Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

A Water Absorption Test For Concrete

Caricato da

khoagleTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

A Water Absorption Test For Concrete

Caricato da

khoagleCopyright:

Formati disponibili

Magazine of Concrete Research: Vol. 40, No.

143: June 1988

A water absorption test for concrete

S. Kelham

B L U EC I R C L EI N D U S T R I E SP L C *

SYNOPSIS

The durability of concrete near an exposed surface is

largely determined by the rate at which harmful agents

can penetrate into the concrete. This paper presents a

simple analysis of the penetration of' water into unsaturated concrete and describes a method by which the

material constant that determines the rate of penetration, the sorptivity, can be measured, together with the

effective porosity. The sorptivity is found to depend on

the permeability and porosity of the concrete and the

strength of capillary forces. The experimental results

conform well to thepredictions of the analysis and

signlJcant variations in sorptivity have been observed

for concretes containing cement replacement materials

and subject to dzfferent curing regimes.

Notation

A

cross-sectional area

of

(m'

flow

1

(Palm>

dp/dx

gradient

pressure

K

intrinsic

permeability

sample

of

material

(m')

m> sample 1 of

length

M

mass

(kg)

of sample

pressure

air

at sample

surface

(Pa)

Pcap mean effective capillary

pressure

(Pa)

air

pressure at air/water

interface

(Pa)

6,

pressure

water

at air/water

interface

waterpressure at samplesurface(Pa)

p,

mass flowof

rate

fluid

(kg/s)

Q

radius

capillary

(m)

r

m>

(PaS tension

surface

sorptivity

S

ea

*Blue Circle Industries PLC, BCC Technical Services Division,

305 London

Road,

Greenhithe, Kent DA9 SJQ, UK.

106

V

X

Z

Ap

rl

CJ

contact

time from

of water with

sample

volume

flow

rate

depth of penetration

effective porosity

(m3w

(m)

(% v/v)

capillary pressure difference

dynamic viscosity of fluid

density of fluid

angle of contact

(Pa>

(Pa S>

(kg/m3>

(rad)

(S)

Introduction

The effect ofthe qualityof concrete nearan exposed

surface on the durability of concrete structures is an

area of current interest"). Those properties controlling

the transport of aggressive materials into the bulk

of theconcrete orto the reinforcement,such

as

the permeability andsorptivity,are

of particular

imp~rtance'~,~'.

The rate at which unsaturated concreteabsorbs water in contact with its surface is

relevant to variousaspectsofdurability.

A large

number of test methods havebeenpublished

(e.g.

References 4-8) but none caneasily provide values for

the two basic parameters associated with absorption:

the mass of water which is required to saturate the

concrete-the effective porosity,and

the rate

penetration-the

of

sorptivity.

The ISATI4),Figg (water)@)and CAT@) methods are

based ontherateof

water absorption, whichis a

combination of the rate of penetration and the effective porosity. The two parameters cannot

be separated

because the volumeof

concretesaturatedduring

the test is not known. Ho et al.(7) measured the

penetration depth at various times directly by splitrequiring

ting

many

to

give reliable data.Methods for measuring the

gas

A water absorption test for concrete

permeability in unsaturated

concrete

and

water

permeability in saturated concrete arewell established

(e.g. Reference 9).

This paper presentsa simple analysis of absorption

and describes a method which enables the porosity

and sorptivity to be measured.

Theoretical model

The flow of a fluid throughaporous

usually follows Darcys law:

medium

Q = KAa(dp/dx)/V . . . . . . . . . . . (1)

where Q

K

A

mass flow rate of thefluid

= intrinsicpermeability of the medium

= cross-sectional

area of

flow

6,rl

= density and viscosity of the fluid

dp/dx = pressure gradient

This expressionis valid for laminar flow and where

the free path of the fluid molecules is small compared

with the pore size in the medium. Consider a cylinder

of concrete, cross-sectional areaA , length l, sealed on

its curved surface, in contact with water at one end

and open to the air at the other (Figure 1). At a time

t after coming into contact

with the concrete the water

will havepenetrated to somedepth x(t). To find

the rateat which x increases itis necessary to know the

pressure gradients within the sample.

Let P, be the

pressure -of the water in contact with the concrete

surface and P, that of the air at the other surface. At

the air/water interface within the sample the pressure

in the air (P,,) and water (P,,) will be different because

of capillary forces.

In a capillary of radius r the pressure difference

across the interface is given by:

P

where

2r

A = n?

2s cos 9/r . . . . . . . . . . . . . (2)

v,

Q , / ~ ,= [KA/V],I[(Pw- Plw)/xI.. . (3)

This mustbe equal to the volume rate of flow of the

air at the interface, which is given by

KA P,, - P, P,, -l

P,

. . . . . (4)

y

(=)(F).

where the term (P,, Pa)/2pI, is associated with

the compressibility of the air. Equating these flows

and using

- P

,, = Pcap(constant)and P, = P ,

(ignoring hydrostatic forces) leads to an expression

relating P,, and x . Becauseof the large difference

between the viscosities of air and waterP,, is found to

be significantly different from P, only for x less than

1/10. For such small values of x the assumption that

equilibrium flow conditions exist is probably invalid.

The high values of P,, predicted by the expression for

small values of x will not be observed because of the

compressibility of the air. We will therefore make the

approximation that P,, = P,. Equation (3) for the rate

of flow of water becomes

ea

surface tension

I3

= angle of contact

V,

To estimatethemagnitude

of this effect foran

air/water interface in concrete we take the radiusof a

largecapillarypore,

r, to be about 1

giving

P

(S

Figure 1: Cross-section of concrete cylinder considered in analysis.

MO x 1 0 3 ~ a

70 x 10-3N/m, cos 0

1)

This is equivalent to a headof about 14mof water.

Thus in many practical situations the capillary forces

will be the dominant driving forces in the absorption

of water by concrete. Hydrostatic pressuredifferences

will therefore be ignored in the analysis.

With reference to Figure 1 the pressures in the air

and water at the interface will be taken to differ by a

constantamount Pcaprthecapillarypressure.

It is

assumed that the concreteis sufficiently homogeneous

for PClpto be independent of x .

Water can be taken as an incompressible fluid and

its volume rate of flow, V,, is thus given by

K A P C a p / x.~.,. . . . . . . . . . ( 5 )

The volume of water required to saturate an element

of thickness dx is given by

dV

dxAz.. ............. (6)

where z is the effective porosity of the concrete,i.e. the

volume of water that unit volume of the concretewill

absorb in the given conditions.Thustherate

of

increase of x is given by

dxldt

V,/Az

KPcap/xztl,....... (7)

This may be integrated to give

x(t) = (2KPc,pt/zq,)~2

.......... (8)

The depthof penetration of water into unsaturated

concrete is thus proportional to the square root

of

time and the constant is known as the sorptivity, S.

S = ( 2 K P c , , / ~ ~ , ) 1. . .2. . . . . . . . (9)

The mass of the concrete cylinderat any time M ( t )

107

Magazine of Concrete Research: Vol. 40, No. 143: June 1988

is equal to the initial mass M(0) plus the mass of

absorbed water. Thus

+ Azo,x(t)

M(0) + AzowSt2... . . . . (10)

M ( t ) = M(0)

=

The sorptivity can thusbe derived from the slope of

a plot of mass vs square rootof time if the porosity is

known. If the absorption is allowed to continue until

the whole cylinder is saturated the porosity can be

obtainedfromthe

difference between thedryand

saturated weights.

z = (M(sat) - M(O))/Ala,. . . . . . . (1 1)

Experimental method

Figure 2 is a schematic drawing of an apparatus

designed to monitor theweight of a concrete cylinder

as it absorbs water under conditions corresponding

those considered in the preceding analysis. The sample

is in the form of a cylinder 150 mm diameter and

50 mm thick. The curved surface is sealed by painting

with bitumen and then covering with waterproof

adhesive tape. The top

surface is covered by a perspex

disc. The disc is sealed with grease to the edge of the

top surface of the sampleand tothe tape andencloses

an air gap of about 2 mm over the concrete surface. A

metal capillary connects this air gap to atmosphere.

The sample and cover are suspended in a sling from a

5 kg capacity load beam, the output of which can be

recorded with a microcomputer-based data logger. At

the startof the test,water is poured into the container

surrounding thesample to a depthof 50 mm above the

top surfaceof the sample. The capillary is 60 mm long

and therefore protrudesabovethe

surface of the

water. The topsurface of the sample thusremains dry

and open to the atmosphere, allowing air to escape as

water is absorbed through the lower surface of the

sample. The weight of the sample is monitored until

the rateof increase becomes very slow, which indicates

that the sample iseffectively saturated. The further

load beam

water

sample

Figure 2: Experimental arrangement.

108

slow increase in weight isassociated with movement of

water into less accessible pores and the flow of water

intothe space between the sample andthe cover

driven by the small (about 50 mm) pressure head. The

measured change in weight is actually the change in

buoyancy of the concrete as the water replaces air

within it. Since the initial weight of the sample in the

water can only be obtained by extrapolatingthe

measured results back to zero time, the weightof

absorbed water was obtained from initial and final

weighings in air. For homogeneous samples that give

very good agreement with the f 1 2 dependance, initial

and final weighings and two during the absorptionare

sufficient to calculate the sorptivity andporosity.

However, with saturation times varying between 2

hoursand several days (for well-cured concrete),

specifying times for taking measurements would need

care. Furthermore, theweight vs square root time plot

togives a useful indication of the homogeneity of the

concrete.

Experimental results

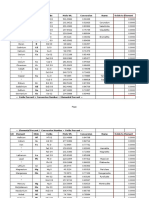

Examples of the results obtained on three mixes are

presented in Figures 3 and 4. The concretes were based

on a 1 : 2-5 : 3.5 (cement : sand :coarse aggregate) mix

with the water content gauged to give a slump of

60mm. Mix 1 contained OPC. In mix 2, 25% of the

OPC (w/w) was replaced by pulverized-fuel ash (pfa)

and in mix 3, 60% (w/w) was replaced by ground

granulatedblastfurnace slag (ggbs). One batch of

samples was de-moulded at 24 hours, cured in water

for 27 days, oven-dried at 105C for 6days and cooled

in a desiccator for l day before testing. The results,

shown in Figure 3, conform very closely to the square

root of time dependence over the whole period of

absorption and change rapidly to an almost constant

value when saturation is complete. Figure 4shows the

results obtained for the second batch of samples from

the same mixes. These were cured in air at 20C and

50% relative humidity for 27 days after de-moulding

at 24 hours. These samples were oven-dried in the

same way as the water-cured samples. The values

derived from these plots are given in Table 1. The

correlation coefficient for the least squares fit to the

linear portion of the plotis generally better than 0.999

for the water-cured samples but somewhat lower,

about 0.99, for the air-cured samples. This is due to

the inhomogeneities caused by the variable degree of

hydrationthroughthe

sample associated with air

curing.

The results forthe water-cured samples demonstrate the beneficial effects of pfa and ggbs hydration

on the transport properties of concrete, despite the

reduction in strength. The time taken for saturationto

a depth of 50mm is at least twice that for the OPC

concrete. The results for the air-cured samples show

the increased sensitivity of the concretes containing

A water absorption test for concrete

pfa or ggbs to poor curing. For the OPC concrete the

time taken to saturate the air-cured sample was half

that for the water-cured sample but for the concrete

containing ggbs the saturationtime was reduced by an

order of magnitude when the curing conditions were

changed. These results were obtained on single discs

from each mix and curing condition butsimilar results

were obtained for equivalent mixes based on 12 other

OPCS.

Application

The technique can be used, for example, to study

the effects of curingconditions,

mix design and

replacement of different levels of cement by secondary

materials, such as pulverized-fuel ash (pfa) and

ground granulated blastfurnace slag (ggbs), on effective porosityandsorptivity. An assessment can be

made of the quality of the surface layer of different

1.20

0

0

o o

l

2

TIME1/-

36

49

h/2

25

16

TIME - h

Figure 4: Experimental resuIts--air-cured concrete.

109

Magazine of Concrete Research: Vol. 40, No. 143: June 1988

T A B L E 1 : Experimental results.

Mix 1

Mix 2

Blend (w/w)

OPc

Water/cement ratio

Curing

Mix 3

0.59

Water

28 day strength (MPa)

44.0

Effective porosity (YO)

Sorptivity (mm/h)

Time to saturate 50mm (h)

12.1

14.3

75zzzaa+

40% OPC

60% ggbs

0.56

Air

Water

0.57

Air

38.6 39.2

12.8

12.9

12.3

20.0

9.9

24.6

4.1

6.2 12.225.5

Water

Air

38.2 31.4 18.9

13.1

13.6

7.6

28.4

43.3

3.1

REFERENCES

concretes designed to give thesame 28 day water1. DHIR, R. K., CHAN, Y. N. and HEWLETT, P. c. Near surface

cured strength.Although all thepresentworkhas

characteristics and durability of concrete: an initial appraisal.

been carried out oncast cylinders of 150 mm diameter,

MagazineofConcreteResearch.

Vol. 38, No. 134, March

similar results would be expected using specimens of

1986. pp. 54-6.

different shapes and sizes. Slices of cylindrical cores

2. THE CONCRETE SOCIETY. Permeability testing of site concrete

takenfromconcretestructures

should be suitable

-a review of methods and experience. Report of a Working

Party. Final draft. Permeability of concrete and its control.

subject to re-conditioning following the wet culling

London, The Concrete Society, 1985. pp. 1-68.

operations.

3. HO, D. W. S. and LEWIS, R. K. The water sorptivity of conWhile oven-drying is a quick andreproducible

cretes: the influence of constituents under continuous curing.

method of conditioning concrete, it is not suitable for

Durability of Building Materials. Vol. 4, 1987. pp. 241-52.

providing data directly applicable to concrete in the

4. BRITISH STANDARDS INSTITUTION. Methods of testing concrete

BS 1881: Part 5: Section 6: 1970. Testfor determining the

field. Some tests have been carried out on samples

initial surface absorption of concrete. Part 122: 1983. Method

cured at 20C and 50% relative humidity for 180 days.

for determination of water absorption.

The results were similar to those obtained after oven5 . RILEM RECOMMENDATIONS. CPC 11.1 Absorption of water by

drying of air-cured samples at 28 days, although there

immersion, CPC 11.2 Absorption of water by capillarity.

was even greater curvature on the

t* plots. Obviously

Materials and Structures: Research and Testing. Vol. 7, No.

40, July-August 1974. pp. 291-7. CPC 11.3 Absorption of

the variation in hydration through the sample is comwater by immersion under vacuum. Vol. 17, No. 101, Septempounded in this case by the variable degree of water

ber-October 1984. pp. 391-4. CPC 13.1 Test for the penretention.

etration of water under pressure on hardened concrete.

Conclusion

A simple analysis of the absorption of water into

unsaturated concrete hasbeen presented. The depthof

penetration is found to be proportional to the square

root of time and a method for determining the constant of proportionality, termed thesorptivity,has

been described. The experimental method includes the

measurement of the effective porosity of the sample.

The analysis shows that the square of the sorptivity is

proportionaltothe

intrinsic permeability of the

sample, the capillary forces and the inverse of the

effective porosity. The available experimental results

closely follow the formexpected from theanalysis and

the derived values for the sorptivity show significant

differences for concretes containing different cements

or subject to different curing regimes. Themethod

may therefore proveuseful in the study of the quality

of concrete surfaces subject to wet/dry cycling. The

sorptivity would seem particularly pertinent to reinforced concrete where the water might carry chloride

or other harmful ions into the concrete.

110

6.

7.

8.

9.

10.

Vol. 12, No. 69, May-June 1979. pp. 224-9.

FIGG, J . W. Methods of measuring air and water permeability

of concrete. Magazine of Concrete Research. Vol. 25, No. 85,

December 1973. pp. 213-219.

HO, D. W. S., HINCZAK, I., CONROY, J. I. and LEWIS, R. K.

Influence of slag cement on the water sorptivity of concrete.

Fly ash. silica fume, slag and natural pozzolans in concrete.

Detroit, American Concrete Institute, 1986. Vol. 2. pp. 146373. ACI SP91.

DHIR, R. K., HEWLETT, P. c. and CHAN, Y. N. Near-surface

characteristics of concrete: assessment and development of in

situ test methods. Magazine of Concrete Research. Vol. 39,

No. 141, December 1987. pp. 183-95.

BAMFORTH, P. B. The relationship between permeability

coefficients for concrete obtained using liquid and gas. Magazine of Concrete Research. Vol. 39, No. 138, March 1987.

pp. 3-1 I .

ODLER, I. and KOSTER, H. Investigations on the structure of

fully hydrated Portland cement and tricalcium silicate pastes.

I1 Total porosity and pore size distribution. Cement and

ConcreteResearch. Vol. 16, No. 6, November 1986. pp.

893-901.

Contributions discussing the above paper should

be in the handsof the

Editor not later than 31 December 1988.

Potrebbero piacerti anche

- ASTM C1556-11a - Determining Apparent Chloride Diffusion Coefficient by Bulk Diffusion PDFDocumento7 pagineASTM C1556-11a - Determining Apparent Chloride Diffusion Coefficient by Bulk Diffusion PDFjerin sam kurianNessuna valutazione finora

- ASTM C1403-13 Standard Test Method For Rate of Water AbsorptionDocumento4 pagineASTM C1403-13 Standard Test Method For Rate of Water AbsorptionEdwin R Ruiz100% (1)

- Astm C1611M-05Documento6 pagineAstm C1611M-05manil_5100% (2)

- New Ansi 118.15Documento2 pagineNew Ansi 118.15Tensile TestingNessuna valutazione finora

- Experiment 4 The Viscosity of FluidDocumento6 pagineExperiment 4 The Viscosity of FluidAzman ZaidiNessuna valutazione finora

- Seatwork 4Documento11 pagineSeatwork 4Emer67% (6)

- Fluid Mechanics 2Documento15 pagineFluid Mechanics 2ROMMEL BALLOCANAG IINessuna valutazione finora

- AAPG M67 Seals, Traps, & The Petroleum System PDFDocumento310 pagineAAPG M67 Seals, Traps, & The Petroleum System PDFCarolina Castaño Uribe100% (1)

- Absorption and Sorptivity TestsDocumento5 pagineAbsorption and Sorptivity Testsourebooks100% (1)

- Astm C87 (2005)Documento4 pagineAstm C87 (2005)Stuar TencioNessuna valutazione finora

- Optimal Mix Design For Pervious ConcreteDocumento9 pagineOptimal Mix Design For Pervious ConcretejanakarajNessuna valutazione finora

- Concrete Slump TestDocumento3 pagineConcrete Slump TestShaan LalwaniNessuna valutazione finora

- CHAPTER 1 FINAL YEAR ProjectDocumento5 pagineCHAPTER 1 FINAL YEAR ProjectdejayzNessuna valutazione finora

- BS 1881-Part 102-83Documento10 pagineBS 1881-Part 102-83karuna346Nessuna valutazione finora

- ASTM C40C40M. Obsoleta2019Documento2 pagineASTM C40C40M. Obsoleta2019JAIME CARDONA DIAZ DIAZ100% (1)

- Aggregates and Their Properties in Concrete Presentation - Mark Alexander PDFDocumento75 pagineAggregates and Their Properties in Concrete Presentation - Mark Alexander PDFharold romuald Lele FotsoNessuna valutazione finora

- BS 1881 Part 122 83Documento8 pagineBS 1881 Part 122 83Jennifer StokesNessuna valutazione finora

- Partial Replacement of Fine Aggregates by Rubber in ConcreteDocumento6 paginePartial Replacement of Fine Aggregates by Rubber in ConcretemuazNessuna valutazione finora

- Investigate The Combination of Coconut Shell and Grained Palm Kernel To Replace Aggregate in Concrete: A Technical ReviewDocumento10 pagineInvestigate The Combination of Coconut Shell and Grained Palm Kernel To Replace Aggregate in Concrete: A Technical ReviewKhan BrothersNessuna valutazione finora

- C495 M - 12Documento3 pagineC495 M - 12Lila Ester Ashook VillarrealNessuna valutazione finora

- Astm C418 PDFDocumento3 pagineAstm C418 PDFmjgutierrezperalta100% (1)

- C348Documento6 pagineC348ranva2001Nessuna valutazione finora

- CORE TESTING FOR CONCRETE STRENGTHDocumento13 pagineCORE TESTING FOR CONCRETE STRENGTHvempadareddyNessuna valutazione finora

- Pervious Concrete As A Sustainable Pavement Material-Research Findings and Future Prospects A State-Of-The-Art-reviewDocumento13 paginePervious Concrete As A Sustainable Pavement Material-Research Findings and Future Prospects A State-Of-The-Art-reviewNoéMestas100% (1)

- Fly Ash Cement Replacement Tds PDFDocumento2 pagineFly Ash Cement Replacement Tds PDFabualamalNessuna valutazione finora

- Laboratory Worksheet: Center For Diploma StudiesDocumento6 pagineLaboratory Worksheet: Center For Diploma StudiesSyihabuddin Yusoff0% (1)

- Astm D7263 PDFDocumento7 pagineAstm D7263 PDFMuhammad AsifNessuna valutazione finora

- Standard Test Method For Potential Alkali Reactivity of Aggregates (Mortar-Bar Method)Documento5 pagineStandard Test Method For Potential Alkali Reactivity of Aggregates (Mortar-Bar Method)WilliamNessuna valutazione finora

- 226 PDFDocumento8 pagine226 PDFBatepola BacNessuna valutazione finora

- Slag Cement For Use in Concrete and MortarsDocumento6 pagineSlag Cement For Use in Concrete and MortarsJose Francisco Villarreal CanalesNessuna valutazione finora

- Quantitative Extraction of Bitumen From Bituminous Paving MixturesDocumento12 pagineQuantitative Extraction of Bitumen From Bituminous Paving Mixturessebastian novoa0% (1)

- BS en 13263-1Documento28 pagineBS en 13263-1daviana100% (1)

- ASTMC39Documento5 pagineASTMC39Isaac NuñezNessuna valutazione finora

- As 2350.14-2006 Methods of Testing Portland Blended and Masonry Cements Length Change of Cement Mortars ExposDocumento2 pagineAs 2350.14-2006 Methods of Testing Portland Blended and Masonry Cements Length Change of Cement Mortars ExposSAI Global - APAC100% (1)

- Guide to Properties of Rendering MortarDocumento18 pagineGuide to Properties of Rendering MortarRachel IngramNessuna valutazione finora

- Flow of Hydraulic Cement Mortar: Standard Test Method ForDocumento2 pagineFlow of Hydraulic Cement Mortar: Standard Test Method ForCarineMolz100% (1)

- Astm 1579Documento7 pagineAstm 1579Paolita Zubieta BelloNessuna valutazione finora

- European International Geotextilestandards Shortguide2010Documento25 pagineEuropean International Geotextilestandards Shortguide2010Michael HarnackNessuna valutazione finora

- Determination of The International Roughness Index (IRI) Using ARRB TR Walking ProfilerDocumento9 pagineDetermination of The International Roughness Index (IRI) Using ARRB TR Walking Profilerतिप्लोकाची तिरुनचिपल्ली केरकेट्टा100% (1)

- Split Tensile Strength of ConcreteDocumento9 pagineSplit Tensile Strength of Concreteabhineet srivastavaNessuna valutazione finora

- In-Place Estimation of Density and Water Content of Soil and Aggregate by Correlation With Complex Impedance MethodDocumento12 pagineIn-Place Estimation of Density and Water Content of Soil and Aggregate by Correlation With Complex Impedance MethodJesús Luis Arce GuillermoNessuna valutazione finora

- Concrete Flow TestDocumento7 pagineConcrete Flow TestDarrenTofuNessuna valutazione finora

- Chemical Analysis Test (ASTM C114)Documento8 pagineChemical Analysis Test (ASTM C114)Ayaz AhmadNessuna valutazione finora

- Astm Mat005 c230Documento6 pagineAstm Mat005 c230Mohsen Tennich100% (1)

- Fiber Reinforced ConcreteDocumento11 pagineFiber Reinforced ConcreteIhtesham HussainNessuna valutazione finora

- Hyper CreteDocumento2 pagineHyper CretedjgiumixNessuna valutazione finora

- Mixing Rooms, Moist Cabinets, Moist Rooms, and Water Storage Tanks Used in The Testing of Hydraulic Cements and ConcretesDocumento3 pagineMixing Rooms, Moist Cabinets, Moist Rooms, and Water Storage Tanks Used in The Testing of Hydraulic Cements and ConcretesSatya kaliprasad vangaraNessuna valutazione finora

- Aashto T307Documento27 pagineAashto T307Viviana CruzNessuna valutazione finora

- Astm C-596 Dry ShringkageDocumento3 pagineAstm C-596 Dry ShringkageMohamad Nurkholis100% (1)

- BS 1881 1983 Part 101Documento10 pagineBS 1881 1983 Part 101paladin7Nessuna valutazione finora

- Compressive Strength Test On Concrete CoreDocumento4 pagineCompressive Strength Test On Concrete CoreSyed Mohd MehdiNessuna valutazione finora

- Yasuda 1974Documento15 pagineYasuda 1974Rodrigo Rodrigues de BarrosNessuna valutazione finora

- Air Trap PipelineDocumento10 pagineAir Trap PipelineJulio César Rodríguez RodríguezNessuna valutazione finora

- Review of Surface Application FundamentalsDocumento42 pagineReview of Surface Application FundamentalsLuis RosesNessuna valutazione finora

- Chapter 3 PDFDocumento11 pagineChapter 3 PDFMohd Khalid AnsariNessuna valutazione finora

- Determine Reservoir Parameters from Drawdown Tests in Multilayer ReservoirsDocumento31 pagineDetermine Reservoir Parameters from Drawdown Tests in Multilayer ReservoirsHichem FakhfekhNessuna valutazione finora

- Simple Model of Foam Drainage - Fortes & Coughlan 1994Documento8 pagineSimple Model of Foam Drainage - Fortes & Coughlan 1994alexnlima852Nessuna valutazione finora

- Viscous Dissipation Term in Energy EquationsDocumento14 pagineViscous Dissipation Term in Energy Equationsscience1990Nessuna valutazione finora

- AMCRPS Impervious enDocumento64 pagineAMCRPS Impervious enonin007Nessuna valutazione finora

- Tablaestacas PDFDocumento18 pagineTablaestacas PDFPaulaNessuna valutazione finora

- Determining relative permeability curves in tight gas sands using log dataDocumento24 pagineDetermining relative permeability curves in tight gas sands using log datatsar_philip2010Nessuna valutazione finora

- Soalan Fizik (Daya Graviti)Documento18 pagineSoalan Fizik (Daya Graviti)Taufik PamisNessuna valutazione finora

- Yaqub 2018 IOP Conf. Ser. Mater. Sci. Eng. 458 012078Documento10 pagineYaqub 2018 IOP Conf. Ser. Mater. Sci. Eng. 458 012078Daniel MoraesNessuna valutazione finora

- Reservoir Engineering CourseDocumento129 pagineReservoir Engineering CourseLeonardo Barrios CarreraNessuna valutazione finora

- Monitoring Sulfide-Oxidizing Biofilm Activity On Cement Surfaces Using Non-Invasive Self-Referencing MicrosensorsDocumento9 pagineMonitoring Sulfide-Oxidizing Biofilm Activity On Cement Surfaces Using Non-Invasive Self-Referencing MicrosensorskhoagleNessuna valutazione finora

- United States Patent (191: Andersen Et A1Documento5 pagineUnited States Patent (191: Andersen Et A1khoagleNessuna valutazione finora

- Generating Surface Crack PatternsDocumento11 pagineGenerating Surface Crack PatternskhoagleNessuna valutazione finora

- Causes of Crackle On Porcelain WareDocumento2 pagineCauses of Crackle On Porcelain WarekhoagleNessuna valutazione finora

- United States Patent (191: Andersen Et A1Documento5 pagineUnited States Patent (191: Andersen Et A1khoagleNessuna valutazione finora

- Comparison of cement grinding technologiesDocumento28 pagineComparison of cement grinding technologiesSai Sricharan Reddy100% (3)

- 陶瓷材料结构与性质Documento3 pagine陶瓷材料结构与性质khoagleNessuna valutazione finora

- Journal Paper IJAETDocumento8 pagineJournal Paper IJAETvempada1942Nessuna valutazione finora

- Useful PhrasesDocumento8 pagineUseful PhraseswinnieXDNessuna valutazione finora

- Electric Mortor For Ball MillDocumento2 pagineElectric Mortor For Ball MillkhoagleNessuna valutazione finora

- Hammer CrusherDocumento4 pagineHammer CrusherkhoagleNessuna valutazione finora

- FAG-Jaw Crusher BearingsDocumento38 pagineFAG-Jaw Crusher BearingsJinto A J100% (2)

- Lecture 2Documento4 pagineLecture 2khoagleNessuna valutazione finora

- Optimisation of The Rotary KilnDocumento34 pagineOptimisation of The Rotary KilnSampathkumar Mtech100% (3)

- Airflex Grinding MillsDocumento6 pagineAirflex Grinding MillskhoagleNessuna valutazione finora

- Choosing The Right Motors For Your Mills: Alex Doll and Derek BarrattDocumento16 pagineChoosing The Right Motors For Your Mills: Alex Doll and Derek Barrattavca65Nessuna valutazione finora

- Properties of Metakaolin Geopolymer Hardened Paste Prepared by High-Pressure CompactionDocumento8 pagineProperties of Metakaolin Geopolymer Hardened Paste Prepared by High-Pressure CompactionkhoagleNessuna valutazione finora

- CA501Documento614 pagineCA501Ignacio AntonioNessuna valutazione finora

- Effect of Curing Temperature On The Development of Hard Structure of Metakaolin-Based GeopolymerDocumento8 pagineEffect of Curing Temperature On The Development of Hard Structure of Metakaolin-Based GeopolymerkhoagleNessuna valutazione finora

- 1Documento6 pagine1basanth_712982Nessuna valutazione finora

- Electrostatic Precipitator - Mechanical DescriptionDocumento19 pagineElectrostatic Precipitator - Mechanical Descriptionhozipek5599Nessuna valutazione finora

- Phu Luc 3Documento2 paginePhu Luc 3khoagleNessuna valutazione finora

- Effect of Porosity On The Absorbed, Reemitted and Transmitted Light by A Geopolymer Metakaolin BaseDocumento4 pagineEffect of Porosity On The Absorbed, Reemitted and Transmitted Light by A Geopolymer Metakaolin BasekhoagleNessuna valutazione finora

- ConvertDocumento8 pagineConvertkhoagleNessuna valutazione finora

- NDT NLU Detection Micro Cracks ConcreteDocumento7 pagineNDT NLU Detection Micro Cracks ConcreteElango PaulchamyNessuna valutazione finora

- PaulingDocumento4 paginePaulingkhoagleNessuna valutazione finora

- PREHEATER OptimizationDocumento2 paginePREHEATER OptimizationsaeedhoseiniNessuna valutazione finora

- Pauling's rules of bonding and coordinationDocumento5 paginePauling's rules of bonding and coordinationkhoagleNessuna valutazione finora

- Calcium Carbonate Precipitation by Different Bacterial StrainsDocumento14 pagineCalcium Carbonate Precipitation by Different Bacterial StrainskhoagleNessuna valutazione finora

- Heat Pipes: An Introduction to Their Concept, Construction and ApplicationsDocumento26 pagineHeat Pipes: An Introduction to Their Concept, Construction and ApplicationsVilas RautNessuna valutazione finora

- F. P. BRETHERTON (1961) The Motion of Long Bubbles in TubesDocumento23 pagineF. P. BRETHERTON (1961) The Motion of Long Bubbles in TubesLy HourNessuna valutazione finora

- Infiltration Measurements For Soil Hydraulic CharacterizationDocumento396 pagineInfiltration Measurements For Soil Hydraulic CharacterizationYessy A. Ruiz100% (1)

- SOIL WATER MOVEMENTDocumento43 pagineSOIL WATER MOVEMENTrieNessuna valutazione finora

- Aesthetic FinishesDocumento5 pagineAesthetic FinishesAnonymous dOdHWHg4Nessuna valutazione finora

- Full Text, Master Thesis, Babak Mohammadi (6200532)Documento123 pagineFull Text, Master Thesis, Babak Mohammadi (6200532)IFTIKUETNessuna valutazione finora

- Soil Water Characteristics and Behavior: A Concise GuideDocumento39 pagineSoil Water Characteristics and Behavior: A Concise GuideSaq-alone SáQîNessuna valutazione finora

- Capillary Pressure Techniques: Application To Exploration and Development GeologyDocumento14 pagineCapillary Pressure Techniques: Application To Exploration and Development Geologyc_b_umashankarNessuna valutazione finora

- Ground Improvement Technioques For High WaysDocumento31 pagineGround Improvement Technioques For High WaysDevendra Sharma100% (1)

- Soil Mechanics: Principle of Effective Stress, Capillarity and Permeability On SoilDocumento54 pagineSoil Mechanics: Principle of Effective Stress, Capillarity and Permeability On SoilAwadhiNessuna valutazione finora

- Parametric Analysis of Loop Heat Pipe Operation A Literature ReviewDocumento16 pagineParametric Analysis of Loop Heat Pipe Operation A Literature ReviewMilan VachhaniNessuna valutazione finora

- Ce 214-Fluid Mechanics Laboratory ManualDocumento39 pagineCe 214-Fluid Mechanics Laboratory ManualAyush ShrivastavaNessuna valutazione finora

- SAC 101 Lecture 18Documento42 pagineSAC 101 Lecture 18rajap02Nessuna valutazione finora

- MODULE 1 HYDRA325 DiscussionDocumento34 pagineMODULE 1 HYDRA325 DiscussionCyruz HimenezNessuna valutazione finora

- Super DisintegrantsDocumento19 pagineSuper Disintegrantsvikaskiran60Nessuna valutazione finora

- ASTM D1018-00 - Hydrogen in Petroleum FractionDocumento4 pagineASTM D1018-00 - Hydrogen in Petroleum FractionKamruzaman MiahNessuna valutazione finora

- ASTM D4772 Water Absorption PaperDocumento10 pagineASTM D4772 Water Absorption PaperGeorge Vekinis100% (1)

- SSS 1 3RD TermDocumento21 pagineSSS 1 3RD TermabiodunokoyaNessuna valutazione finora

- RETENTION Stability Support ProsthoDocumento13 pagineRETENTION Stability Support ProsthoFourthMolar.com100% (1)

- VMRDocumento117 pagineVMRM Sandesh ShenoyNessuna valutazione finora

- Chapter 1 - Flow in SoilDocumento47 pagineChapter 1 - Flow in Soilain sahirahNessuna valutazione finora

- Ijftr 37 (3) 231-237 PDFDocumento7 pagineIjftr 37 (3) 231-237 PDFPriya LathaNessuna valutazione finora

- Gaugler, R. S. (1944) - U.S.A. Patent No. 2350348.Documento5 pagineGaugler, R. S. (1944) - U.S.A. Patent No. 2350348.pathiNessuna valutazione finora

- Fluid Mechanics (Mechanics of Fluids/Hydraulics)Documento12 pagineFluid Mechanics (Mechanics of Fluids/Hydraulics)Jordan MagalaNessuna valutazione finora

- PolyCom Durability Assessment of Pavement Foundation Materials Treated With A Polymeric Based AdditiveDocumento12 paginePolyCom Durability Assessment of Pavement Foundation Materials Treated With A Polymeric Based AdditiveChristopher TanjungNessuna valutazione finora

- Lab Manual - Physics PDFDocumento69 pagineLab Manual - Physics PDFbookdigitNessuna valutazione finora