Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

NuFlo Liquid Turbine Flowmeters

Caricato da

phostyCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

NuFlo Liquid Turbine Flowmeters

Caricato da

phostyCopyright:

Formati disponibili

MEASUREMENT SYSTEMS

NUFLO

Liquid Turbine

Flowmeters

Accurate Flow Measurement

In 1957, this flowmeter was developed with a tungsten-carbide shaft and bearing to withstand the rugged conditions of the oil

field. Over the years, it has earned an unsurpassed reputation for withstanding severe punishment while maintaining operational

and measurement integrity. Today, it remains a bestseller among Camerons NuFlo liquid measurement products.

NuFlo turbine flowmeters indicate flow rate and measure total throughput of a liquid line. As liquid flows through the meter and

over the rotor, the rotor turns at a speed that is directly proportional to the flow rate. A magnetic pickup senses the rotor blades as

they pass and generates an electrical (sine wave) signal. These electrical pulses are then transmitted to the flow measurement

readout equipment.

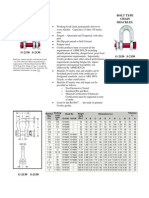

First Class Design Delivers First Class Performance

4

1. Permanent conduit connection is standard.

2. ROTOR is pitched and pre-calibrated to determine accuracy.

3. END CONNECTIONS available, flanged or threaded,

standard or special.

4. FLOW VANES increase performance at low rates.

5. FLOW VANE HUB supports rotor assembly.

6. ROTOR SHAFT, BEARINGS, AND THRUST BALL are made of

tungsten carbide for long service without lubrication other

than by the liquid being measured.

7. RETAINING RINGS make disassembly easy.

8. FLOWMETER BODY is sturdy, one-piece construction,

precision finished.

Applications

for applications where higher accuracy is not required. For

higher accuracy applications, an Industrial Grade meter can be

used. Such meters can achieve even greater accuracy if the

range of the flow through the meter is specified.

Cameron offers turbine flowmeters in a variety of end

connections and accuracy levels. Typical applications are:

Water-injection measurement

Heater treaters

Test and production separators

Disposal wells

CO2 injection

Steam generator fuel and feed water

Metering liquid fertilizer

Water, fuel, and chemical measurement in plant settings

Chemical tank loading and unloading

Measuring liquid propane

Insitu mining and leaching

Accuracy

NuFlo meters are classified as Standard Grade and Industrial

Grade, based on the linearity of the meter. The Standard

Grade meter provides a cost-effective measurement solution

Meter Grade

Linearity

Repeatability

Standard*

1% of reading

0.05%

Industrial*

0.5% of reading

0.02%

Enhanced accuracy

Consult factory

Consult factory

* For 3/8 in. meters, linearity is 2% of reading (standard) and 1% of

reading (industrial).

Temperature Range (magnetic pickup)

Temperature Range

Flowmeter Size

Standard

-67 to 225F -55 to 107C

3/8 in. through 3/4 in.

Standard

-67 to 250F -55 to 121C

7/8 in. through 8 in.

Medium

-67 to 450F -55 to 232C

all sizes

Note: Consult Cameron's Measurement Systems division for any use of turbine

flowmeters above 450F (232C).

MEASUREMENT SYSTEMS

Compliances

Benefits

CSA certified for hazardous areas, Class I, Div. 1,

Groups A, B, C, D

Meters with maximum working pressures below 7500 psi

are compliant with ANSI 12.27.01-2003 Single Seal

EZ-IN meters and 1502 WECO union meters available

with CE mark for Pressure Equipment Directive

(PED, 97/23/EC)

Meter Body (Standard)

Meter Body (High Pressure)

Vanes

Rotor

Shaft & Bearings

Accurate and repeatable measurement

An economical solution for turbine flowmeter applications

Easy installation and a variety of end connections

Minimum maintenance required

Long service life even in severe applications

Meter Size Selection

Flowmeter size selection should be based on the instantaneous

flow rate of the line into which the meter will be mounted.

Meter size should never be based on the nominal piping size

of the installation. Refer to the Linear Flow Range chart below

for meter size selection. The meter will remain accurate at flow

rates higher than its rating, but bearing wear and pressure

drop across the meter can shorten the life span of the meter.

NuFlo flowmeters can be over-ranged by 10% for short

periods without damage.

Materials of Construction

Grade 316L stainless steel*

A286 stainless steel*

Grade 316L stainless steel

CD-4MCu

Tungsten Carbide

* Traceability of pressure-containing components available on request..

Optional Materials

Shaft

Binderless carbide for

enhanced corrosion resistance

to selected chemicals

Silver brazing to withstand

temperatures to 550F and

chemicals that attack epoxy

bonding bearing materials

Nickel plating for enhanced

corrosion resistance to selected

chemicals (especially acids that

corrode ferrous materials)

Shaft & Bearings

Rotor

Installation

The meter should be installed with the arrow on the meter

body corresponding to flow direction of the line.

A 10-diameter length of straight unrestricted pipe must be

upstream and a 5-diameter length of straight unrestricted

pipe must be downstream of the flowmeter. Both pipe

sections should be the same nominal pipe size as the

flowmeters end connection.

Throttling/control valves should be located downstream of

the flowmeter.

Linear Flow Range (1, 2, 3)

Nominal (2)

Calibration Factor

Flowmeter

size (3)

mm

3/8

10

0.3 - 3

1/2

13

0.75 - 7.5

3/4

19

2 - 15

7/8

22

3 - 30

25

5 - 50

1-1/2

38

15 - 180

51

40 - 400

GPM

m /HR

3

0.068 - 0.68

BPD

Pulses

Gallon

Pulses x

1000/m3

Maximum

Output

Frequency

Pulses/Sec

P at Maximum

Flow (2)

psi

4.0

kPa

10 - 100

22000

(5812)

1100

28

0.17 - 1.70

25 - 250

14500

(3830)

1815

12.0

83

0.45 - 3.41

68 - 515

2950

(780)

740

18.0

124

0.68 - 6.81

100 - 1000

2350

(621)

1175

20.0

138

1.14 - 11.36

170 - 1700

900

(238)

750

20.0

138

3.41 - 40.88

515 - 6000

325

(86)

975

16.0

110

9.09 - 90.85

1300 - 13000

55

(14.5)

365

22.0

152

76

80 - 800

18.16 - 181.66

2750 - 27500

57

(15.2)

760

20.0

138

102

100 - 1200

22.71 - 272.55

3400 - 41000

30

(7.9)

600

10.0

69

152

250 - 2500

56.78 - 567.82

8600 - 86000

(1.8)

290

10.0

203

350 - 3500

79.49 - 794.94

12000 - 120000

(.8)

175

6.0

41

1. The linear flow range of liquids with non-lubricating characteristics is limited to the upper 60% of rating.

2. Based on water.

3. Consult Cameron's Measurement Systems division for engineering assistance with applications involving liquids of viscosities greater than 5 centistokes on 3/8-in. through

3/4-in. meters.

Conduit Thread Data

Threaded (NPT) End Connection

Conduit threads are 1 in. NPT and are rated for -20F to

450F (-28.8C to 232C).

Consult Cameron's Measurement Systems division for

turbine flowmeter applications requiring temperatures

above 450F (232C).

Threaded meter sizes range from 3/8-in. to 2-in.

Meter sizes from 3/8-in. to 1-in. pipe all have 1-in. NPT end

connections to simplify meter size changes.

All meter sizes other than the 2-in. have male threads.

End Connections

Flowmeter Size x

End Connection Size

in.

Length

mm

3/8 x 1 in.

4.0

102

7500

51.7

1/2 x 1 in.

4.0

102

7500

51.7

3/4 x 1 in.

4.0

102

7500

51.7

7/8 x 1 in.

4.0

102

5000

34.5

1 x 1 in.

4.0

102

5000

34.5

1-1/2 x 1-1/2 in.

6.0

152

5000

34.5

1-1/2 x 2 in.

6.0

152

5000

34.5

2 x 2 in.

10.0

254

5000

34.5

Flowmeter Size x

End Connection Size

in.

mm

3/8 x 1/2 in.*

5.0

127.0

1/2 x 1/2 in.*

5.0

127.0

NuFlo flowmeters are available in a variety of end connections:

threaded

grooved

flanged

EZ-IN

WECO 1502

Flanged End Connection

Turbine flowmeters with flanged end connections are available

in both raised-face (RF) models and ring-type joint (RTJ)

models. Flanged materials can be carbon steel or stainless

steel. All flanged NuFlo meters are equipped with slip-on

flanges, which are then welded to the outside of the meter

rather than being welded to the end of the meter body.

Thus, the flange never comes into contact with the fluid

being measured. The flanges are designed to mate with

ANSI B16.5 flanges.

Working Pressure

psi

MPa

Length

3/4 x 3/4 in.*

5.0

127.0

7/8 x 1 in.

6.0

152.4

1 x 1 in.

6.0

152.4

1-1/2 x 1-1/2 in.

7.0

177.8

2 x 2 in.

8.5

215.9

3 x 3 in.**

10.0

254.0

4 x 4 in.

12.0

304.8

6 x 6 in.***

12.0

304.8

8 x 8 in.***

12.0

304.8

Flange Pressure Rating

* 3/8 in. through

3/4 in. 900#,

1500#, 2500#

is 6-1/4 in.

(158.8 mm)

** 3 in. 2500# is

12 in. (304.8 mm)

*** 6 in. and 8 in.

2500# is 14 in.

(355.6 mm)

CS = Carbon Steel SS = Stainless Steel

Flange Classification

150 #

Flange Material

CS

300 #

600 #

900 #

1500 #

2500 #

SS

CS

SS

CS

SS

CS

SS

CS

SS

CS

SS

1480

1440

2220

2160

3705

3600

6170

6000

Design-Operating Temperature Range

-20 to 100 F

Max

(-28.8 to

Working

37.7 C )

Pressure

-20 to 200 F

Max

(-28.8 to

Working

93.3 C )

Pressure

-20 to 400 F

Max

(-28.8 to

Working

204.4 C )

Pressure

-20 to 450 F

Max

(-28.8 to

Working

232 C )

Pressure

psi

285

275

740

720

mPa

1.96

1.89

5.10

4.96

10.2

9.92

15.3

14.9

25.5

24.8

42.5

41.3

psi

260

235

680

600

1360

1200

2035

1800

3395

3000

5655

5000

mPa

1.79

1.62

4.69

4.14

9.38

8.27

14.03

12.41

23.4

20.68

38.99

34.47

psi

200

195

635

495

1265

995

1900

1490

3170

2485

5280

4140

mPa

1.38

1.34

4.38

3.41

8.72

6.86

13.1

10.27

21.8

17.13

36.4

28.54

psi

185

183

620

480

1235

963

1855

1443

3093

2408

5153

4010

mPa

1.28

1.26

4.27

3.31

8.52

6.64

12.65

9.95

21.33

16.60

35.53

27.65

Test Pressure: 1.5 times maximum working pressure at -20 to 100 F (-28.8 to 37.7 C)

MEASUREMENT SYSTEMS

Grooved End Connection

WECO 1502 Union End Connection

Flowmeters with grooved end connections are available in

7/8-in. through 8-in. sizes.

Flowmeters with 1502 end connections are commonly used

in high-pressure oilwell service applications. Meter sizes 1,

11/2 and 2 have 2 union end connections with a wing nut

on one end and thread on the other end. The 3" meters have

3" union end connections with the option of a wing nut on

one end and thread on the other, or threads on both ends.

All 1502 union end meters have two pickup adapters.

Flowmeter Size x

End Connection Size

in.

Length

mm

7/8 x 1 in.

4.0

102

Working Pressure

psi

MPa

1000

6.9

1 x 1 in.

4.0

102

1000

6.9

1-1/2 x 1-1/2 in.

6.0

152

1000

6.9

1-1/2 x 2 in.

6.0

152

1000

6.9

1-1/2 x 2 in.

6.0

152

2500

17.2

2 x 2-1/2 in.

10.0

254

1000

6.9

3 x 3 in.

12.5

318

1000

6.9

4 x 4 in.

12.0

305

1000

6.9

6 x 6 in.

12.0

305

800

5.5

Flowmeter Size x

End Connection Size

in.

Length

mm

Working Pressure

psi

MPa

1 x 2 in.

8.00

203.3

15000

103

1-1/2 x 2 in.

8.60

218.4

15000

103

2 x 2 in.

9.00

228.6

15000

103

3 x 3 in.

13.0

330.2

15000

103

WECO is a federally registered trademark of FMC Technologies, Inc.

8 x 8 in.

12.0

305

EZ-IN End Connection

Series BF turbine flowmeters with EZ-IN

connections provide a cost-effective

alternative to typical flanged-meter

applications. Series BF meters with

EZ-IN connections offer the accuracy,

rugged construction, and maintenancefree operation of conventional NuFlo

flowmeters plus the following

advantages:

Lower installation cost.

Less expensive than a conventional,

flanged meter.

Spreader nuts enable easy removal

and inspection.

The raised-face EZ-IN meter will

mate to any flange rated ANSI 150#

to 1500#. The ring-joint (RTJ)

version will mate to ANSI 900#,

1500# or 2500# RTJ flange. Specify

flange type when ordering.

CE-marked 8 x 8-in. EZ-IN RF

requires special centering rings.

Specialized Flowmeters

High-pressure

CO2

Corrosive-service

Nitrogen

Cement-slurry

Drilling fluids

800

5.5

Flowmeter Size x

End Connection Size

1 in.

Raised Face Flange Lengths, in. (mm)

2 in.

3 in.

4 in.

6 in.

3/8 x 1 in.

4.0 (102)

3/8 x 2 in.

2.5 (63.5)

1/2 x 1 in.

4.0 (102)

1/2 x 2 in.

2.5 (63.5)

3/4 x 1 in.

4.0 (102)

3/4 x 2 in.

2.5 (63.5)

7/8 x 1 in.

4.0 (102)

7/8 x 2 in.

2.5 (63.5)

1 x 1 in.

4.0 (102)

1 x 2 in.

2.5 (63.5)

1-1/2 x 2 in.

2.5 (63.5)

2 x 2 in.

2.5 (63.5)

3 x 3 in.

4.25 (108)

4 x 4 in.

5.0 (127)

6 x 6 in.

5.75 (146.1)

8 x 8 in.

6.25 (158.8)

1 x 2 in.

3.5 (88.9)

1-1/2 x 2 in.

3.5 (88.9)

2 x 2 in.

3.5 (88.9)

3 x 3 in.

4.25 (108)

4 x 4 in.

5.0 (127)

6 x 6 in.

5.75 (146.1)

8 x 8 in.

6.25 (158.8)

8 in.

Ring Joint Flange Lengths, in. (mm)

Contact Cameron's Measurement

Systems division for application

assistance.

MEASUREMENT SYSTEMS

Pressure Drop Curve for NuFlo Turbine Flowmeters

Flow Rate -BPD

30

10

50

100

500 1,000

5,000 10,000

50,000 100,000

(206.84)

10

(68.95)

Pressure Drop - PSI (kPa)

(34.47)

1

(6.90)

0.5

3/ 4"

(3.45)

7/ 8" 1 "

0.1

1/ 2"

(.690)

11/ 2"

2"

3"

4"

0.05

(.345)

6" 8"

3/ 8"

0.01

(.069) 0.1

(.02)

0.5

(.11)

(.23)

10

(1.14) (2.27)

100

500 1000

5000

(11.36) (22.71)

50

(113.6) (227.1)

(1136.4)

Flow Rate - GPM (m3/hr)

(Fluid is water @ 68F)

Companion readout

instruments for NuFlo turbine

flowmeters are also available.

MEASUREMENT SYSTEMS

HOUSTON

HEAD OFFICE

2 81 . 582. 9500

NORTH

AMERICA

1. 800. 65 4 . 3 7 6 0

ms-us @ c-a-m.com

ASIA

PACIFIC

+603.5569.0501

ms-kl@c-a-m.com

U S A C A N A D A U K C H I N A U A E A L G E R I A M A L AY S I A I N D I A K E N YA

TUR-LIQ NF00001 1001 Copyright 2010 Cameron International Corp. All Rights Reserved.

EUROPE,

MIDDLE EAST

& AFRICA

+ 4 4 . 1 2 4 3 .8 2 6 7 4 1

ms-uk@c-a-m.com

w w w. c - a - m . c o m / f l o

Potrebbero piacerti anche

- WS-600SH-OMM For PPS3228383 PDFDocumento46 pagineWS-600SH-OMM For PPS3228383 PDFAndres NavarroNessuna valutazione finora

- 01 - ValvesDocumento25 pagine01 - ValvesMahmoud Ahmed Ali Abdelrazik100% (1)

- Foss & Gaul PDFDocumento17 pagineFoss & Gaul PDFnicolasbelliniNessuna valutazione finora

- Flodri CatalogDocumento4 pagineFlodri CatalogphostyNessuna valutazione finora

- MSS SP-68 High Pressure Butterfly Valves With Offset Design PDFDocumento9 pagineMSS SP-68 High Pressure Butterfly Valves With Offset Design PDFmohamed ahmedNessuna valutazione finora

- Ledeen GS, SY, VA Series Installation ManualDocumento27 pagineLedeen GS, SY, VA Series Installation ManualJors SanzNessuna valutazione finora

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryDa EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNessuna valutazione finora

- Section 34 - Sight GlassDocumento27 pagineSection 34 - Sight GlasshammamiNessuna valutazione finora

- Turbine Flowmeters-Commonly Asked Questions and Answers: For Chemical Composition Information.)Documento8 pagineTurbine Flowmeters-Commonly Asked Questions and Answers: For Chemical Composition Information.)Alexander KlmNessuna valutazione finora

- SPM Full Bore Emergency Unloading Valve Manual PDFDocumento9 pagineSPM Full Bore Emergency Unloading Valve Manual PDFPablo SotoNessuna valutazione finora

- Ees ExampleDocumento12 pagineEes ExamplesbjNessuna valutazione finora

- Oilfield Processing Measurement and Control Oil and Gas SeparationDocumento8 pagineOilfield Processing Measurement and Control Oil and Gas SeparationAnonymous 8te2h1Nessuna valutazione finora

- Crosby ShacklesDocumento6 pagineCrosby Shacklessabah8800Nessuna valutazione finora

- 1290 RegulatorsDocumento3 pagine1290 RegulatorsPitichai PakornrersiriNessuna valutazione finora

- 154 HP Skid Mounted HPUDocumento2 pagine154 HP Skid Mounted HPUYadi KusmayadiNessuna valutazione finora

- Den Con CatalogDocumento36 pagineDen Con Catalogbaskaran vNessuna valutazione finora

- Piping: Wing Union ConnectionsDocumento8 paginePiping: Wing Union ConnectionsMahmoud Ahmed Ali AbdelrazikNessuna valutazione finora

- Heat Rejection and Coolant NotesDocumento10 pagineHeat Rejection and Coolant NotesMohamed HamedNessuna valutazione finora

- Presentation CVM Zwick PDFDocumento19 paginePresentation CVM Zwick PDFteacgNessuna valutazione finora

- Operation and Maintenance Manual Double Pump Skid B01!00!073 - A英文说明书Documento57 pagineOperation and Maintenance Manual Double Pump Skid B01!00!073 - A英文说明书Doni Kurniawan100% (1)

- Oil Field ManagerDocumento3 pagineOil Field ManagerWalter Eloy Ramirez CarranzaNessuna valutazione finora

- Bettis Service Instructions For Hd732-s HydraulicDocumento27 pagineBettis Service Instructions For Hd732-s Hydraulicrangga advNessuna valutazione finora

- ActuationDocumento12 pagineActuationZeeshan KhanNessuna valutazione finora

- Manual Embudo SidewinderDocumento18 pagineManual Embudo SidewinderHugo VillcaNessuna valutazione finora

- SPE - 22559 Advancements in Dynamic-Kill Calculations For Blowout Wells - G E KoubaDocumento10 pagineSPE - 22559 Advancements in Dynamic-Kill Calculations For Blowout Wells - G E KoubaAsahel NuñezNessuna valutazione finora

- Megastream Control Valves: General InstructionsDocumento4 pagineMegastream Control Valves: General InstructionsCarlos Alberto Dum GomezNessuna valutazione finora

- An Explicit Equation For Friction Factor in PipeDocumento2 pagineAn Explicit Equation For Friction Factor in PipeRiddhesh PatelNessuna valutazione finora

- Motor Standard, IP55, (Ah 180 - 315) - ENDocumento60 pagineMotor Standard, IP55, (Ah 180 - 315) - ENkfathi55Nessuna valutazione finora

- PSL DefinationDocumento2 paginePSL DefinationRamesh KrishnanNessuna valutazione finora

- 8 Dynamic Well SimulationsDocumento24 pagine8 Dynamic Well SimulationsBAGHFAY16Nessuna valutazione finora

- Nuflo Turbine Meter Manual PDFDocumento16 pagineNuflo Turbine Meter Manual PDFfatsfinderNessuna valutazione finora

- N2 Triplex Pump - 1Documento6 pagineN2 Triplex Pump - 1Ibrahim AhmedNessuna valutazione finora

- Datasheet Foxboro 13A 13HA 15A - 18230465Documento12 pagineDatasheet Foxboro 13A 13HA 15A - 18230465Emiro Revilla CatariNessuna valutazione finora

- Manual XrodDocumento80 pagineManual Xrodalexverde3Nessuna valutazione finora

- Swagelok Fittings SpecificationsDocumento3 pagineSwagelok Fittings SpecificationsSam Chong Ks100% (1)

- Section 9, Rigging Up and DownDocumento24 pagineSection 9, Rigging Up and Downhammami100% (1)

- C Tuthill PDFDocumento37 pagineC Tuthill PDFRaulEfrainCharrezCastilloNessuna valutazione finora

- Hydrocyclones: D-Sa N Der D-SilterDocumento10 pagineHydrocyclones: D-Sa N Der D-Siltersaa6383Nessuna valutazione finora

- Well-Vac v.2 2-18Documento133 pagineWell-Vac v.2 2-18Nerymar Coromoto Parra BustamanteNessuna valutazione finora

- Cooling Circuit Installation and MaintenanceDocumento1 paginaCooling Circuit Installation and MaintenanceMohamed HamedNessuna valutazione finora

- PVT Data Useful For Design of Oil Production FacilitiesDocumento4 paginePVT Data Useful For Design of Oil Production FacilitiesBesan LaduNessuna valutazione finora

- LPR-N Tester Valve Funcionamiento 1Documento33 pagineLPR-N Tester Valve Funcionamiento 1Александр КинтероNessuna valutazione finora

- Hydroseal Series 3500 Pilot Operated Relief ValvesDocumento8 pagineHydroseal Series 3500 Pilot Operated Relief Valvesprihartono_diasNessuna valutazione finora

- VIBXPERT Catalog - English PDFDocumento72 pagineVIBXPERT Catalog - English PDFMuammad SanwalNessuna valutazione finora

- 1 Meters For Liquids, Gases, and Solids in Suspension: Table 1: Applicability of Flow Metering TechnologiesDocumento15 pagine1 Meters For Liquids, Gases, and Solids in Suspension: Table 1: Applicability of Flow Metering Technologiespk_zhotNessuna valutazione finora

- 120 Inch Fore Pump and Worm Oil Pump ADocumento12 pagine120 Inch Fore Pump and Worm Oil Pump AcarlosorizabaNessuna valutazione finora

- JWS-340 Well Servicing Pump BrochureDocumento4 pagineJWS-340 Well Servicing Pump BrochureCesar MoraNessuna valutazione finora

- Safety For Hydraulics: Compac Type Proportional Valves Series CVDocumento32 pagineSafety For Hydraulics: Compac Type Proportional Valves Series CVthierrylindoNessuna valutazione finora

- Hoses and Couplings For Oil IndustryDocumento24 pagineHoses and Couplings For Oil IndustryGordan KanižajNessuna valutazione finora

- DTA - Dynamic Torque Anchor Technical DatasheetDocumento5 pagineDTA - Dynamic Torque Anchor Technical DatasheetEvolution Oil ToolsNessuna valutazione finora

- Reciprocating Pumps - NDPDDocumento2 pagineReciprocating Pumps - NDPDDhanny MiharjaNessuna valutazione finora

- SAIC-G-2017 Rev 0 - Mechanical & Chemical Cleaning of Lube Andor Seal Oil SystemDocumento3 pagineSAIC-G-2017 Rev 0 - Mechanical & Chemical Cleaning of Lube Andor Seal Oil Systemবিপ্লব পালNessuna valutazione finora

- Steel Bars, Carbon, Hot-Wrought, Special Quality: Standard Specification ForDocumento6 pagineSteel Bars, Carbon, Hot-Wrought, Special Quality: Standard Specification ForIngrid Tatiana RojasNessuna valutazione finora

- A Simple Model For Annular Two Phase Flow in WellboresDocumento8 pagineA Simple Model For Annular Two Phase Flow in WellboresMohammad HaqNessuna valutazione finora

- Beam Pump - Safe Operation Guideline PDFDocumento43 pagineBeam Pump - Safe Operation Guideline PDFwilzy74Nessuna valutazione finora

- Slug CatcherDocumento3 pagineSlug Catcherwkhan_55Nessuna valutazione finora

- Peso Tipo 40Documento118 paginePeso Tipo 40Miguel angel leon bautistaNessuna valutazione finora

- CV Control Solutions CatalogDocumento148 pagineCV Control Solutions CatalogAnoop ChulliyanNessuna valutazione finora

- Laminar Flow and Convective Transport Processes: Scaling Principles and Asymptotic AnalysisDa EverandLaminar Flow and Convective Transport Processes: Scaling Principles and Asymptotic AnalysisNessuna valutazione finora

- Senior Pump Operator: Passbooks Study GuideDa EverandSenior Pump Operator: Passbooks Study GuideNessuna valutazione finora

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationDa EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationNessuna valutazione finora

- ABSA 'The Pressure News' 1997-02 V2-Iss1Documento4 pagineABSA 'The Pressure News' 1997-02 V2-Iss1phostyNessuna valutazione finora

- Thermal Destruction of BenzeneDocumento1 paginaThermal Destruction of BenzenephostyNessuna valutazione finora

- CN Valve Sizing Tech Spec GEA31796C EnglishDocumento28 pagineCN Valve Sizing Tech Spec GEA31796C EnglishphostyNessuna valutazione finora

- HIPPSDocumento6 pagineHIPPSGhaya Bani Rushaid100% (2)

- Manual Bomba EspumaDocumento108 pagineManual Bomba EspumaFrancisco ManriquezNessuna valutazione finora

- Fire Safe Isolation Kit: Seal Tight. Seal SafeDocumento2 pagineFire Safe Isolation Kit: Seal Tight. Seal SafeAnonymous Dp4DdscGSNessuna valutazione finora

- Bombas Paletas VQ SimplesDocumento13 pagineBombas Paletas VQ Simplesona onainaNessuna valutazione finora

- TFCC-4: Heavy Duty PerformanceDocumento3 pagineTFCC-4: Heavy Duty PerformanceAmir50% (2)

- BS FlangeDocumento7 pagineBS FlangeMeleti Meleti MeletiouNessuna valutazione finora

- MSS SP-25 (2008)Documento27 pagineMSS SP-25 (2008)adprimNessuna valutazione finora

- Flanged X Flanged DBB Type X': General InformationDocumento2 pagineFlanged X Flanged DBB Type X': General InformationShahulNessuna valutazione finora

- Anderson Greenwood Series 60 andDocumento48 pagineAnderson Greenwood Series 60 andjairo moralesNessuna valutazione finora

- Visual Vessel DesignDocumento22 pagineVisual Vessel DesignRebecca CameronNessuna valutazione finora

- Fail Safe or TR RegulatorDocumento2 pagineFail Safe or TR RegulatorYeit HauNessuna valutazione finora

- Wheel-Defects IRDocumento61 pagineWheel-Defects IRmajjisatNessuna valutazione finora

- Mark 57 Series: Externally Piloted Back Pressure RegulatorsDocumento4 pagineMark 57 Series: Externally Piloted Back Pressure Regulatorsbenzerga karimNessuna valutazione finora

- Katalog 2 enDocumento1.060 pagineKatalog 2 enmunhNessuna valutazione finora

- Papcel: Coach Agitators CA Main Parts AuxiliariesDocumento65 paginePapcel: Coach Agitators CA Main Parts AuxiliariesmiguelamenozaNessuna valutazione finora

- Yamaha Rhino 5b48 - 2008Documento86 pagineYamaha Rhino 5b48 - 2008Luis Reinaldo Ramirez ContrerasNessuna valutazione finora

- Orn471 BSL Forged Right Angle Beam Clamp Installation InstructionsDocumento4 pagineOrn471 BSL Forged Right Angle Beam Clamp Installation InstructionsNizam ShahNessuna valutazione finora

- XJ750MKDocumento61 pagineXJ750MKMike NorrisNessuna valutazione finora

- 15510Documento13 pagine15510uddinnadeemNessuna valutazione finora

- HFY-PIP-SP-00008 X Specification - For - Insulation - A-CommentedDocumento13 pagineHFY-PIP-SP-00008 X Specification - For - Insulation - A-CommentedVignesh PanchabakesanNessuna valutazione finora

- A 727 - A 727M - 02 Qtcyny9bnzi3tqDocumento4 pagineA 727 - A 727M - 02 Qtcyny9bnzi3tqalucard375Nessuna valutazione finora

- Design Calculations For Pressure VesselsDocumento54 pagineDesign Calculations For Pressure VesselsEdgar A. Arredondo QuirozNessuna valutazione finora

- Garlock Metallic Gasket CatalogDocumento46 pagineGarlock Metallic Gasket CatalogPeterSPNessuna valutazione finora

- Precision Meters: User ManualDocumento24 paginePrecision Meters: User ManualJuan Flores GraweNessuna valutazione finora

- Del OI ERHARD Nozzle Check Valve DN80 600 enDocumento18 pagineDel OI ERHARD Nozzle Check Valve DN80 600 enpppppp5Nessuna valutazione finora

- Hein Krimpenfort - TECNIFLOW Feluwa-RELAVES PERU 20 DEEVDocumento40 pagineHein Krimpenfort - TECNIFLOW Feluwa-RELAVES PERU 20 DEEVrolandoh1Nessuna valutazione finora

- Saic L 2015Documento8 pagineSaic L 2015Engr IrfanNessuna valutazione finora

- IPS-MBD20031-In-511B-Data Sheet of Level Gauge (Top Mounted) - ADocumento3 pagineIPS-MBD20031-In-511B-Data Sheet of Level Gauge (Top Mounted) - ANikhil KarkeraNessuna valutazione finora

- MEC-SPE - Air Cooled Heat ExchangersDocumento30 pagineMEC-SPE - Air Cooled Heat Exchangershasan_676489616Nessuna valutazione finora