Buchi R-300Documento102 pagineRotavapor Buchi R-300ViridianaGarciaNessuna valutazione finora

- InstrumentationDocumento7 pagineInstrumentationEmmanuel Enriquez0% (1)

- ECE 306 Lab 4: Class AB Amplifier EfficiencyDocumento8 pagineECE 306 Lab 4: Class AB Amplifier EfficiencyShehzadtajNessuna valutazione finora

- Current Issues in Environmental Management in Australia: What Do People Think?Documento21 pagineCurrent Issues in Environmental Management in Australia: What Do People Think?Mahwestie PwarnasoekmaNessuna valutazione finora

- Dsi - Eds Solar Thermal - Did1050enDocumento2 pagineDsi - Eds Solar Thermal - Did1050eningrcNessuna valutazione finora

- Part 7 RCM Pump Reliability 33Documento33 paginePart 7 RCM Pump Reliability 33Aenur RofiiqNessuna valutazione finora

- WEG w22 Three Phase Electric MotorDocumento44 pagineWEG w22 Three Phase Electric MotorMATIAS GODOYNessuna valutazione finora

- MD Class Test 1Documento5 pagineMD Class Test 1Sambit Das0% (1)

- LESCO - Web Bill-February 2023Documento2 pagineLESCO - Web Bill-February 2023MudassirNessuna valutazione finora

- FisherLabs tw6 PDFDocumento24 pagineFisherLabs tw6 PDFJorge B. Briceño GomezNessuna valutazione finora

- Ho-SolarToday-April13 - v2Documento4 pagineHo-SolarToday-April13 - v2Danny Sánchez YánezNessuna valutazione finora

- Filipinnovation Publication v02Documento15 pagineFilipinnovation Publication v02ajesgNessuna valutazione finora

- India Genset DemandDocumento139 pagineIndia Genset DemandYanyan2009Nessuna valutazione finora

- Icl7660 PDFDocumento11 pagineIcl7660 PDFfran01334Nessuna valutazione finora

- Energy StarDocumento2 pagineEnergy StarsandyolkowskiNessuna valutazione finora

- Compressible Flow + Fanno Lines For Different Mass FluxesDocumento135 pagineCompressible Flow + Fanno Lines For Different Mass Fluxesmyself_riteshNessuna valutazione finora

- Grid Code-Chapter10Documento36 pagineGrid Code-Chapter10Xavier Aldrin Abanilla AustriaNessuna valutazione finora

- Hooke's Law Lab ExplainedDocumento13 pagineHooke's Law Lab ExplainednmadakiNessuna valutazione finora

- 4 RotationDocumento121 pagine4 RotationMarcus PoonNessuna valutazione finora

- Color Kinetics Inc b2bDocumento8 pagineColor Kinetics Inc b2bKaushal RaiNessuna valutazione finora

- Castell Switchgear Applications GuideDocumento20 pagineCastell Switchgear Applications GuideAnonymous w63sFQiQNessuna valutazione finora

- Rolling Mill Shutdown Report Aug-Sept 2022Documento3 pagineRolling Mill Shutdown Report Aug-Sept 2022ravi kumarNessuna valutazione finora

- LED Signalling Handbook CatalogueDocumento31 pagineLED Signalling Handbook CatalogueSteven David Bates100% (1)

- Exercises On Design of Biogas PlantDocumento2 pagineExercises On Design of Biogas Plantمحمود صالح محمود عليNessuna valutazione finora

- b8 Photosynthesis Mark SchemeDocumento20 pagineb8 Photosynthesis Mark Schememuhammedinshal04Nessuna valutazione finora

- Pro E System - ABBDocumento12 paginePro E System - ABBJhonSitanala100% (1)